Waste recycling device for building construction

A waste recycling and building construction technology, applied in grain processing, etc., can solve the problems of difficult extraction of magnetic materials and insufficient fineness of construction waste screening, and achieve the effect of convenient crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

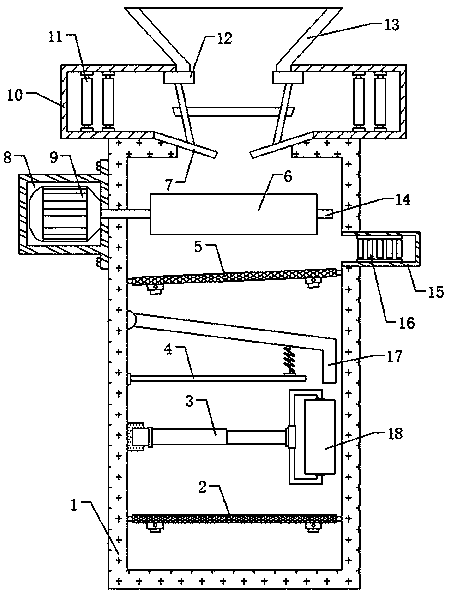

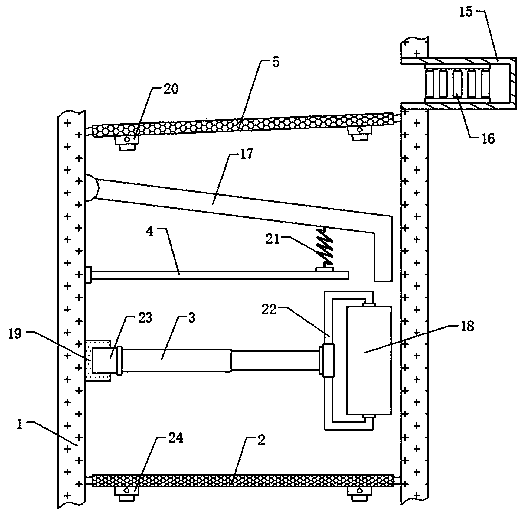

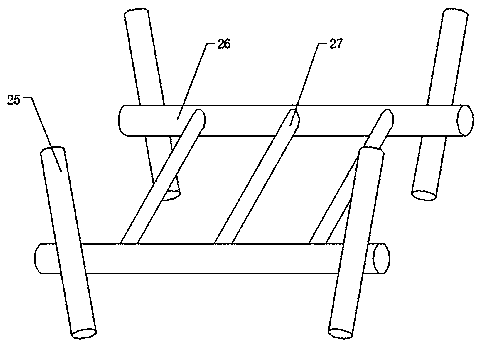

[0030] refer to Figure 1-4 , a waste recycling device for building construction, comprising a box body 1, a storage box 10 is welded on the top outer wall of the box body 1, and a feed hopper 13 is welded at the middle position of the top outer wall of the storage box 10, and one side of the box body 1 The outer wall is provided with two crushing mechanisms near the position of the storage box 10. The box body 1, the storage box 10 and the feed hopper 13 are connected. Both sides of the outer wall of the bottom of the box 10 are welded with a slant plate 7, and one end of the slant plate 7 is located inside the box body 1, and two stoppers 12 are welded on both sides of the inner wall of the top of the storage box 10 near the feed hopper 13, and The bottom outer walls of the four stoppers 12 are welded with retaining rods 25, the outer walls of one side of the two retaining rods 25 are welded with cross bars 26, and the outer walls of the opposite side of the two cross bars 2...

Embodiment 2

[0035] refer to Figure 5 , a waste recovery device for building construction. Compared with Embodiment 1, this embodiment also includes a material guide plate 29. The plate 29 is located directly above the crushing roller 6 .

[0036] When in use, the material guide plate 29 makes the construction waste move towards the middle of the crushing roller 6, avoiding moving to both sides of the box body 1, so as to facilitate better crushing of the construction waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com