Counter play sifting method and screen employing drop energy of screening material

A screening and material technology, applied in chemical instruments and methods, filtration, solid separation, etc., can solve the problem of unsatisfactory screening of viscous materials, and achieve the effect of favorable screening and effective screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

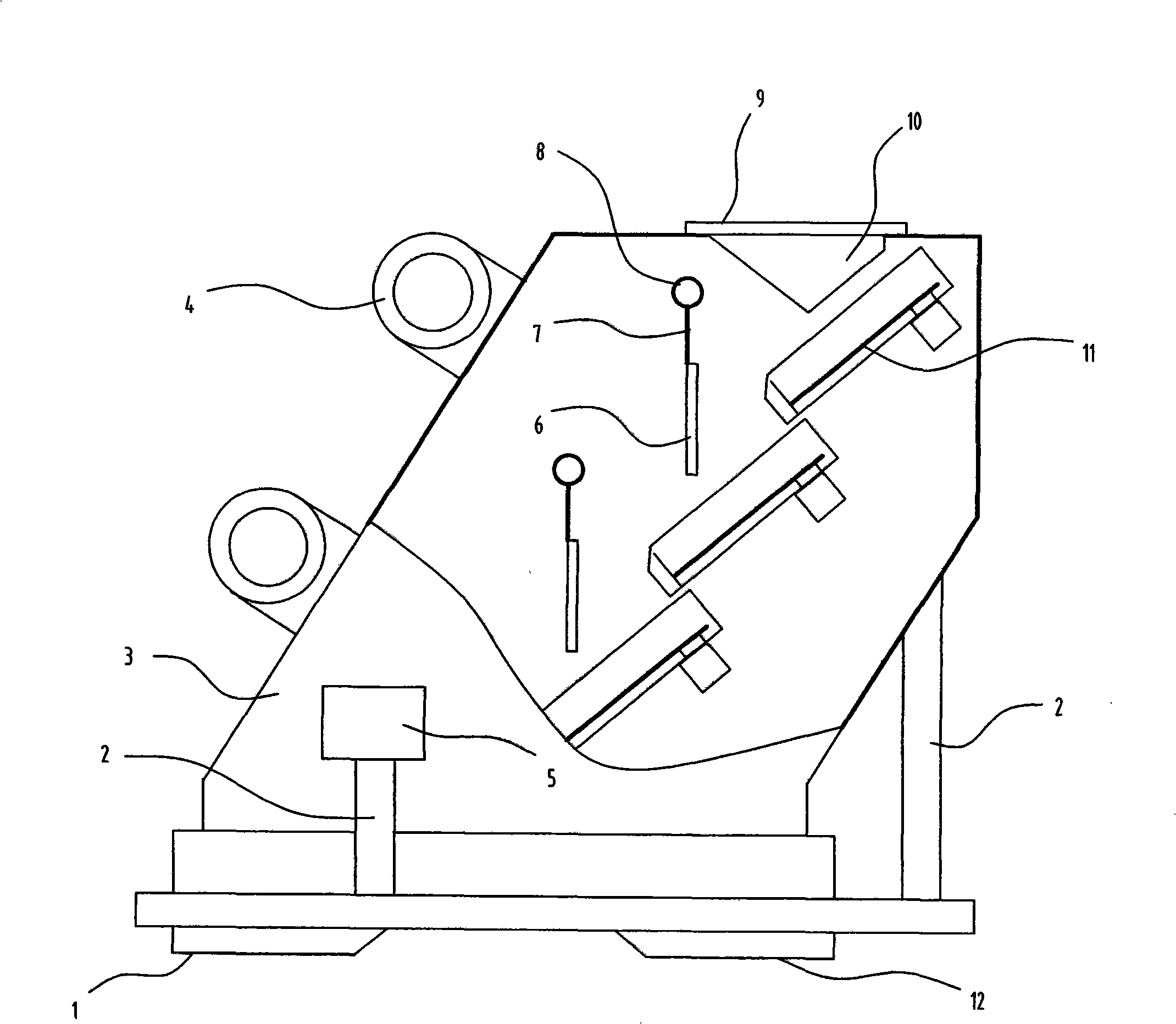

[0010] In order to clearly illustrate the technical characteristics of this scheme, the counterattack screening method and the counterattack sieve of this scheme using the falling energy of sieving materials will be described through a specific implementation mode and the accompanying drawings.

[0011] It can be seen from the accompanying drawings that the impact screen described in this program has a bracket 2, which is connected to the inclined box body 3 through a shock absorber 5, and the box body 3 has a feeding port connected to the feeding chute 10 below. 9. On-sieve material outlet 1, under-sieve material outlet 12 and vibration source 4. There is a screen 11 in the box body 3. The screen 11 described in this program is an elastic screen 11 and there are at least two , what this specific embodiment adopts is three screens 11. Each of the screens 11 is arranged in an inclined step, and at the outlet of the corresponding screen 11, there is a counter-attack plate 6 abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com