Production system of desulfurized stone powder

A production system and technology of stone powder, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of manpower and material resources, large volume occupation, cumbersome process, etc., and achieve the effect of increasing processing capacity, low cost, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to specific embodiments. This embodiment is based on the technical solution of the present invention as a prerequisite, and provides detailed implementation manners and specific operation procedures.

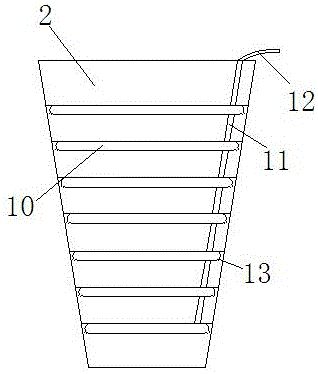

[0023] The present invention is a production system for desulfurized stone powder. The desulfurized stone powder raw material is crushed by the crusher 1 and then sent to the screening machine 14 through the conveyor to screen the particle size of the raw material, and the fine-grained raw material selected is sent to the grinding machine through a conveyor belt Grinding is carried out in the middle, and finally the powder that meets the requirements is sent to the bin 2 through the elevator.

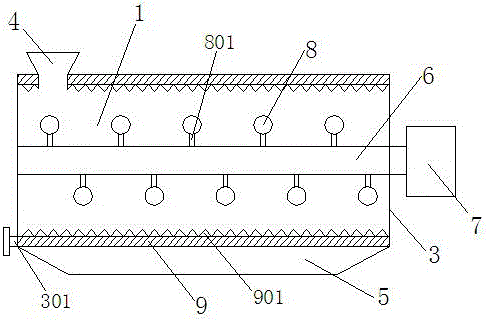

[0024] Such as figure 1 As shown, the crusher 1 includes a body 3, a feeding bin 4 and a discharging bin 5 respectively arranged at the top and bottom of the body 3, a rotating shaft 6 horizontally arranged in the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com