A method for producing concentrated brine from sea salt

A technology for concentrating brine and sea salt, which is applied in seawater treatment, general water supply conservation, chemical instruments and methods, etc., can solve the problems of severe climate impact, long salt production cycle, and large land occupation, so as to reduce the tanning area, The effect of increasing water production rate and reducing treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

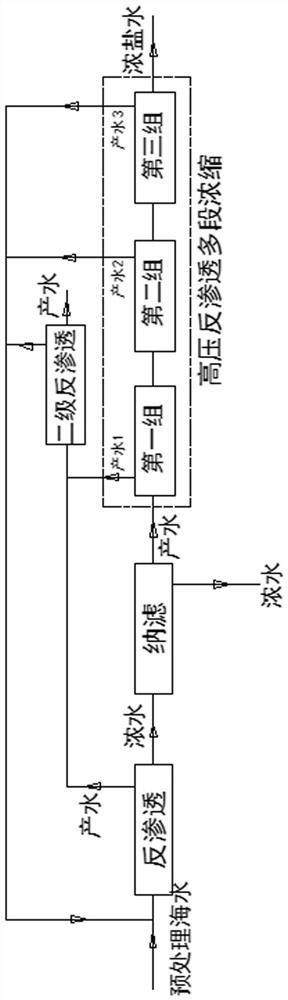

[0038] The production capacity of raw seawater or concentrated seawater pretreatment is 15,000 tons / day, after that, the concentration of concentrated seawater is 4~5°Bé, of which sodium ion is 18.3g / L, calcium ion is 0.6~0.7g / L, magnesium ion is 1.8~2.2 g / L, sulfate ion 3.5~4.5g / L, chloride ion 29~31g / L, bromide ion 0.1g / L.

[0039] Concentrated seawater enters the nanofiltration device, the recovery rate is 55%~65%, the concentration of nanofiltration water is 3~4°Bé, sodium ion is 16~17g / L, calcium ion is 0.05g / L, magnesium ion is 0.02g / L, sulfate radical Ion 0.02g / L, chloride ion 26~27g / L.

[0040] The water produced by the nanofiltration device enters the high-pressure reverse osmosis device for concentration. After concentration, the concentration of the product water is 9-12°Bé, the sodium ion is 60-65g / L, the calcium ion is 0.15g / L, the magnesium ion is 0.06g / L, and the sulfate ion is 0.06 g / L, chloride ion 60~100g / L; the better conductivity of the high-pressure rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com