A method and device for safely dismantling and recycling lithium-ion batteries

A lithium-ion battery and recycling device technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as fire, inability to classify and recycle waste battery electrolyte, and poor disassembly efficiency, and achieves increased application sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

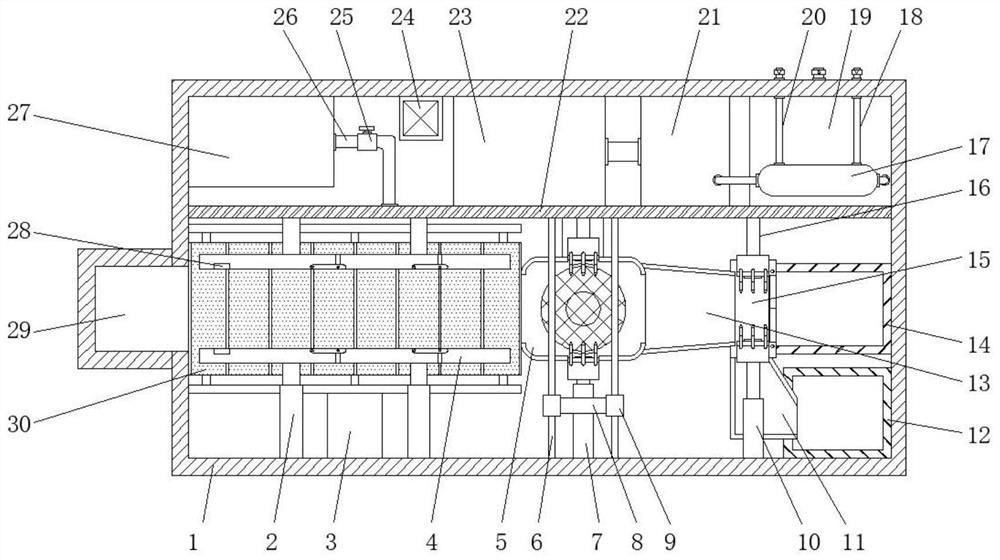

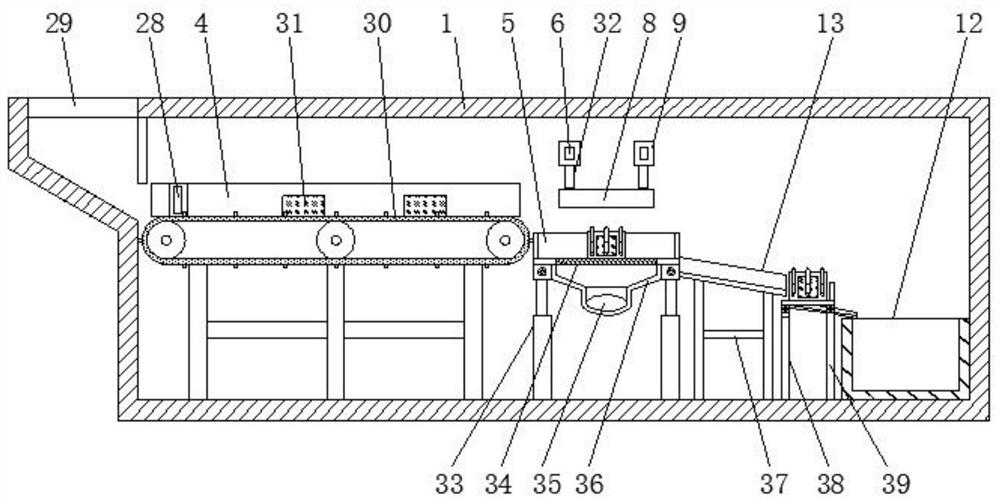

[0042] A method for safely dismantling and recycling lithium-ion batteries, comprising the steps of:

[0043] Step 1: Regulate the pressure of the injected inert gas through the pressure reducing valve 25, and pass the inert gas in the gas tank 27 into the body 1 through the gas pipe 26 as a protective gas. The inert gas in the gas tank 27 is nitrogen or argon , Effectively form an inert gas protective layer at the cutting position to ensure the stability of the waste battery during dismantling, thereby avoiding the phenomenon of fire during the dismantling of the waste battery and increasing the safety of the device;

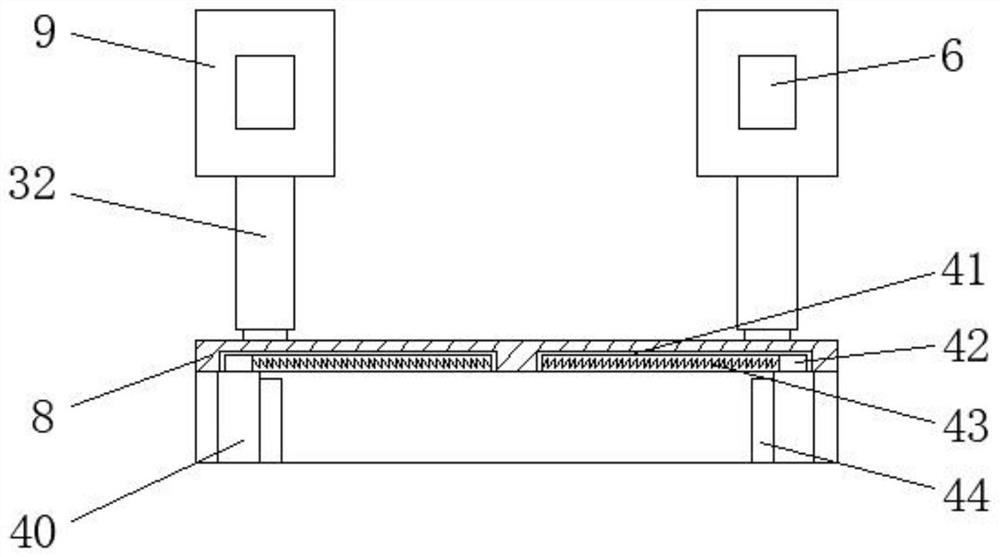

[0044] Step 2: Put the lithium-ion battery into the body 1 through the waste battery inlet 29, pass through the baffle plate in the waste battery transportation channel and overturn it initially, so that the waste battery falls smoothly on the transportation mechanism, and passes through the battery terminals on both sides of the transportation mechanism. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com