Sludge treatment method and device for urban drainage pipe network

A technology for drainage pipe network and sludge treatment, which is applied in the direction of dewatering/drying/concentrating sludge treatment, etc., which can solve the problem of high water content of sludge in urban drainage pipe network, increased landfill area, and sludge transportation costs. Increase and other problems, to achieve the effect of reducing the amount of outbound transportation, large processing capacity, and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

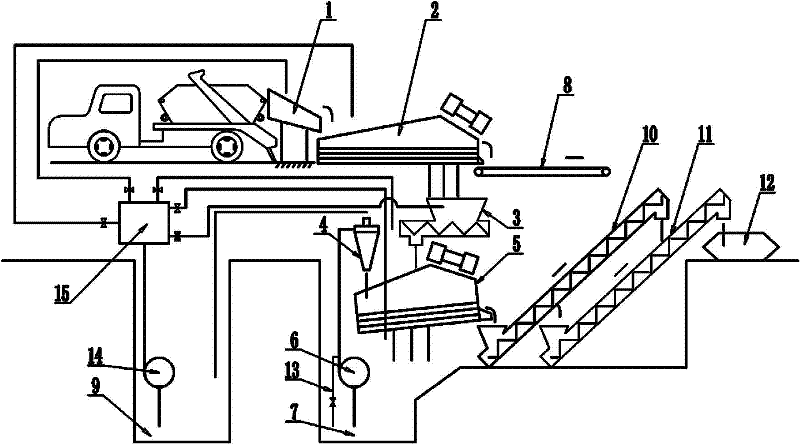

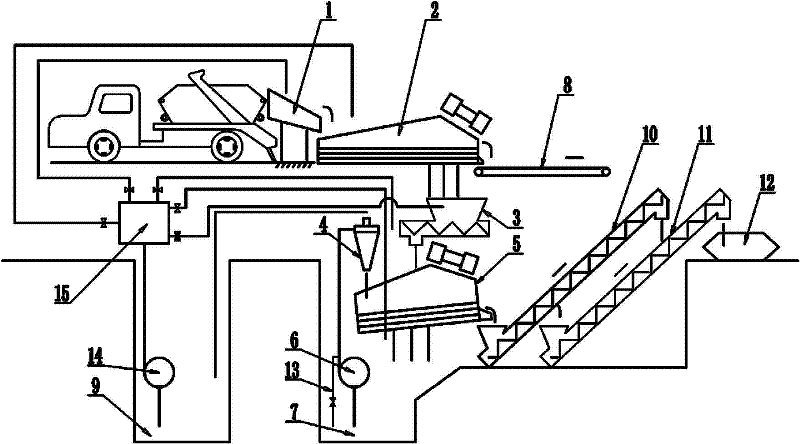

[0030] Such as figure 1 Among them, a kind of urban drainage pipe network sludge treatment method comprises the following steps:

[0031] 1) Steps of multi-stage screening:

[0032] 2) The step of transporting the separated slag to the garbage hopper 12 through the conveying equipment;

[0033] 3) The step of sending the separated sewage to the sewage pond 7;

[0034] 4) The first submersible sewage pump 6 is installed in the sewage pool 7, and the outlet of the first submersible sewage pump 6 is connected to the inlet of the cyclone desander 4, which is used to separate the fine particle size mud and sand, and the separated mud and sand are removed from the cyclone The grit chamber of the sander 4 is discharged to the fine sieve of the vibrating screen 5 in step 1 for dehydration and screening, and the separated sewage enters the underground drainage pipe network from the overflow pipe of the cyclone desander 4;

[0035] 5) Set up the regenerated water pool 9 and use the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com