Method for co-preparation of bamboo activated carbon, bamboo vinegar and bamboo tar

A technology of bamboo tar and bamboo vinegar, which is applied in chemical instruments and methods, coking ovens, petroleum industry, etc., can solve the problems of unsatisfactory quality of vinegar and bamboo tar, and achieve large processing capacity, high recovery efficiency and less pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

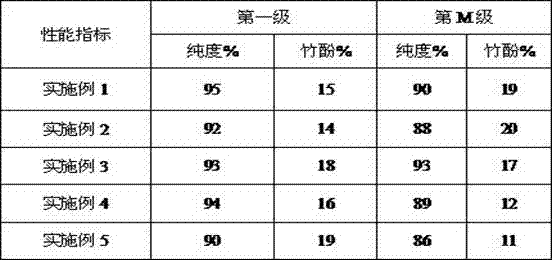

Examples

Embodiment 1

[0028] (1) Use a pulverizer to pulverize hemp bamboo to pass through a 50-mesh sieve, blow into dry air with a pressure of 0.1KPa at 100°C, and dry for 60 minutes to obtain dried bamboo powder;

[0029] (2) Pass the bamboo powder through a three-stage conical screw extruder, and then pass through the carbonization section, dry distillation section and activation section of the three-stage conical screw extruder in sequence. The carbonization section is equipped with a five-stage pressure pump, and the dry distillation section is provided with three temperature zones from the feed end to the discharge end. From the first temperature zone to the third temperature zone, the carbonization temperature increases from 200°C to 400°C. The temperature gradient between two adjacent temperature zones is 100°C, a vacuum port is set in each of the three temperature zones, and a water condensation device is set at the outlet of the at least one vacuum port; in the activation section, a The ...

Embodiment 2

[0034] (1) Use a pulverizer to crush the mixture of green bamboo, thorny bamboo, long-branched bamboo, and Penglai bamboo until it passes through a 50-mesh sieve, blow into dry air with a pressure of 0.2KPa at 105°C, and dry for 120 minutes to obtain dried bamboo powder;

[0035](2) Pass the bamboo powder through a three-stage conical screw extruder, and then pass through the carbonization section, dry distillation section and activation section of the three-stage conical screw extruder in sequence. The carbonization section is equipped with a three-stage pressure pump, and the carbonization section is provided with five temperature zones from the feed end to the discharge end. From the first temperature zone to the fifth temperature zone, the carbonization temperature is increased from 200°C to 400°C. The temperature gradient of two adjacent temperature zones is 40°C, at least one vacuum port is set in each of the five temperature zones, and a water condensation device is set...

Embodiment 3

[0040] (1) Use a pulverizer to crush the thorny bamboo to pass through a 50-mesh sieve, blow into dry air with a pressure of 0.5KPa at 100°C, and dry for 70 minutes to obtain dried bamboo powder;

[0041] (2) Pass the bamboo powder through a three-stage conical screw extruder, and then pass through the carbonization section, dry distillation section and activation section of the three-stage conical screw extruder in sequence. The carbonization section is equipped with a three-stage pressure pump, and the dry distillation section is provided with four temperature zones from the feed end to the discharge end. From the first temperature zone to the fourth temperature zone, the carbonization temperature increases from 200°C to 400°C. The temperature gradient of two adjacent temperature zones is 50°C, at least one vacuum port is set in each of the four temperature zones, and a water condensation device is set at the outlet of the at least one vacuum port; Section, set the gas deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com