Method for deep treatment on difficultly-degraded organic nitrogen-containing industrial wastewater

A technology for industrial wastewater and advanced treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. The problem of high cost, to achieve the effect of good removal capacity, good fixation, good mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, the water quality of the biochemically treated refractory organic nitrogen-containing industrial wastewater: the COD concentration is 300 mg / L, the ammonia nitrogen concentration is 20 mg / L, and the pH value is 7.5.

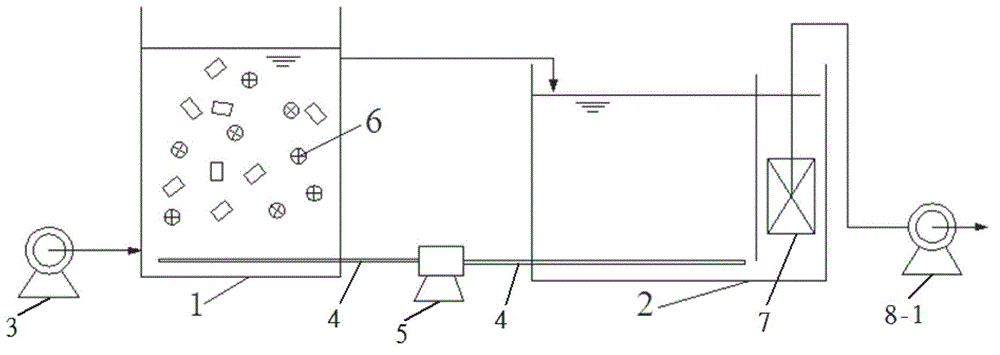

[0033] In this embodiment, the advanced treatment process of refractory organic nitrogen-containing industrial wastewater is as follows: figure 1 As described, the steps are as follows:

[0034] (1) Put the suspended filler 6 made of polyethylene into the moving bed biofilm reactor 1 and carry out biofilm culture. The amount of the suspended filler 6 is 25% of the effective volume of the moving bed biofilm reactor. The biofilm culture method is as follows: adding wastewater with a COD concentration of 500 mg / L and an ammonia nitrogen concentration of 40 mg / L into the moving bed biofilm reactor, the amount of the wastewater being added is 90% of the effective volume of the reactor, and then adding activated sludge , the dosage of activated...

Embodiment 2

[0039] In this example, the water quality of the refractory organic nitrogen-containing industrial wastewater after biochemical treatment: the COD concentration is 300 mg / L, the ammonia nitrogen concentration is 20 mg / L, and the pH value is 7.5.

[0040] In this embodiment, the advanced treatment process of refractory organic nitrogen-containing industrial wastewater is as follows: figure 1 As mentioned, the steps are as follows:

[0041] (1) Put the suspended filler 6 made of polyethylene into the moving bed biofilm reactor 1 and carry out biofilm cultivation, the amount of the suspended filler is 45% of the effective volume of the moving bed biofilm reactor, and the biological The membrane culture method is as follows: add wastewater with a COD concentration of 300mg / L and an ammonia nitrogen concentration of 15mg / L to the moving bed biofilm reactor, the amount of wastewater added is 70% of the effective volume of the reactor, and then add activated sludge, The dosage of ac...

Embodiment 3

[0046] In this example, the water quality of the refractory organic nitrogen-containing industrial wastewater after biochemical treatment: the COD concentration is 300 mg / L, the ammonia nitrogen concentration is 20 mg / L, and the pH value is 7.5.

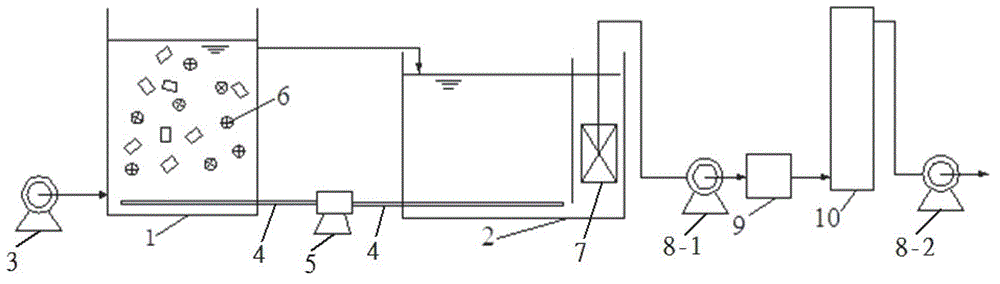

[0047] In this embodiment, the advanced treatment process of refractory organic nitrogen-containing industrial wastewater is as follows: figure 2 As mentioned, the steps are as follows:

[0048] (1) Put the suspended filler 6 made of polyethylene into the moving bed biofilm reactor 1 and carry out biofilm cultivation, the amount of the suspended filler is 25% of the effective volume of the moving bed biofilm reactor, and the biological The membrane culture method is as follows: add COD concentration 500mg / L, ammonia nitrogen concentration 40mg / L wastewater into the moving bed biofilm reactor, the amount of wastewater added is 90% of the effective volume of the reactor, and then add activated sludge, The dosage of activated sludge i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com