System and method for continuously preparing furfural from lignocellulose raw material

A technology of lignocellulose and raw materials, which is applied in the field of continuous preparation of furfural by two-step method, can solve the problems of many reaction by-products, inability to react continuously, and low furfural yield, so as to reduce the generation of by-products, avoid side reactions, The effect of high yield of furfural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

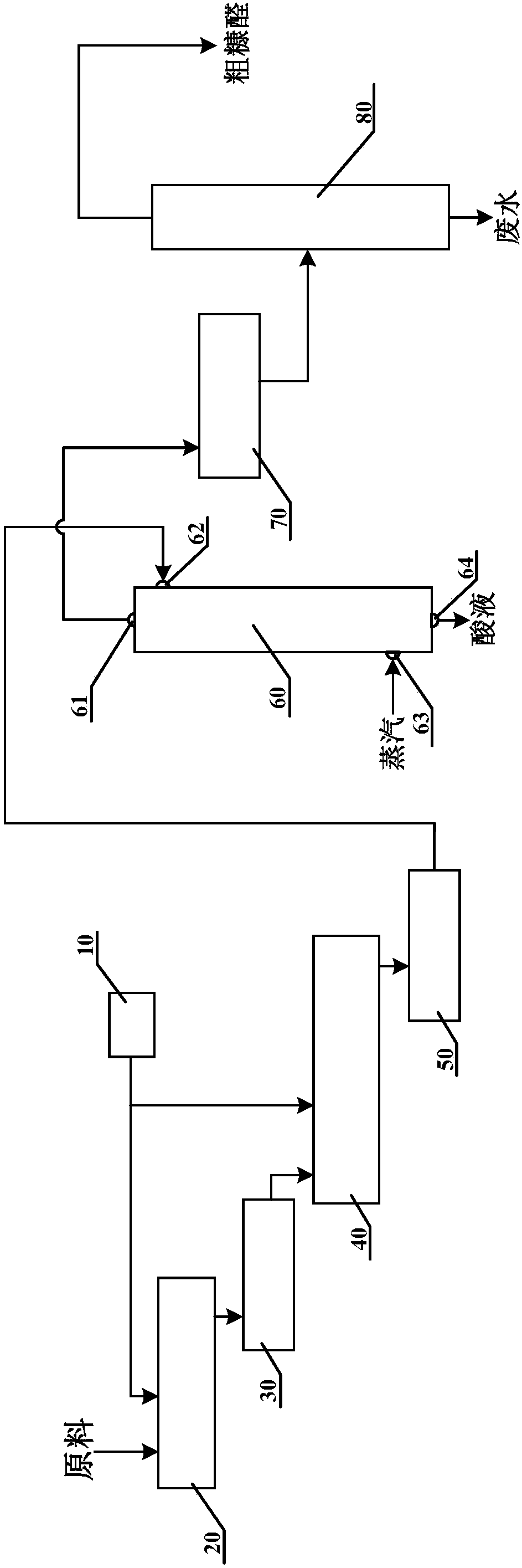

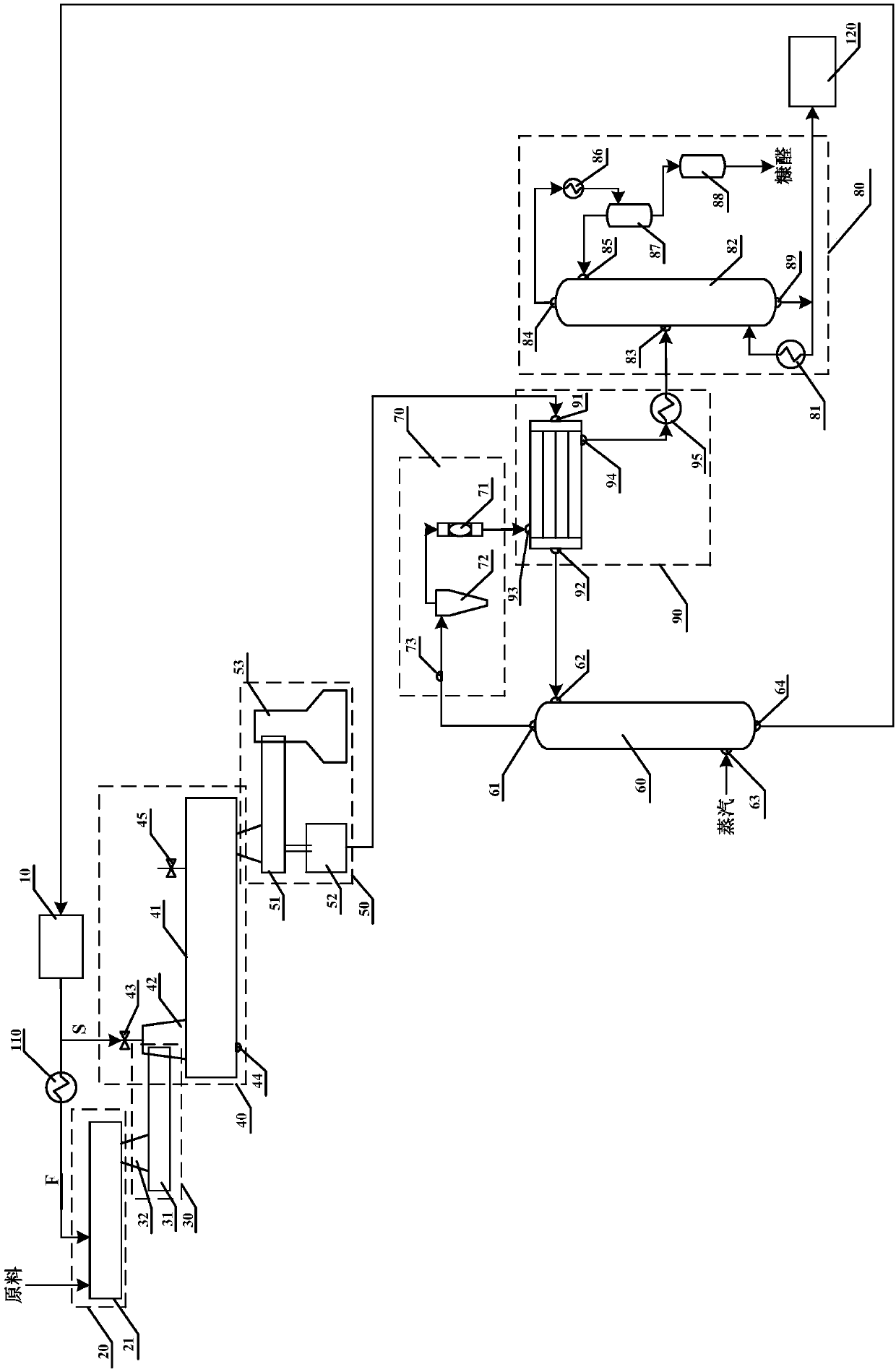

[0097] use as figure 2 The shown system utilizes lignocellulosic raw materials to continuously prepare furfural.

[0098] The lignocellulosic raw material is continuously fed into the raw material mixing unit 20, wherein the raw material mixing unit 20 includes a spiral mixer 21, and the raw material is mixed uniformly with the first acid solution (as shown by arrow F) in a certain proportion in the spiral mixer 21 , to form a mixture and continuously output the mixture, the first acid liquid is a part of the acid liquid at the bottom of the stripping reaction tower 60, and the acid liquid heat exchanger 110 is heat-exchanged to cool down to 60°C.

[0099] The uniformly mixed solid-liquid mixture enters the feed unit 30, which includes a screw feeder 31 and the first tapered feeder 32; the mixture enters the screw feeder 31 continuously through the first tapered feeder 32, and the screw feeder The feeder 31 has a compression function, which includes a compression section and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com