Preparation method of low-viscosity cation starch

A cationic starch and low-viscosity technology, which is applied in the field of starch denaturation, can solve problems such as difficulty in the fluidity of starch paste, reduction of positive charge or even negative charge of starch granules, so as to improve the efficiency of etherification reaction and shorten the reaction time of etherification , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

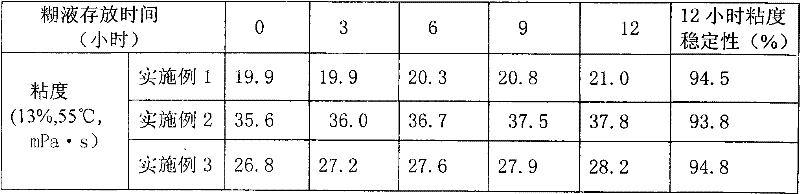

Embodiment 1

[0033] 60m 3 Fresh tapioca starch milk with a concentration of 38% (or water and native starch mixed into starch milk), add 945kg of sodium sulfate, 310kg of calcium oxide, 27kg of urea, and 7.5kg of copper sulfate under stirring. Heat to 42℃ and add 2007kg of 3-chloro-2-hydroxypropyltrimethylammonium chloride activated by on-site alkali (use 637kg of 30% sodium hydroxide to activate 1370kg of 69% 3-chloro-2-hydroxypropyltrimethyl) Base ammonium chloride), keep 47~48℃, react for 2 hours; add 945kg hydrogen peroxide in continuous flow for oxidation reaction for 4 hours; then lower the temperature of starch suspension to 35℃, adjust the suspension PH=8.5 with hydrochloric acid, and continue to flow Add 1800kg of sodium hypochlorite solution and adjust the starch suspension PH=9.0~9.2 with 8% sodium hydroxide solution, keep it at 35~36℃, carry out oxidation reaction for 1.5 hours, adjust the suspension pH=6.5 with hydrochloric acid, add sodium sulfite 10.8kg, washed, dehydrated an...

Embodiment 2

[0035] 60m 3 Fresh tapioca starch milk with a concentration of 38% (or water and native starch mixed into starch milk), add 1215kg of sodium chloride, 230kg of calcium oxide, 162kg of sodium silicate, and 5.4kg of iron sulfate under stirring, and heat to 42 ℃, add 2178kg of 3-chloro-2-hydroxypropyltrimethylammonium chloride activated by in-situ alkali (use 691kg of 30% sodium hydroxide to activate 1487kg of 69% 3-chloro-2-hydroxypropyl Trimethylammonium chloride), keep at 49~50℃, react for 1.5 hours; add 1215kg of hydrogen peroxide in continuous flow for oxidation reaction for 4.5 hours; then reduce the temperature of the starch suspension to 33℃, adjust the suspension PH=8.5 with hydrochloric acid , Add 1350kg of sodium hypochlorite solution in continuous flow, and adjust the starch suspension PH=8.8~9.0 with potassium hydroxide solution with a concentration of 8%, keep it at 33~35℃, carry out oxidation reaction for 1 hour, adjust the suspension PH=6.5 with hydrochloric acid ,...

Embodiment 3

[0037] 60m 3 Fresh tapioca starch milk with a concentration of 38% (or water and native starch mixed into starch milk), add sodium sulfate 756kg, sodium chloride 270kg, calcium oxide 351kg, nickel sulfate 4kg in sequence under stirring, and heat to 42℃. Add 1749 kg of 3-chloro-2-hydroxypropyl trimethyl ammonium chloride activated by on-site alkali (use 575 kg of 30% sodium hydroxide to activate 1174 kg of 69% 3-chloro-2-hydroxypropyl trimethyl ammonium chloride). Methyl ammonium chloride), keep at 50~51℃, react for 2.5 hours; add 1026kg hydrogen peroxide in continuous flow for oxidation reaction for 4 hours; then reduce the temperature of starch suspension to 35℃, adjust the suspension PH=8.5 with hydrochloric acid, continue Add 1463kg of sodium hypochlorite solution, while adjusting the starch suspension PH=8.8~9.0 with an alkaline catalyst, keep it at 35~37℃, carry out oxidation reaction for 1 hour and 20 minutes; then adjust the suspension pH=6.5 with hydrochloric acid, add h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com