Dust fall liquid integrating active trapping, moistening and coagulation, dust fall system and dust fall method

An active, dust-liquid technology, applied in chemical instruments and methods, separation methods, dust prevention, etc., can solve the problems of coal dust explosion, little effect, poor dust reduction effect, etc., achieve rapid dust removal, reduce risk, and save water amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

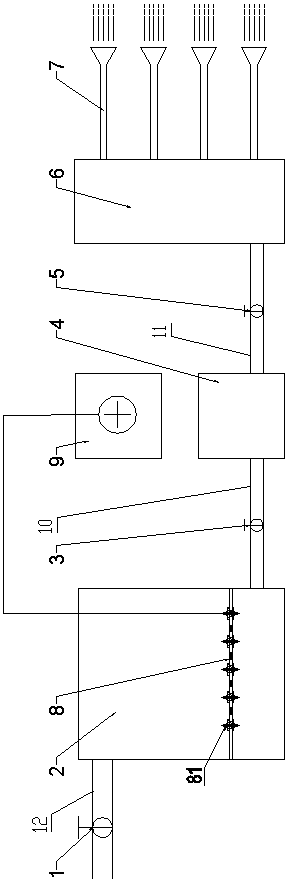

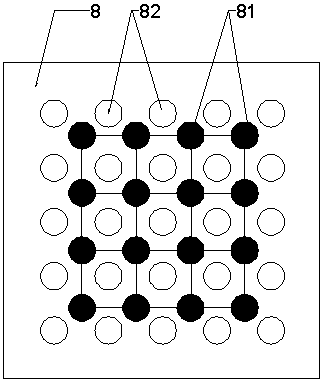

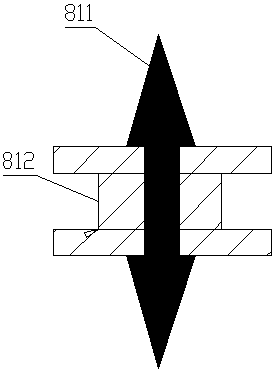

Image

Examples

Embodiment 1

[0052] In this embodiment, the mass concentrations of alum, sulfite and potassium permanganate in the dust-falling liquid are 0.02%, 0.02% and 0.01%, respectively.

Embodiment 2

[0054] In this embodiment, the mass concentrations of alum, sulfite and potassium permanganate in the dust-falling liquid are 0.08%, 0.8% and 0.5%, respectively.

Embodiment 3

[0056] In this embodiment, the mass concentrations of alum, sulfite and potassium permanganate in the dust-falling liquid are 0.2%, 1% and 0.8%, respectively.

[0057] Spray tests were carried out on-site using the dust-precipitating fluids in Examples 1 to 3, and the dust concentrations in the fully mechanized mining face without any dust control measures and in the three embodiments of the present invention were measured, as shown in Table 1.

[0058] Table 1 shows the dust data measured at various points in the fully mechanized mining face when different measures are adopted.

[0059] Table 1:

[0060]

[0061] As can be seen from Table 1, the embodiment 1, embodiment 2 and embodiment 3 of the method of the present invention are sprayed at the three main dust-producing points at the moving frame of the fully mechanized mining face, the coal cutting place and the coal discharge port. After dust reduction, the dust reduction rate of the whole dust is significantly improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com