Method for automatic disassembly and recovery of waste printed circuit boards by using industrial waste heat

A technology for printed circuit boards and industrial waste heat, applied in the field of comprehensive utilization of electronic waste resources, can solve the problems of low recovery rate of electronic components, uneven heating of waste printed circuit boards, secondary pollution, etc., and achieve efficient separation and classification recovery. , to achieve the effect of harmless automatic disassembly and separation, energy saving, emission reduction and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments.

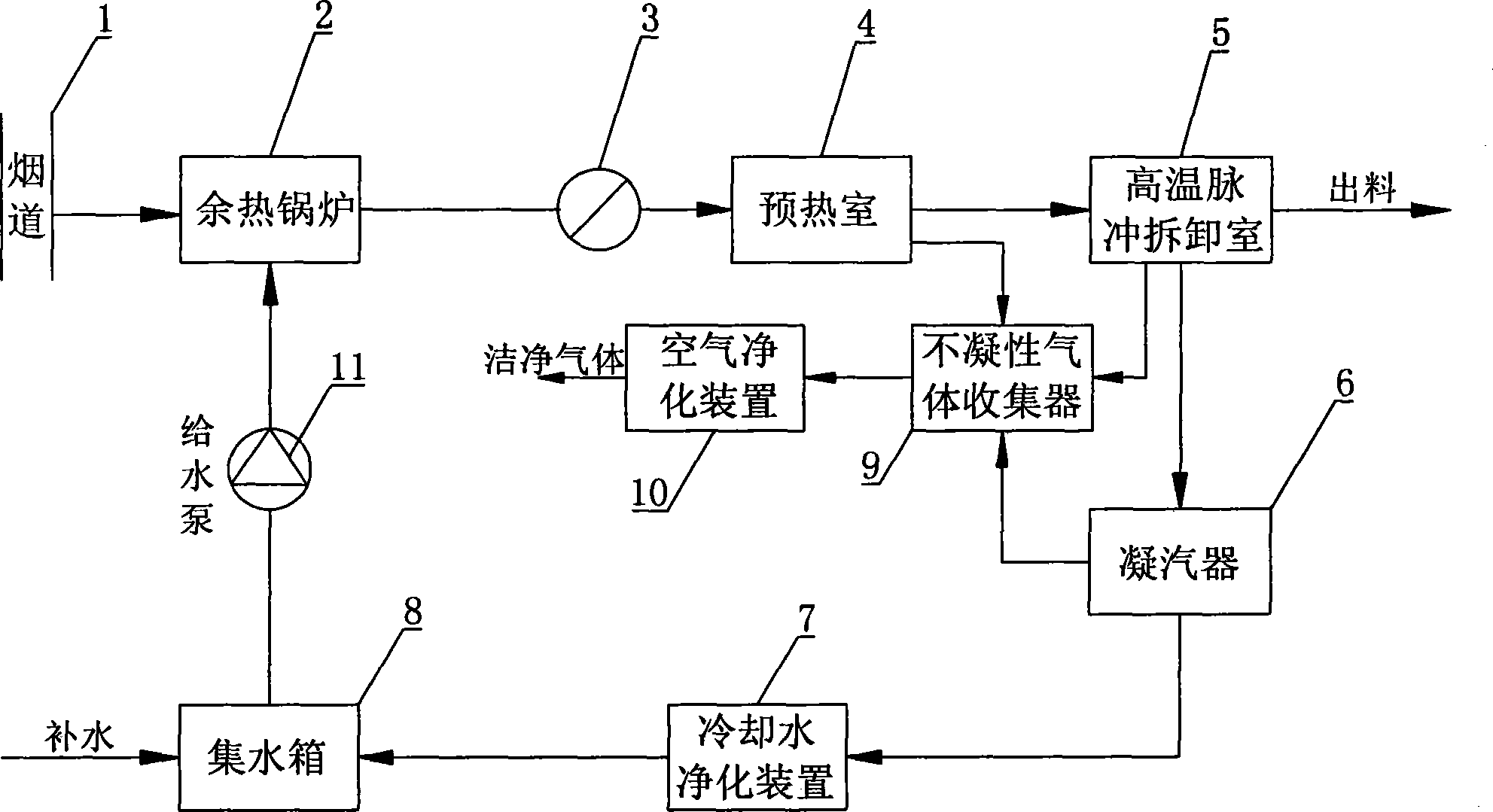

[0025] Such as figure 1 Shown is the process flow chart of the present invention.

[0026] The industrial waste heat from the flue 1 is used to heat the waste heat boiler 2, and the superheated steam generated by the waste heat boiler 2 is used as a heat source and power, and enters the preheating chamber 4 through the steam condition control component 3, where the waste printed circuit board is After preheating, the superheated steam enters the high-temperature pulse dismantling chamber, and is sprayed by high-temperature pulse through the nozzle to disassemble the electronic components of the circuit board from the circuit board, and realize the classification and automatic recycling after screening;

[0027] The superheated steam after work passes through the condenser 6 and enters the water collection tank 8 through the cooling water purification device 7, and return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com