Composite electrode material and method for manufacturing the same, composite electrode containing the said composite electrode material, and li-based battery

一种复合电极、制作方法的技术,应用在电极制造、用于材料和表面科学的纳米技术、二次电池等方向,能够解决锂离子无法嵌入和脱嵌、电池寿命缩短、失去储电容量等问题,达到良好充放电特性及库仑效率、良好充放电特性、提升循环寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The implementation of the present invention is described below through specific specific examples, and the following specific examples should be interpreted as illustrative only, and do not limit the remaining parts disclosed in this specification in any way. Those skilled in the art can learn from this Other advantages and effects of the present invention can be easily understood from the contents disclosed in the specification. The present invention can also be implemented or applied through other different specific embodiments, and various modifications and changes can be made to the details in this specification for different viewpoints and applications without departing from the spirit of this creation.

[0051] Preparation of Composite Electrode Material - Process 1

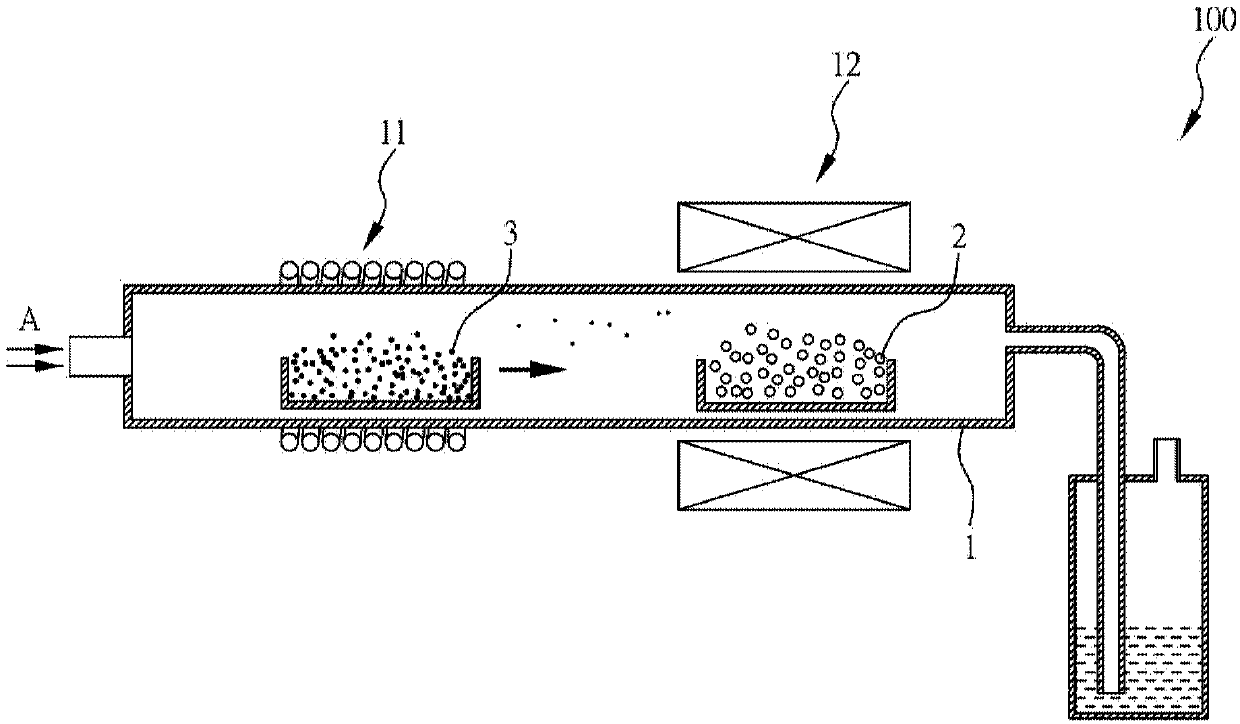

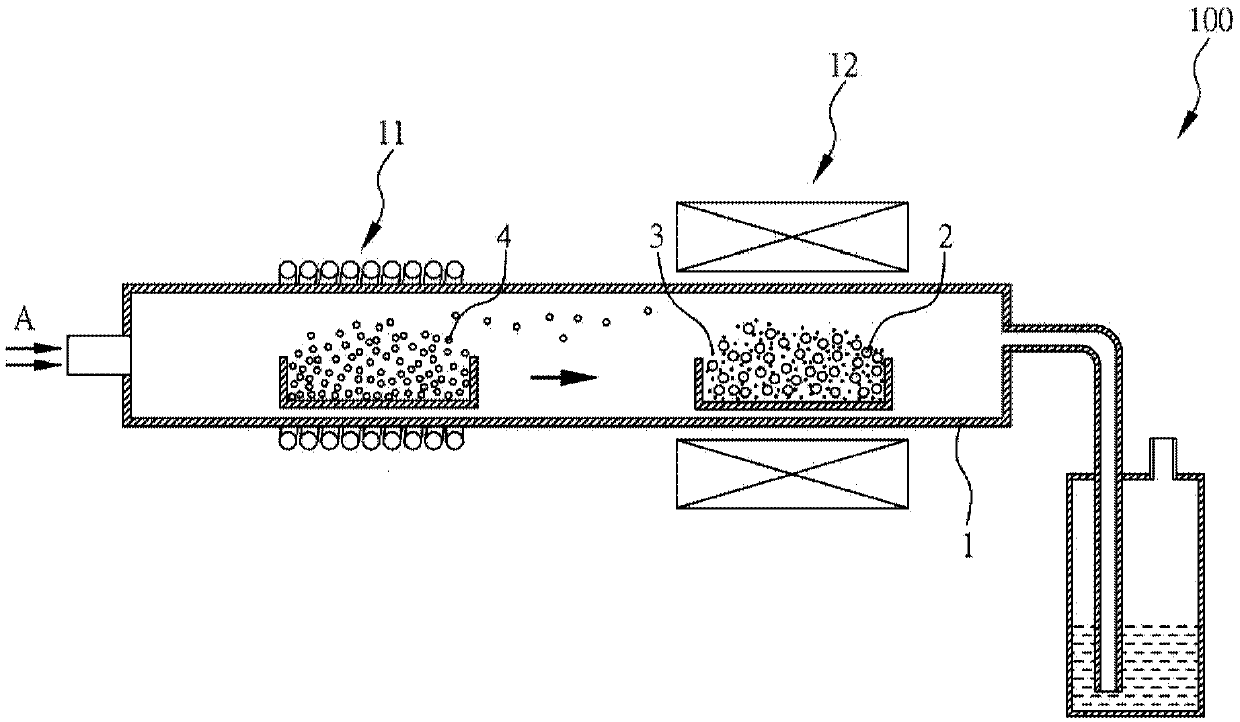

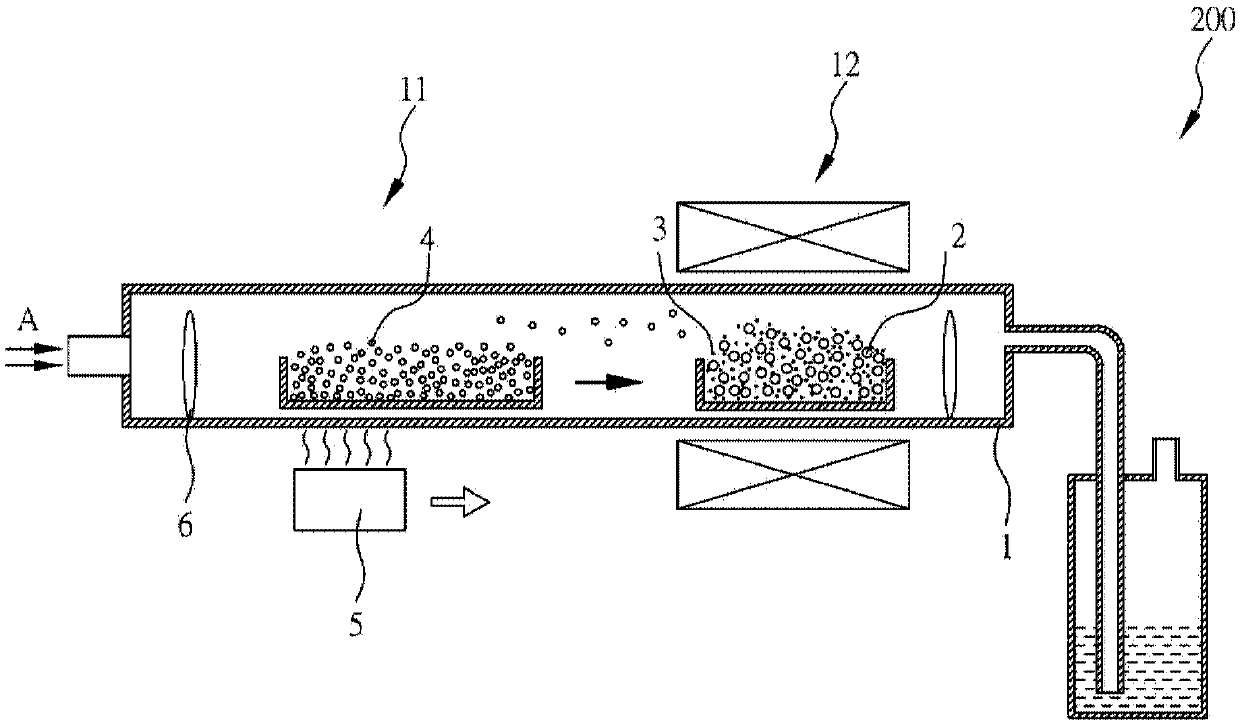

[0052] Figure 1A and 1B It is the schematic diagram of the process of this embodiment. A silicon wafer 2 (0.7g) with an average thickness of 100nm and an average length and width of about 850nm is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com