Composite material special for blow molding of reinforced nylon air inlet pipe and preparation method thereof

A composite material and air intake pipe technology, which is applied in the field of special nylon materials for auto parts, can solve the problems of high dependence, difficulty in one-time molding, plasticization, etc., and achieve excellent impact resistance and high temperature resistance, and excellent gasoline barrier performance , the effect of good blow molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

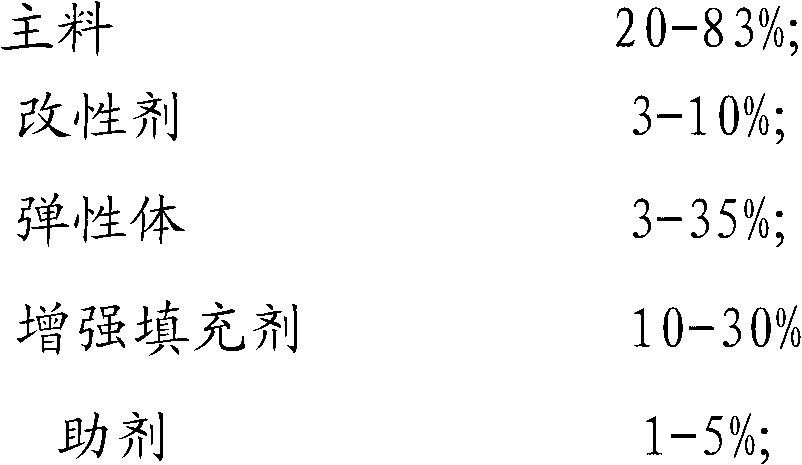

[0028] A special composite material for blow molding of reinforced nylon intake pipe, comprising components and the mass percentages of each component are as follows:

[0029]

[0030] Wherein, the main material is selected from nylon 6; the modifier is selected from a mixture of polybutylene terephthalate (PBT) and polyethylene terephthalate (PET); the elastic The body is selected from polyolefin elastomer (POE); the reinforcing filler is selected from a mixture of alkali-free glass fiber and kaolin; the additives include temperature-resistant and anti-aging agents, lubricants, nucleating agents and tackifiers. The mass percentages of the following components in the total amount of the reinforced nylon air intake pipe blow molding special composite material are:

[0031]

[0032] The temperature-resistant anti-aging agent is selected from hindered phenolic antioxidants. The lubricant is selected from calcium stearate. The nucleating agent is selected from talcum powde...

Embodiment 2

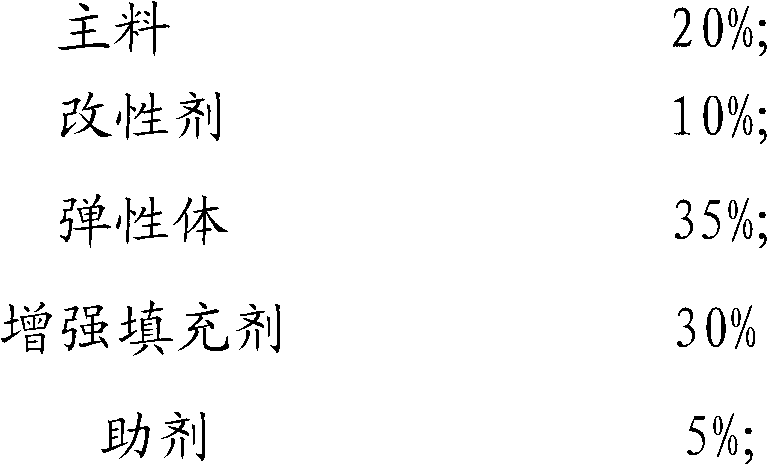

[0034] A special composite material for blow molding of reinforced nylon intake pipe, comprising components and the mass percentages of each component are as follows:

[0035]

[0036] Wherein, the main material is selected from nylon 66, and nylon 6 / 66 copolymer or any thereof; the modifier is selected from acrylonitrile-butadiene-styrene terpolymer resin (ABS) and high-density poly A mixture of ethylene (HDPE); the elastomer is selected from thermoplastic elastomers (TPE); the reinforcing filler is selected from montmorillonite; the additives include temperature-resistant and anti-aging agents, lubricants, nucleating agents and tackifiers agent. The mass percentages of the following components in the total amount of the reinforced nylon air intake pipe blow molding special composite material are:

[0037]

[0038] The temperature-resistant anti-aging agent is selected from phosphite antioxidants. The lubricant is selected from a mixture of ethylene bis stearic acid a...

Embodiment 3

[0040] A special composite material for blow molding of reinforced nylon intake pipe, comprising components and the mass percentages of each component are as follows:

[0041]

[0042] Wherein, the main material is selected from nylon 6 / 66 copolymer; the modifier is selected from acrylonitrile-butadiene-styrene terpolymer resin (ABS); the elastomer is selected from EPDM Rubber (EPDM); the reinforcing filler is selected from a mixture of calcium carbonate and barium sulfate; the additives include temperature-resistant and anti-aging agents, lubricants, nucleating agents and tackifiers. The mass percentages of the following components in the total amount of the reinforced nylon air intake pipe blow molding special composite material are:

[0043]

[0044] The temperature-resistant anti-aging agent is selected from alkali metal halides. The lubricant is selected from silicone powder. The nucleating agent is selected from talcum powder. The maleic anhydride grafted nylon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com