Transferring, shifting and collection method for goods

A technology of cargo and load transfer, which is applied in the field of logistics transmission, can solve the problems of low loading efficiency, achieve the effects of cost saving, time saving, and improvement of transportation and loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

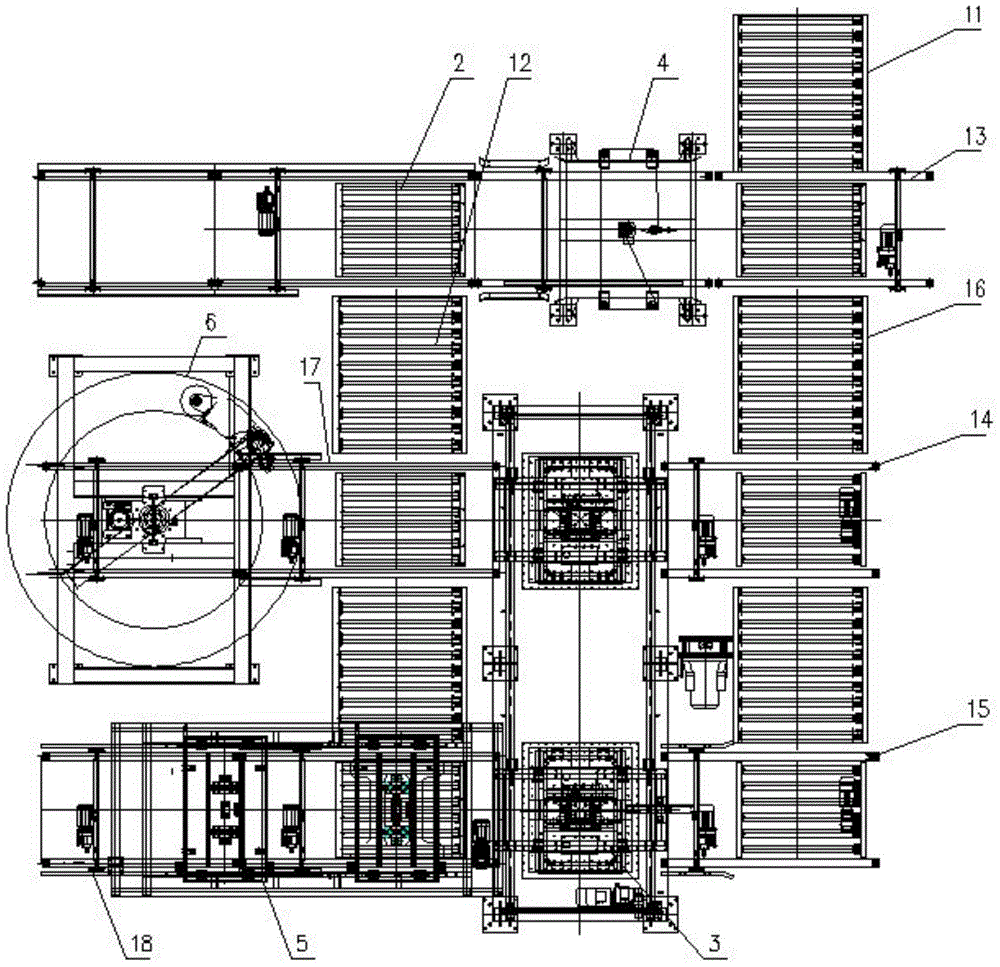

[0029] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

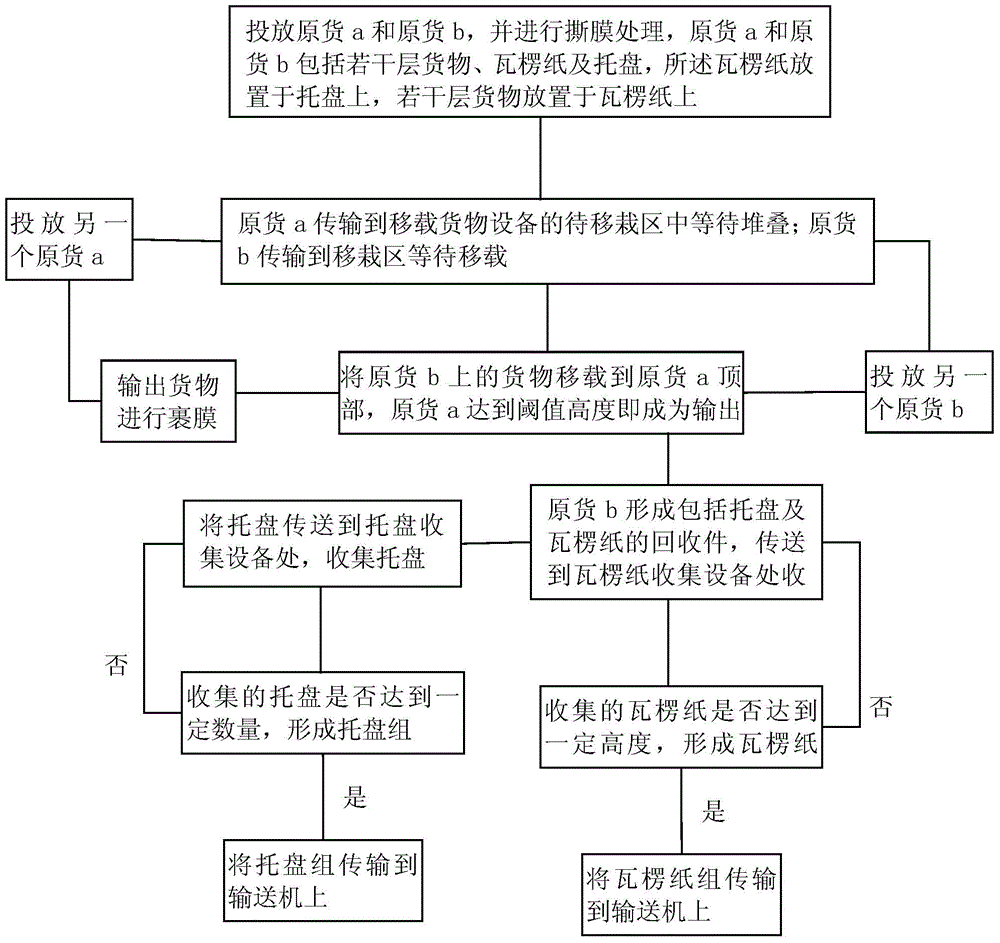

[0030] Such as figure 1 As shown, the cargo transmission, transfer and collection method of the present invention comprises the following steps:

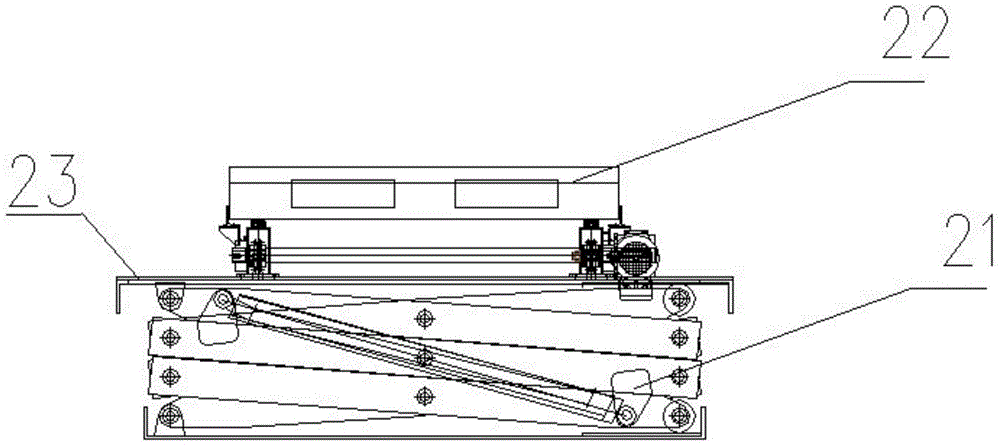

[0031] 1. The operator puts the original goods a with five layers of goods and corrugated paper on the pallet into the first goods entrance of the first longitudinal conveyor, and puts the same original goods b into the second goods at the front end of the first transverse conveyor At the entrance, the original product b is lowered to the first longitudinal conveyor through the jacking conveying mechanism. The original product a and the original product b follow the first longitudinal conveyor to the manual tearing port, and the manual film tearing operation is performed to remove the wrapping on the pallet. outer film. Since the original goods include five goods, corrugated paper and pallets, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com