Overhead insulation lead hot melting peeling knife

A technology of overhead insulated wires and stripping knives, which is applied to cable installation devices, electrical components, and equipment for dismantling/armoured cables, etc., which can solve problems such as time-consuming and physical effort, reduced work efficiency, and difficulty in peeling off the insulation layer. Save operating time, reduce labor intensity, and quickly peel the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

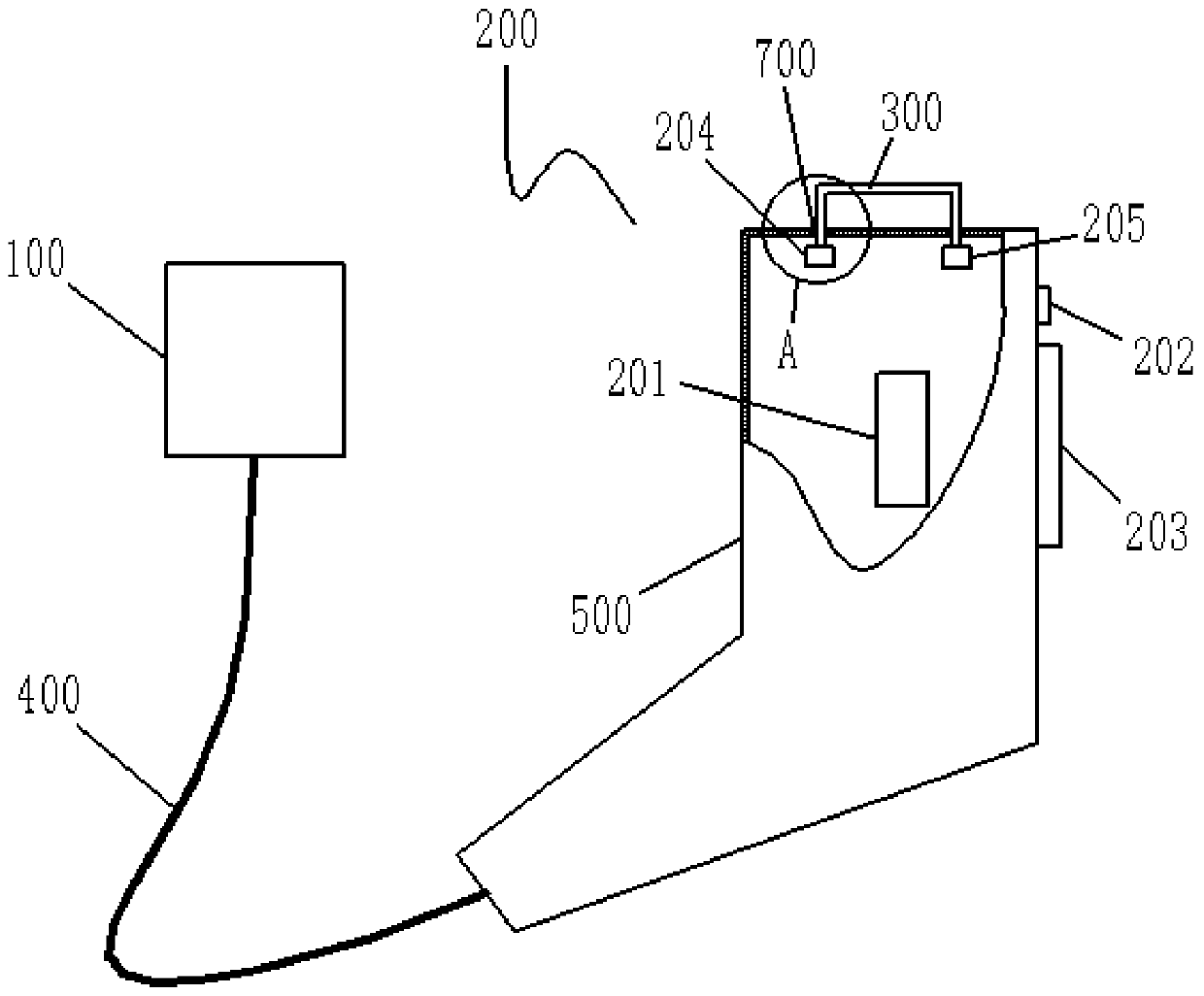

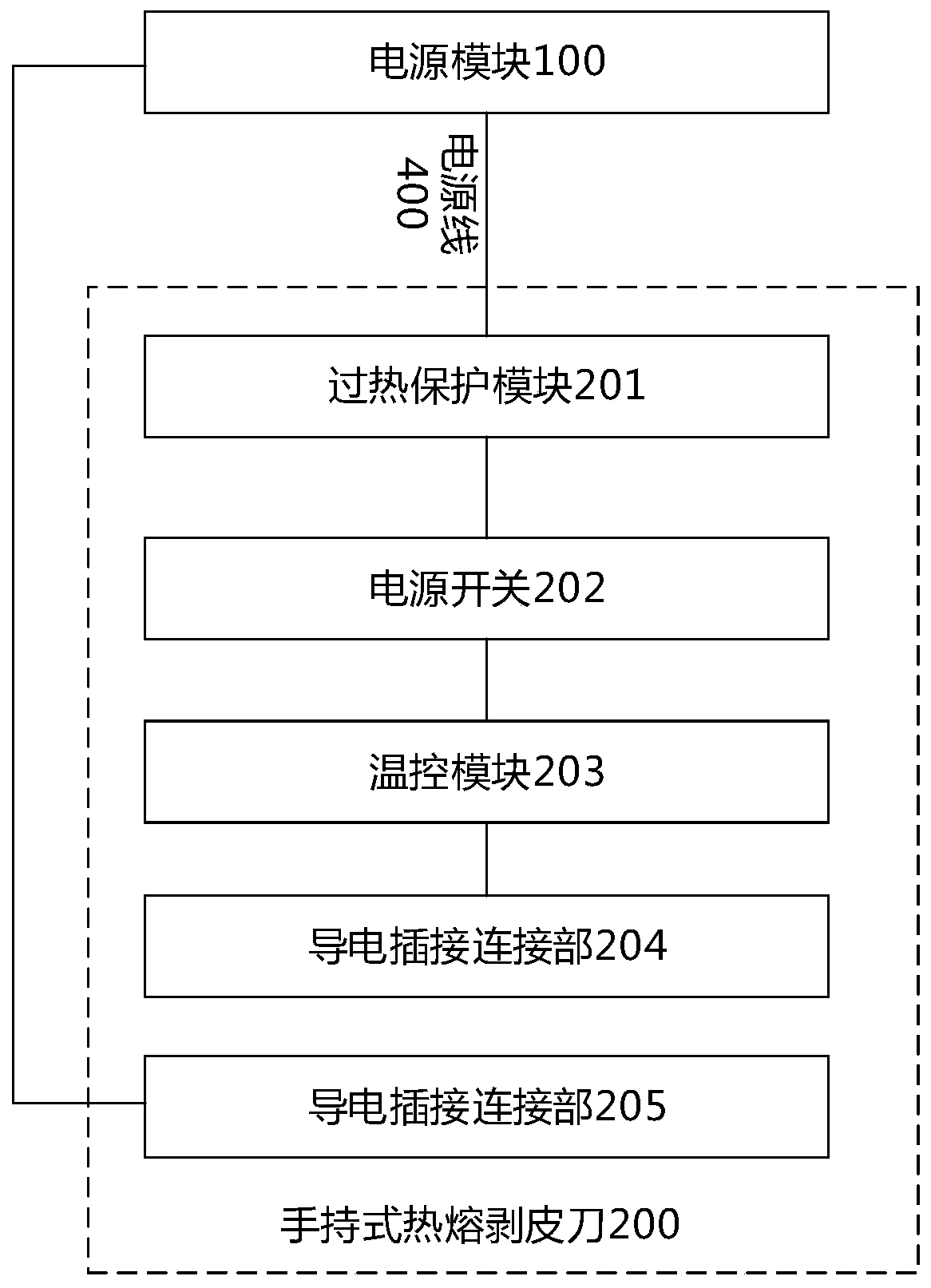

[0033] figure 1 , figure 2 , image 3 and Figure 5 It is a schematic structural diagram of a hot-melt stripping knife for overhead insulated conductors according to an embodiment of the present invention.

[0034] Such as Figure 1-Figure 3 and Figure 5 As shown, the hot-melt skinning knife for overhead insulated wires includes a power module 100 and a handheld hot-melt skinning knife 200 , and the power module 100 is connected to the hand-held hot-melt skinning knife 200 through a power cord 400 . The hand-held hot-melt peeling knife 200 includes an insulating shell 500 and a metal hot-melt cutter 300, both ends of the hot-melt cutter 300 have conductive plug connectors, and the insulating shell 500 is integrated with a power supply Switch 202, an overheating protection module 201 and two conductive sockets (conductive plug connector 204 and conductive plug connector 205) are integrated in the insulating housing 500, and the insulating housing 500 is provided with two...

Embodiment 2

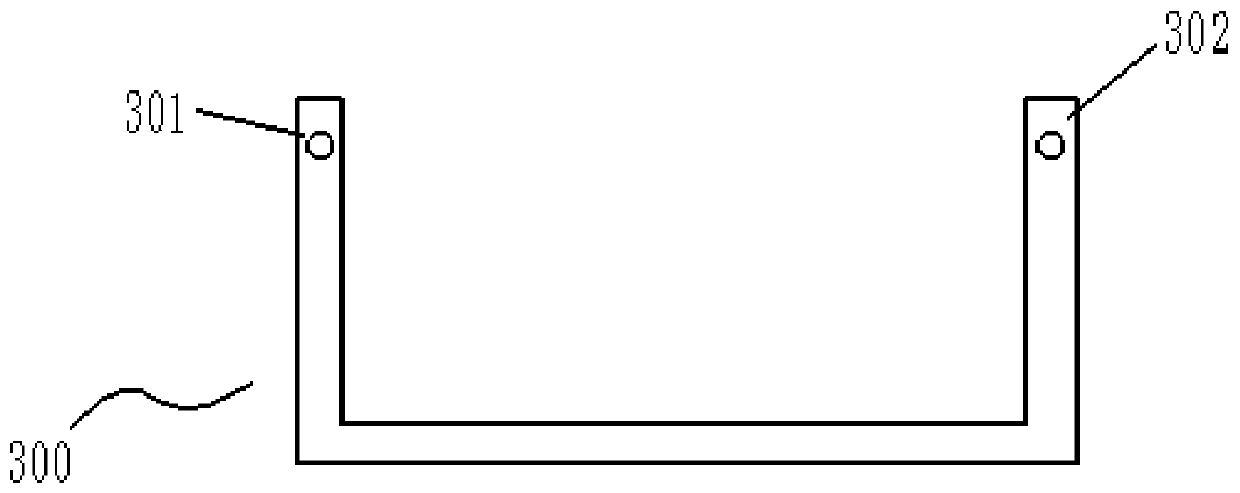

[0042] Compared with Embodiment 1, this embodiment is different in that, the overhead insulated wire hot-melt stripping knife described in this embodiment has a hub 600 for collecting the power cord 400 on the top of the power module 100 . The hub 600 is used to collect the power cord 400 . When not in use, the power cord 400 is collected on the hub 600; when in use, the power cord 400 can be removed from the hub 600. Easy to use. The schematic diagram of the structure of the hub 600 and the power module 100 is as follows Figure 6 As shown, the hub 600 in the figure is U-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com