Deep-treatment and reusing system and method for industrial standard-meeting externally-discharged wastewater

A technology for advanced treatment and waste water, applied in the field of water treatment, can solve the problems of high cost, poor pollutant removal effect, low water production rate, etc., and achieve high water production rate, low energy consumption and equipment investment, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

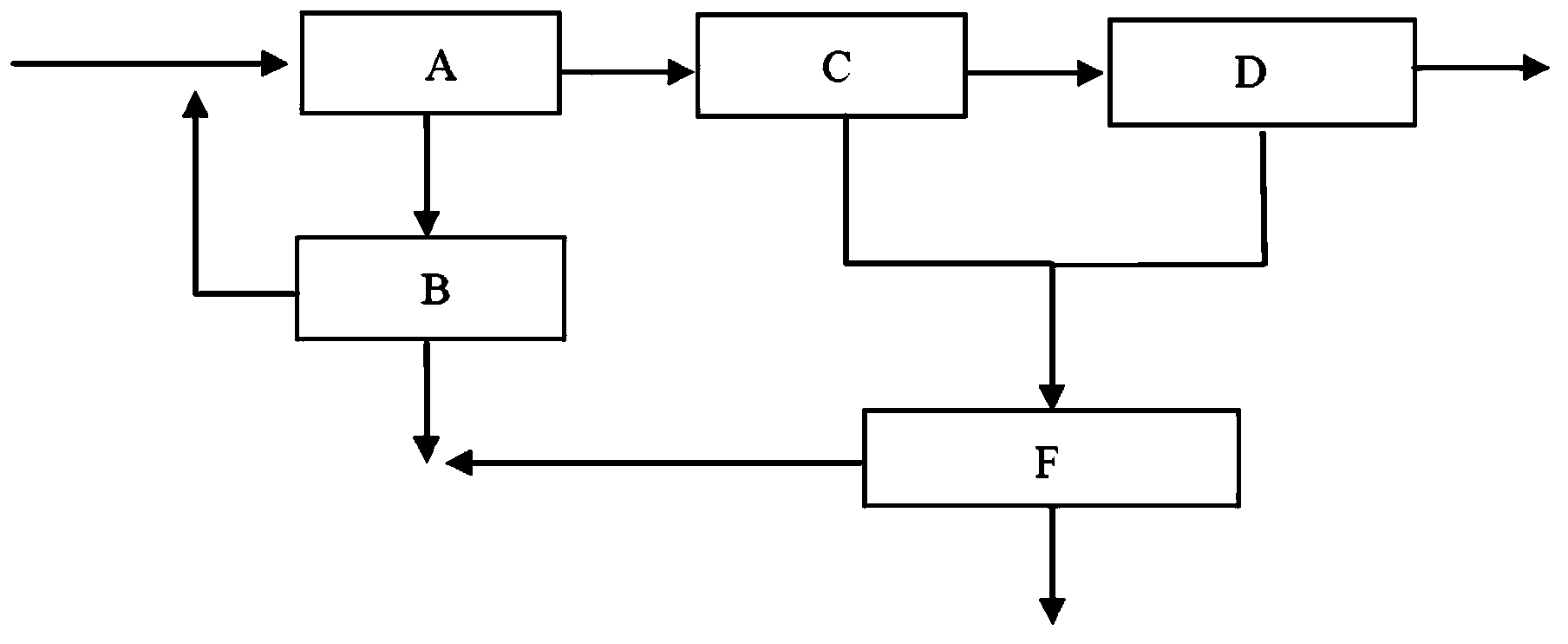

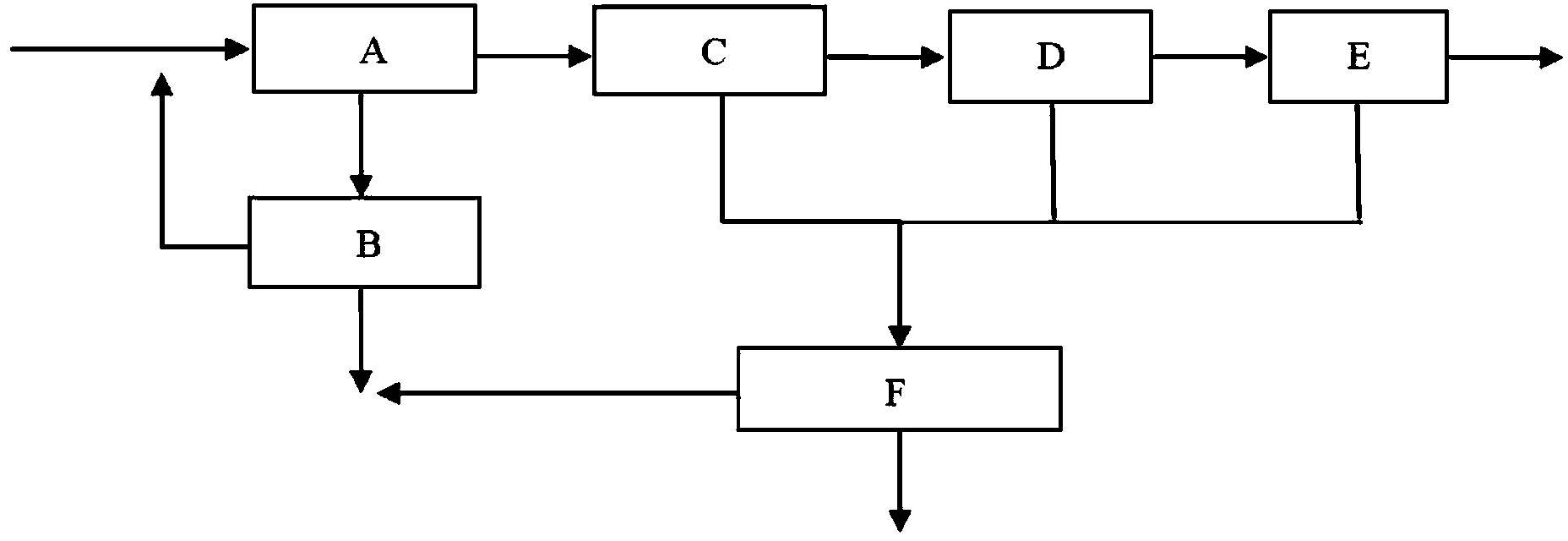

[0034] Such as figure 1 As shown, the advanced treatment and reuse system of industrial waste water up to standard in this embodiment includes: ultrafiltration device A, coagulation device B, nanofiltration device C, electrosorption desalination device D and coagulation / electrocoagulation / Enzyme electropolymerization-electrocoagulation device F;

[0035] The ultrafiltration fresh water outlet of the ultrafiltration device A is connected to the inlet of the nanofiltration device C and the electric adsorption desalination device D through pipelines in turn; The outlet of the adsorption concentrated water is connected with the inlet of the coagulation / electrocoagulation / enzyme electropolymerization-electrocoagulation device F; the outlet of the ultrafiltration concentrated water of the ultrafiltration device A is connected with the inlet of the coagulation device B; The water outlet of the coagulation device B is connected with the waste water inlet of the ultrafiltration devic...

Embodiment 2

[0037]Compared with Example 1, the coagulation / electrocoagulation / enzyme electropolymerization-electrocoagulation device F is an electrocoagulation device, and the rest of the structure is the same as that of Example 1.

Embodiment 3

[0039] Compared with Example 1, the coagulation / electrocoagulation / enzyme electropolymerization-electrocoagulation device F is an enzyme electropolymerization-electrocoagulation device, and the rest of the structure is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com