Drainage recycling channel device for desulfurization island and desulfurization island drainage recycling system

A desulfurization island and drainage ditch technology, applied in waterway systems, water supply devices, sewage removal, etc., can solve the problems of slurry leakage, waste of water resources, large process water consumption, etc., to reduce treatment costs, reduce water consumption, reduce The effect of environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

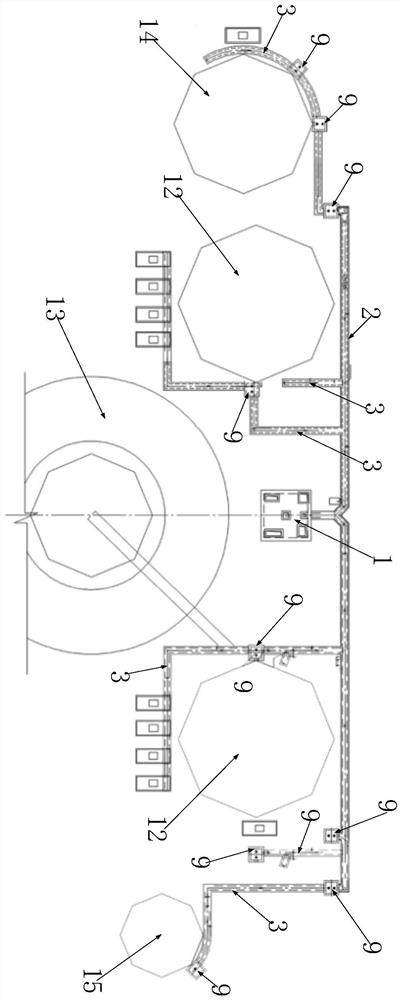

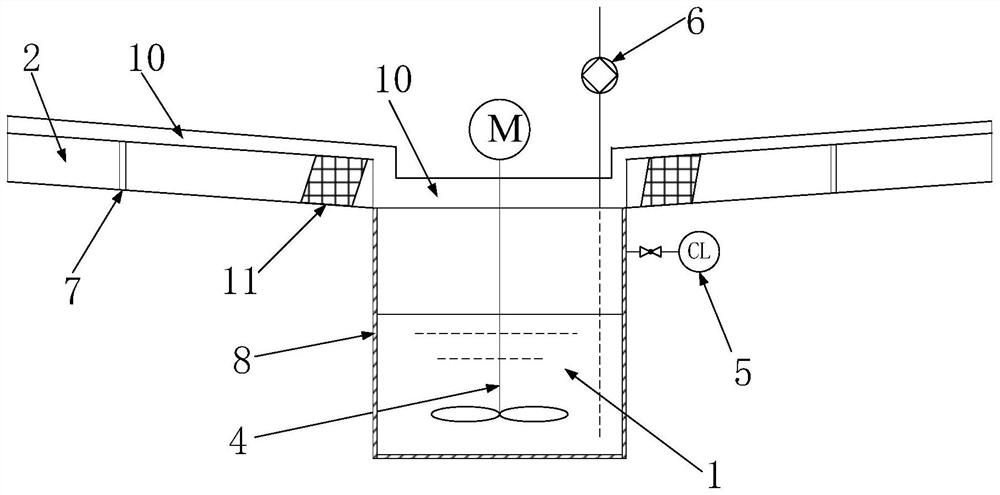

[0027] A drainage recovery ditch device for a desulfurization island, including a drainage pit 1, a main drainage ditch 2 and a plurality of recovery ditch components used to recover the desulfurization facility drainage of the desulfurization island, the recovery gutter component includes a plurality of recovery gutter components Ditch 3 and recovery ditch 3 are arranged around the desulfurization facility. The water outlet of recovery ditch 3 communicates with main drainage ditch 2 , and the outlet end of main drainage ditch 2 communicates with drainage pit 1 .

[0028] In this example, if figure 1 As shown, the desulfurization facility of the desulfurization island includes an accident slurry tank 14, two absorption towers 12, a chimney 13 and a process water tank 15, figure 1 The desulfurization facilities share a set of drainage recovery channel device.

[0029] Specifically, such as figure 1 As shown, the peripheral side of the absorption tower 12 is provided with two ...

Embodiment 2

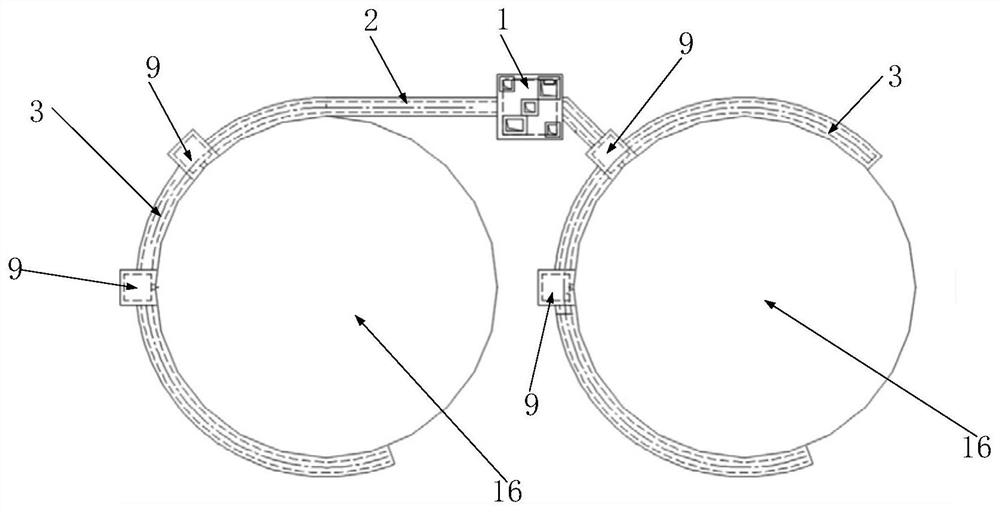

[0035] A desulfurization island drainage recovery system is used to recover the desulfurization facility drainage of the desulfurization island, including multiple desulfurization facilities and multiple sets of drainage recovery channel devices for the desulfurization island.

[0036] In this embodiment, the desulfurization facility includes an emergency slurry tank 14, two absorption towers 12, a chimney 13, a process water tank 15, two limestone slurry tanks 16 and two gypsum slurry tanks.

[0037] During specific implementation, three sets of drainage recovery channel devices are provided. The accident slurry tank 14, two absorption towers 12, chimney 13 and process water tank 15 share a set of drainage recovery channel devices, and the two limestone slurry tanks 16 share a set of drainage recovery channels. Channel device, two gypsum slurry tanks share a drainage recovery channel device.

[0038] The structure of the emergency slurry tank 14, the two absorption towers 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com