Patents

Literature

86results about How to "Avoid overreaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal-matrix composite material and preparation method thereof

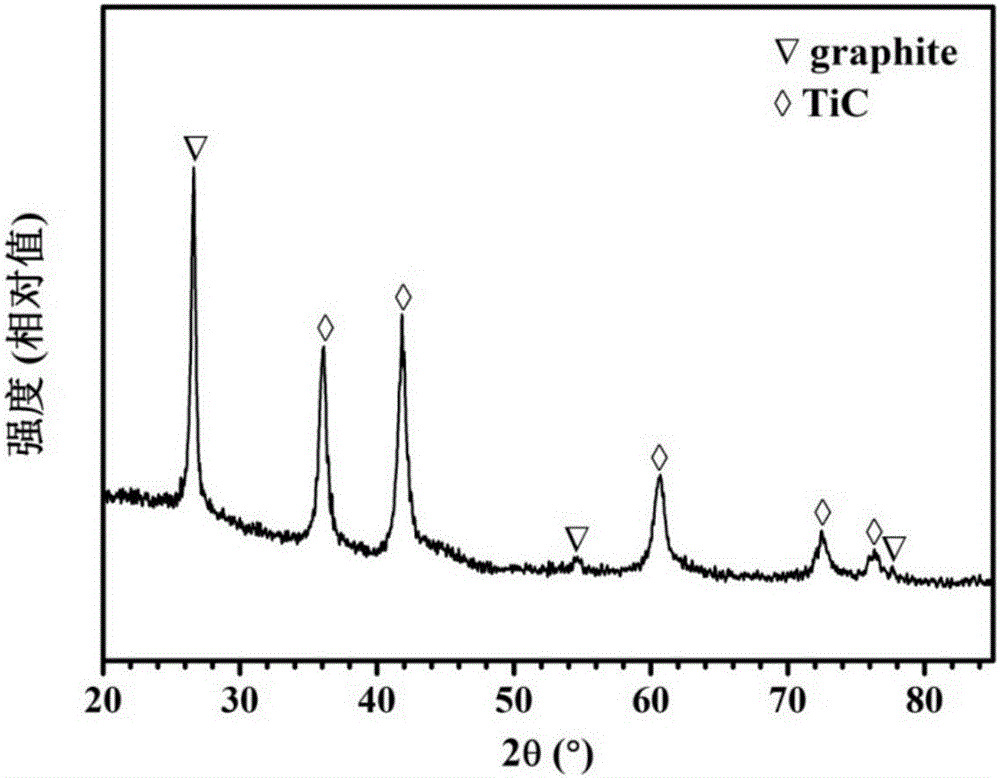

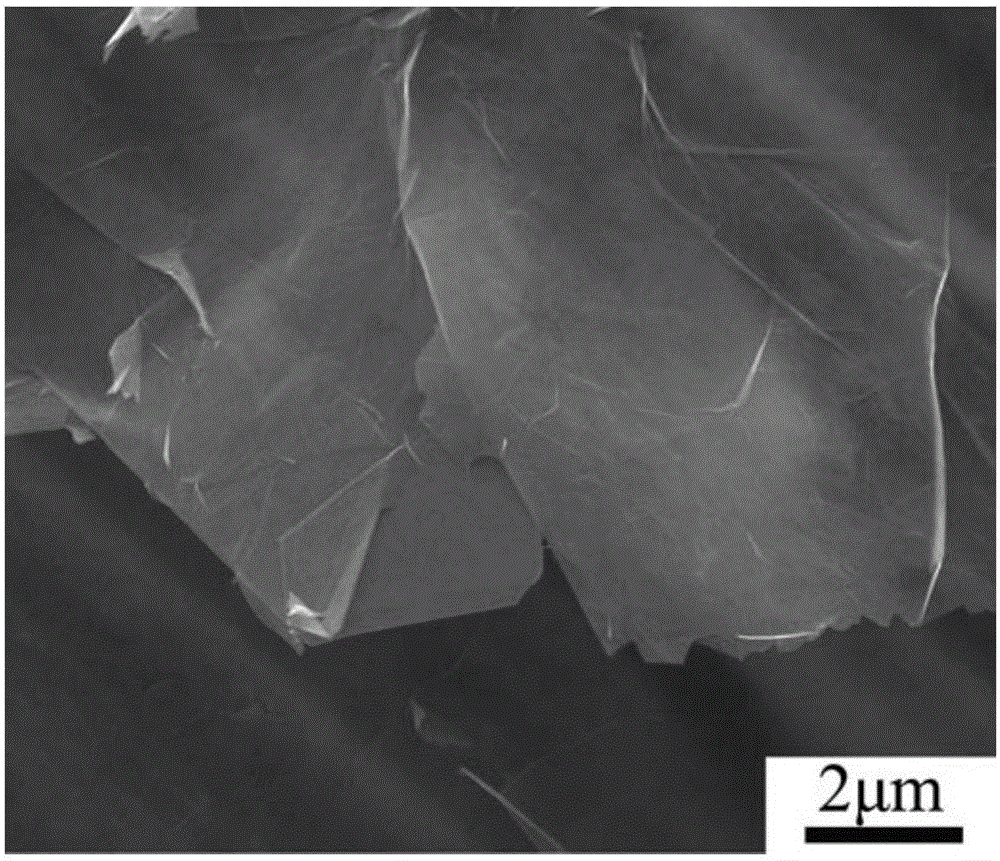

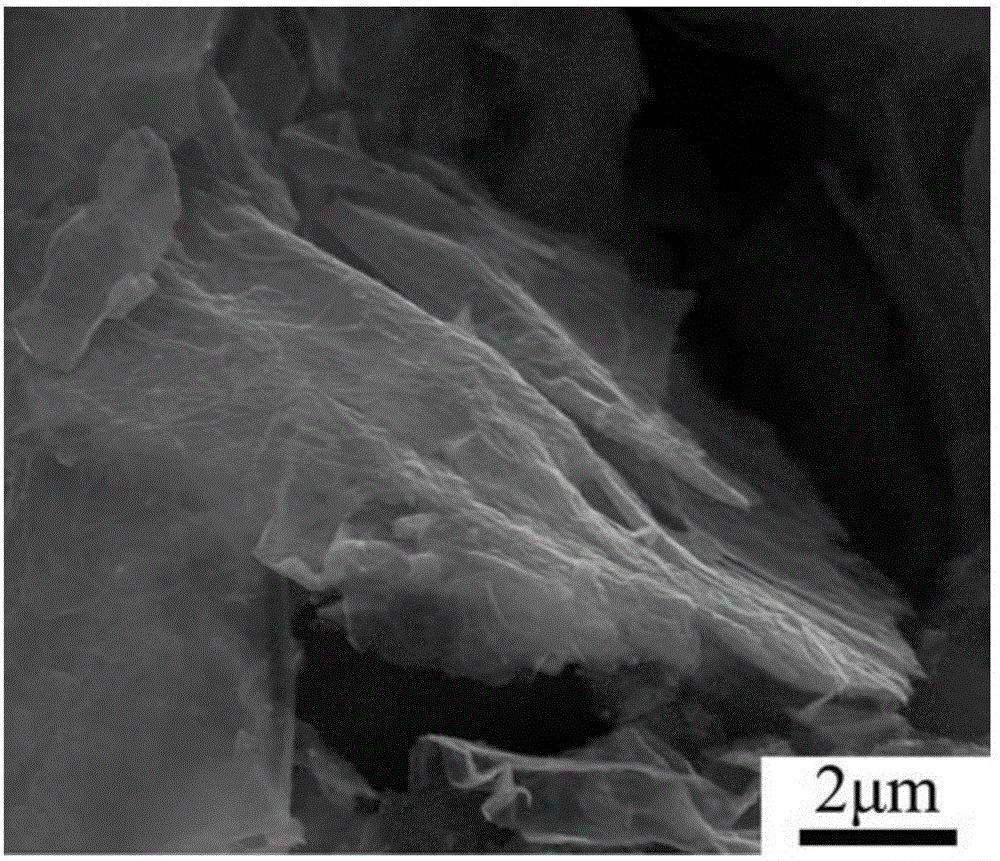

InactiveCN105861866AImprove interfacial bond strengthModulation of interfacial binding strengthCvd grapheneBlock layer

The invention provides a metal matrix composite material, which uses metal as a matrix and uses graphene modified on the surface of carbide as a reinforcement. Due to the surface modification of the carbide, the interface bonding strength between the metal matrix and the graphene can be adjusted. For example, when the chemical affinity between graphene and the metal matrix is too strong and an excessive reaction occurs, resulting in an excessively strong interface bond, the carbide can be used as a diffusion barrier to avoid the overreaction and weaken the interface bond; When the interfacial affinity is weak, the carbide can be used as a transition layer to promote interfacial wetting and improve interfacial bonding force.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

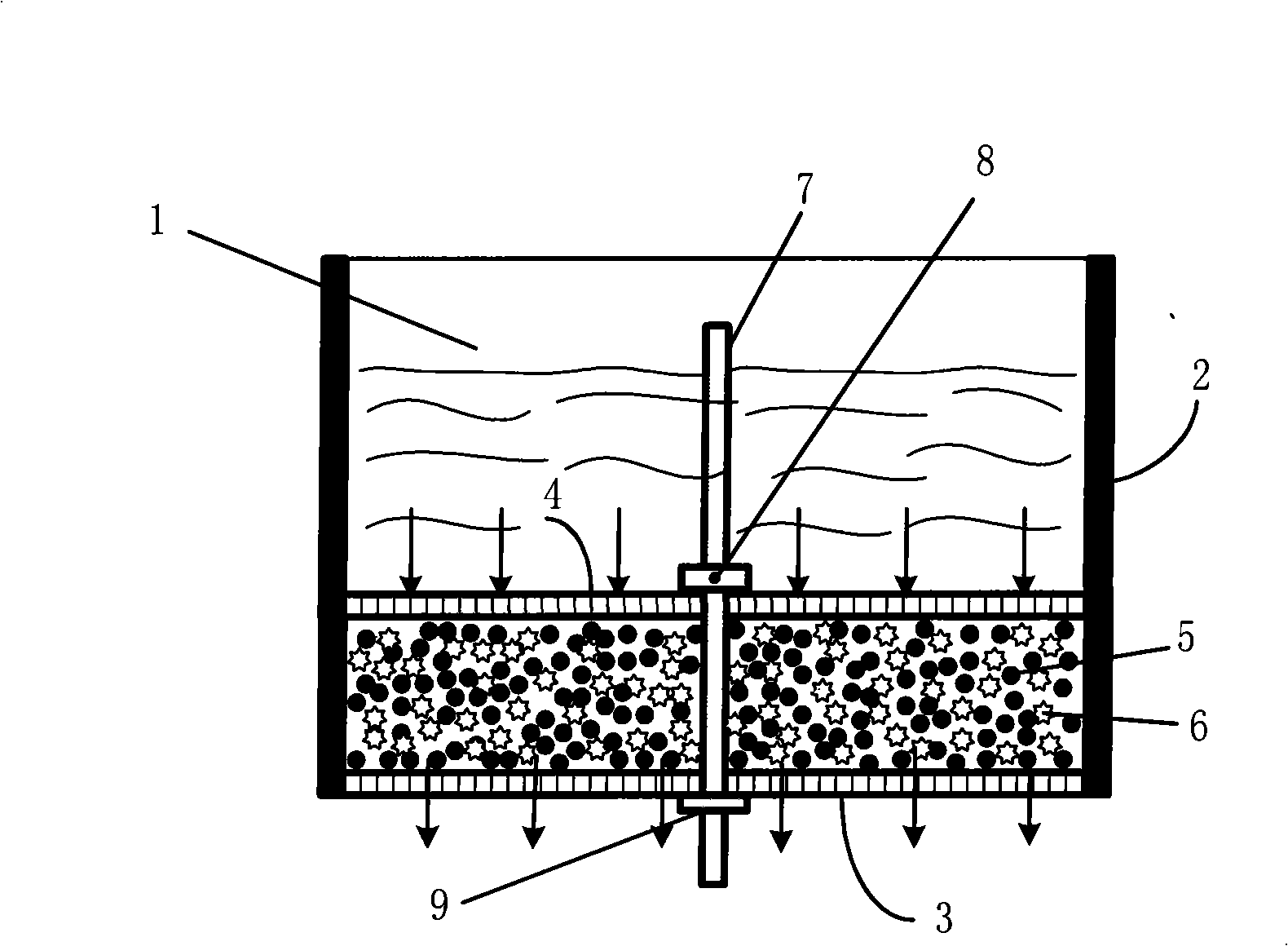

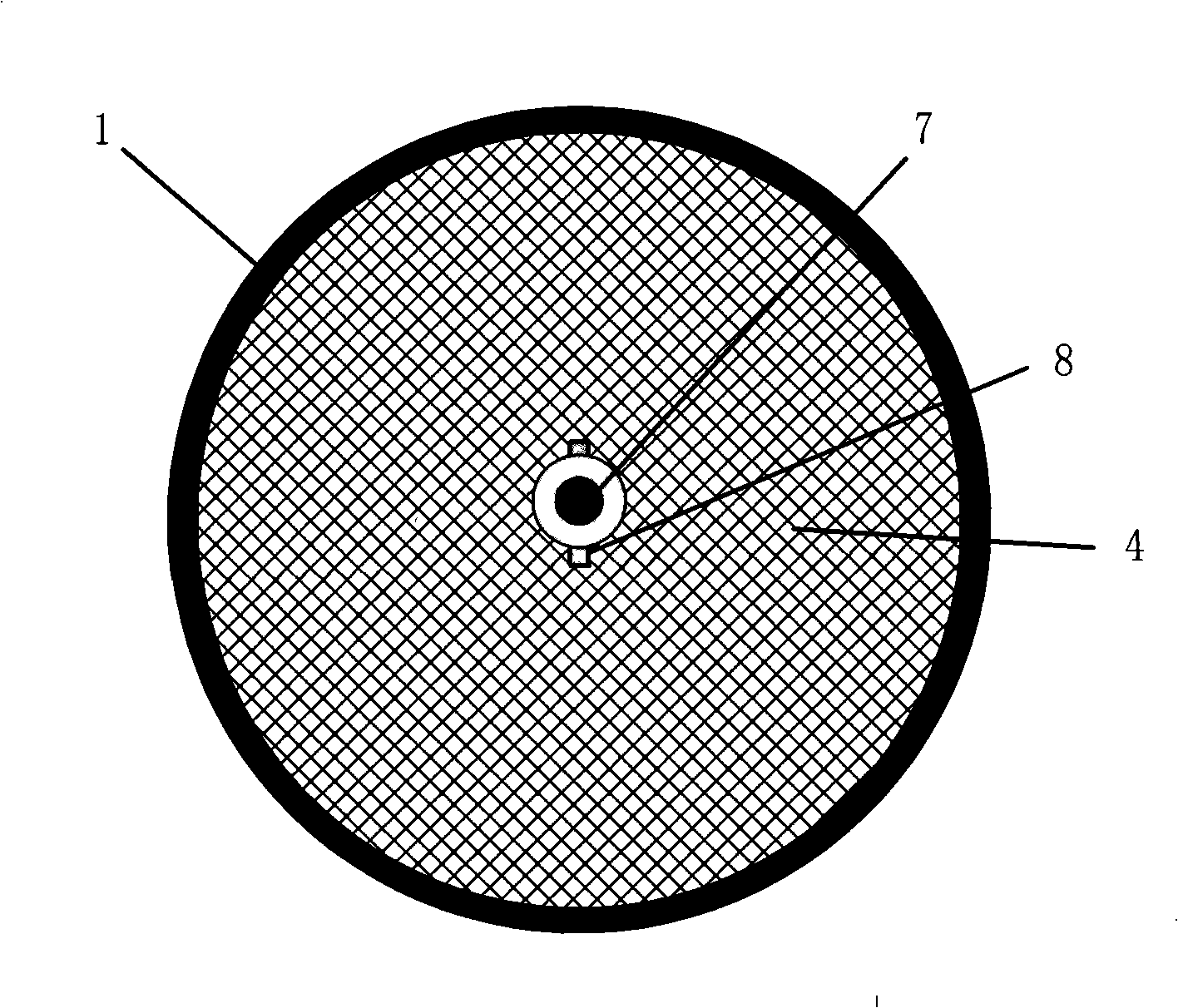

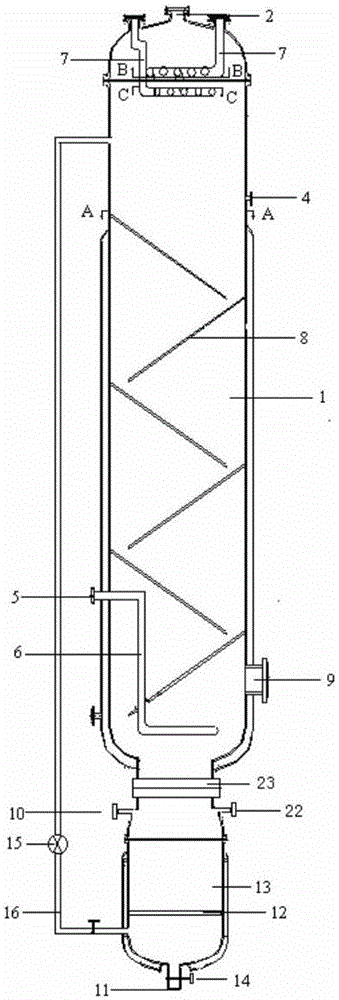

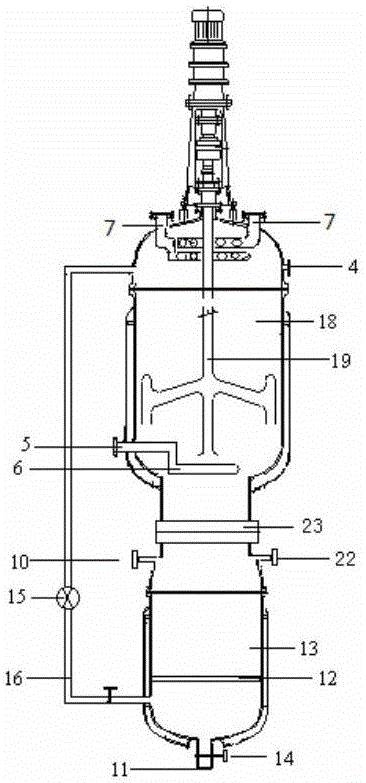

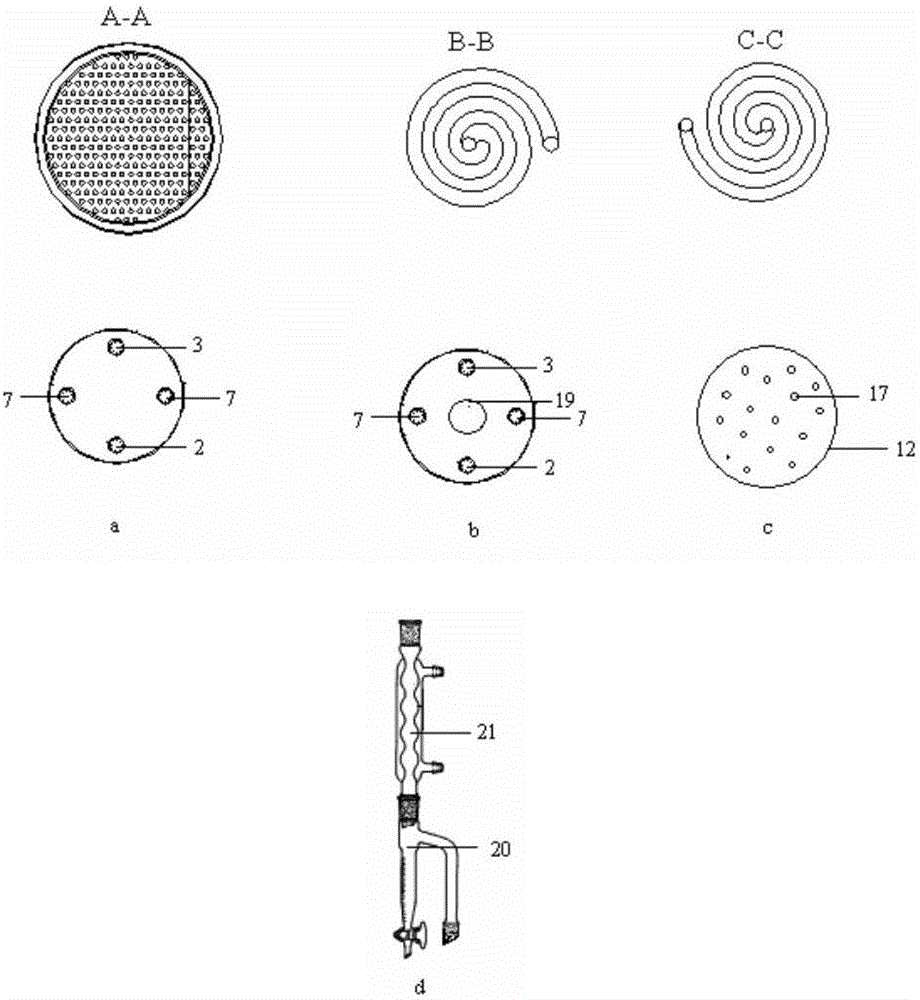

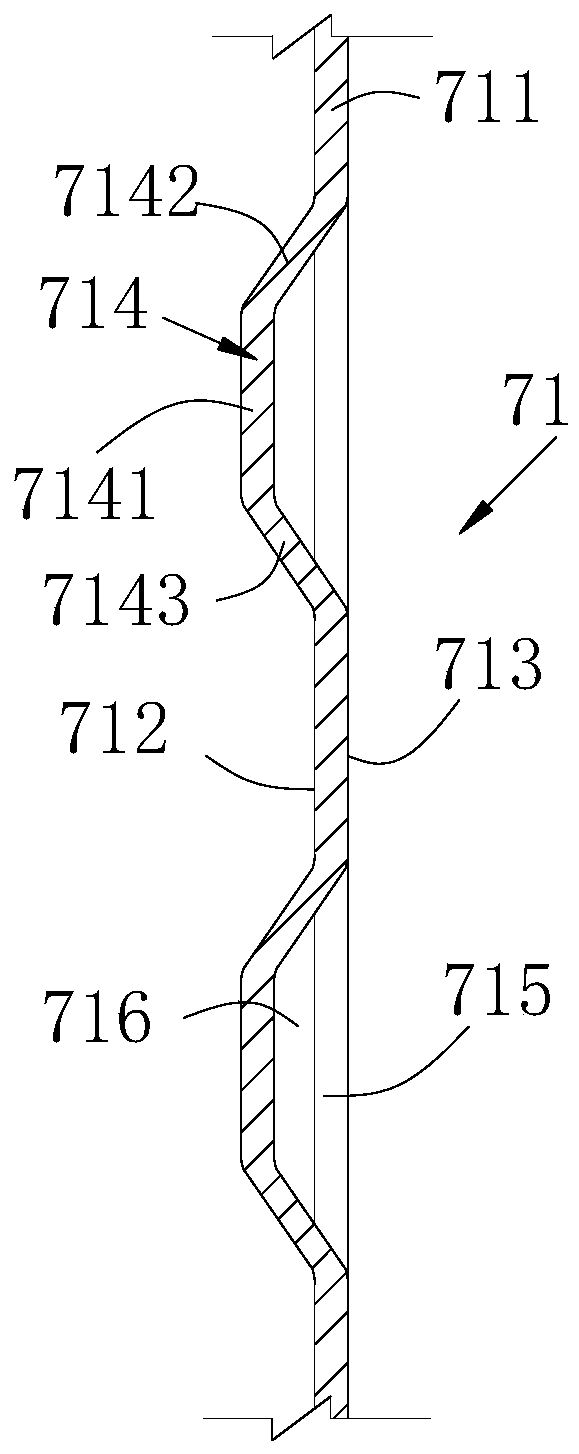

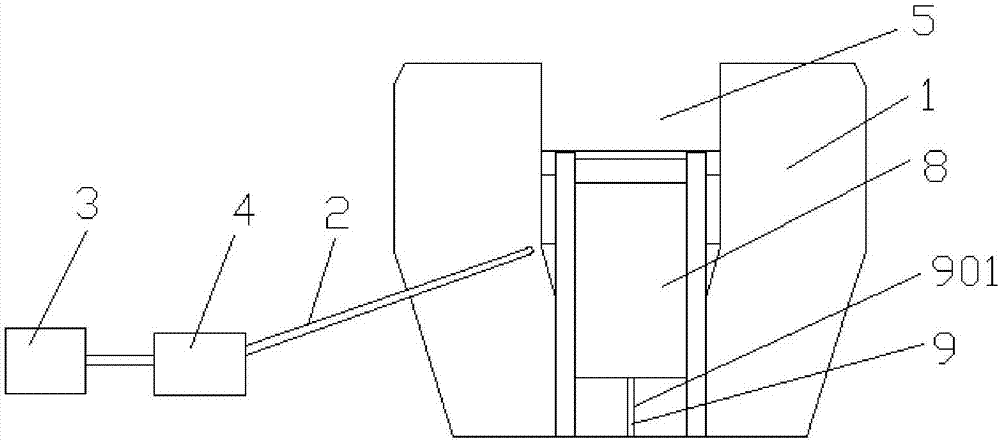

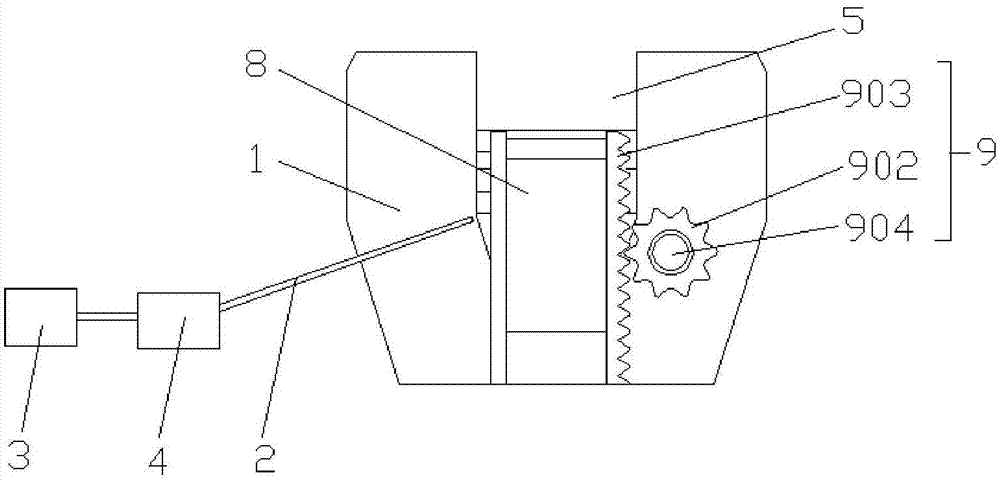

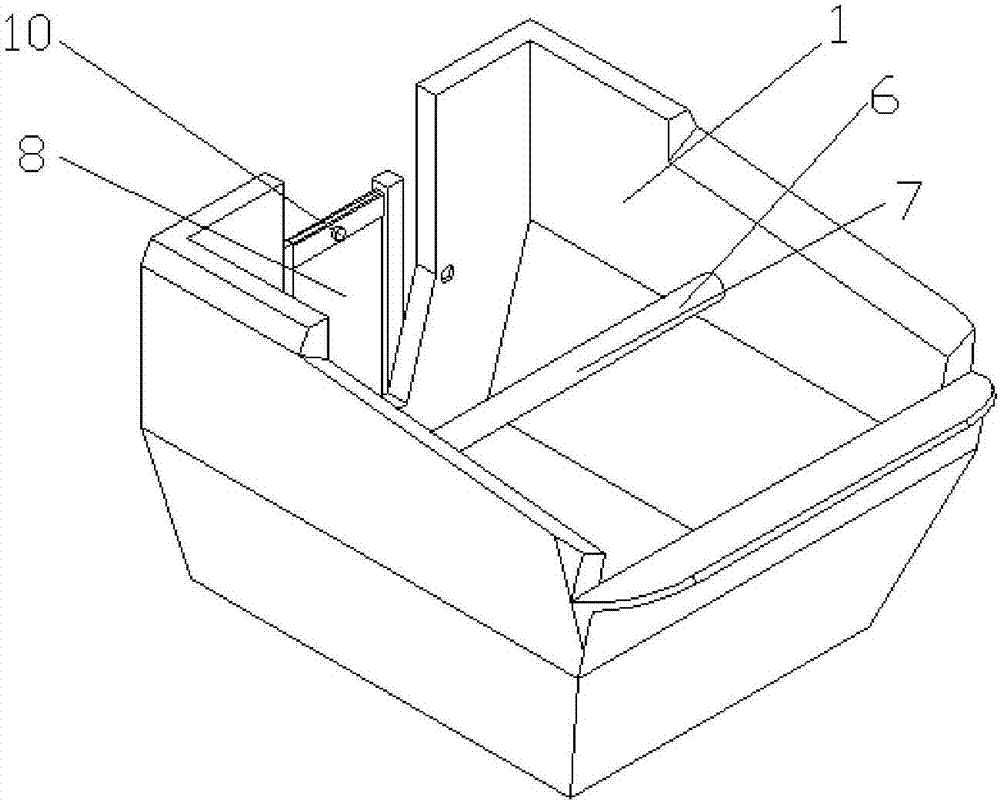

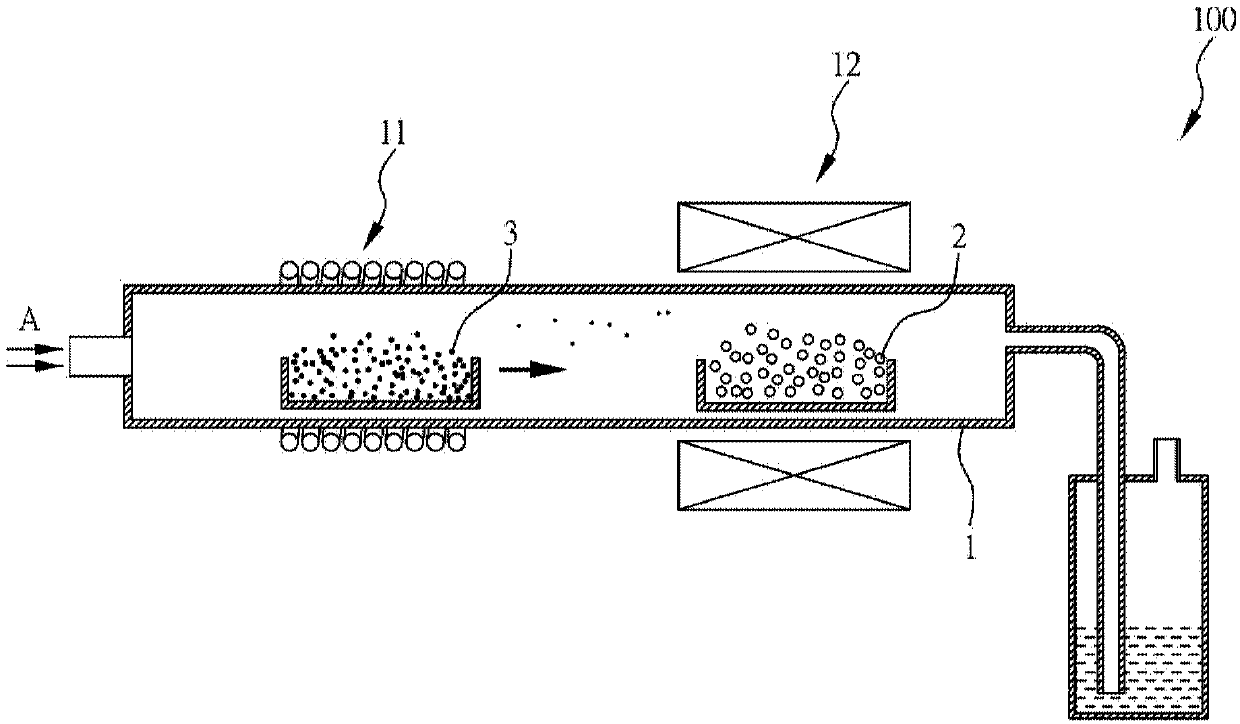

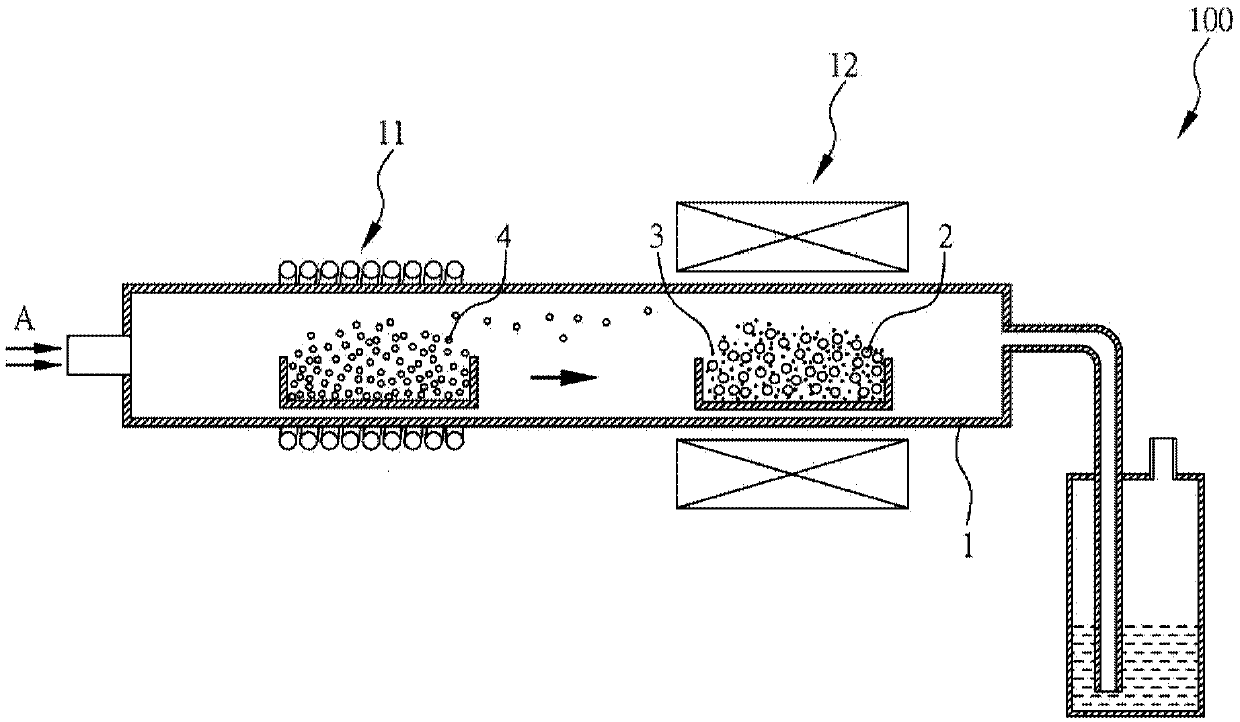

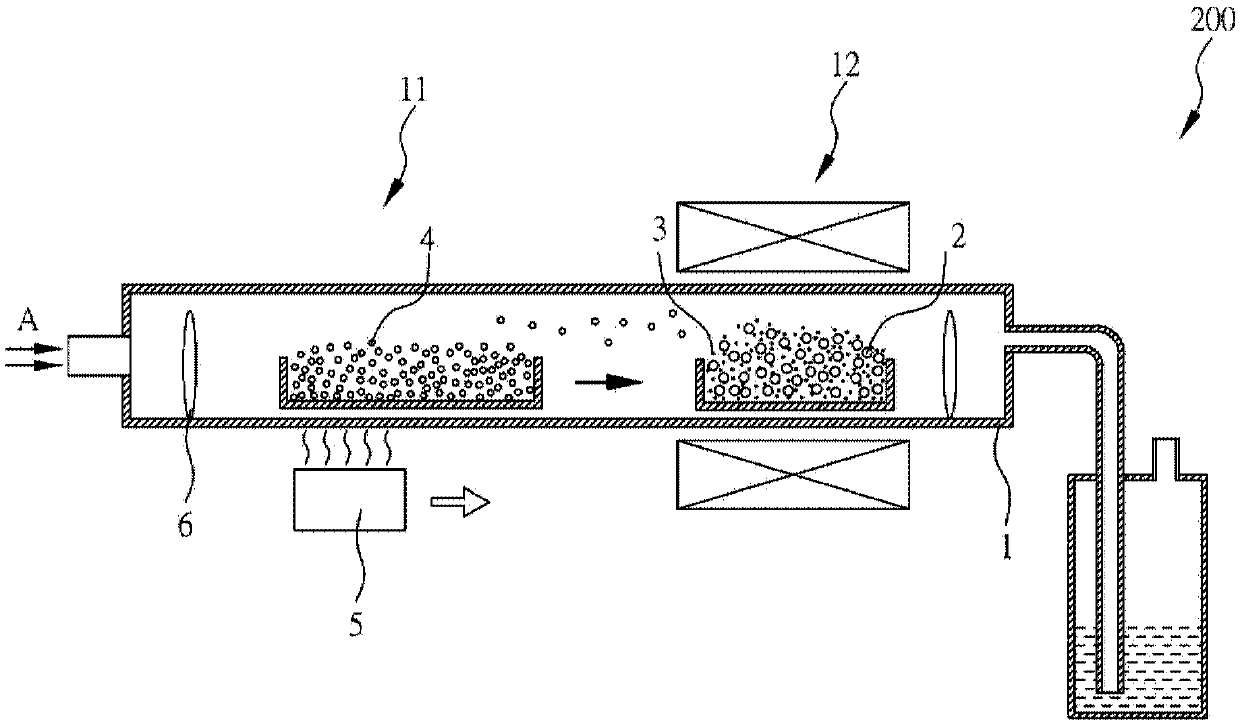

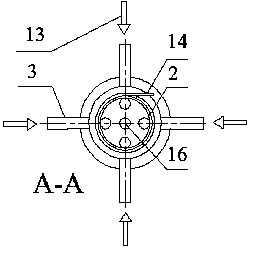

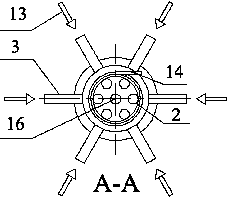

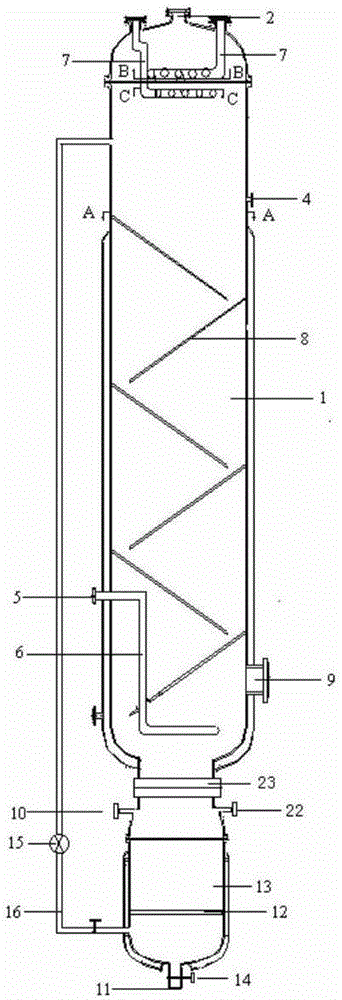

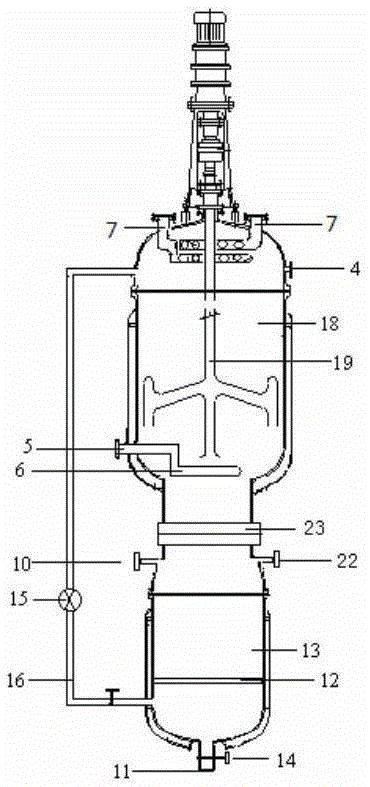

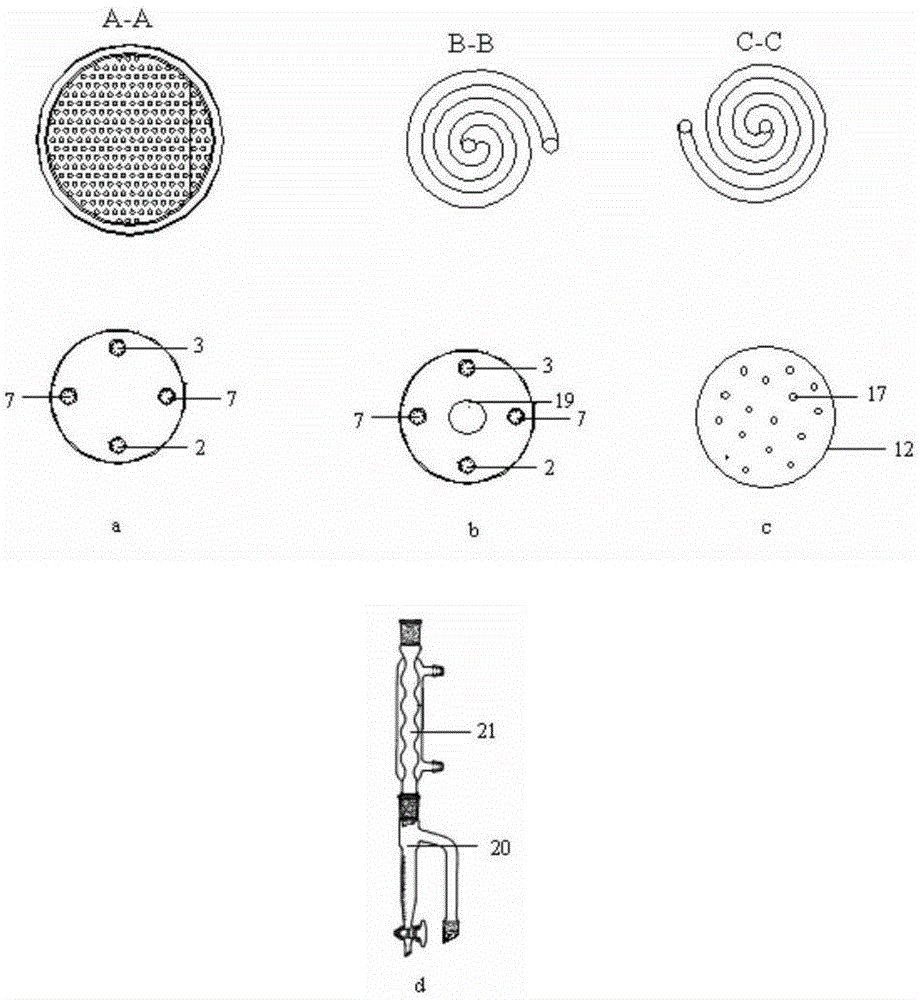

Catalyst distillation column internals for high effective mass transfer

ActiveCN101306256AControl dwell timeFully contactedDistillation separationChemical/physical/physico-chemical processesRetention timeCatalytic distillation

The invention relates to an internal part of a high efficient mass transfer catalytic distillation tower. Wherein, the internal part 1 is composed of a porous container and a filler 5 with catalytic performance therein, the side wall and the lower bottom surface of the container are fixed, at least one longitudinal sliding bar 7 is arranged at the middle part of the lower bottom surface, the upper bottom surface can move up and down along the longitudinal sliding bar and be fixed at an arbitrary height of the sliding bar by a bolt 8, the side wall 2 of the container is not transparent, the upper bottom surface 4 and the lower bottom surface 3 of the container are wire screen plates or porous plates, the internal part is fixed on a grid-shaped support 10 by a nut 9, and the grid-shaped support is fixed on the wall 13 of the catalytic distillation tower. The height of the upper bottom surface of the internal part of the catalytic distillation tower of the invention is lower than the side wall, thereby accumulating liquid with a certain height above a catalyst; reactants are promoted to enter a catalyst bed with the help of the gravity of the liquid, thereby allowing the reactants to be fully contacted with the surface of the catalyst; products are simultaneously impelled to be moved out of the catalyst bed, thereby avoiding the excessive reaction and effectively controlling the retention time of the reactants on the surface of the catalyst.

Owner:TIANJIN UNIV

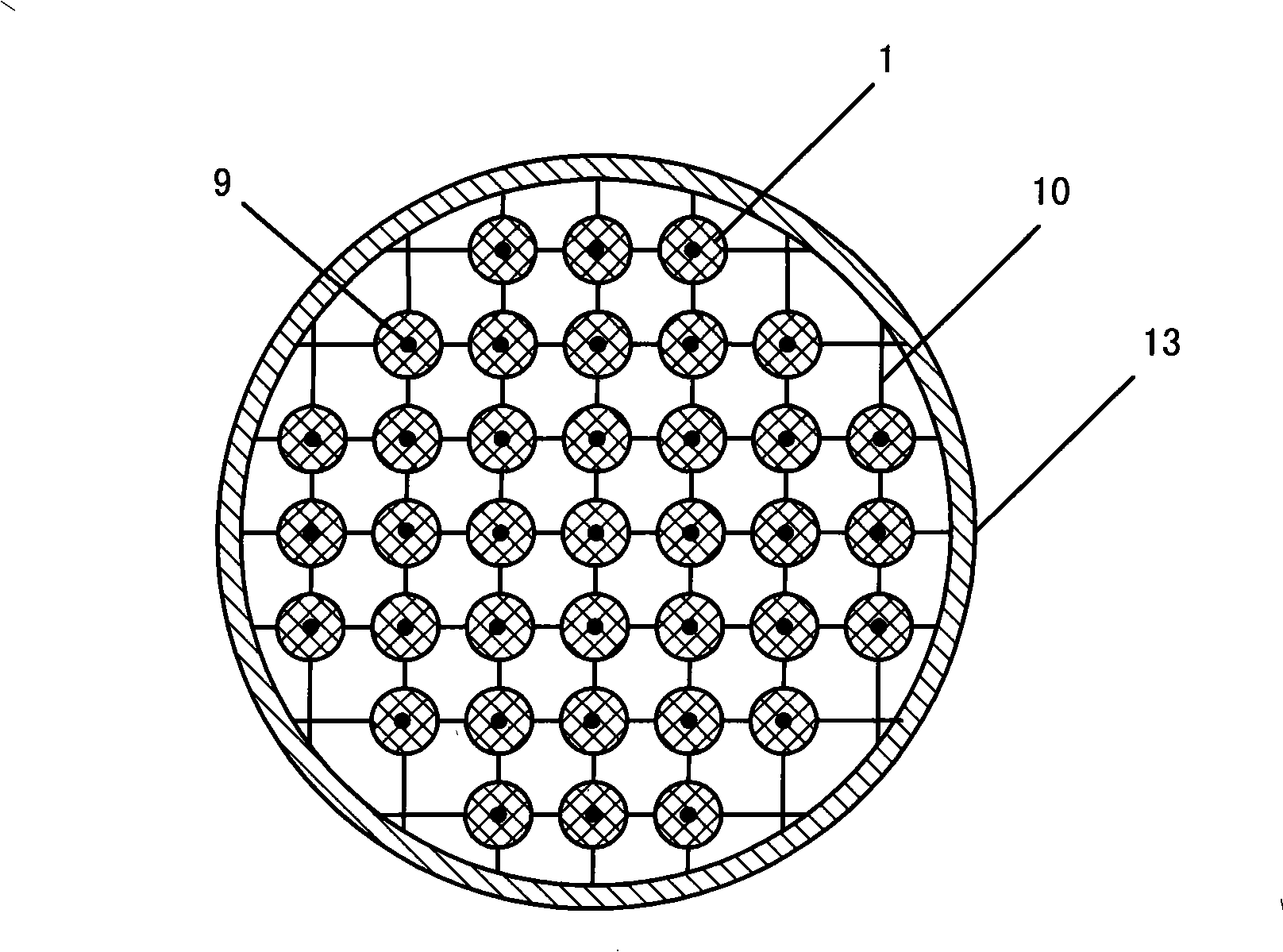

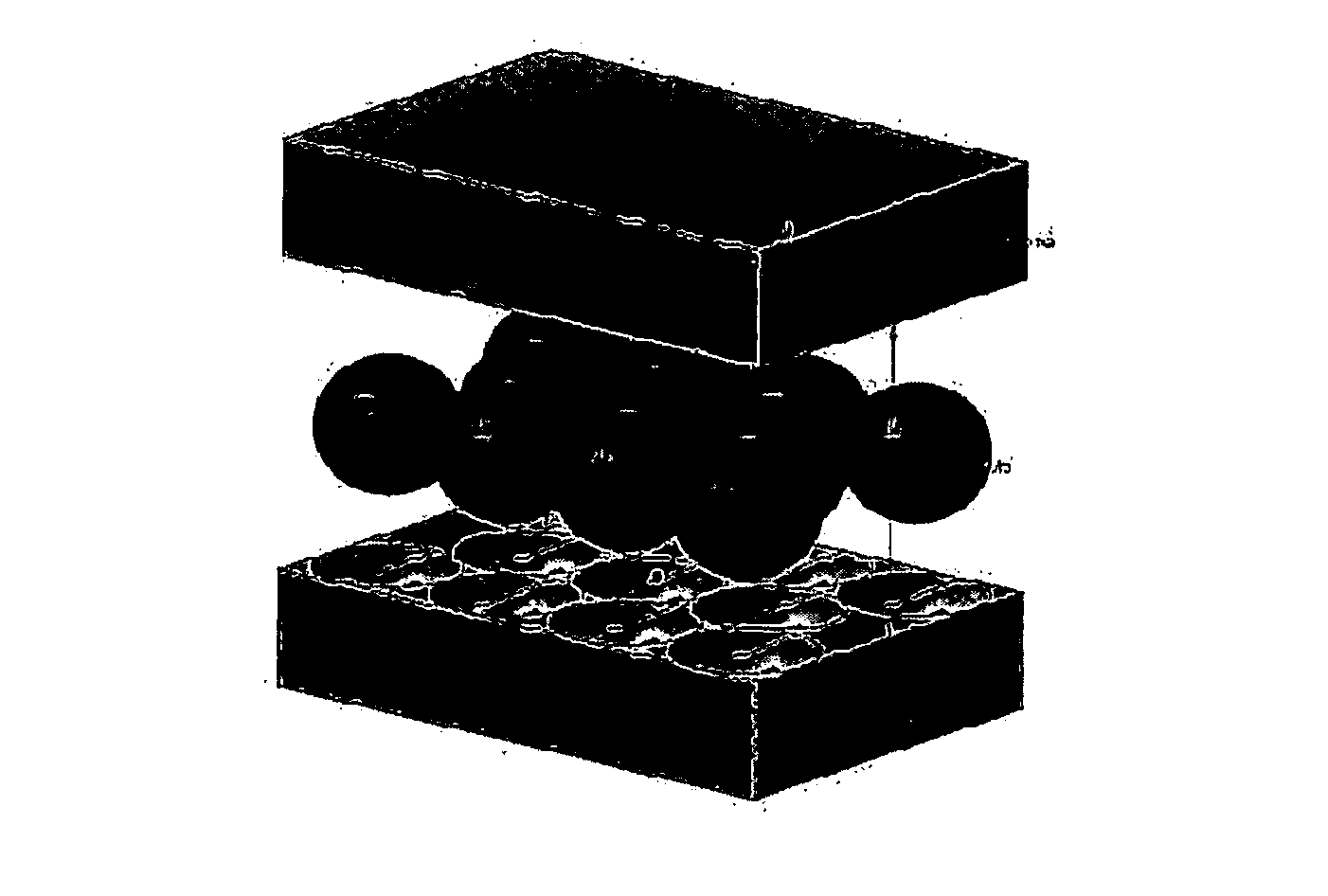

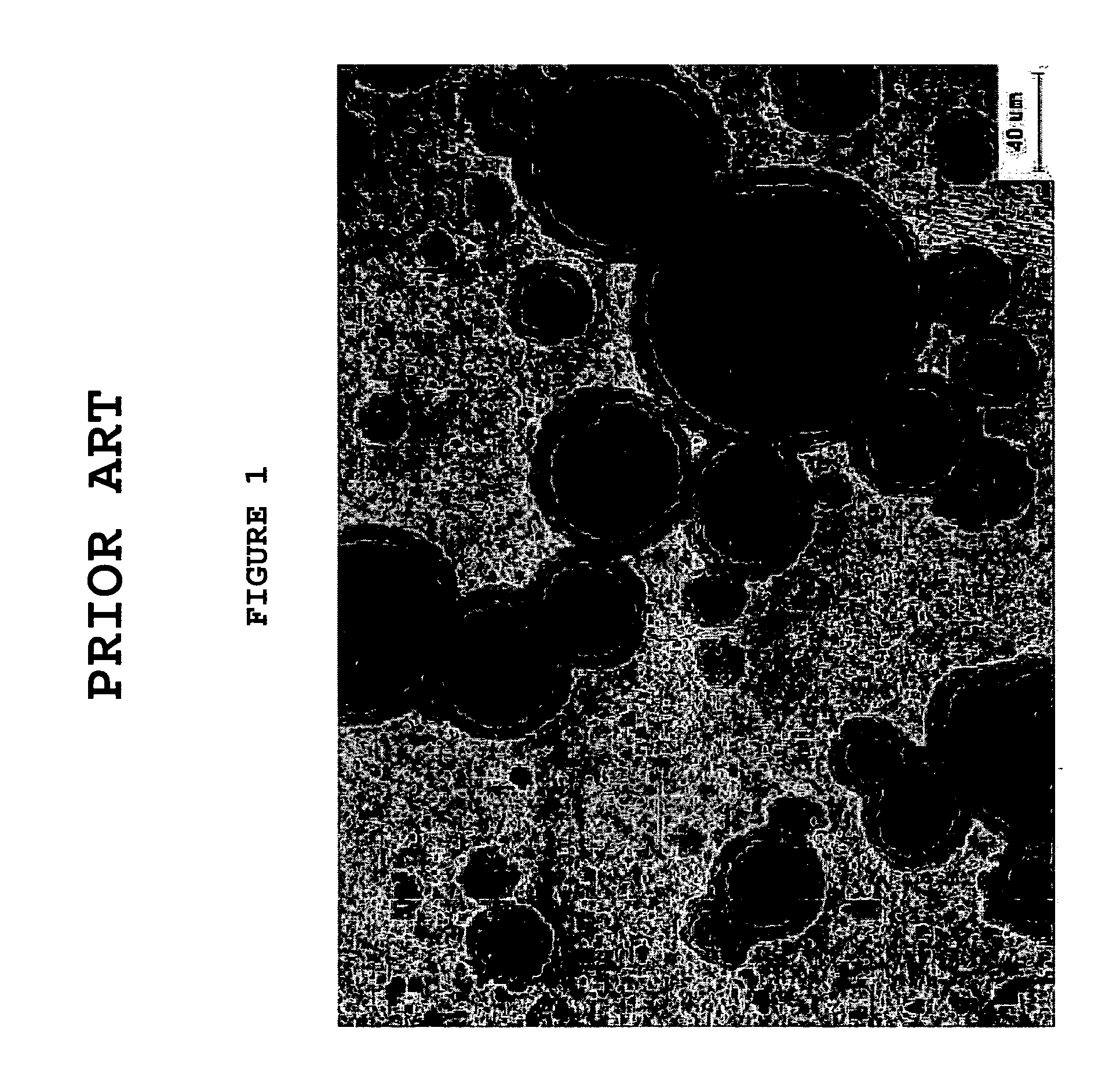

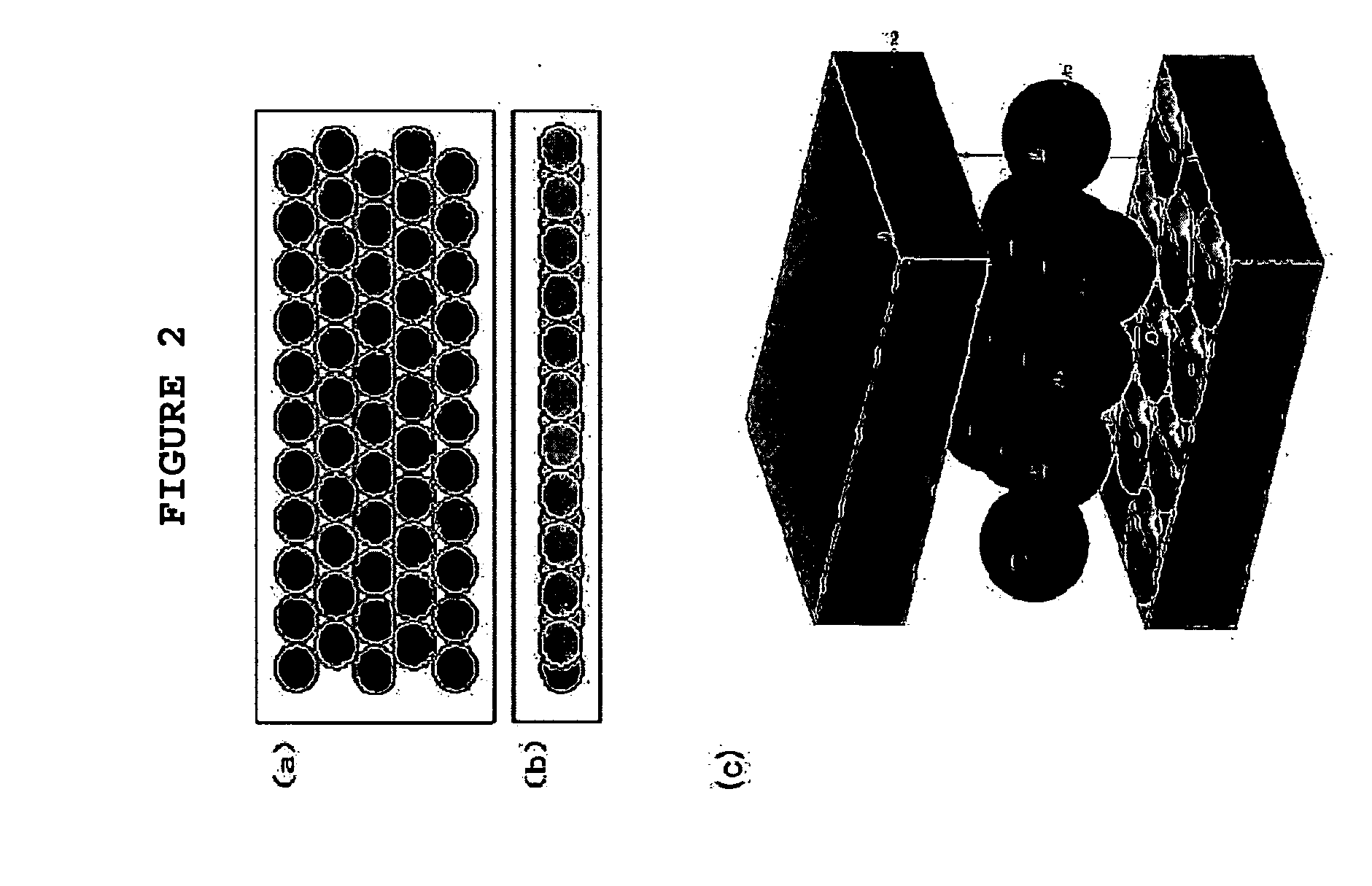

Plate-type nuclear fuels having regularly arranged coarse spherical particles of U-Mo- or U-Mo-X alloy and fabrication method thereof

InactiveUS20070036261A1Avoid overreactionMinimize pore and swellingFuel elementsNuclear energy generationReaction layerInteraction layer

A plate-type nuclear fuel having regularly arranged coarse particles of a gamma-phase U—Mo or U—Mo—X alloy and a fabrication method thereof and, more particularly, to a plate-type nuclear fuel having coarse spherical particles of a stable gamma-phase U—Mo or U—Mo—X alloy arranged regularly on an aluminum cladding in at least one layer and a fabrication method thereof. Operation limit power, high temperature irradiation stability and performance are advantageously improved by preventing excessive reaction between a nuclear fuel and aluminum matrix through minimization of the area of interaction layers between the fuel and aluminum matrix, minimizing pores and swelling by restraining reaction layer formation of an intermetallic compound, and maintaining high thermal conductivity to transfer internal temperature of the nuclear fuel smoothly.

Owner:KOREA ATOMIC ENERGY RES INST +1

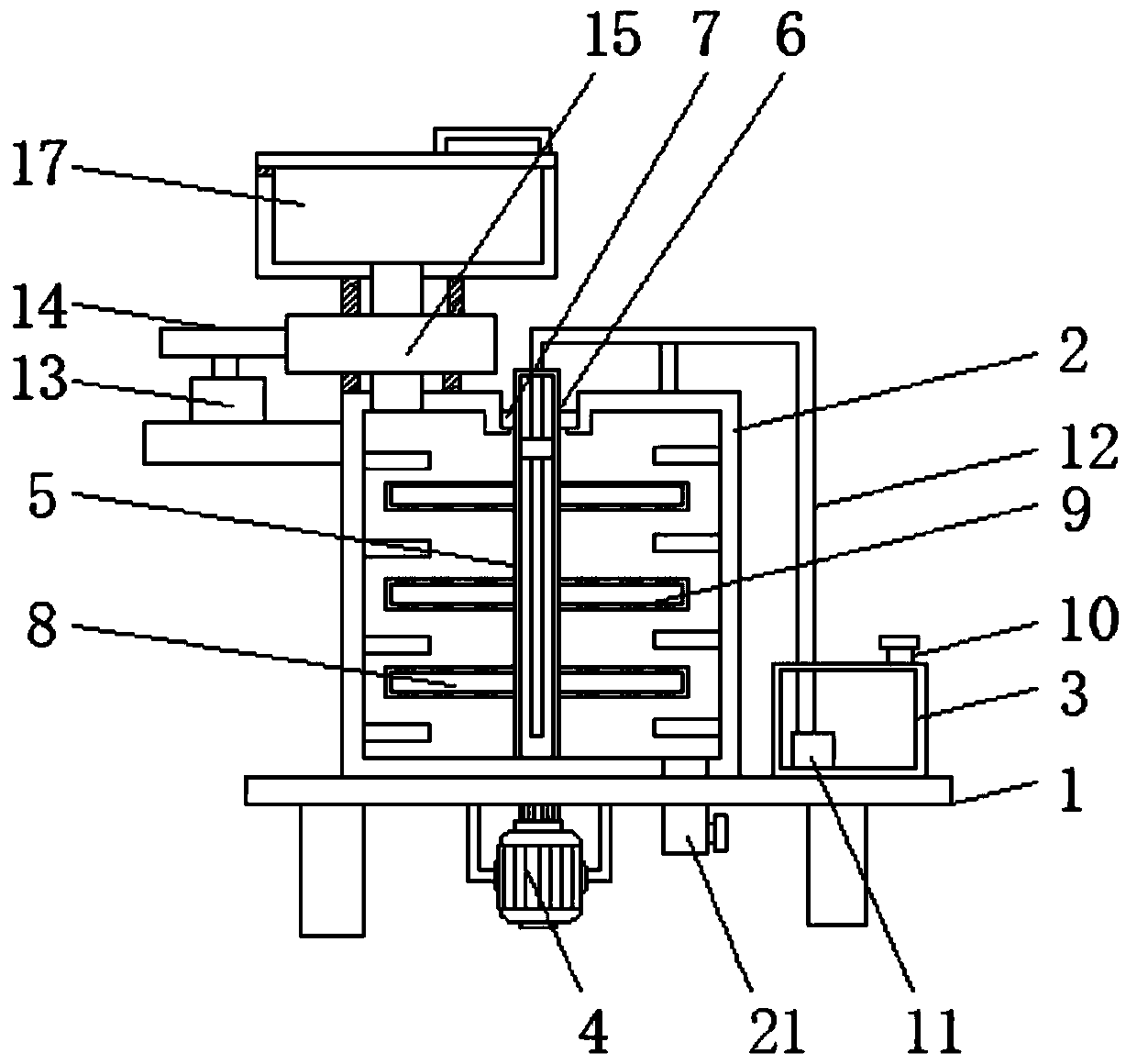

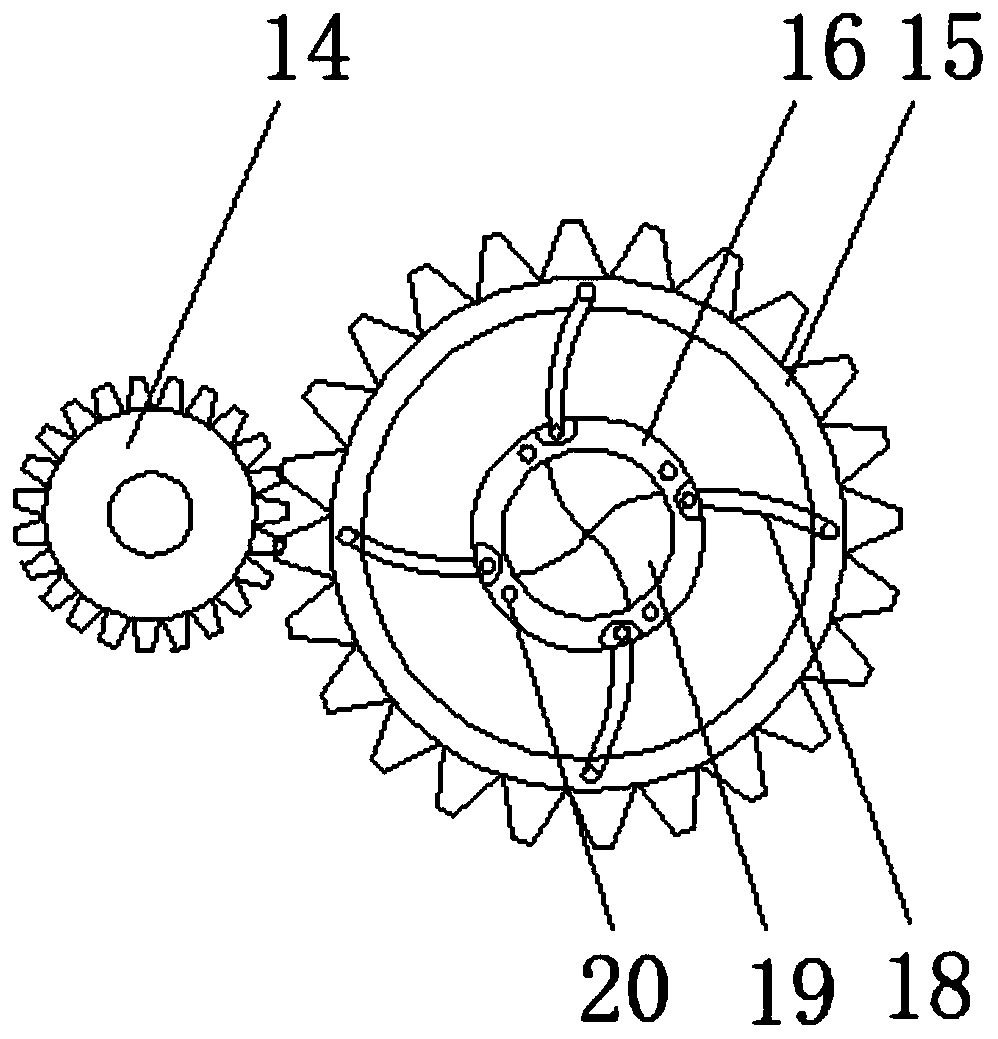

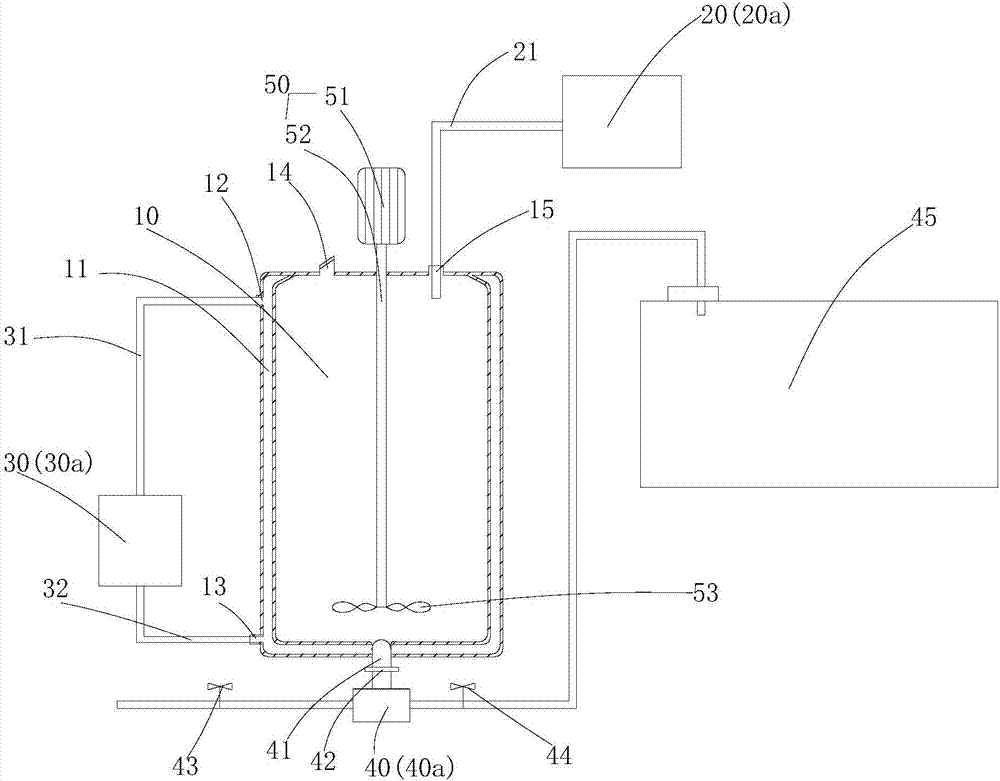

Solid-liquid mixing and stirring device and stirring method

PendingCN110975704AImprove efficiencyImprove the effectRotary stirring mixersTransportation and packagingPhysicsEngineering

The invention discloses a solid-liquid mixing and stirring device in the technical field of solid-liquid mixing and stirring. The device comprises a base. A stirring tank and a liquid storage tank arerespectively installed on the left and right sides of the top of the base. A stirring motor is installed on the bottom of the base through a fixing frame. A water pump is installed at the bottom of the inner cavity of the liquid storage tank; a liquid feeding pipe is installed at the water outlet end of the water pump; one end, of the liquid feeding pipe, far from the water pump extends to the bottom of the inner cavity of a hollow rotating shaft. An output end of a rotary motor is provided with a driving gear the right side of which is meshed with a driven gear. A fixed ring is installed onthe inner side of the driven gear, and the bottom of the fixed ring is connected to the left side of the top of the stirring tank through fixing bars. The driven gear is hinged with four groups of connecting bars. One side, of each of the four groups of connecting bars, far from the driven gear is hinged with a movable block. The four groups of movable blocks are fixed to the fixed ring through pin rolls. The stirring efficiency can be increased and the material mixing effect is improved.

Owner:江苏易金达新材料科技有限公司

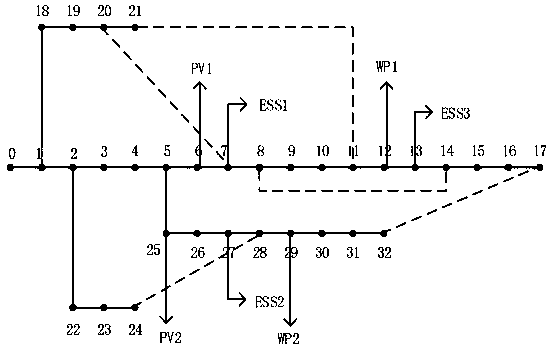

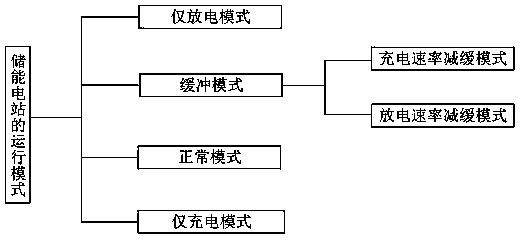

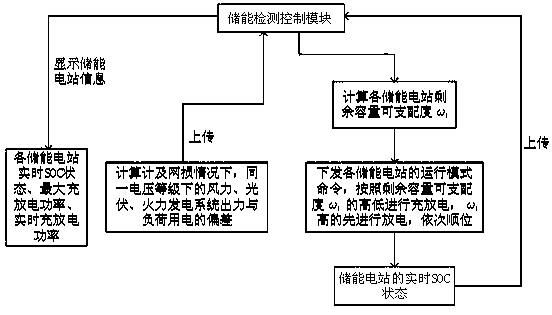

Control method for improving power grid stability by applying energy storage device

ActiveCN111509743APromote resultsAvoid overreactionSingle network parallel feeding arrangementsAc network load balancingSmart gridDevice Grid

The invention relates to the technical field of intelligent power grids, and discloses a control method for improving the power grid stability by applying an energy storage device. A double-layer control method is adopted, a stability control layer adopts short-time scale control, the control factor is system stability, wind power and photovoltaic output connected into the system and load and voltage fluctuation values of power consumers are tracked, energy storage active power and energy storage reactive power are obtained through load flow calculation and a particle swarm algorithm and fed back to an energy storage device grid-connected inverter interface to serve as reference values, and when load abrupt change occurs, the energy storage system can give a response prior to other power generation devices of the system according to the reference values. The optimization control layer adopts long-time scale control; the stability and economy of the system and the real-time state and the service life of the energy storage system are comprehensively considered, the charging and discharging power and the residual capacity of energy storage are obtained through the particle swarm algorithm, the result obtained by the stability control layer is optimized and uploaded to the energy storage detection control module, and finally the operation mode and the charging and discharging powerare determined.

Owner:国网江苏省电力有限公司淮安供电分公司

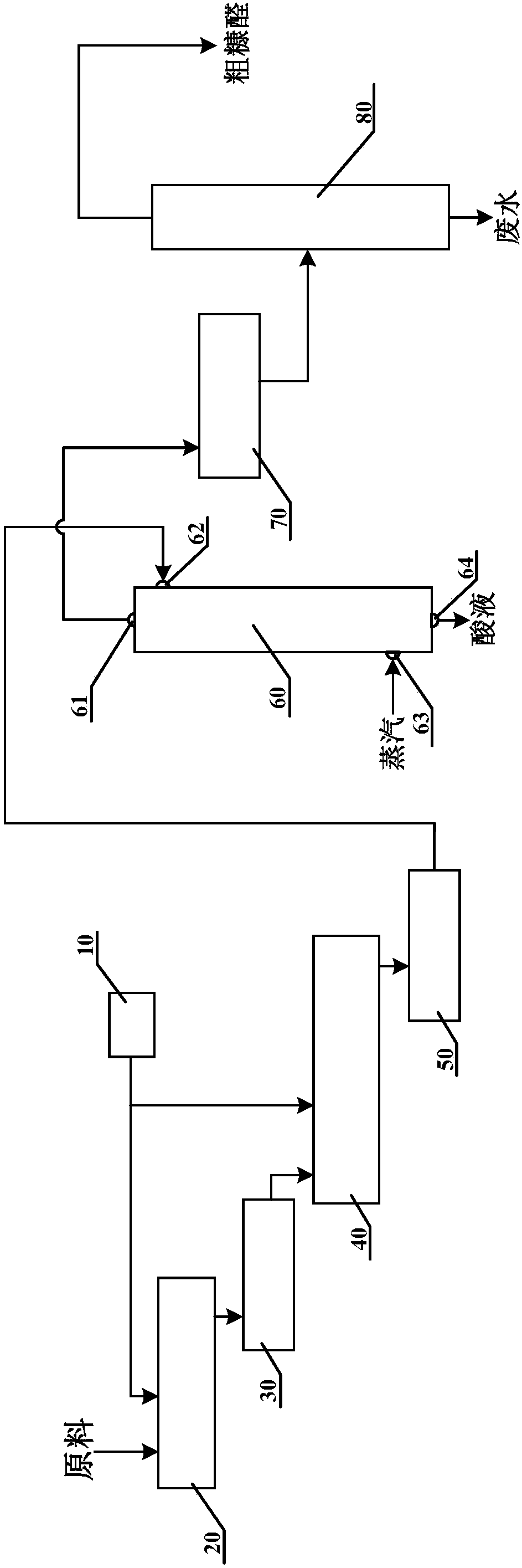

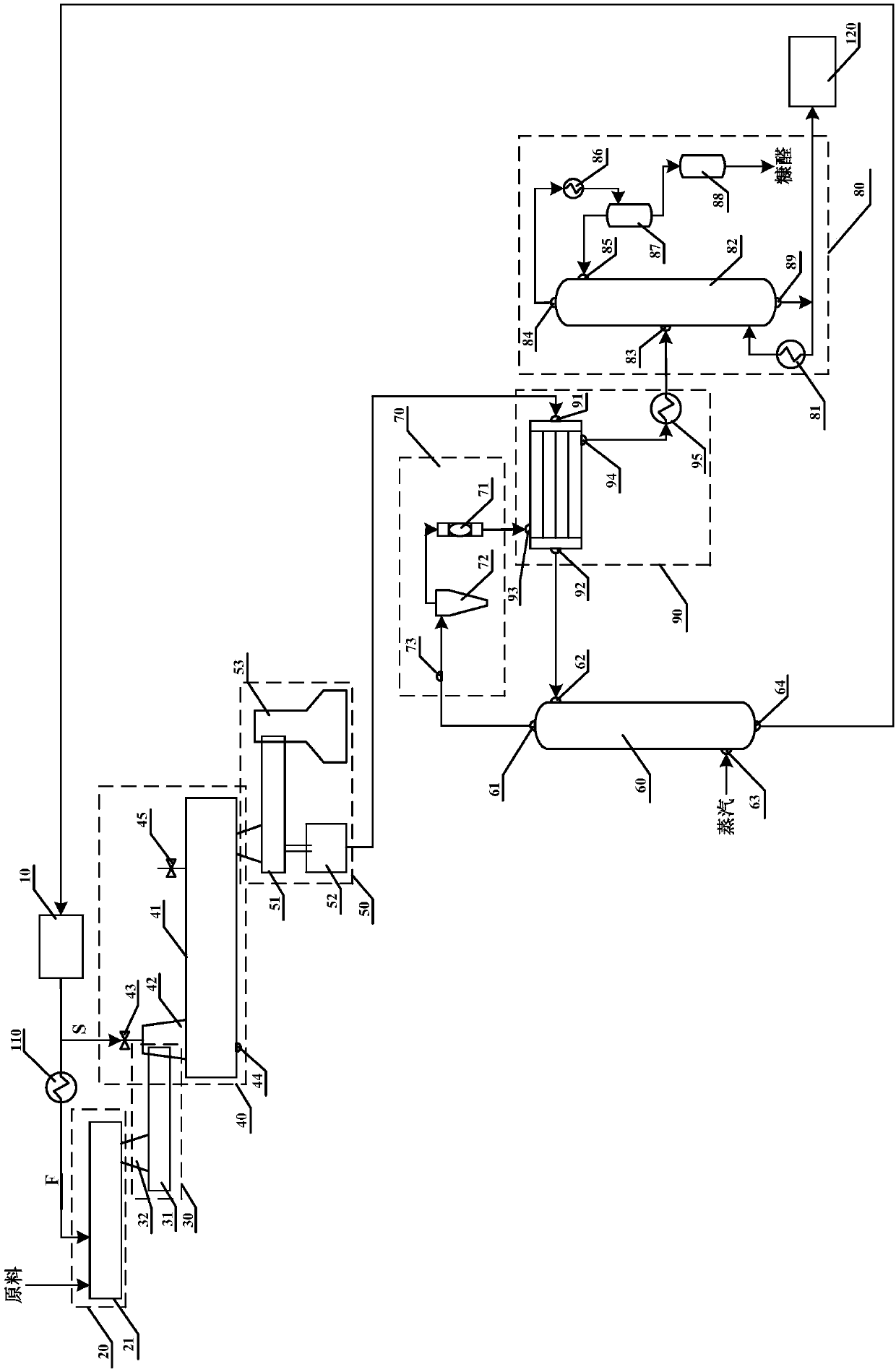

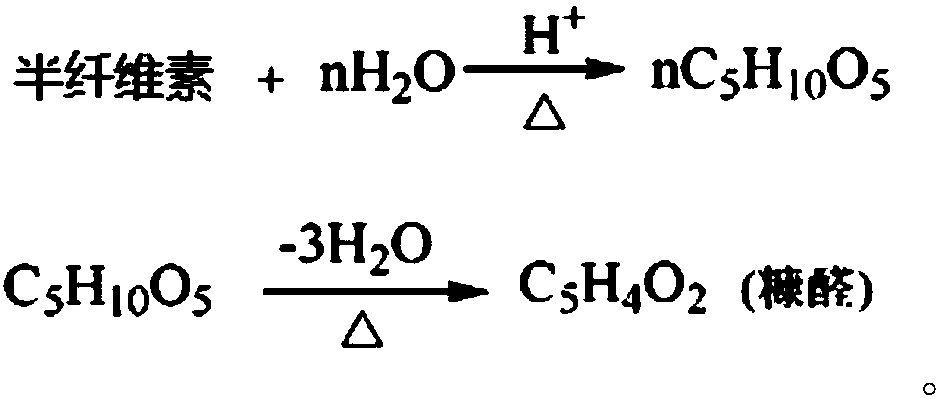

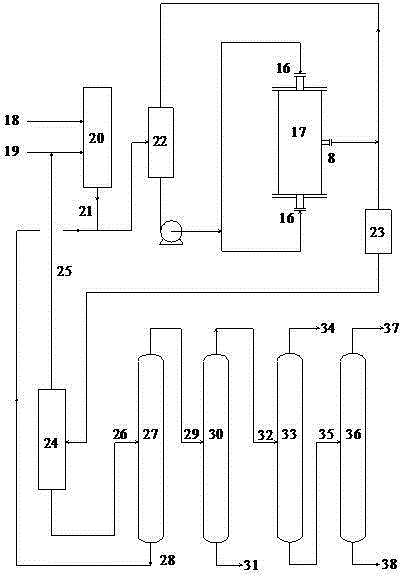

System and method for continuously preparing furfural from lignocellulose raw material

ActiveCN107827847AReduce labor intensityIncrease productivityOrganic chemistryChemistryContinuous production

The invention relates to a system and method for continuously preparing furfural from a lignocellulose raw material. The system comprises an acid liquor discharging unit, a raw material mixing unit, afeeding unit, a main body reaction unit, a discharging unit, a steam stripping tower, a separating unit and a purifying unit. The method comprises the following steps: acid liquor discharging, raw material mixing, feeding, hydrolysis reaction, discharging, steam stripping reaction, separating and purifying. The system is a real continuous production system, continuous collection of the products is realized on time, the labor intensity is reduced, and the production efficiency is improved. The whole process is reasonable in design, high in yield of furfural and low in unit energy consumption.

Owner:易高生物质能技术有限公司

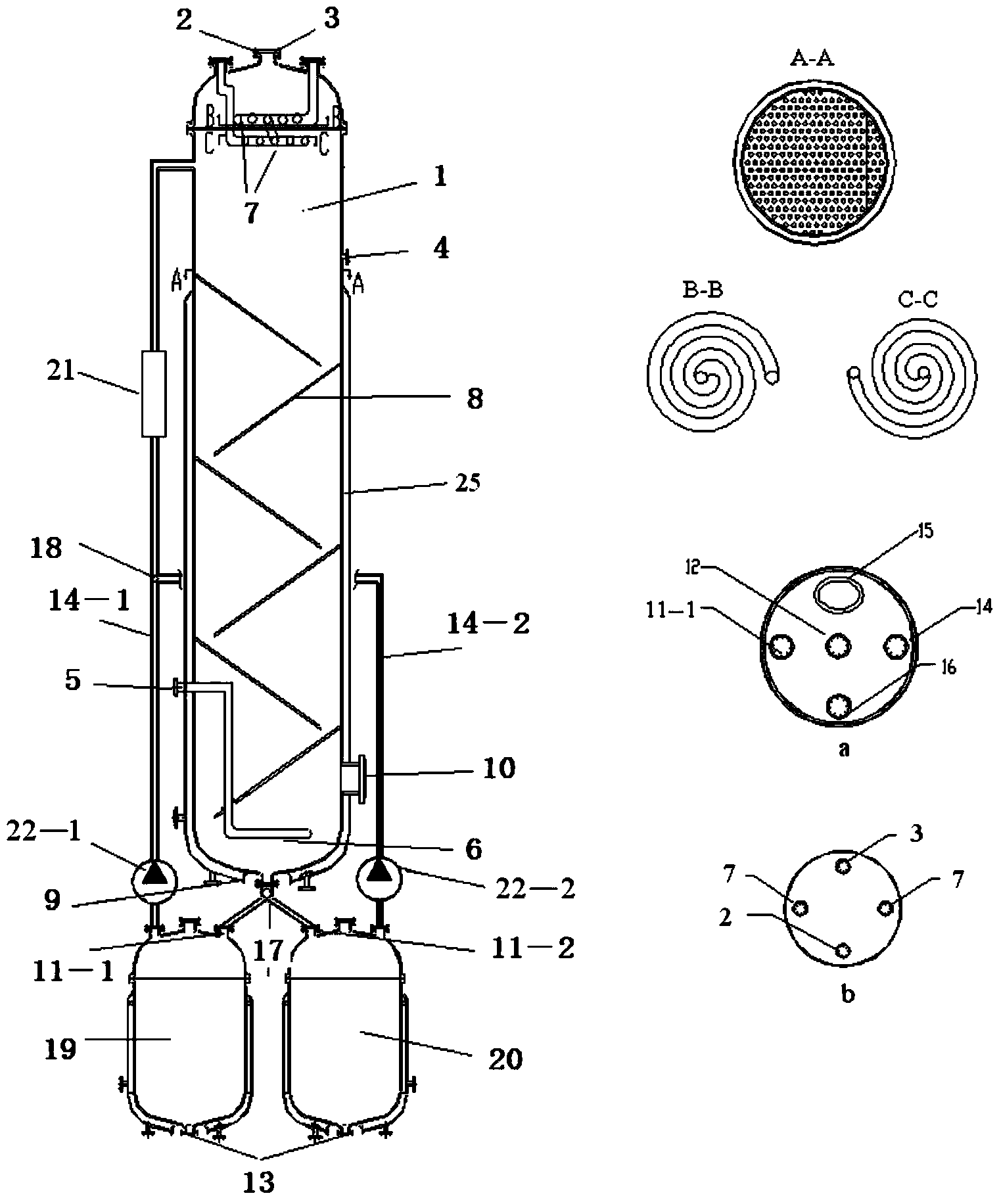

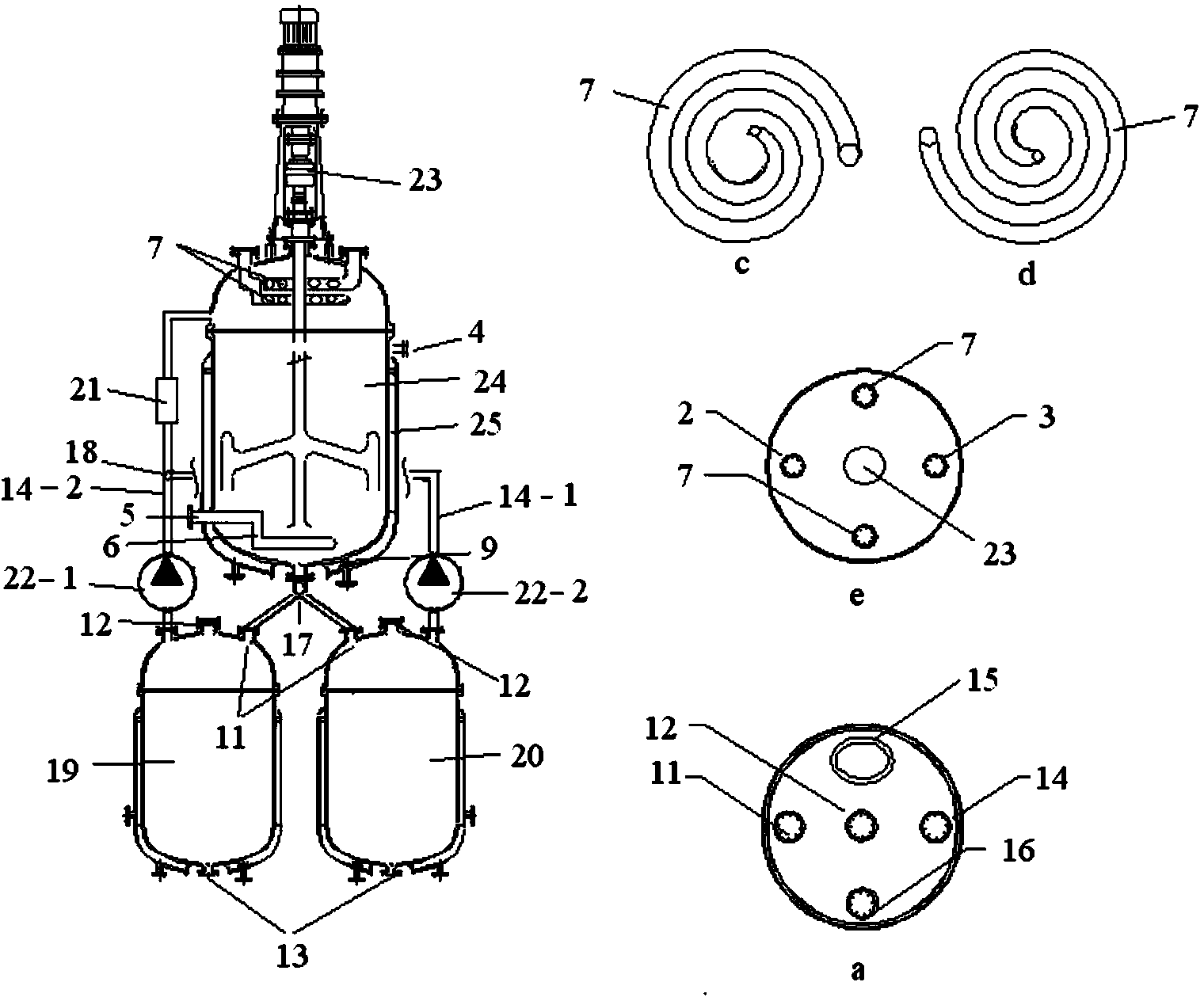

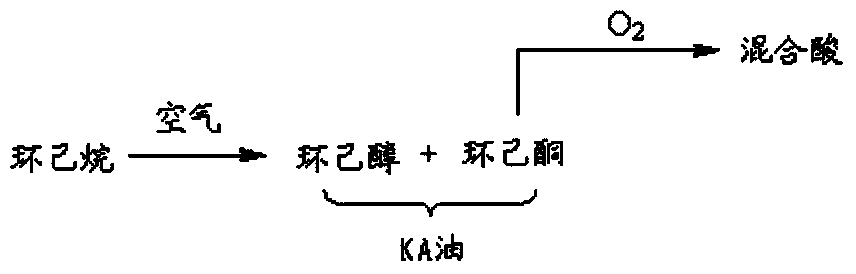

Method for producing KA oil through oxidizing cyclohexane by using air on basis of gas-liquid-solid heterogeneous reaction separation synchronization reactor

ActiveCN103755521AHigh yieldReduce the effect of settling velocityPreparation by oxidation reactionsOrganic compound preparationGas phaseOil phase

The invention discloses a method for producing KA oil through oxidizing cyclohexane by using air on the basis of a gas-liquid-solid heterogeneous reaction separation synchronization reactor, wherein the water-containing cyclohexane is added into the reactor, the reactor comprises a reaction tower and at least two constant temperature settlement towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase area, an oxidization area and a gas outlet; the oxidization area and the constant temperature settlement towers are filled with the cyclohexane in the reaction, the air is introduced continuously from the bottom of the oxidization area and is in contact with the cyclohexane to carry out the oxidization reaction, meanwhile, the produced KA oil is blended with water to form a KA oil phase, the KA oil phase is settled into the constant temperature settlement tower, the cyclohexane in the constant temperature settlement tower at the moment enters the oxidization area through an external circulation system, so that the reaction is conducted continuously, the KA oil phase continues to settle in the constant temperature settlement tower until the constant temperature settlement tower is fully filled the KA oil phase, then the reaction tower is switched to be communicated with the other constant temperature settlement tower filled with the cyclohexane, the operation is conducted on the constant temperature settlement towers alternatively to continuously produce the KA oil. The method is used to continuously produce the KA oil with high percent of conversion and high selectivity, the production efficiency is improved, and the production cost is lowered.

Owner:新疆普禾粟新型环保材料有限公司

Lead-free glass powder for aluminium paste of solar cell

The invention relates to a lead-free glass powder for the aluminium paste of a solar cell and a preparation method for the same. The lead-free glass powder comprises the following components in percentage by weight: 20-29% of bismuth oxide, 5-15% of boron oxide, 21-39% of silicon oxide, 5-30% of zinc oxide, 1-10% of calcium oxide, 1-10% of antimony oxide and 0.5-5% of tin oxide, wherein the total of the percentages by weight of the raw material components is 100%; the median particle diameter of the glass powder is 2 mum, and the maximum particle diameter of the glass powder is 5 mum; and the softening temperature of the glass powder is 400-550 DEG C. Compared with the prior art, the lead-free glass powder for the aluminium paste of a solar cell disclosed by the invention is low in the content of the bismuth oxide component, high in the contents of the silicon oxide component and the boron oxide component, good in wettability with a silicon substrate, and capable of forming good bonding with the silicon substrate; and moreover, the glass powder is capable of avoiding damages on the substrate due to the over-reaction of the glass powder and the silicon substrate during sintering, beneficial to the epitaxial growth of the silicon substrate to form a P+ layer, and capable of increasing the electric performance of the cell slice.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Method for producing KA oil and adipic acid by utilizing air oxidized cyclohexane based on improved reaction-separation synchronous reactor

ActiveCN105085169AAvoid overreactionHigh purityPreparation by oxidation reactionsOrganic compound preparationChemistrySettling

The invention discloses a method for producing KA oil and adipic acid by utilizing air oxidized cyclohexane based on an improved reaction-separation synchronous reactor. The improved reaction-separation synchronous reactor comprises a bubble gravity reaction tower or stirring reaction tower and a constant-temperature settling tower, wherein an upper gas-phase region, a middle-lower reaction region and a top reaction gas outlet are arranged inside the reaction tower; multiple groups of gravity settling plates are obliquely arranged on the tower wall in the reaction region of the bubble gravity reaction tower, and are distributed alternately; a stirrer is arranged in the reaction region of the stirring reaction tower; and a gas inlet and a gas distributor are arranged in the bottom of the reaction region of the reaction tower. The main improvement of the invention lies in that the bubble gravity reaction tower or stirring reaction tower is connected with the constant-temperature settling tower by virtue of a flange, a microporous filter plate through which a liquid can flow is arranged in the constant-temperature settling tower, and a circulating pipe is arranged at the lower part of the microporous filter plate in the constant-temperature settling tower, and is connected with the upper part of the reaction region of the reaction tower. Cyclohexane is subjected to air oxidation by utilizing the improved device to produce KA oil and adipic acid, overreaction of a product in the reaction tower is reduced, high-purity KA oil and adipic acid can be obtained, the connecting pipeline and circulating pipeline between a reaction kettle and the constant-temperature settling tower are prevented from being plugged, and the KA oil and adipic acid can be respectively effectively separated in time during reactions.

Owner:新疆普禾粟新型环保材料有限公司

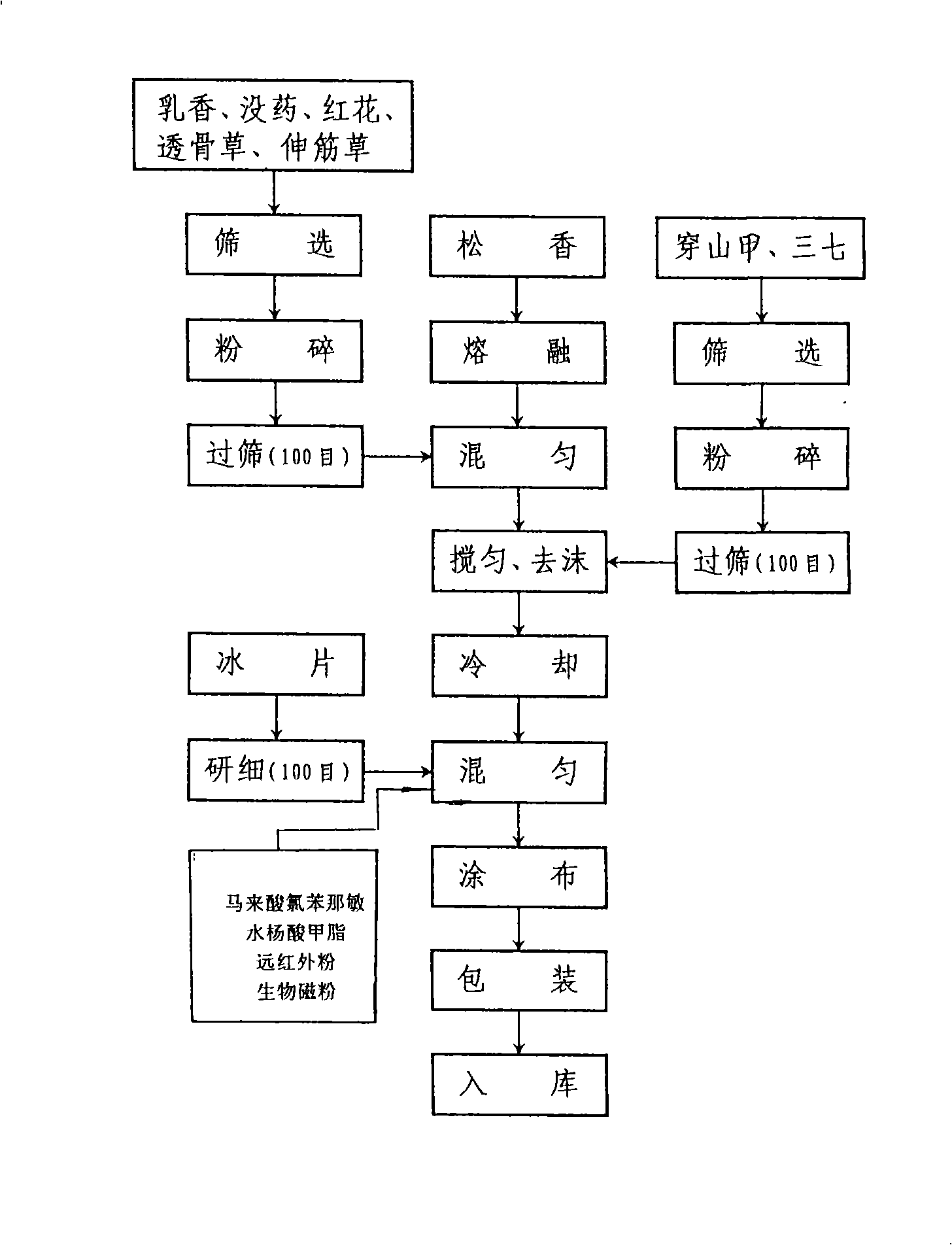

Babu far infrared medicinal plaster for treating arthralgia and myalgia, and wind-cold syndrome and numbness

InactiveCN101301339AReduce adverse reactionsEasy to useSalicyclic acid active ingredientsHeavy metal active ingredientsMyrrhSide effect

The invention aims to provide a cataplasm far-infrared medical application for treating arthralgia, myalgia, wind cold and numbness, which is elaborately developed by adopting rare pure traditional Chinese medicinal materials, a scientific novel method and a novel process. The application takes a formula in portion by weight: 40 g of borneol, 20 g of frankincense, 20 g of myrrh, 10 g of safflower, 10 g of panax notoginseng, 20 g of pangolin, 60 g of garden balsam stem, 20 g of common clubmoss herb and 400 g of colophony. The main composition of the formula is the pangolin, namely pangolin scales which is salty in taste and slightly cold in property, mainly treats wind cold and limbs numbness, and has the efficacy of dehumidifying, dissolving turbidity, diminishing inflammation and removing pain. The medical application has chlorpheniramine maleate and methyl salicylate which are effective compositions of western medicine added in preparation process, and uses far-infrared powder and biological magnetic powder which are the latest scientific achievements. The application has the advantages of clear effective compositions, obvious efficacy, few side effects, stable preparation and strict quality standard, thereby meeting the requirements of modern Chinese medicine on safety, high efficiency, stability and controllability.

Owner:牛天卓

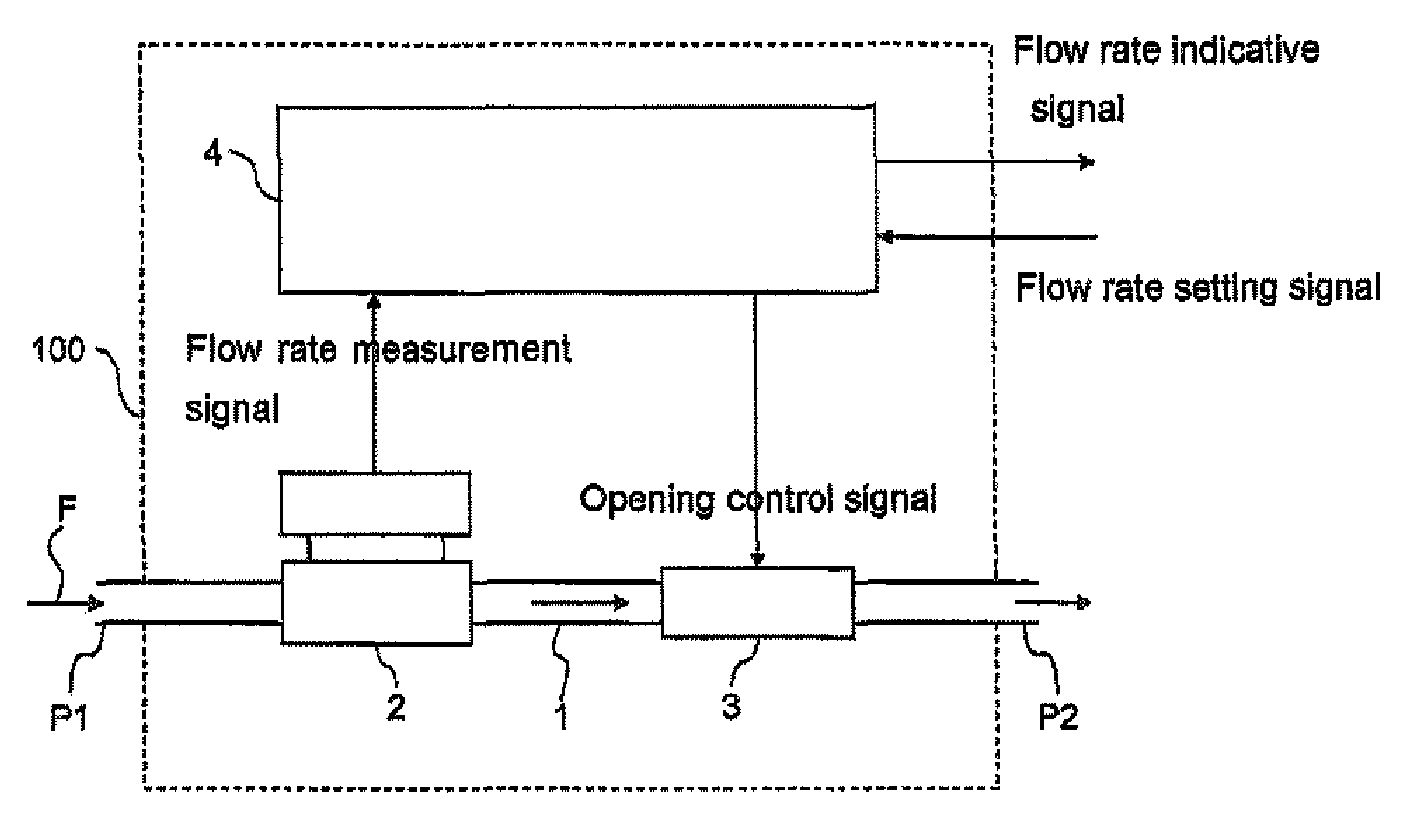

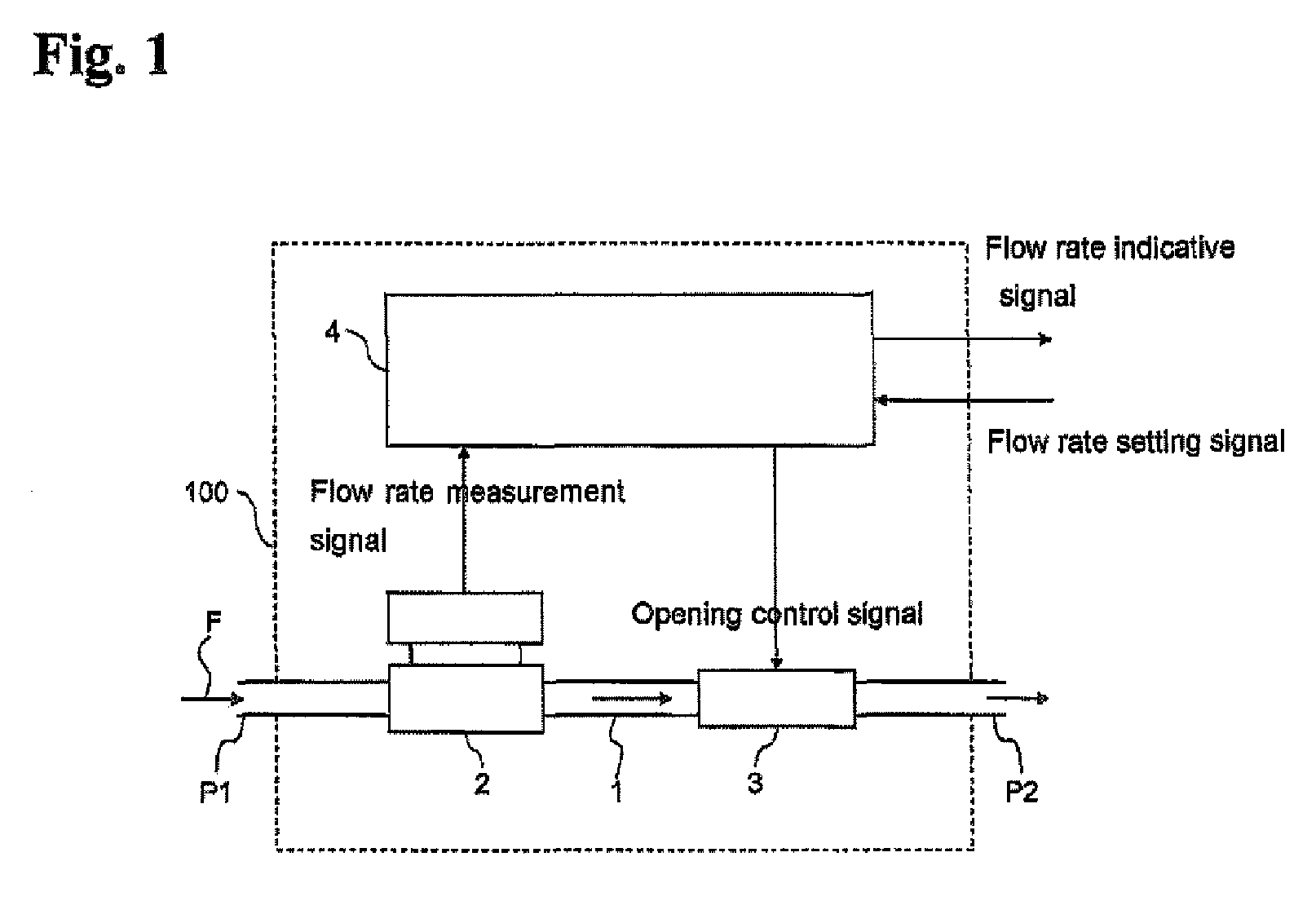

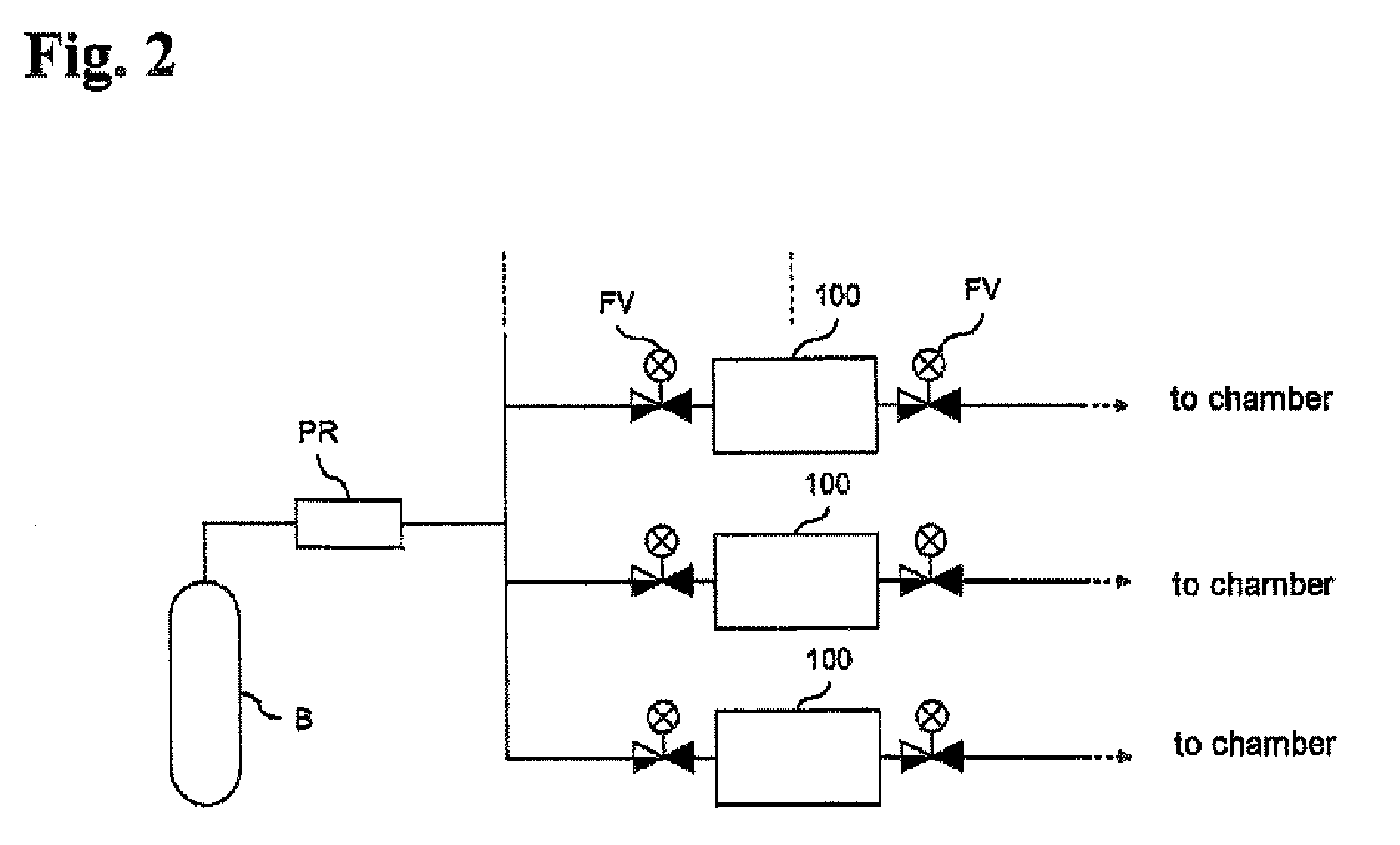

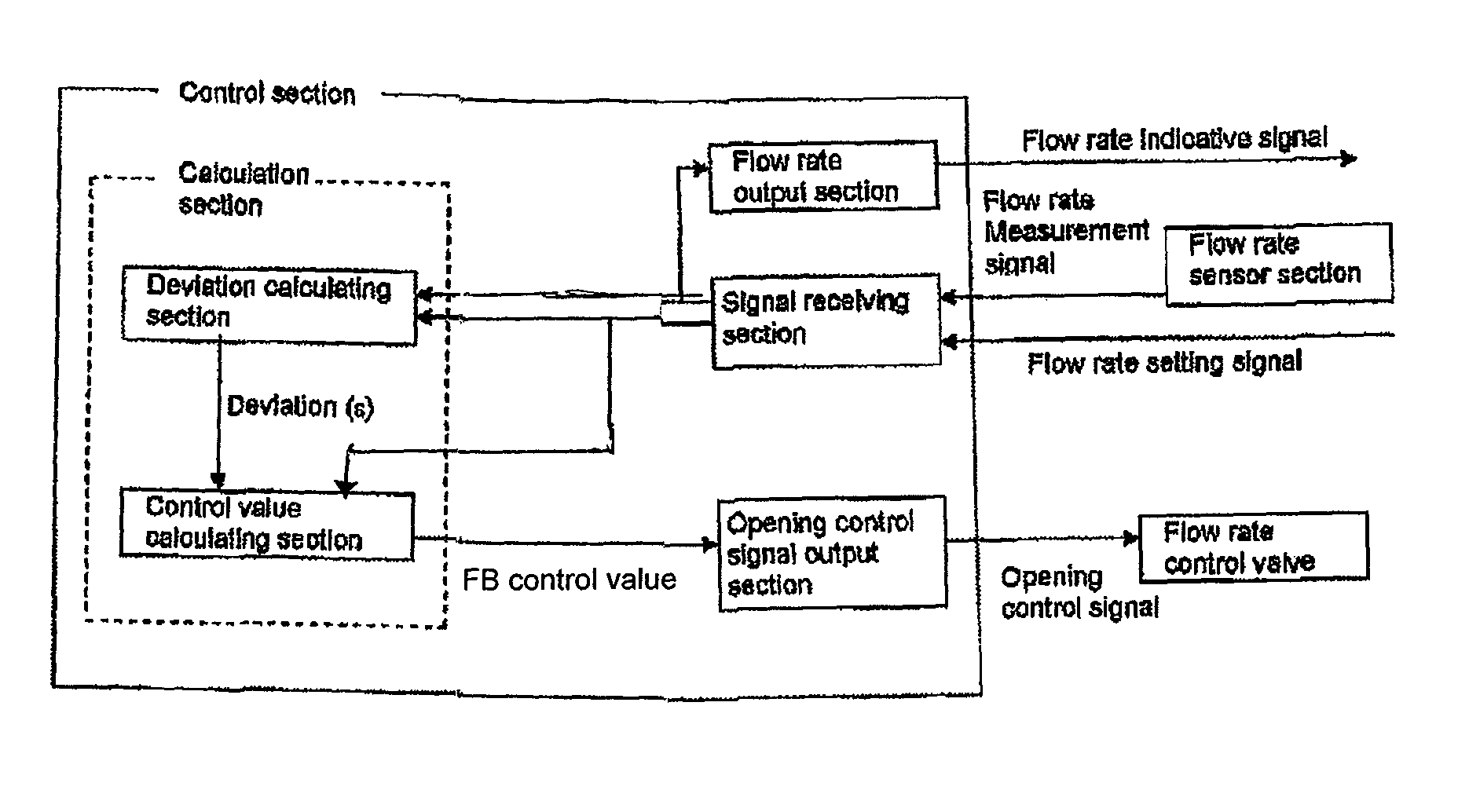

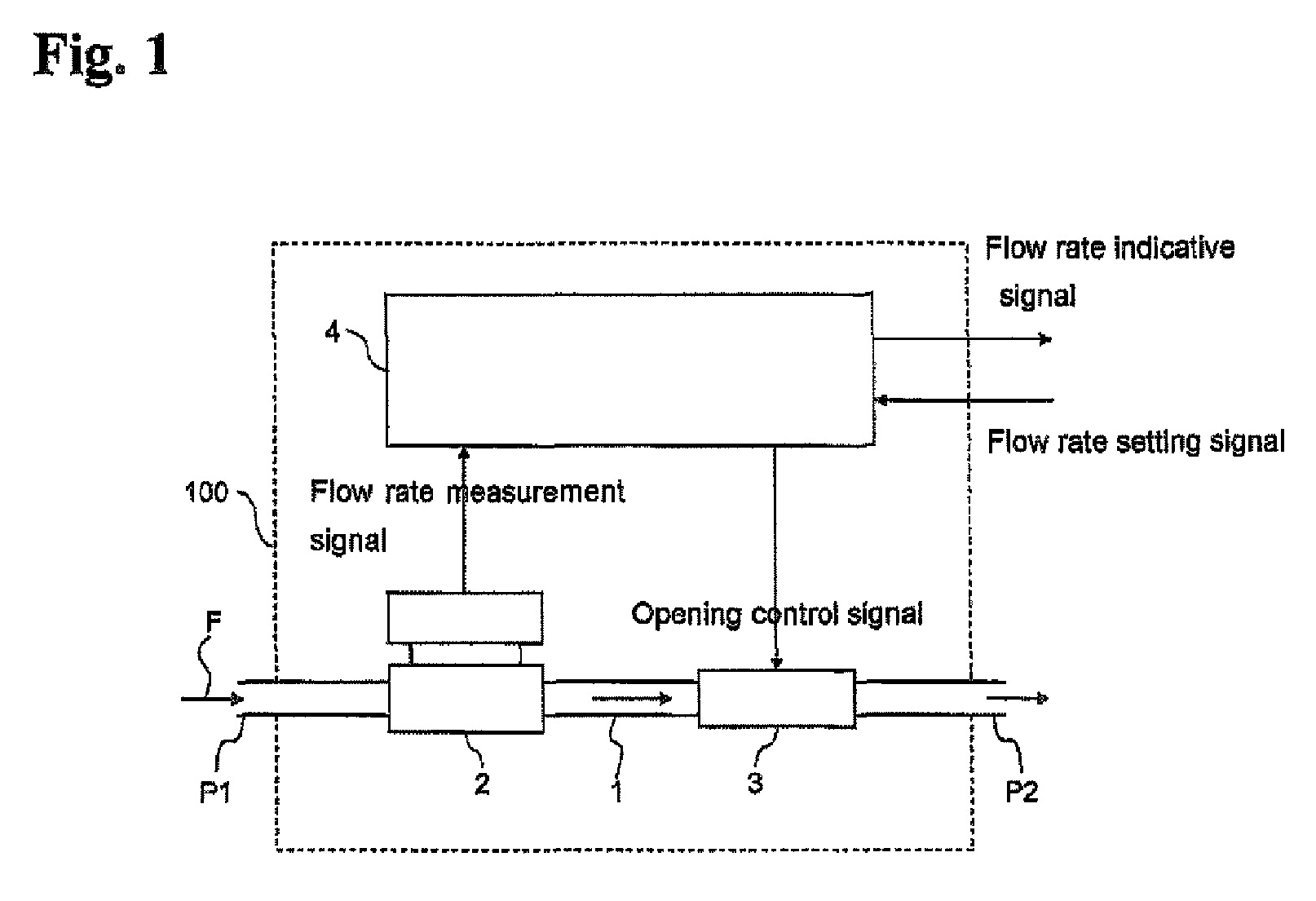

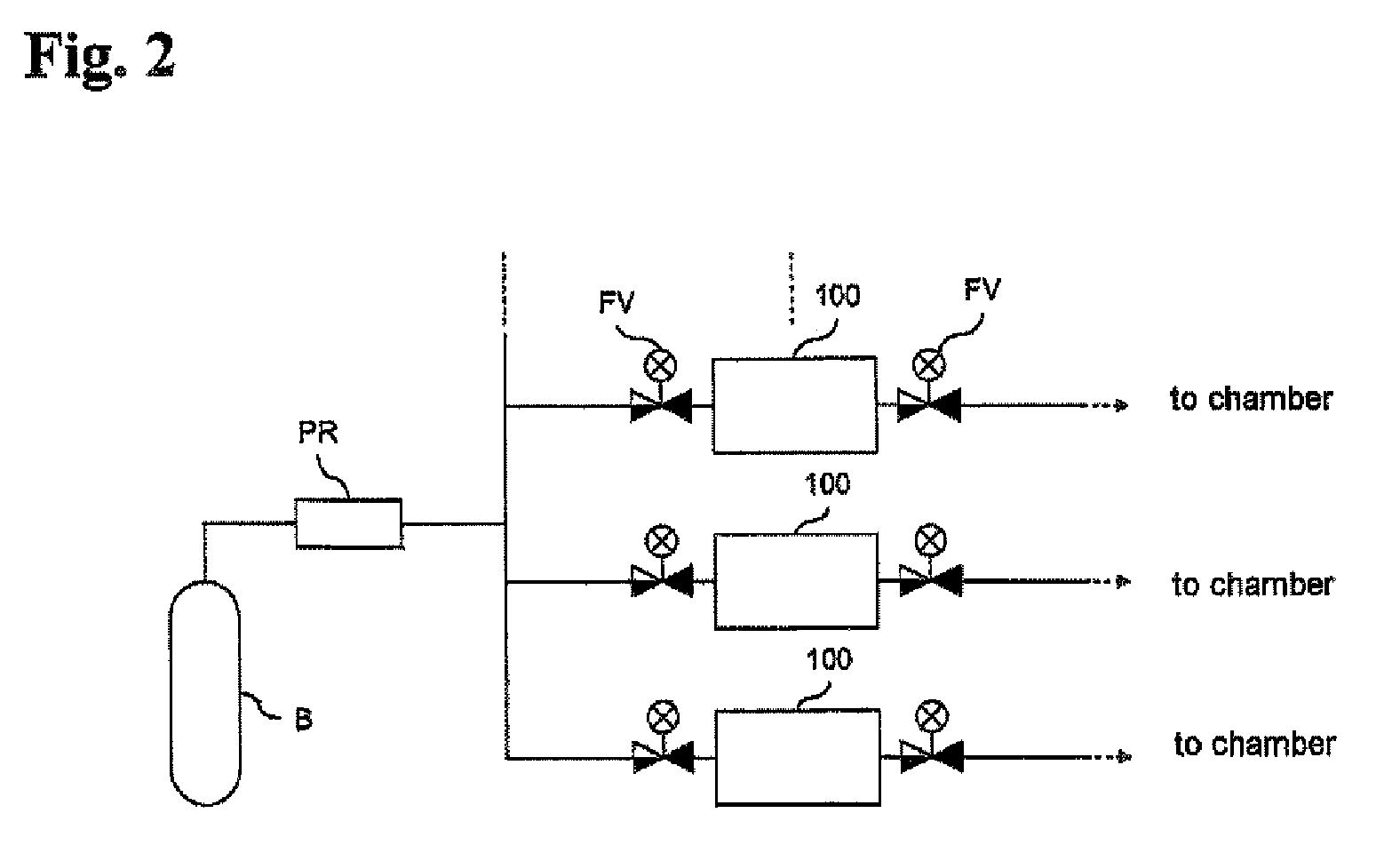

Mass flow controller

ActiveUS20080295892A1Sacrifice speedSuppress changeOperating means/releasing devices for valvesThin material handlingRate measurementEngineering

A mass flow controller has: a flow rate sensor section that measures the flow rate of a fluid and outputs a flow rate measurement signal indicating the measurement value; a flow rate control valve disposed upstream or downstream of the flow rate sensor section; a calculation section that calculates a feedback control value to the supplied to the flow rate control valve by performing at least a proportional calculation on the deviation of the flow rate measurement value indicated by the flow rate measurement signal from a flow rate setting value; and an opening control signal output section that generates an opening control signal based on the feedback control value and outputs the opening control signal to the flow rate control valve. The function used for calculating the gain value in the proportional calculation differs between a changing period and a stable period.

Owner:HORIBA STEC CO LTD

Mass flow controller

ActiveUS8056579B2Avoid overreactionStable flow rateOperating means/releasing devices for valvesThin material handlingControl signalEngineering

A mass flow controller has: a flow rate sensor section that measures the flow rate of a fluid and outputs a flow rate measurement signal indicating the measurement value; a flow rate control valve disposed upstream or downstream of the flow rate sensor section; a calculation section that calculates a feedback control value to be supplied to the flow rate control valve by performing at least a proportional calculation on the deviation of the flow rate measurement value indicated by the flow rate measurement signal from a flow rate setting value; and an opening control signal output section that generates an opening control signal based on the feedback control value and outputs the opening control signal to the flow rate control valve. The function used for calculating the gain value in the proportional calculation differs between a changing period and a stable period.

Owner:HORIBA STEC CO LTD

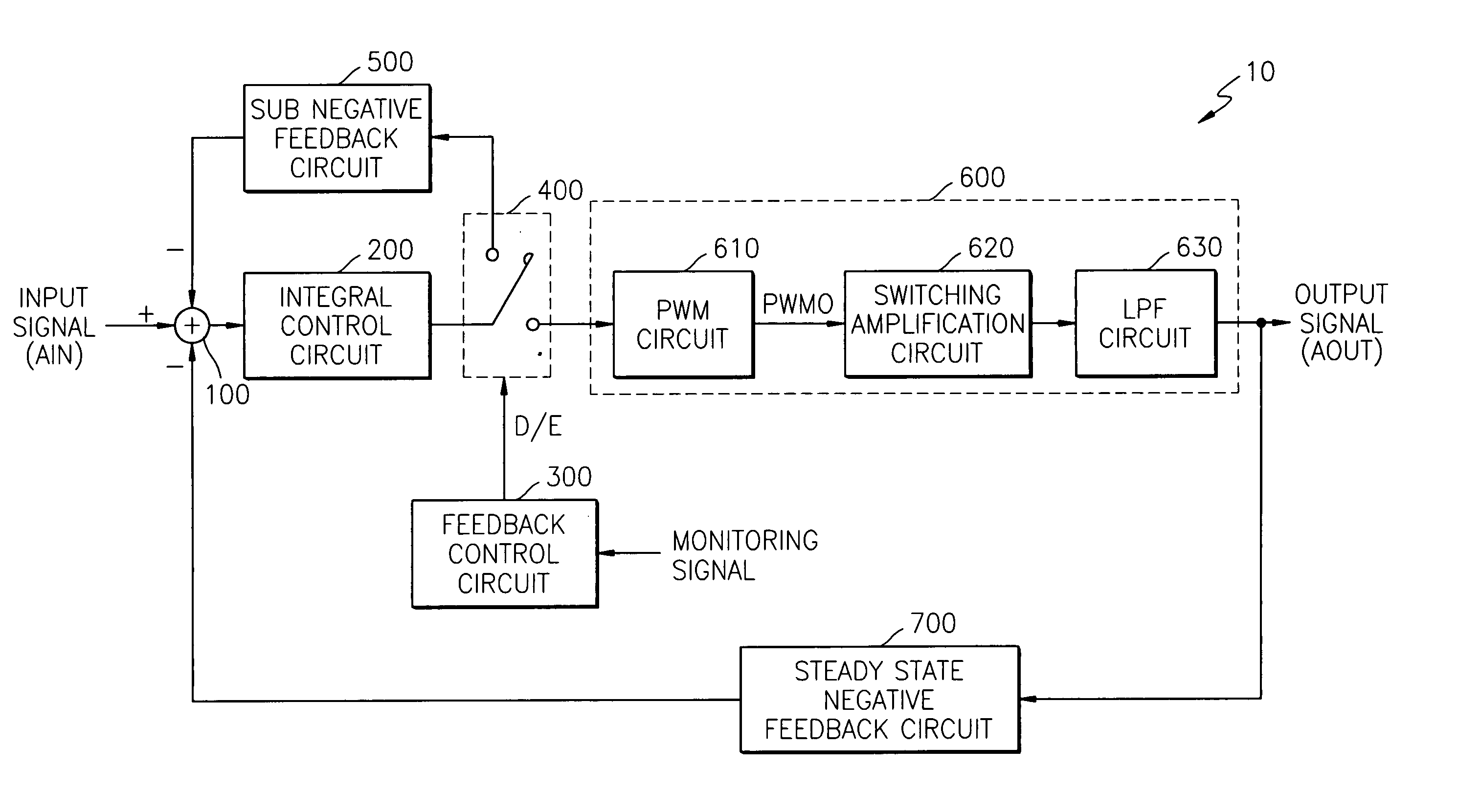

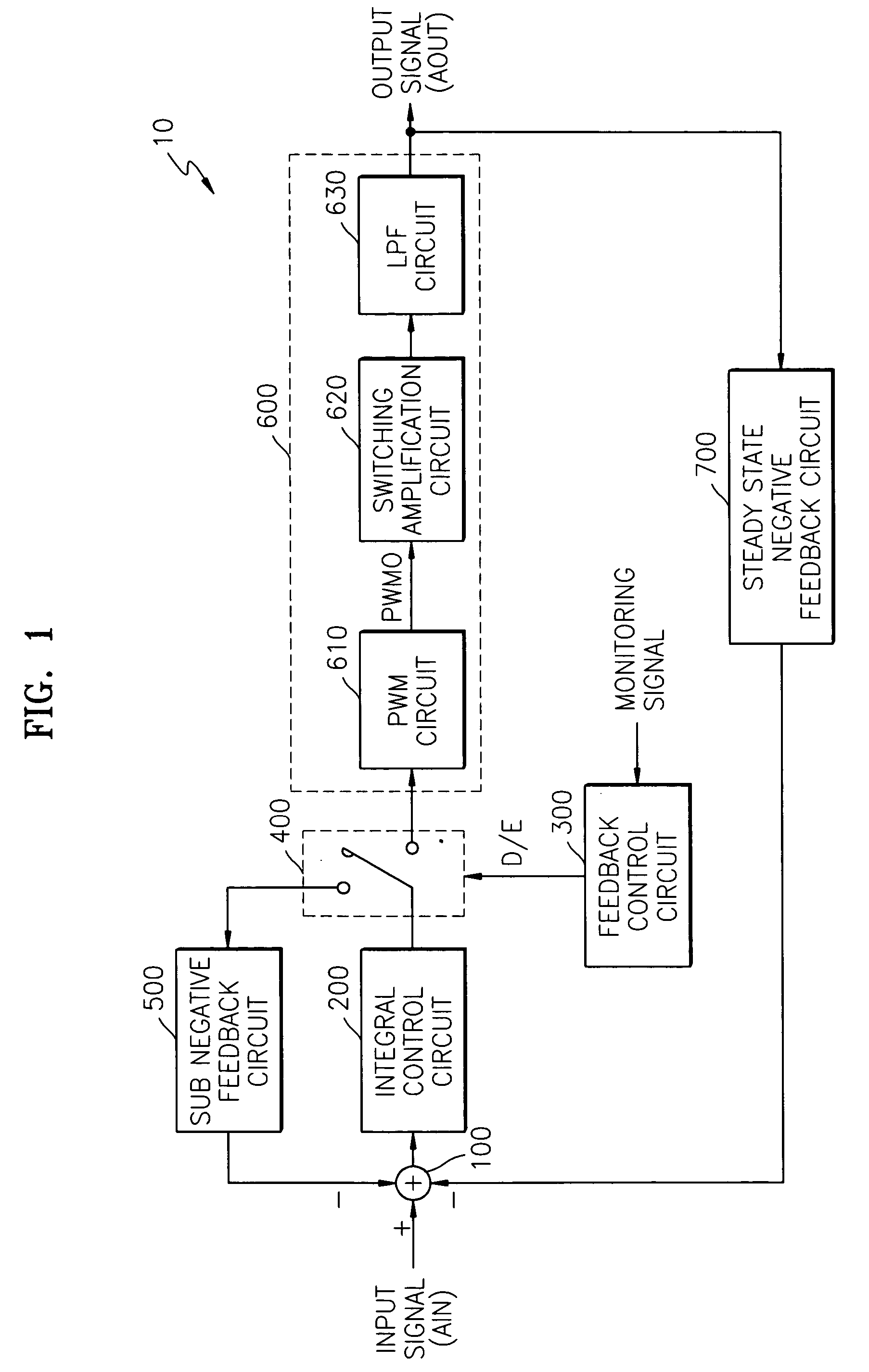

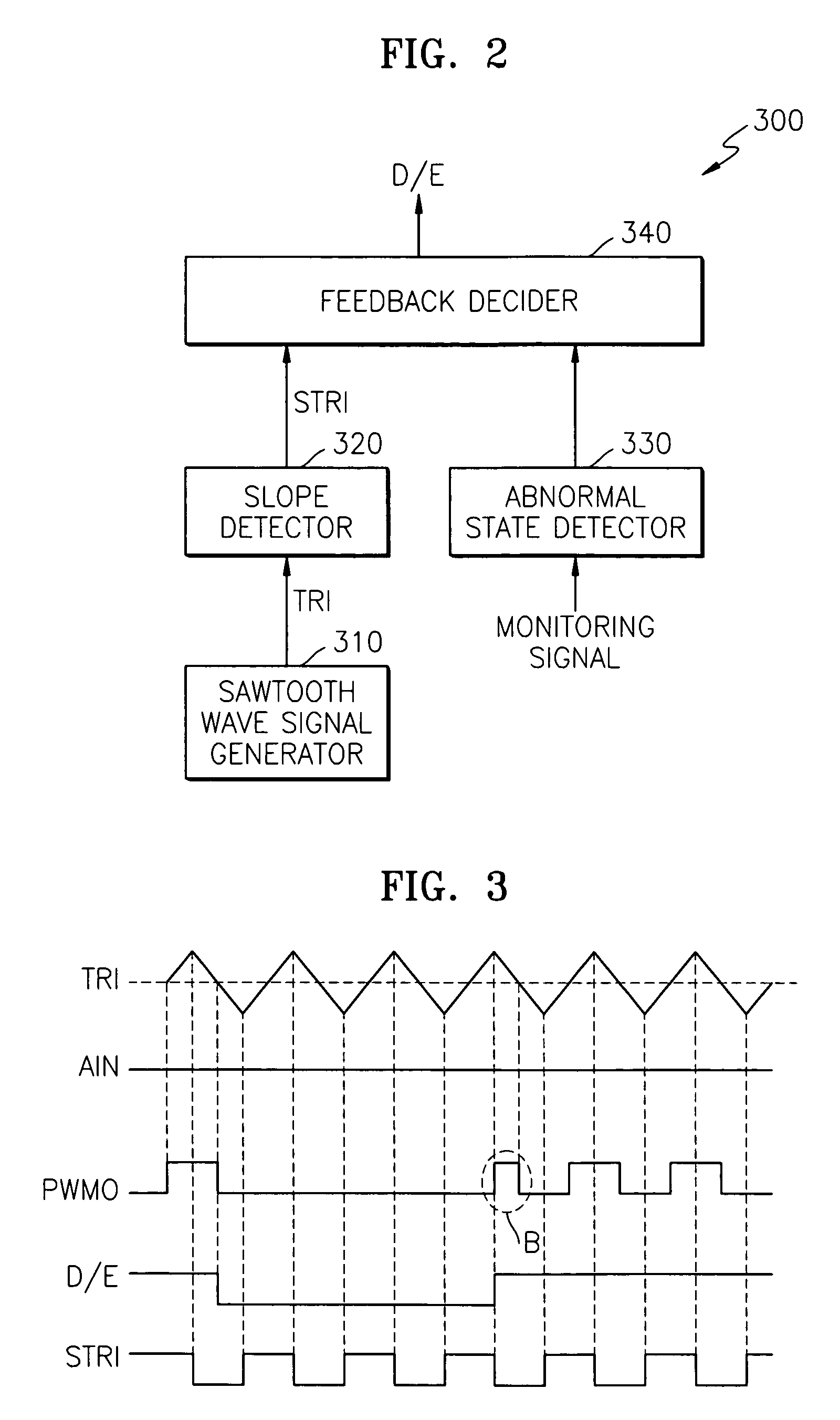

Class-D power amplifier capable of eliminating excessive response phenomenon when returning to a steady state from an abnormal state and an amplification method thereof

ActiveUS7113030B2Avoid overreactionNegative-feedback-circuit arrangementsAmplifier modifications to reduce noise influenceNegative feedbackStable state

A class-D power amplifier, which prevents excessive response phenomenon from occurring when returning to a steady state from an abnormal state and an amplification method of the class-D power amplifier are provided. The class-D power amplifier prevents an integral control circuit or a proportional integral control circuit from becoming saturated by using sub-negative feedback loop operations, without using a high-capacity output blocking switch in an initial state or an abnormal state. Thus, suppressing pop noise due to the excessive response phenomenon caused when the class-D power amplifier returns to the steady state from the initial state or the abnormal state and reducing power consumption.

Owner:SAMSUNG ELECTRONICS CO LTD

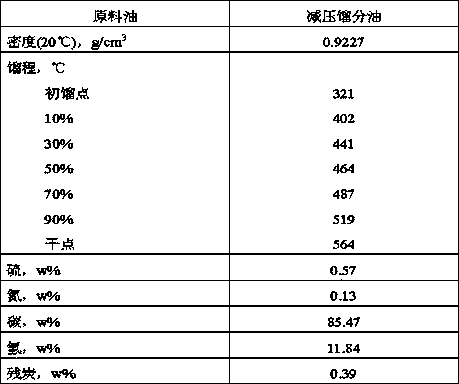

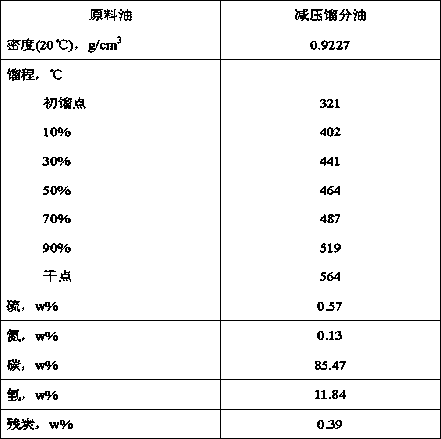

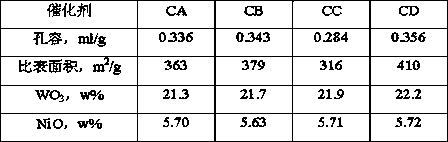

Carrier containing dual-molecular sieves, catalyst containing dual-molecular sieves and preparation methods and application of carrier and catalyst

ActiveCN108067290AImprove stabilityReduced Diffusion ResistanceMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The invention provides a carrier containing dual-molecular sieves, a catalyst containing dual-molecular sieves and preparation methods and application of the carrier and the catalyst. The carrier is prepared from 48.5wt%-89.9wt% of a modified Y molecular sieve, 0.1wt%-1.5wt% of an SBA-15 molecular sieve and 10wt%-50wt% of aluminum oxide by weight of the carrier; the catalyst is prepared from 28.5wt%-74.9wt% of the modified Y molecular sieve and 0.1wt%-1.5wt% of an SBA-15 mesoporous molecular sieve by weight of the catalyst; and group VIB metal accounts for 10.0-25.0wt% in terms of its oxides,group VIII metal accounts for 3.0-8.0wt% in terms of its oxides, and the aluminum oxide accounts for 10-30wt%. The carrier is especially suitable for preparing a light oil type hydrocracking catalystand has high catalytic cracking activity and high target product selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

5-hydroxymethylfurfural production technology

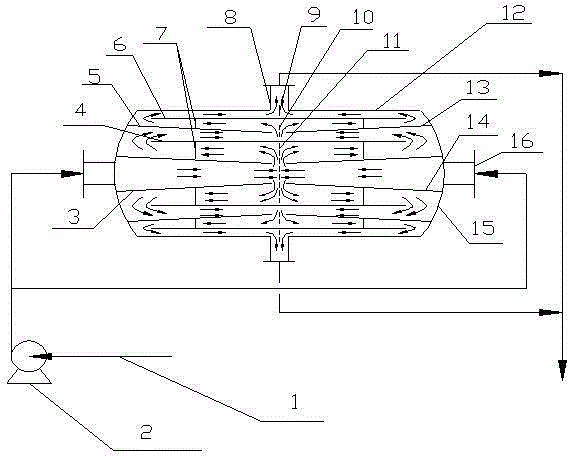

InactiveCN106146436AEnhanced mass transferHigh proportion of flow channel volumeCarboxylic compound separation/purificationChemistryFormic acid

The invention discloses a novel technology for producing 5-hydroxymethylfurfural and simultaneously recovering formic acid and acetic acid. The technology utilizes an impinging stream reactor especially suitable for the technology. Through multiple impinging processes, fluid mixing is realized and good microscopic mixing effects are obtained. The mixed liquid is horizontally pushed to flow outside an impinging zone so that enough staying time is supplied for materials, a stepwise reaction is realized and a desired conversion rate is realized through channel and liquid flow rate designs. The technology solves the problem that the existing impinging stream reactor cannot realize a high conversion rate through a single reactor, simplifies processes, reduces a production cost and an equipment investment and guarantees long-term equipment operation. The technology does not discharge a waste liquid in production and is a green environmental protection technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Centrifugal centripetal flow beam tube type water bed reactor

The invention discloses a centrifugal centripetal flow beam tube type water bed reactor which comprises a shell, and a radial distributor comprising an inner radial basket diameter and an outer radialbasket diameter is arranged in the shell. An annular gap is formed between an outer radial basket and a cylinder body, a reaction area is formed between an inner radial basket and the outer radial basket, and the inner radial basket comprises a gas inlet part and a gas outlet part which are connected up and down. A first airflow channel is arranged on the air inlet part. A second airflow channelis arranged on the gas outlet part. A third airflow channel is arranged on the outer radial basket. The reaction area is divided into an upper reaction area and a lower reaction area. A first reactiongas enters the upper reaction area through the gas inlet part for reaction to form a partial reaction gas, and then the partial reaction gas enters the annular gap. A second reaction gas enters the annular gap through a side reaction gas inlet pipe and is mixed with the partial reaction gas to form mixed reaction gas, and the mixed reaction gas enters the lower reaction area for reaction. By utilizing the reactor, the retention time of reaction gas in the reactor can be effectively prolonged, so that the one-way reaction efficiency is improved.

Owner:NANJING JUTUO CHEM TECH

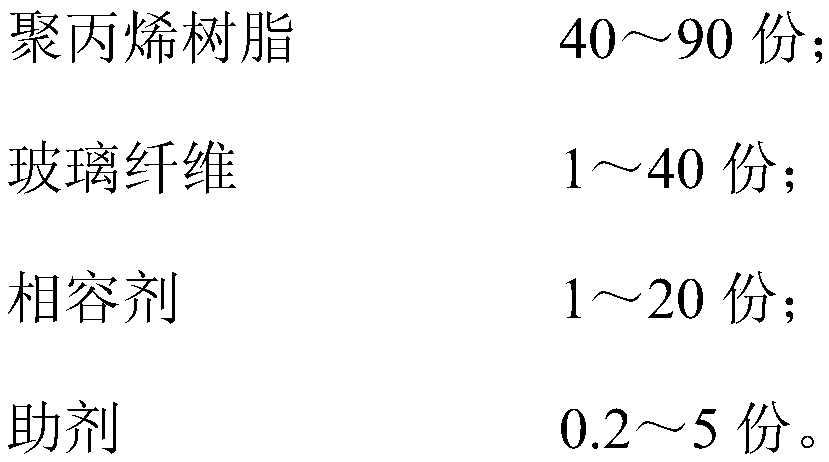

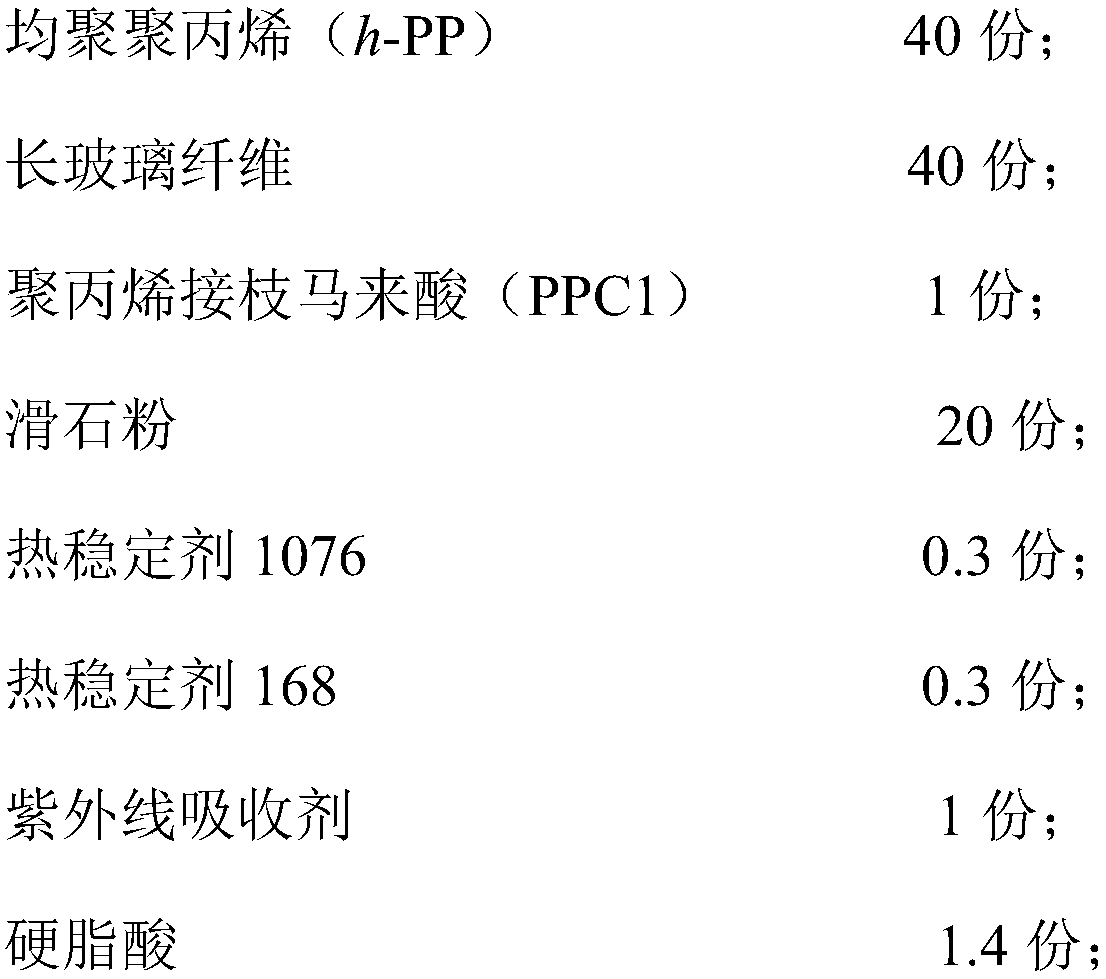

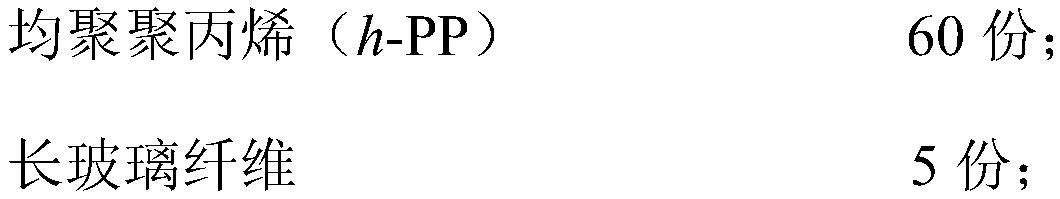

Low-emission glass fiber reinforced polypropylene composite material and preparation method thereof

The invention provides a low-emission glass fiber reinforced polypropylene composite material and a preparation method thereof. The preparation method comprises the following steps of: obtaining raw material polypropylene resin, glass fiber, compatibilizer and auxiliary agents, blending the polypropylene resin, the compatilizer and the auxiliary agents to obtain a mixture; feeding the mixture andthe glass fibers to an extruder and melt-extruding under microwave conditions. In that preparation of the composite material, the microwave is introduced into the preparation of the composite material, the heat can be ensured to penetrate into the interior of the polypropylene macromolecule and the additive molecule, the excessive overheating caused by partial overheating is avoided, thereby effectively reducing the amount of the polypropylene or the additive decomposed into the volatile organic small molecular compound when the glass fiber reinforced polypropylene composite material is produced, and obviously reducing the emission of the organic small molecules in the glass fiber reinforced polypropylene composite material; the process is simple, green and environment-friendly, and the auxiliary agents for reducing the organic small molecule are not required to be added in addition; and the performance of the glass fiber reinforced polypropylene composite material is not affected.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

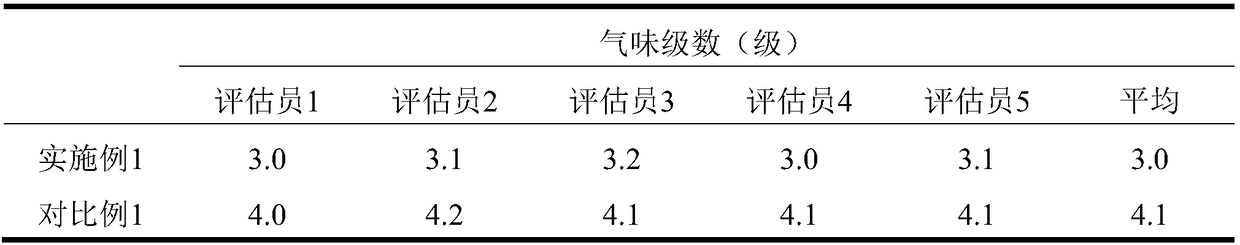

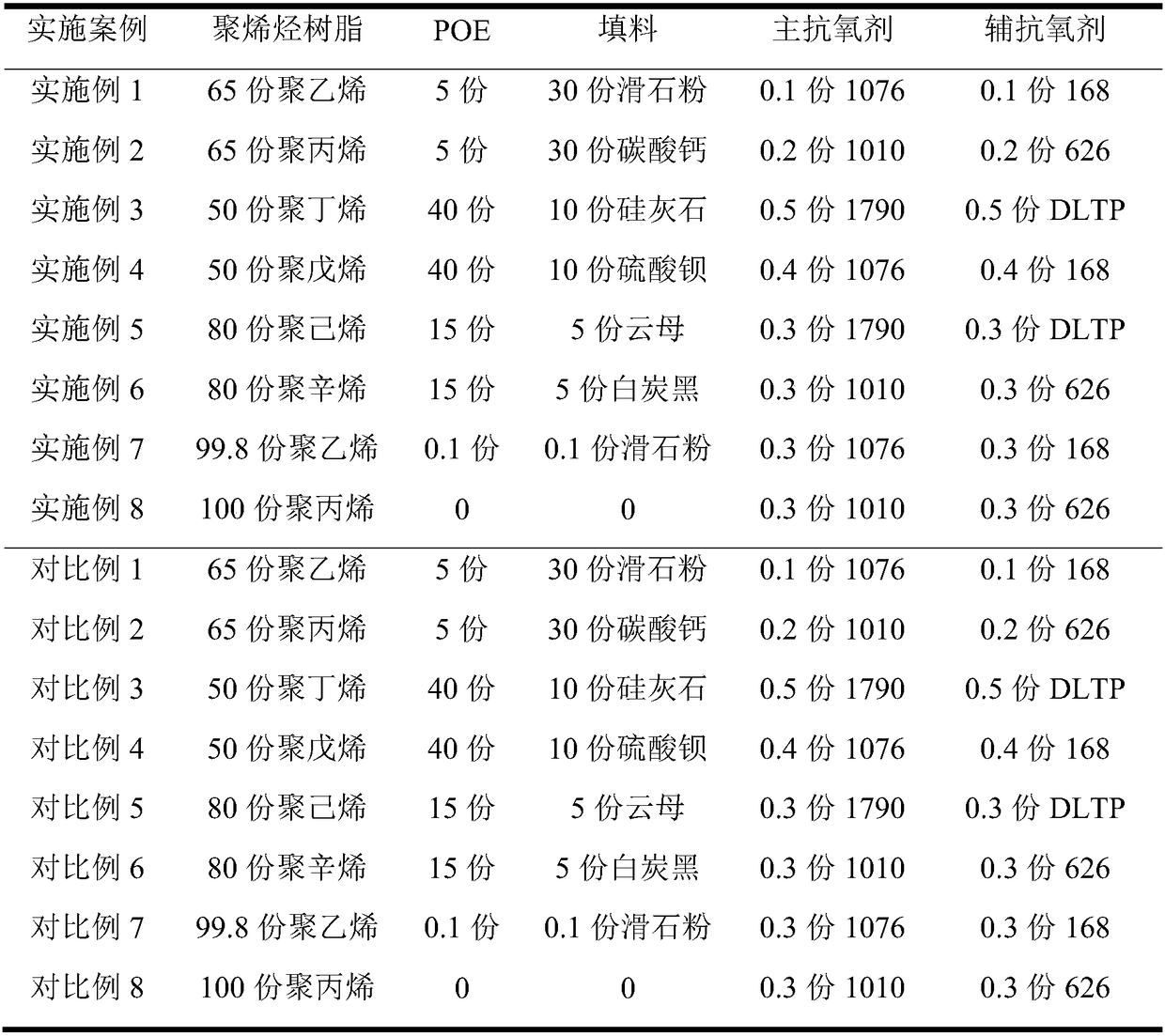

Polyolefin composite material and preparation method thereof

The invention relates to a polyolefin composite material and a preparation method thereof. The raw material composition of the polyolefin composite material comprises polyolefin resin and additives. The preparation method comprises the following steps: (1) blending the polyolefin resin and the additives to obtain a mixture; and (2) heating the mixture in step (1) through microwaves to 160-280 DEGC for reaction for 3-600s under the microwave heating conditions of the microwave power being 50-8000W and the microwave frequency being 500-270000 MHz, thereby obtaining the polyolefin composite material. The method can effectively reduce the odor of the polyolefin composite material obtained by production, does not need to additionally add additives, does not change the original performance of the polyolefin composite material, and is simple, low in production cost and convenient for industrial application.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

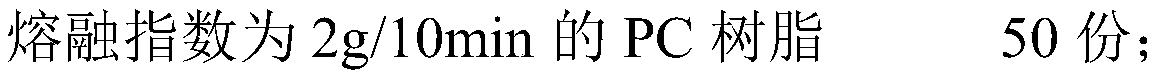

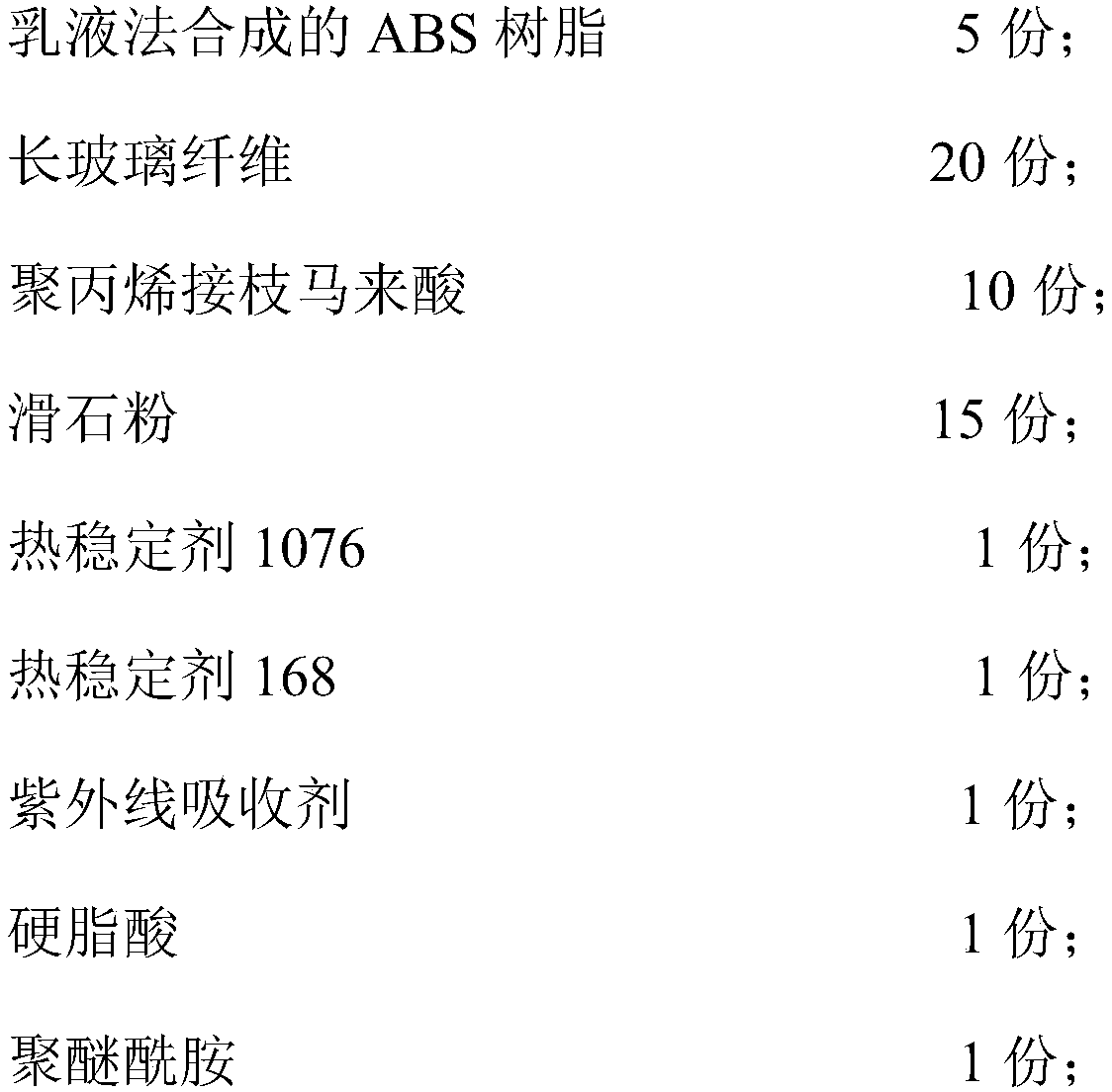

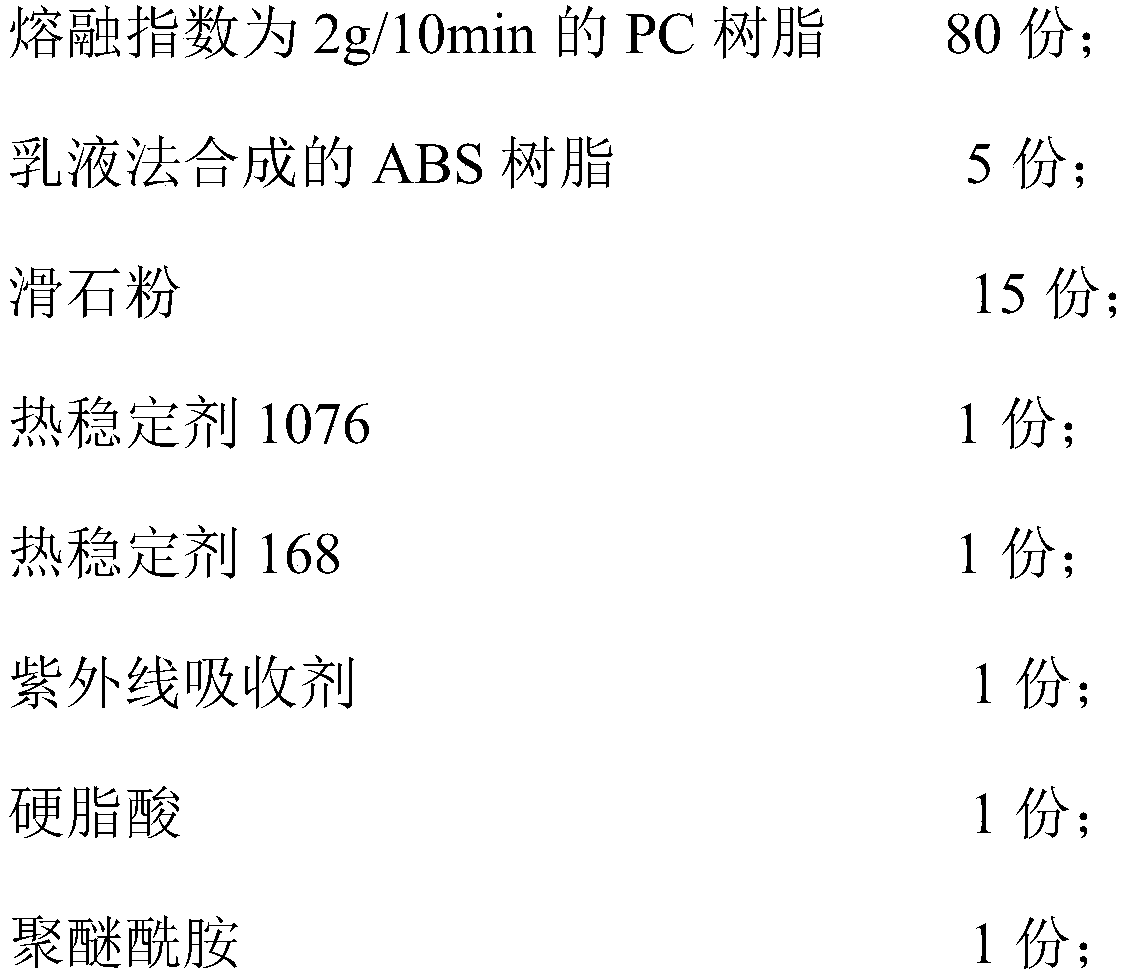

Low smell glass fiber-reinforced polycarbonate/acrylonitrile-butadiene styrene (PC/ABS) alloy and preparation method thereof

The invention provides a low smell glass fiber-reinforced polycarbonate / acrylonitrile-butadiene styrene (PC / ABS) alloy and a preparation method thereof. The preparation method includes the following steps: weighing preparation raw materials in parts by weight, wherein the preparation raw material is prepared from 5-80 parts of polycarbonate resin, 5-80 parts of acrylonitrile-butadiene-styrene resin, 1-40 parts of glass fiber, 1-20 parts of compatibilizer, 0-20 parts of filler, and 0.2-10 parts of assistant; blending the polycarbonate resin, the acrylonitrile-butadiene-styrene resin, the compatibilizer, the filler and the assistant to obtain a mixture; feeding the mixture and the glass fiber to an extruder, and performing melting, extrusion and granulation under microwave heating conditions. The preparation method can surely avoid unnecessary over-reaction caused by local overheating, reduce decomposition of the preparation raw materials into small molecular compounds having off-odor and reduce the odor level of the alloy. The preparation method is simple in process and environmentally friendly, and does not need to additionally add assistant to reduce organic small molecules and does not affect the performance of the alloy.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Method for detecting process and end point of sulfur trioxide sulfonation

InactiveCN101692063AAccurate judgmentEasy to solveMaterial resistanceSulfonic acid preparationSulfur trioxideReagent

The invention discloses a method for detecting process and end point of sulfur trioxide sulfonation. The method comprises the following steps that: (1) a conductance-detecting electrode is inserted into reactant subjected to sulfonation; the conductance of the reactant is detected and displayed in real time; the conductance of the reactant decreases along with the process of sulfonation; and sulfur dioxide gas is adopted as a sulfonating agent in the sulfonation; and (2) when the conductance of the reactant is detected to decrease to zero, the sulfonation reaches the end for sure. The method has the advantages of tracking the process of the sulfonation in real time through the conductance change of sulfonation solution, accurately judging the end point of the sulfonation, reminding operators in real time, ensuring that reaction cannot exceed the end point, leaving out the trouble of chemical sampling detection and avoiding the phenomenon that the chemical sampling detection is not timely and accurate enough in results.

Owner:WUHAN QINGJIANG CHEM IND

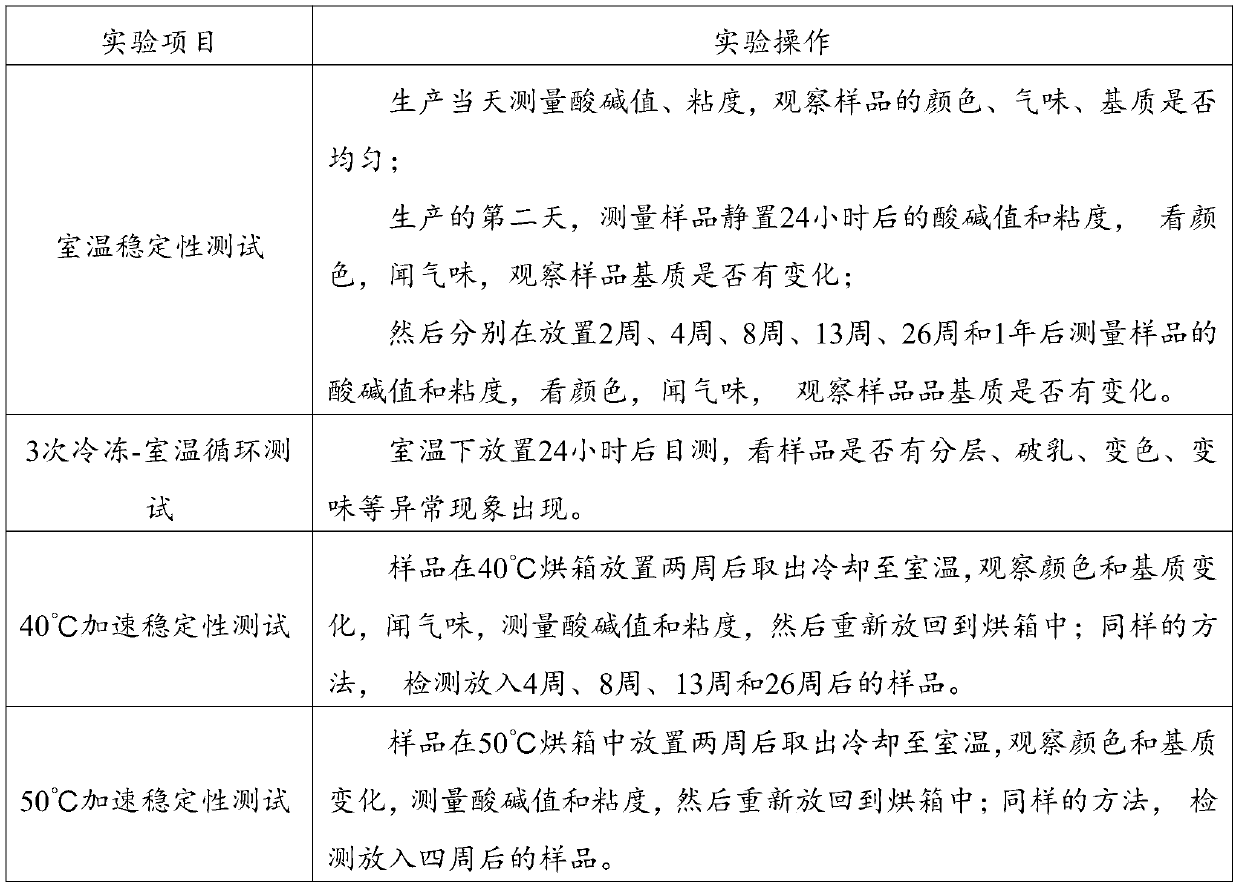

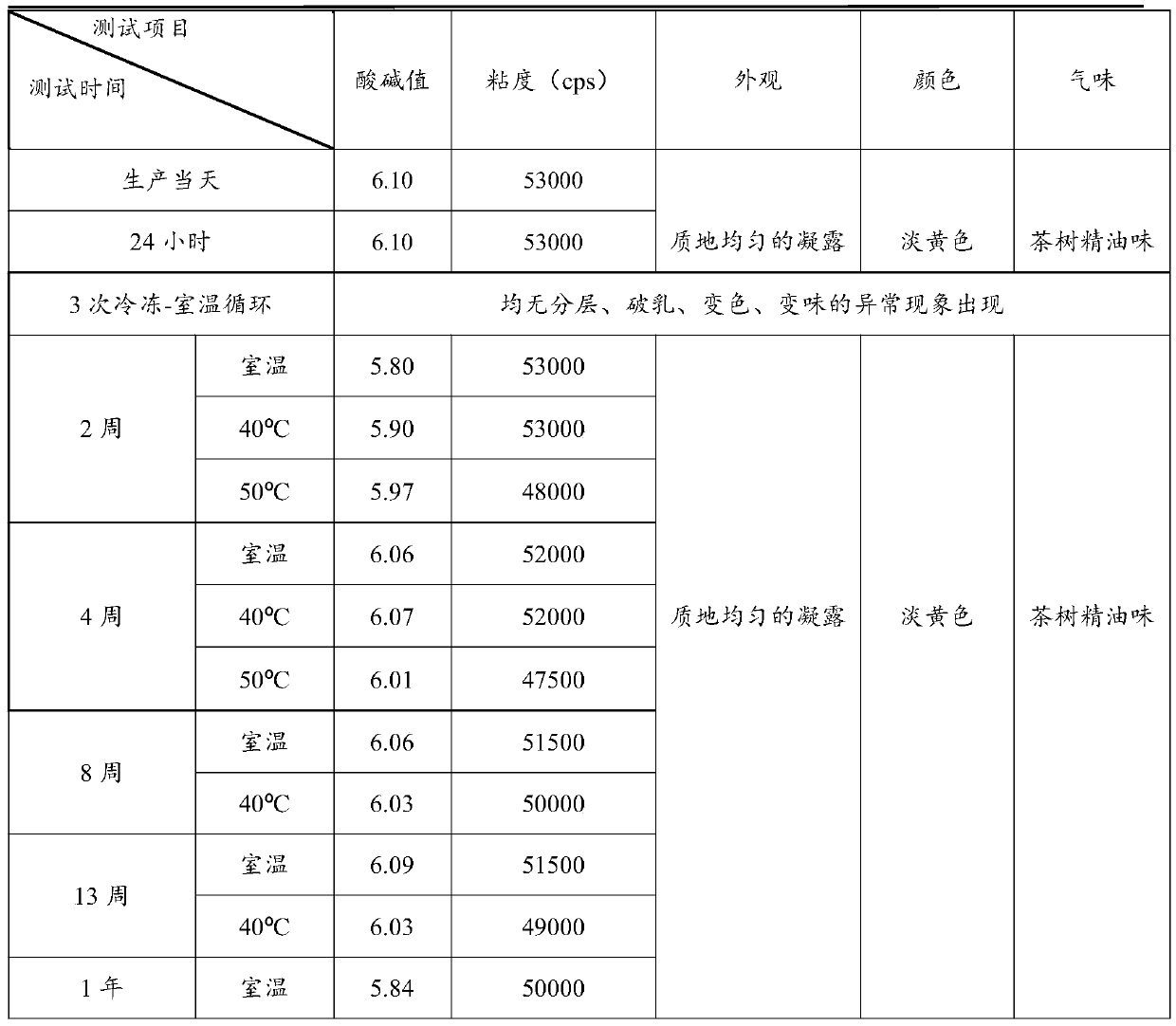

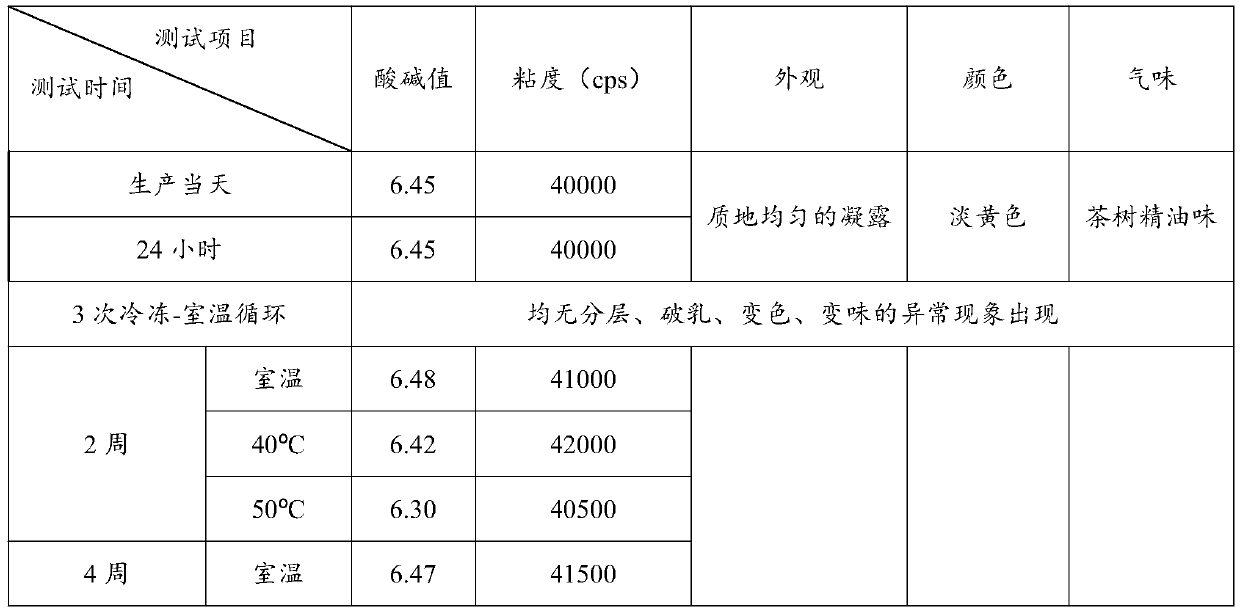

Multi-effect skin relaxing gel and preparation method thereof

PendingCN111481461AStable in natureLong-term useCosmetic preparationsToilet preparationsAloinAntiseptic Agent

The invention provides multi-effect skin relaxing gel and a preparation method thereof, and relates to the technical field of skin health care products. The multi-effect skin relaxing gel provided bythe invention comprises deionized water, a water-soluble component and a fat-soluble component, wherein the water-soluble component comprises a first skin soothing agent, a first anti-inflammatory bactericide, a humectant, a thickener, a preservative, an acid-base regulator and a chelating agent; the fat-soluble component comprises a second skin soothing agent, a second anti-inflammatory bactericide, an emollient and an antioxidant; wherein the first skin soothing agent is allantoin, and the first anti-inflammatory bactericide is aloe vera leaf juice powder and rosemary leaf extract; the second skin soothing agent is prepared from cynanchum glaucescens seed oil, sunflower seed oil unsaponifiable matter and ribes nigrum seed oil, and the second anti-inflammatory bactericide is prepared froma bougainvillea speetabilis flower / leaf / vine extract and tea tree essential oil. The product can effectively relieve various discomfort of sensitive skin, is safe, has no side effect, can be used fora long time, is suitable for large-area use, and is simple and convenient to prepare and mild in condition.

Owner:湖南翠铂丽斯生物科技有限责任公司

Pasture feeding device and system with monitoring function

PendingCN107996428AAvoid overreactionEasy to grasp in real timeAnimal feeding devicesProgramme control in sequence/logic controllersGas collecting tubeGas detector

The invention provides a pasture feeding device and system with a monitoring function, and relates to the technical field of the livestock environmental engineering. The pasture feeding device with the monitoring function comprises a feeding tank, a gas collecting tube, a gas detector and an exhaust fan. One side of the feeding tank is provided with an opening, and the feeding tank is used for loading a fodder. One end of the gas collecting tube is communicated with the gas detector, and the other end is fixedly connected with the edge of the opening. The exhaust fan is installed at one end, adjacent to the gas detector, of the gas collecting tube. The gas detector is used for detecting the concentration of the gas exhaled by a dairy cow. The pasture feeding device with the monitoring function is capable of simultaneously realizing the functions of providing the feeding platform and monitoring the gas. The functions are diversified, and the more information of the dairy cow can be collected. A worker can conveniently master the dynamic information of the dairy cow in real time in a feeding behavior process, so a better feeding scheme is developed.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

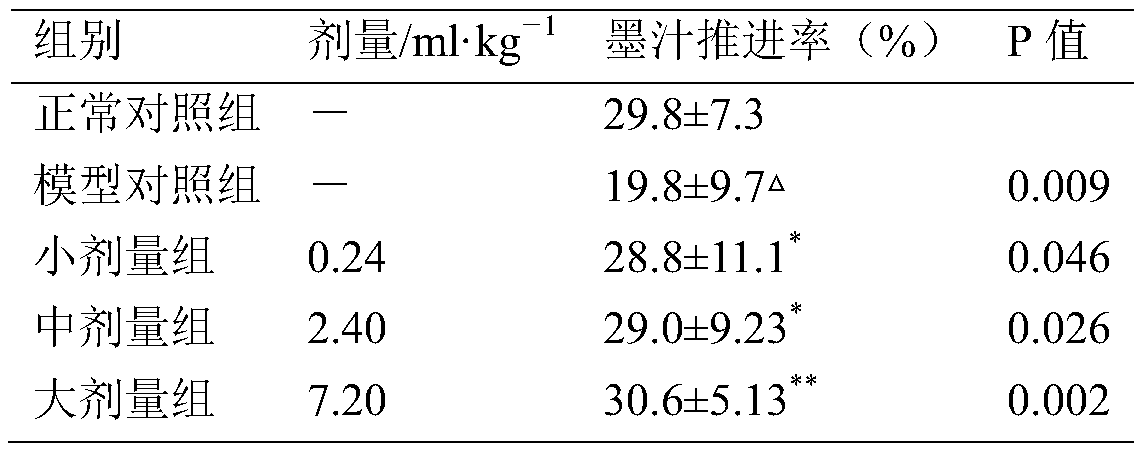

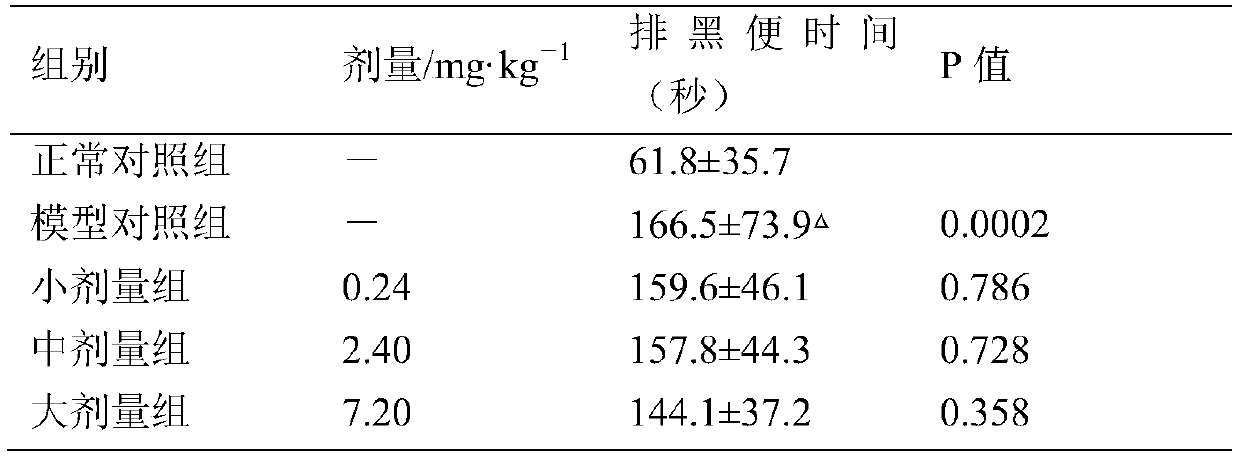

Traditional Chinese medicine composition for relaxing bowels, preparation method and application thereof

PendingCN109939168ASimple ingredientsAvoid overreactionDigestive systemPlant ingredientsSide effectAngelica Sinensis Root

The invention discloses a traditional Chinese medicine composition for relaxing bowels and a preparation method and application thereof. The active ingredients of the traditional Chinese medicine composition are prepared from the extracts of medicinal raw materials, and the medicinal raw materials include aloe and angelica sinensis with the mass ratio of (2-5) to (1.5-12). By applying the technical scheme of the invention, the traditional Chinese medicine composition for relaxing bowels is simple in composition, the effective ingredients are extracted from the aloe and angelica sinensis, possibly existing excessive reactions of complicated ingredients are avoided, the risk of side effects generated after medicine taking is obviously reduced, and the traditional Chinese medicine compositionhas a good bowel relaxing effect.

Owner:TSING HUA DE REN XIAN HAPPINESS PHARMA

Composite electrode material and method for manufacturing the same, composite electrode containing the said composite electrode material, and li-based battery

InactiveCN110635118ABuffer volume change stressAvoid overreactionMaterial nanotechnologySecondary cells servicing/maintenanceComposite electrodeCarbon Nanoparticles

Provided are a composite electrode material and a method for manufacturing the same, a composite electrode containing the said composite electrode material, and a li-based battery. The composite electrode material of the present invention comprises: a core, wherein a material of the core is at least one selected from the group consisting of Sn, Sb, Si, Ge, C, a compound thereof and a complex thereof; and a conductive carbon nanoparticle, wherein the conductive carbon nanoparticle grows on a surface of the core.

Owner:曾永华

Reaction kettle

PendingCN107456937AAvoid errorsCool down quicklyProcess control/regulationChemical/physical/physico-chemical stationary reactorsTemperature controlReaction temperature

The invention belongs to the technical field of chemical engineering reaction equipment, and provides a reaction kettle. The reaction kettle comprises a reaction cavity, a material inlet, a speed control assembly, a temperature control assembly, a material discharging assembly and a stirring assembly, wherein the material inlet is connected to the upper end of the reaction cavity; the speed control assembly is communicated with the material inlet; the temperature control assembly is connected to the reaction cavity and is used for controlling the temperature in the reaction cavity; the material discharging assembly is connected with the bottom part of the reaction cavity, and is used for accelerating material discharging; the stirring assembly is connected to the reaction cavity, and is used for accelerating the reaction; the temperature control assembly comprises a heat conduction passage and a circulating pump, the heat conduction passage is attached to the inner wall of the reaction cavity, and the circulating pump is connected to the heat conduction passage; the material discharging assembly comprises a material discharging pump and a material storage box, and the material storage box is communicated with the material discharging pump. By adopting the design, the reaction kettle can solve the problems of large discharging error, failure to intelligently control the reaction temperature, and excessive reaction due to longer discharging time in the existing reaction equipment.

Owner:珠海纳金科技有限公司

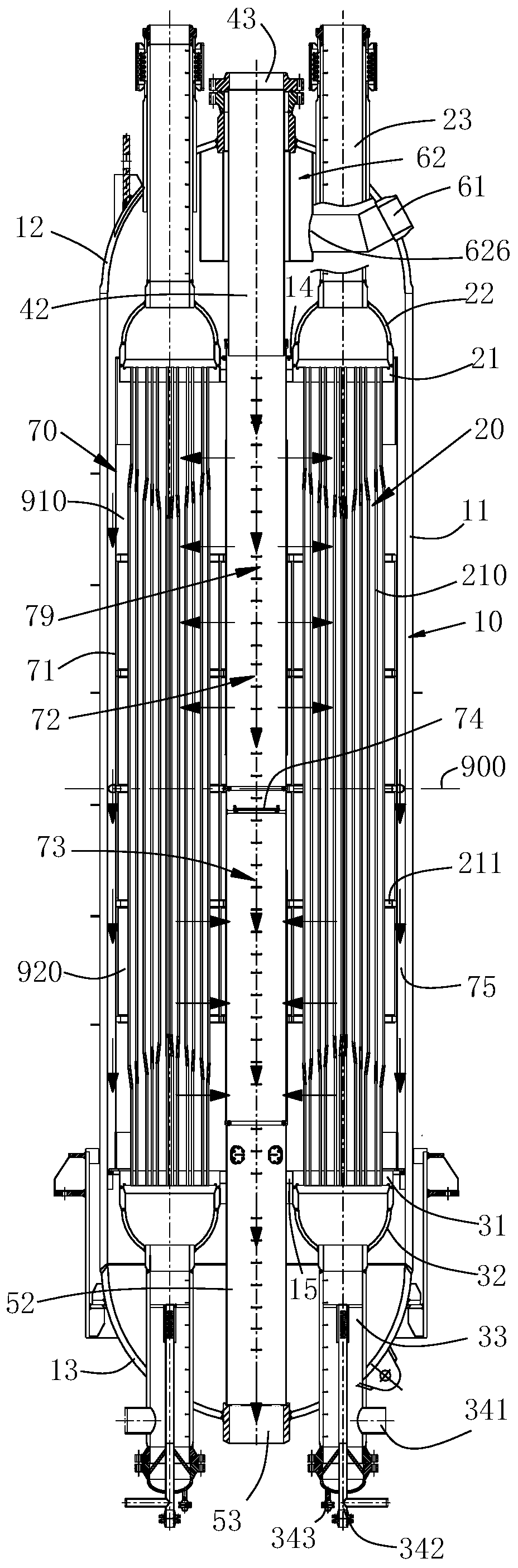

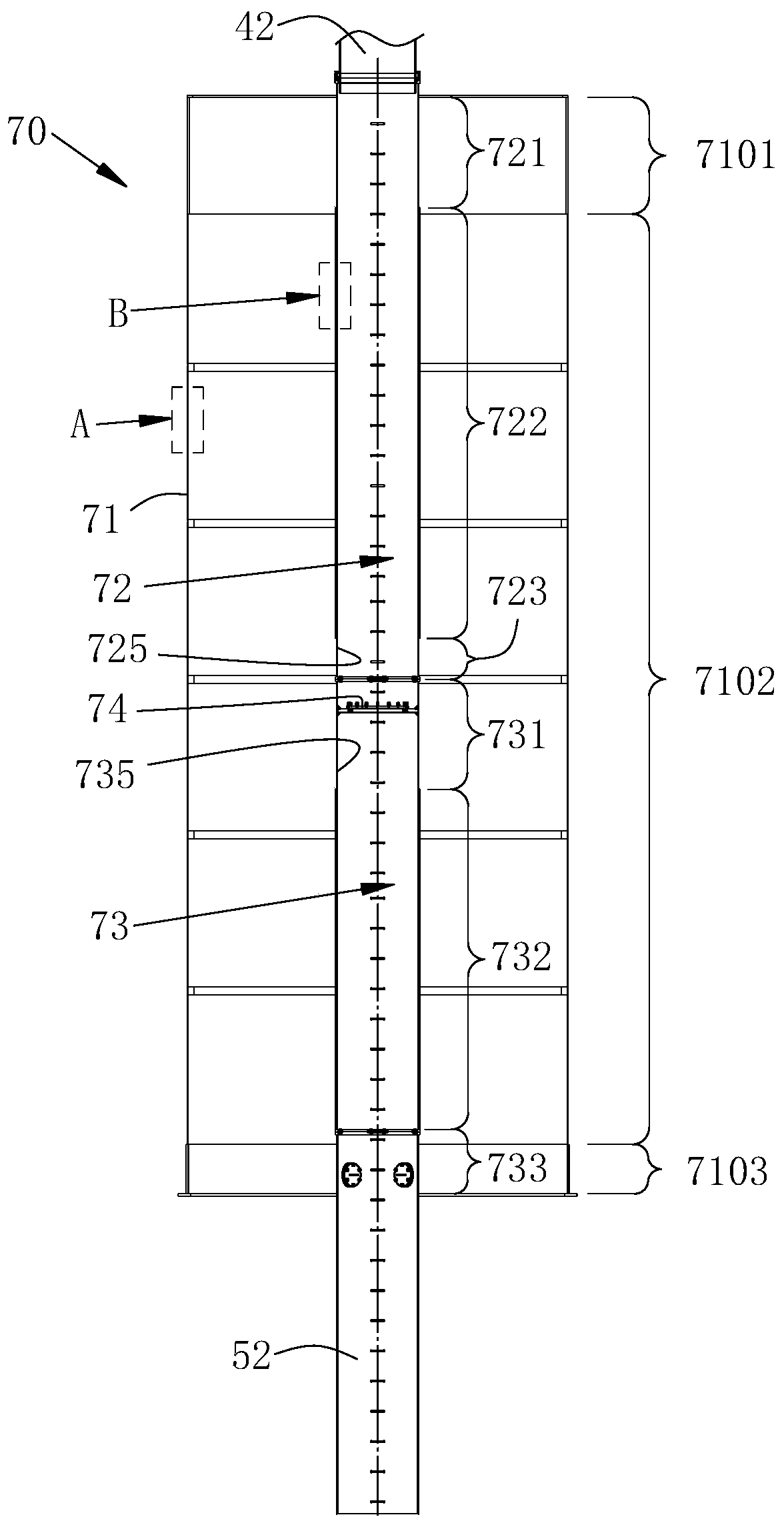

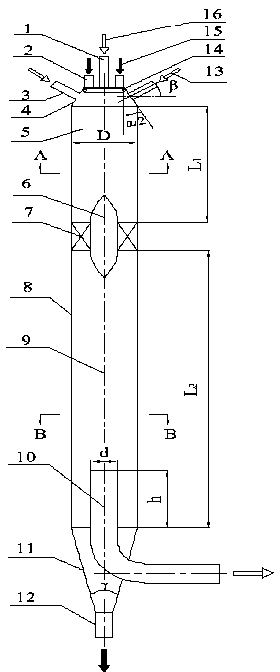

Direct-current type short contact rotational flow reactor

The invention discloses a direct-current type short contact rotational flow reactor, and belongs to contact catalysis reaction equipment when a gas solid phase is in shortage. The direct-current type short contact rotational flow reactor is characterized in that a guiding blade (7) is arranged in a barrel (8), the central position of the guiding blade (7) is provided with a fairing cone (6), and the fairing cone (6) and the barrel (8) are coaxial; the guiding blade (7) and the fairing cone (6) can divide the barrel (8) into an upper mixing region (5) and a lower reaction / separation region (9); the upper end of the mixing region (5) is provided with an inlet cone section (4), multiple catalyst feeding pipes (2) are uniformly arranged on the periphery of the top of the inlet cone section (4), a cone surface of the inlet cone section (4) is provided with multiple fresh raw material introducing devices (3), and an anti-coking steam distributor (14) is arranged below the top of the inlet cone section (4). The direct-current type short contact rotational flow reactor provided by the invention has the advantages that the gas-solid standing time is short, the axial backmixing is little, and a catalyst and a gas product are separated in real time.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Improved reaction and separation synchronous reactor

ActiveCN105195064AEliminate cloggingSimple process operationOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationMicropore FilterSpecific gravity

The invention discloses an improved reaction and separation synchronous reactor. The improved reaction and separation synchronous reactor comprises a bubble gravity reaction tower or stirring reaction tower and a constant-temperature settling tower, and is mainly characterized in that the bubble gravity reaction tower or stirring reaction tower is connected with the constant-temperature settling tower through a flange, a micropore filter plate allowing liquid to pass through is arranged in the constant-temperature settling tower, and a circulating pipeline is arranged at the position, on the lower portion of the micropore filter plate, of the constant-temperature settling tower and connected with the upper portion of a reaction zone of the reaction tower. According to the improved multiphase reactor, overreaction of products in a reaction kettle can be reduced so as to obtain a product with higher purity, blockage of a connecting pipeline between the reaction kettle and the constant-temperature settling tower and the circulating pipeline can be prevented, and a liquid product and a solid product can be effectively separated in time on the premise of completing reaction. The improved multiphase reactor is especially suitable for reactions where the specific gravity of products is larger than that of reactants and the products are insoluble for one another and comprise solids.

Owner:YUANJIANG HUALONG CATALYST TECH

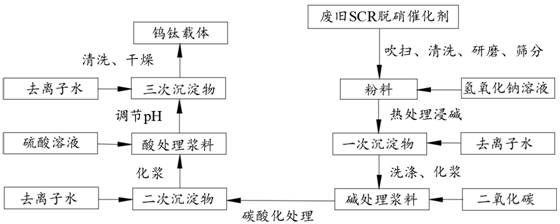

Method for adjusting titanium-tungsten carrier pore passage in waste SCR denitration catalyst and application

ActiveCN112547136AImprove the pore structureMaintain stabilityCatalyst carriersDispersed particle separationAcid treatmentSulfuric acid

The invention discloses a method for adjusting a titanium-tungsten carrier pore passage in a waste SCR denitration catalyst and application, and the method comprises the following steps: placing the waste SCR denitration catalyst in a sodium hydroxide solution for slurrying heat treatment to obtain a primary precipitate; and cleaning the primary precipitate, slurrying to obtain alkali treatment slurry, and carrying out carbonation treatment on the alkali treatment slurry to obtain a secondary precipitate; and slurrying the secondary precipitate to obtain acid treatment slurry, adding a sulfuric acid solution into the acid treatment slurry, and adjusting the pH of the acid treatment slurry to a preset pH value to obtain a tertiary precipitate; and washing the tertiary precipitate with water, and drying to obtain the titanium-tungsten carrier with the adjusted pore structure. By adding alkali into the waste SCR denitration catalyst, performing heat treatment and soaking and then performing secondary acidification treatment, the pore channel structure of the recycled titanium-tungsten carrier can be effectively adjusted, the pore volume of the titanium-tungsten carrier can reach 0.40cm < 3 > / g or above, the pore volume requirement that the titanium-tungsten carrier is applied to preparation of a new SCR denitration catalyst is fully met, and generation of salt-containing wastewater can also be reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

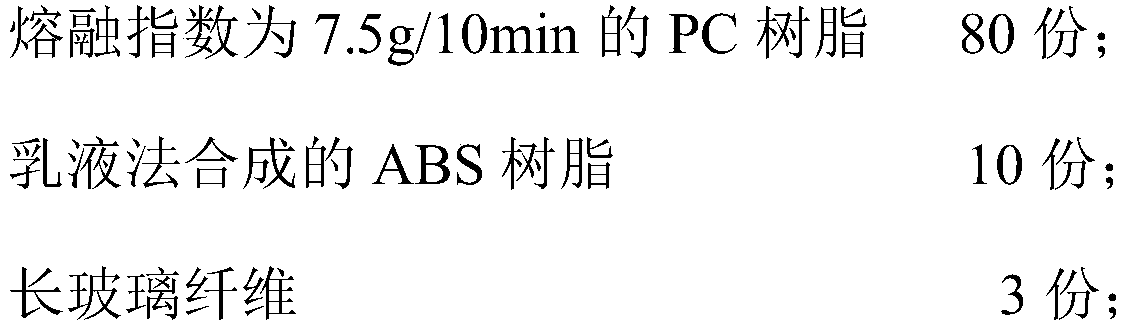

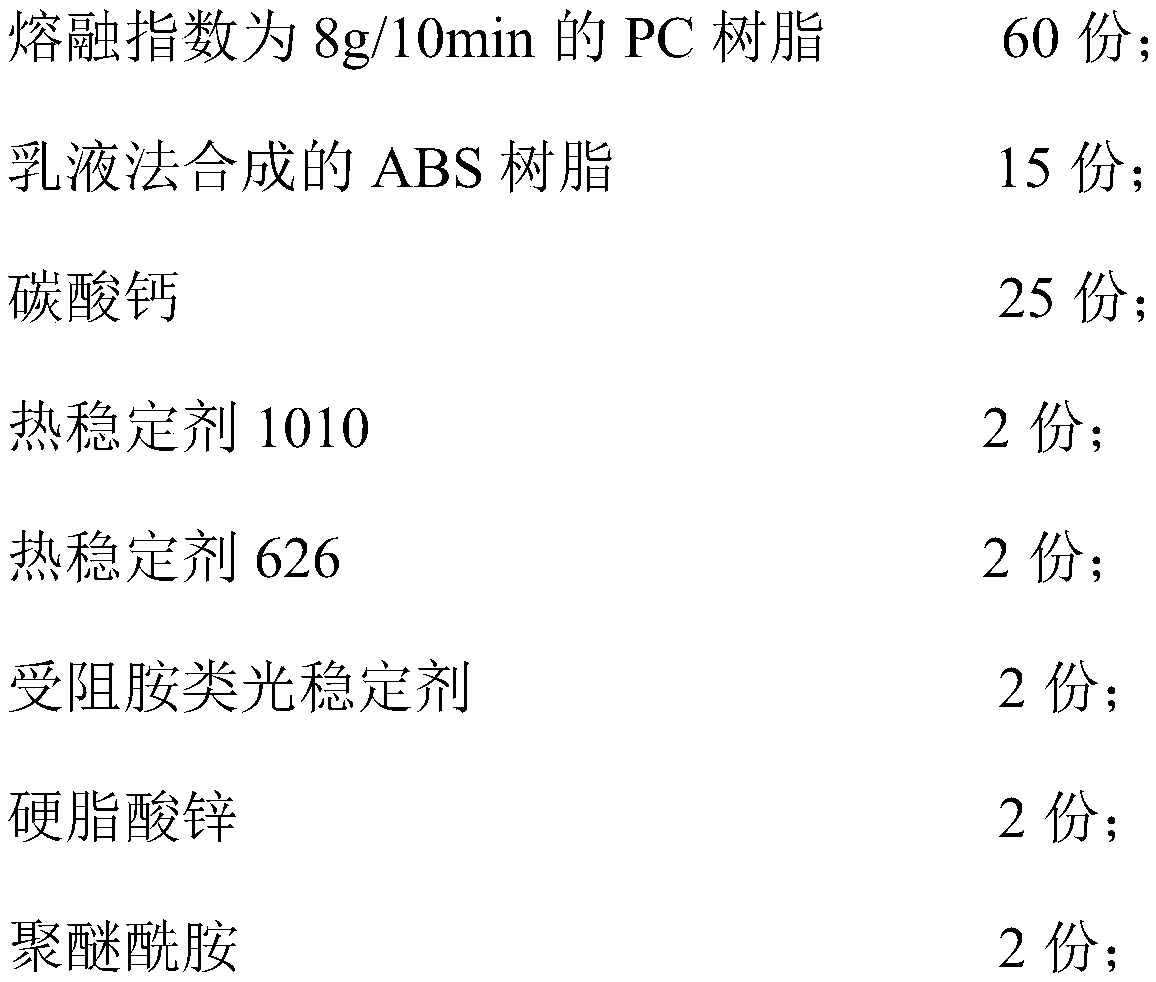

Low-smell PC/ABS alloy and preparation method thereof

The invention provides low-smell PC / ABS alloy and a preparation method thereof. The preparation method comprises the following steps: weighing preparation raw materials, and mixing the preparation rawmaterials to obtain mixture, wherein the preparation raw materials are prepared from the following components in parts by weight: 5-80 parts of polycarbonate resin, 5-80 parts of acrylonitrile-butadiene-styrene resin, 0-40 parts of filler and 0.2-10 parts of additives; and feeding the mixture into an extruding machine, and performing melting, extrusion and granulation under the condition of microwave heating. Microwaves are introduced to preparation of a PC / ABS composite material to ensure that heat penetrates into the interior of the raw materials to avoid unnecessary over-reaction caused bylocal overheating, thereby effectively reducing the decomposition of the raw materials into small molecular compounds with peculiar smell during production, and obviously reducing the smell level ofthe PC / ABS alloy; the process is simple and environment-friendly, and additives for reducing organic small molecules do not need to be added additionally; and the properties of the PC / ABS alloy can not be influenced.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Traditional Chinese medicine composition for relaxing bowels, preparation method and application thereof

PendingCN109939167ASimple ingredientsAvoid overreactionDigestive systemPlant ingredientsSide effectAdditive ingredient

The invention discloses a traditional Chinese medicine composition for relaxing bowels and a preparation method and application thereof. The active ingredients of the traditional Chinese medicine composition are prepared from the extracts of medicinal raw materials, and the medicinal raw materials include aloe and angelica sinensis according to the mass ratio of (2-5) to (1-10). By applying the technical scheme of the invention, the traditional Chinese medicine composition for relaxing bowels is simple in composition, the effective ingredients are extracted from the aloe and fructus aurantii,possibly existing excessive reactions of the complicated ingredients are avoided, the risk of side effects generated after medicine taking is obviously reduced, and the traditional Chinese medicine composition has a good bowel relaxing effect.

Owner:TSING HUA DE REN XIAN HAPPINESS PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com