Garbage classification, recovery and treatment device

A technology for recycling and sorting garbage. It is used in garbage collection, trash cans, grain processing, etc. It can solve the problems of poor filling, affecting the air environment, and unpleasant gas, so as to achieve the effect of convenient taking out and putting in and convenient collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

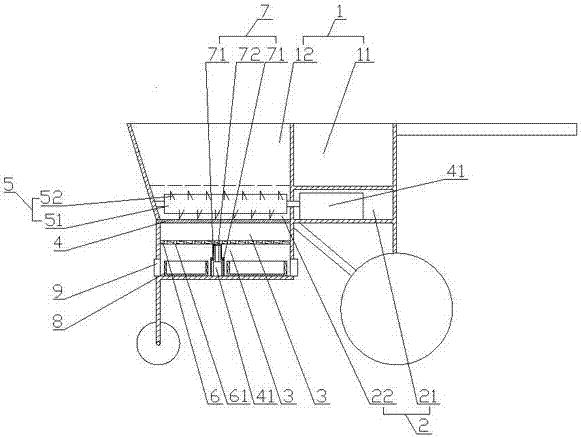

[0031] Such as figure 1 As shown, the garbage sorting and recycling device includes a cart body. The cart body is divided into a feeding chamber 1, a processing chamber 2, and a collection chamber 3 from top to bottom. The feeding chamber 1 is divided into a recycling chamber 11 and a kitchen garbage collection chamber. The chamber 12 and the processing chamber 2 are horizontally divided into a motor placement chamber 21 and a crushing cutter placement chamber 22, the kitchen waste chamber 12 communicates with the crushing cutter placement chamber 22, and the crushing cutter placement chamber 22 is connected to the collection chamber 3 Connected, and a movable baffle 4 is inserted between the crushing cutter placement chamber 22 and the collection chamber 3; a motor 41 is arranged in the motor placement chamber 21, and a crushing cutter 5 and a motor 41 are arranged in the crushing cutter 5 placement chamber 22 The crushing tool 5 is driven, and an extruding plate 6 is arrange...

Embodiment 2

[0034] Such as figure 1 As shown, compared with Embodiment 1, this embodiment optimizes the crushing tool 5, which includes a tool spindle 51 and a crushing knife 52, the crushing knife 52 is installed on the cutter spindle 51, and the motor 41 drives the cutter spindle 51.

[0035] In this embodiment, the pulverizing knife 52 is driven to rotate by the tool spindle 51, so that the pulverizing effect can be further improved by adopting a method similar to a hob.

Embodiment 3

[0037] Such as figure 1 As shown, compared with Embodiment 1, this embodiment adds a baffle opening, the cart body at the junction of the pulverizing tool placement chamber 22 and the collection chamber 3 is provided with a baffle opening, and the mobile baffle 4 is set through the baffle opening Between the crushing tool placement cavity 22 and the collection cavity 3 .

[0038] In this embodiment, the movable baffle 4 can be conveniently inserted between the pulverizing tool placement cavity 22 and the collection cavity 3 through the baffle opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com