Waste liquid treatment method of aluminum-air battery

A waste liquid treatment and battery technology, applied in aluminate/alumina/aluminum hydroxide purification, alkali metal aluminate/alumina/aluminum hydroxide preparation, alkali metal chloride, etc., can solve the problem that aluminum ions cannot Complete recovery of recycling value and other issues to achieve high recycling value and increase the effect of recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

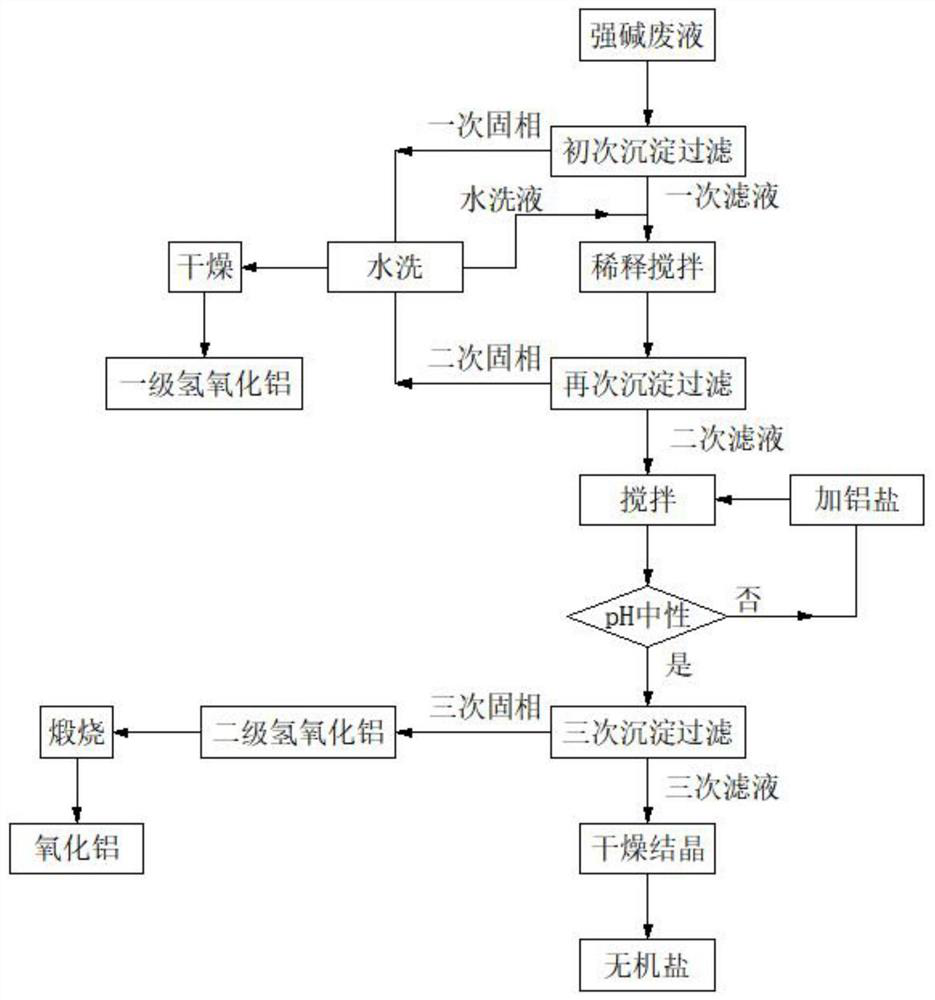

[0023] Such as figure 1 As shown, the waste liquid treatment method of the aluminum-air battery of this embodiment, the waste liquid treatment method includes the following steps:

[0024] S1: The electrolyte participates in the chemical reaction inside the aluminum-air battery. After the battery is discharged, the electrolyte becomes a strong alkali waste solution containing aluminum hydroxide precipitates and metaaluminate. Among them, the metaaluminate is electrochemically dissolved by the aluminum substrate. Aluminum ions are precipitated in the form and react with hydroxide in the electrolyte to form aluminum hydroxide precipitates, and part of the aluminum hydroxide precipitates further react with hydroxide ions in the electrolyte to obtain metaaluminate; the initial freshly prepared electrolyte is High-concentration sodium hydroxide or potassium hydroxide solution, when it participates in the electrochemical reaction of the aluminum-air battery, the electrolyte waste so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com