Battery temperature control device and method, controller, storage medium and charging converter station

A battery temperature, charging and swapping station technology, applied in the field of battery temperature control devices, can solve the problems of unmaintainable temperature, low water temperature of the water cooling system, limited cooling capacity and heating capacity of the water cooling system, etc., to achieve rapid and effective control and prevent volume changes , to ensure the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

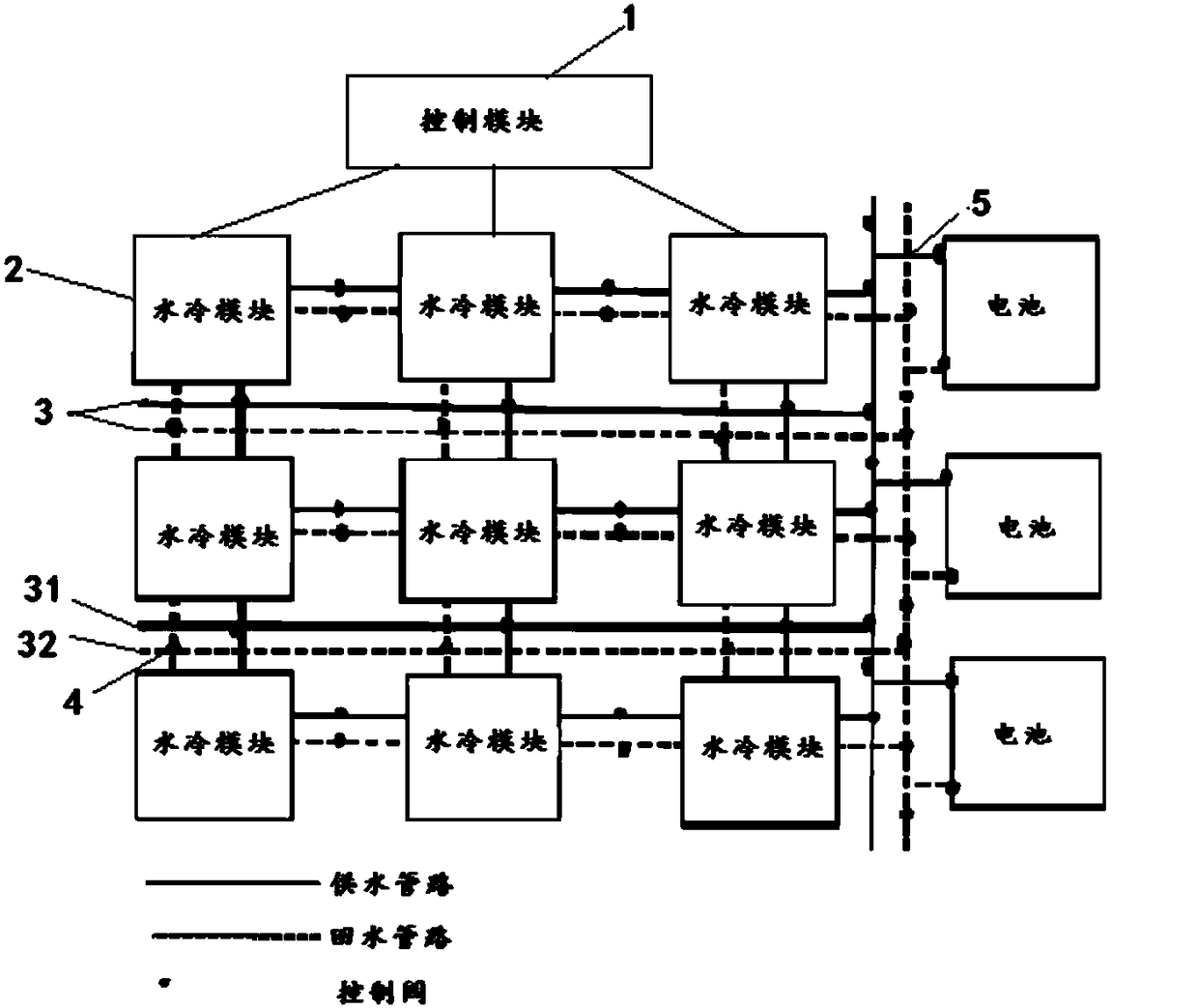

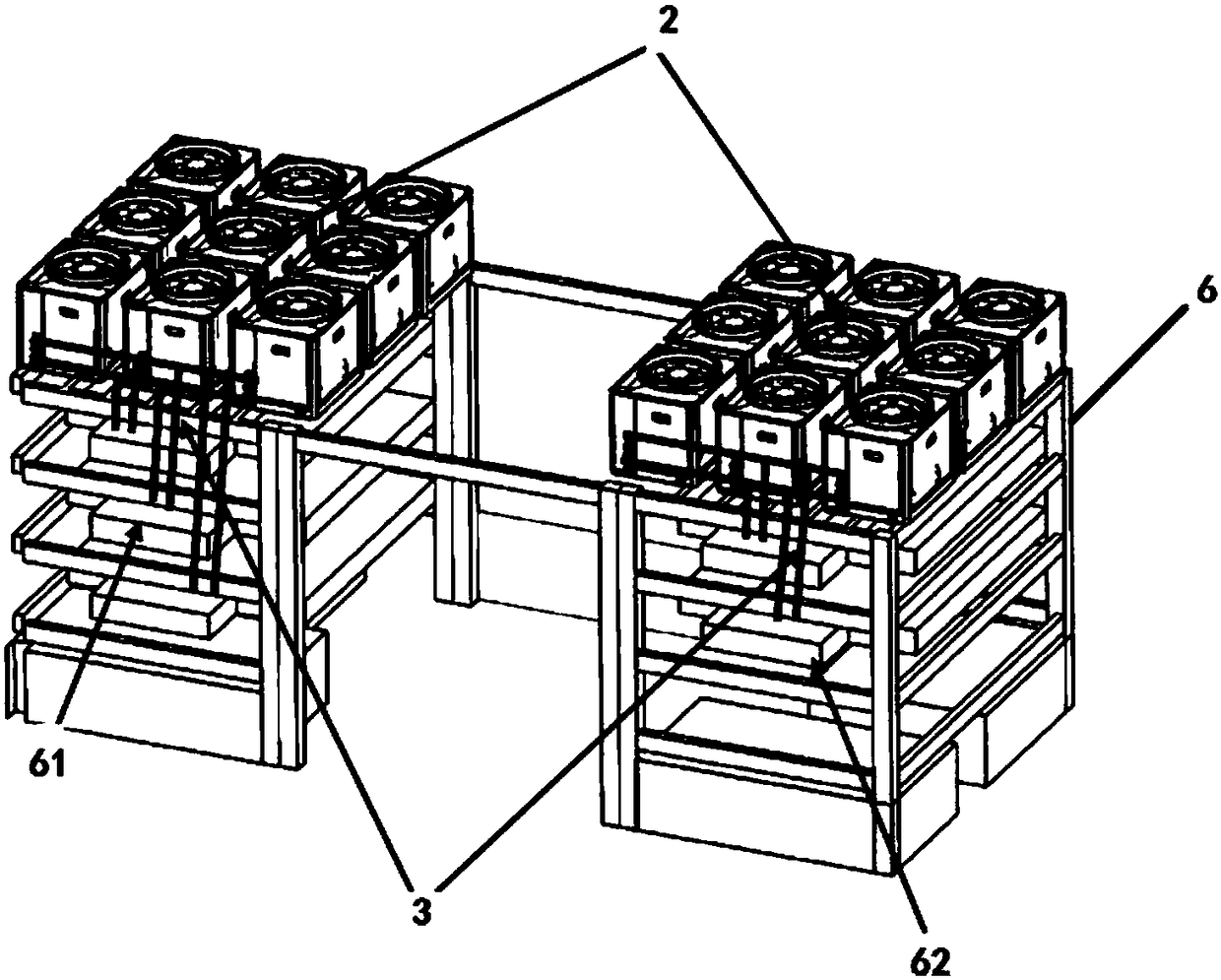

[0064] When the control module 1 is used in the electric vehicle battery replacement process, it includes: a parameter acquisition unit, a configuration unit and an execution unit, wherein the parameter acquisition unit is connected to the configuration unit, the configuration unit is connected to the execution unit, and the parameter acquisition unit It is used to obtain the battery temperature state of the vehicle to be replaced and the temperature state of the battery that is about to be replaced to the vehicle to be replaced; the configuration unit is used to obtain the temperature state of the battery of the vehicle to be replaced and the The temperature state of the battery of the electric vehicle, the number of water-cooling modules 2 that need to be connected to the configuration, and the cooling capacity and heating capacity of each connected water-cooling module 2 are used as an example. The cell temperature of the battery is -20°C, and the cell temperature of the bat...

Embodiment 2

[0068] When the control module 1 is used in the battery charging process, it also includes: a temperature acquisition unit and an adjustment unit, the temperature acquisition unit and the adjustment unit are connected, wherein the temperature acquisition unit is used to acquire the temperature state of the rechargeable battery (for example, it can be used at regular intervals) collecting temperature data), the rechargeable battery is a battery in a charging state in the electric vehicle charging and swapping station. During the charging process of the rechargeable battery, the battery BMS (battery management system) can feed back the temperature state of the rechargeable battery to the temperature acquisition unit in real time; the adjustment unit is used to adjust the access to the rechargeable battery according to the temperature state of the rechargeable battery The number of water-cooling modules 2, as well as the cooling capacity and heating capacity of each connected wate...

Embodiment 3

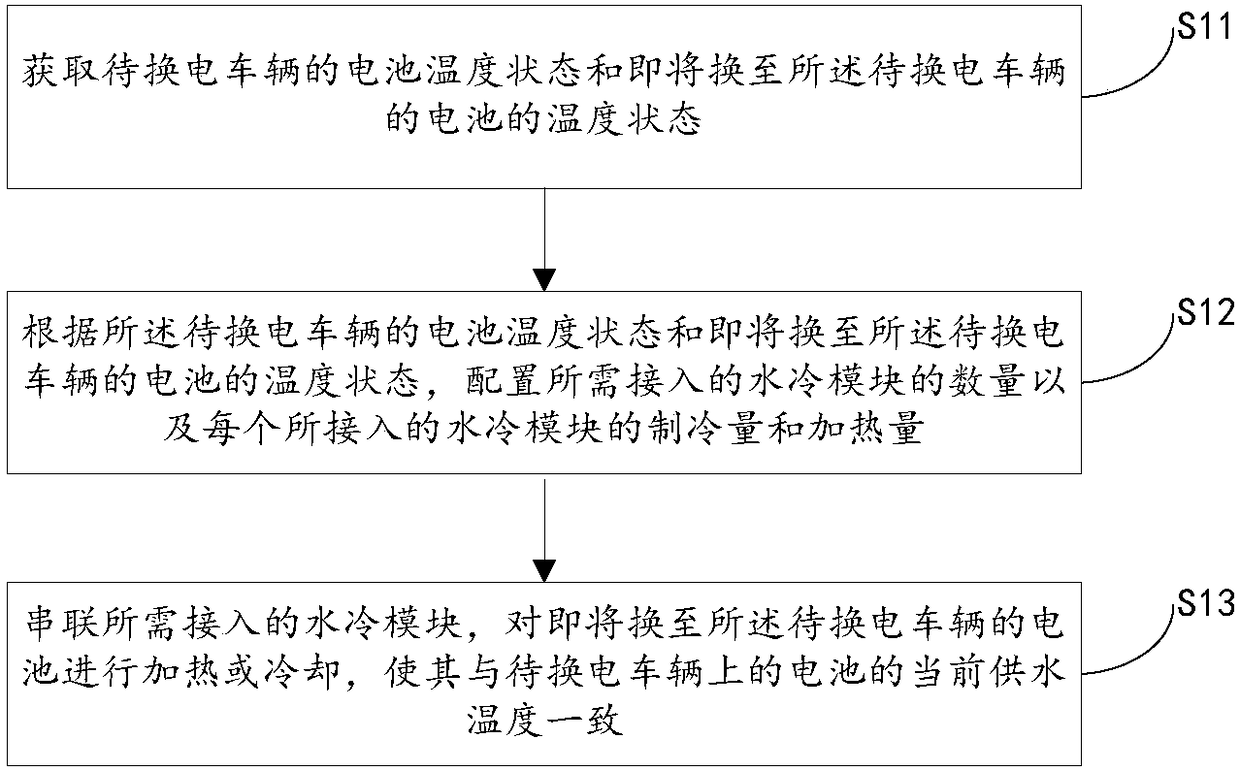

[0081] When the method is used in the electric vehicle battery replacement process, when controlling the battery temperature, the method specifically includes the following steps:

[0082] Step S11, acquiring the temperature state of the battery of the vehicle to be replaced and the temperature state of the battery to be replaced by the vehicle to be replaced;

[0083] Before step S11, the method may also include the following steps:

[0084] Step S100, collecting a plurality of battery temperature data under each driving condition in advance, so as to obtain the corresponding relationship between each driving condition and the battery temperature state;

[0085]S101. According to the corresponding temperature range under all driving conditions, set a reasonable cooling capacity range and heating capacity range of each water-cooling module 2, that is, the maximum cooling capacity, the minimum cooling capacity, the maximum heating capacity and the maximum heating capacity of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com