Two-time brick-concrete separating process for building wastes

A construction waste and brick-concrete technology, which is applied in grain processing and other fields, can solve the problems of low material utilization rate, low added value, and low income from construction waste treatment and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

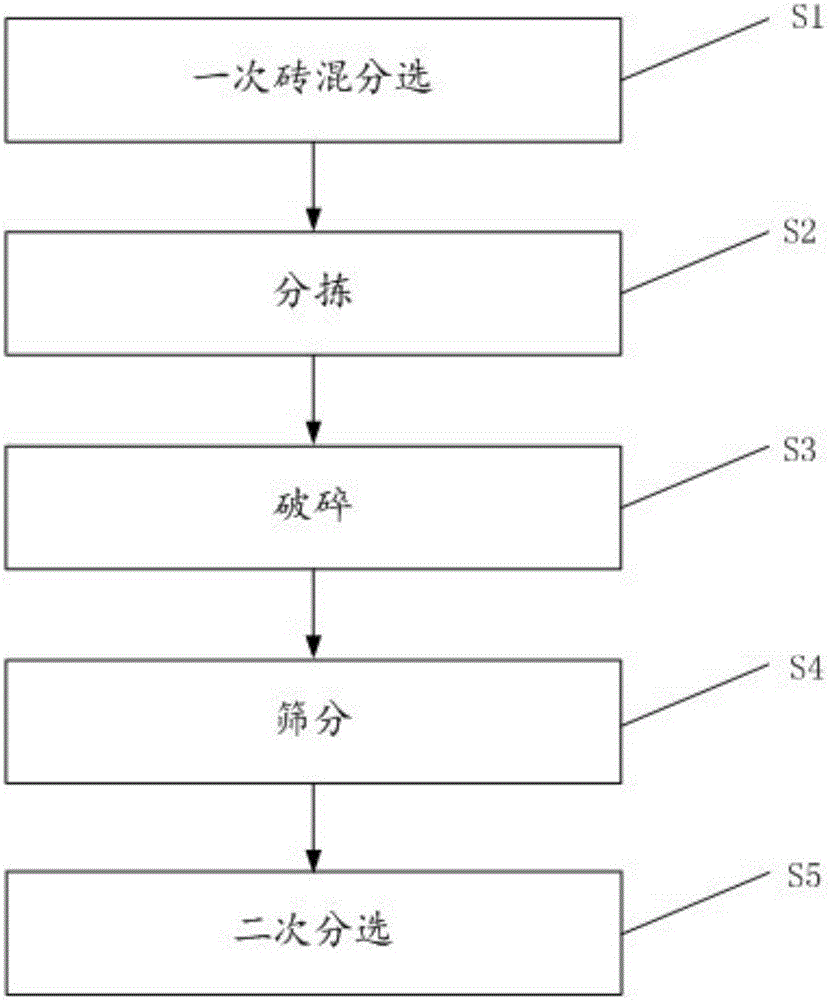

[0050] Such as figure 1 As shown, the construction waste twice brick-concrete separation process that the present embodiment provides, it comprises the following steps:

[0051] S1, a brick-concrete sorting

[0052] Sorting the construction waste raw materials once to obtain the first material, the second material and the third material, and output the first material, the second material and the third material respectively;

[0053] S2, sorting

[0054] Sorting the first material to remove sundries in the first material;

[0055] S3, Broken

[0056] Transport the sorted first material to the crusher for crushing:

[0057] S4, screening

[0058] transporting the crushed first material to a first screening device for screening, obtaining muck, first coarse material and first fine material, and outputting the first fine material;

[0059] S5, secondary sorting

[0060] The first fine material is transported to the first flotation device for secondary separation to obtain b...

Embodiment 2

[0066] The two-time brick-concrete separation process for construction waste provided in this example, on the basis of Example 1, provides an optimal process for brick-concrete separation in step S1, as follows.

[0067] The step S1 specifically includes the following steps:

[0068] S1-1, transport the raw materials of construction waste to the grate feeder, separate the third material through the grate gap of the grate feeder, and output the unseparated mixture of the first material and the second material:

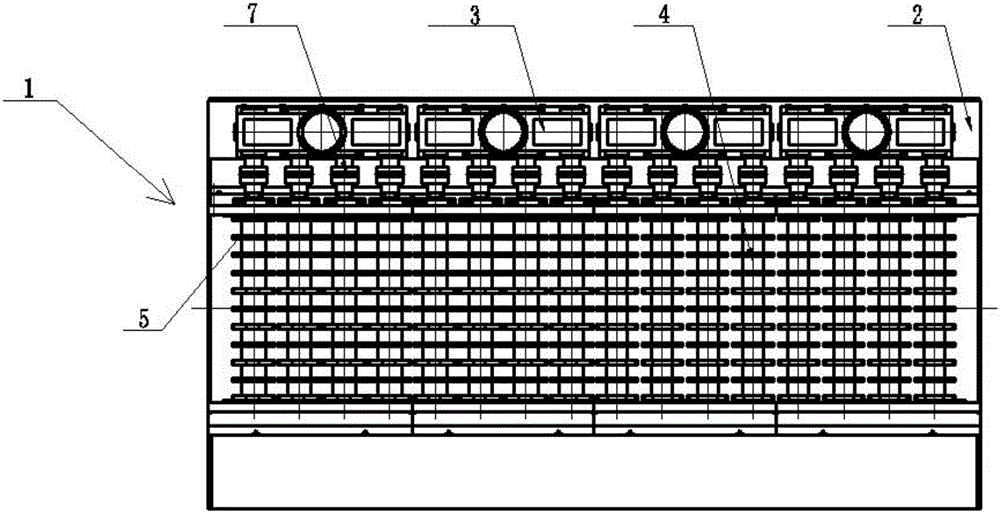

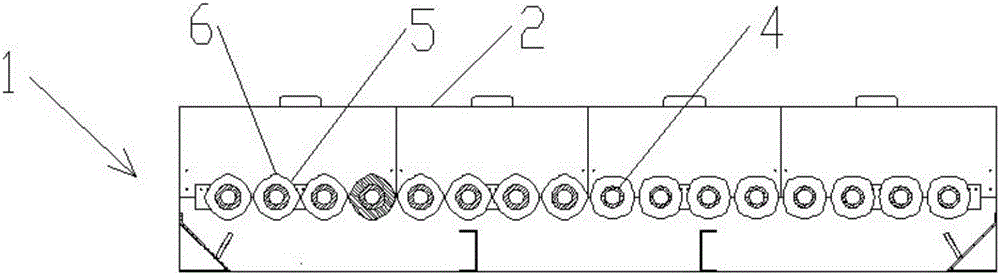

[0069] S1-2, transporting the unseparated mixture of the first material and the second material to the brick-mix separator, implementing brick-mix separation, and obtaining the separated first material and second material;

[0070] S1-3, performing crushing and iron removal treatment on the separated first material: performing crushing treatment on the separated second material.

[0071] The raw materials of construction waste can be shoveled out by excavators and tran...

Embodiment 3

[0076] Embodiment 1 provides the subsequent treatment process of the crushed first material with concrete as the main component. The construction waste separation process of brick and concrete twice provided in this embodiment, in addition to the process provided in Embodiment 1 or Embodiment 2 In addition to the process scheme, it also includes the following specific process scheme.

[0077] Said step S4 also includes the following steps:

[0078] S4-1, returning the first coarse material to the crusher for re-crushing, and transporting it to the first screening device for screening to obtain muck, coarse material of the first size and first fine material;

[0079] S4-2, returning the coarse material of the first size to the crusher for re-crushing, and transporting it to the first screening device for screening to obtain muck, coarse material of the second size and first fine material;

[0080] S4-3, returning the coarse material of the second size to the crusher for crushi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com