Flotation device and method suitable for coarse slime separation

A flotation device and coarse coal slime technology, which is applied in flotation, solid separation, etc., can solve the problems of low recovery rate of coarse coal slime and poor sorting accuracy, so as to facilitate flotation recovery, efficient sorting and recovery, and improve rough running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

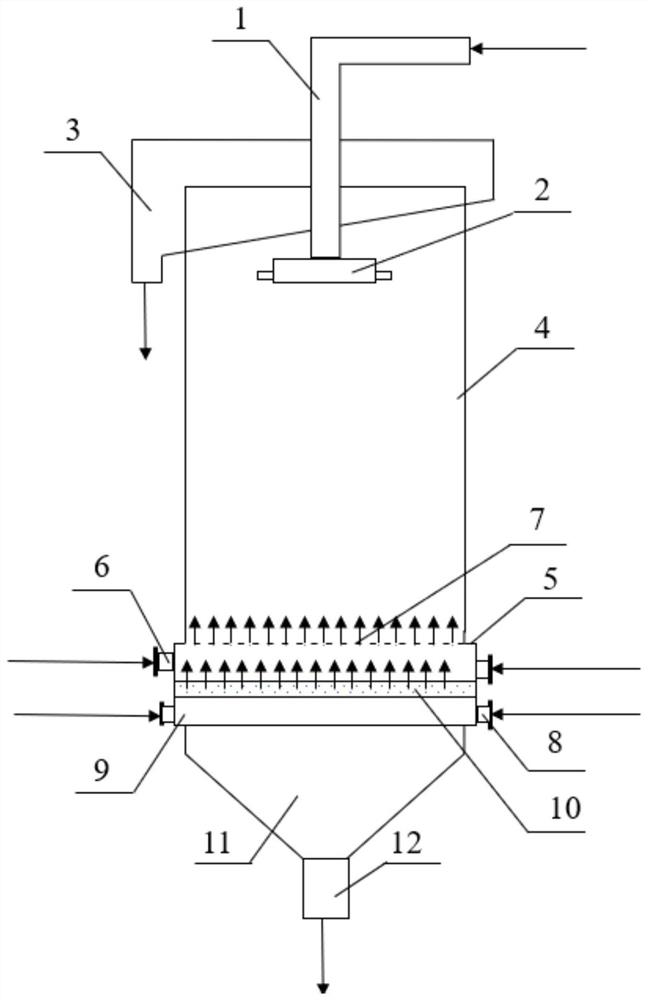

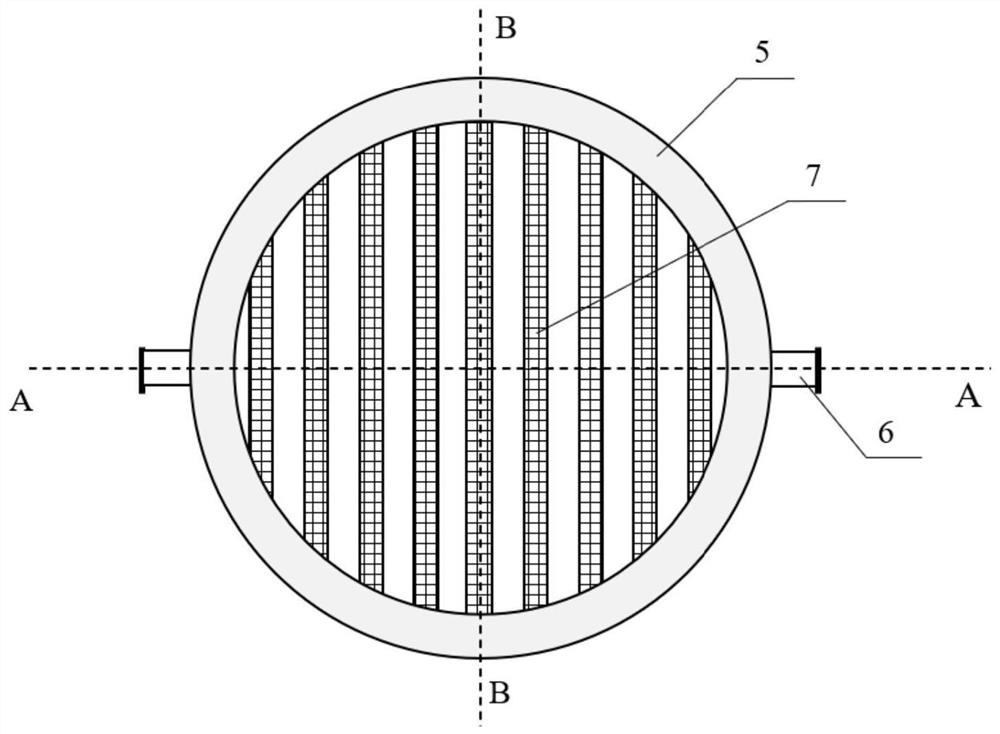

[0045] A specific embodiment of the present invention, such as figure 1 As shown in the figure, a flotation device suitable for coarse slime separation is disclosed, including a flotation column 4 and a gas-water distribution unit. The water distribution unit includes a first air distribution unit and an air-water mixing distribution unit. The air-water mixing distribution unit is located above the first air distribution unit. The air bubbles generated by the first air distribution unit are mixed with the fluidized water and then enter the air-water distribution unit. Above the flotation column 4.

[0046] Compared with the prior art, the flotation device suitable for coarse slime separation provided by this embodiment includes a gas-water distribution unit, and the gas-water distribution unit includes a first gas distribution unit and a gas-water mixing unit arranged up and down. The bubbles generated by the air distribution unit enter the air-water mixing and distribution u...

Embodiment 2

[0076] Another specific embodiment of the present invention discloses a flotation method suitable for the separation of coarse slime, using the flotation device suitable for the separation of coarse slime in Example 1, when only the flotation column 4 exists In the case of a primary air distribution unit, the steps include:

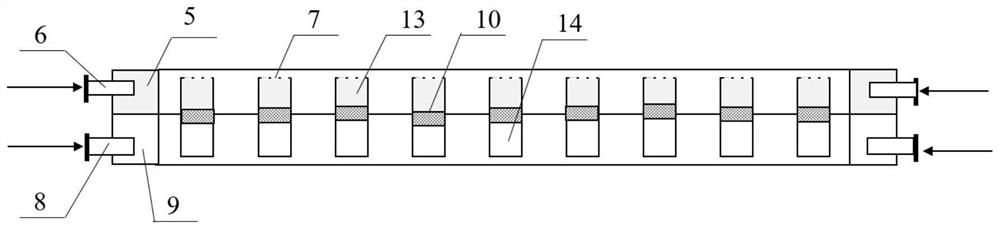

[0077] Step 1: inject fluidized water containing a foaming agent into the annular water tank 5 through the water delivery pipe 6, and the fluidized water containing the foaming agent enters the strip-shaped air-water mixing chamber 13 through the annular water tank 5; 8 Input compressed air into the first annular high-pressure air chamber 9, the air enters the first strip-shaped high-pressure air chamber 14 through the first annular high-pressure air chamber 9, and is dispersed into microbubbles through the first bubble generating plate 10 to form a rising microbubble flow and enter The strip-shaped gas-water mixing chamber 13 is fully mixed with the flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com