Low-smell PC/ABS alloy and preparation method thereof

A low-odor, alloy technology, applied in the field of low-odor PC/ABS alloy and its preparation, can solve the problems of harsh processing conditions, increased production cost and production difficulty, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

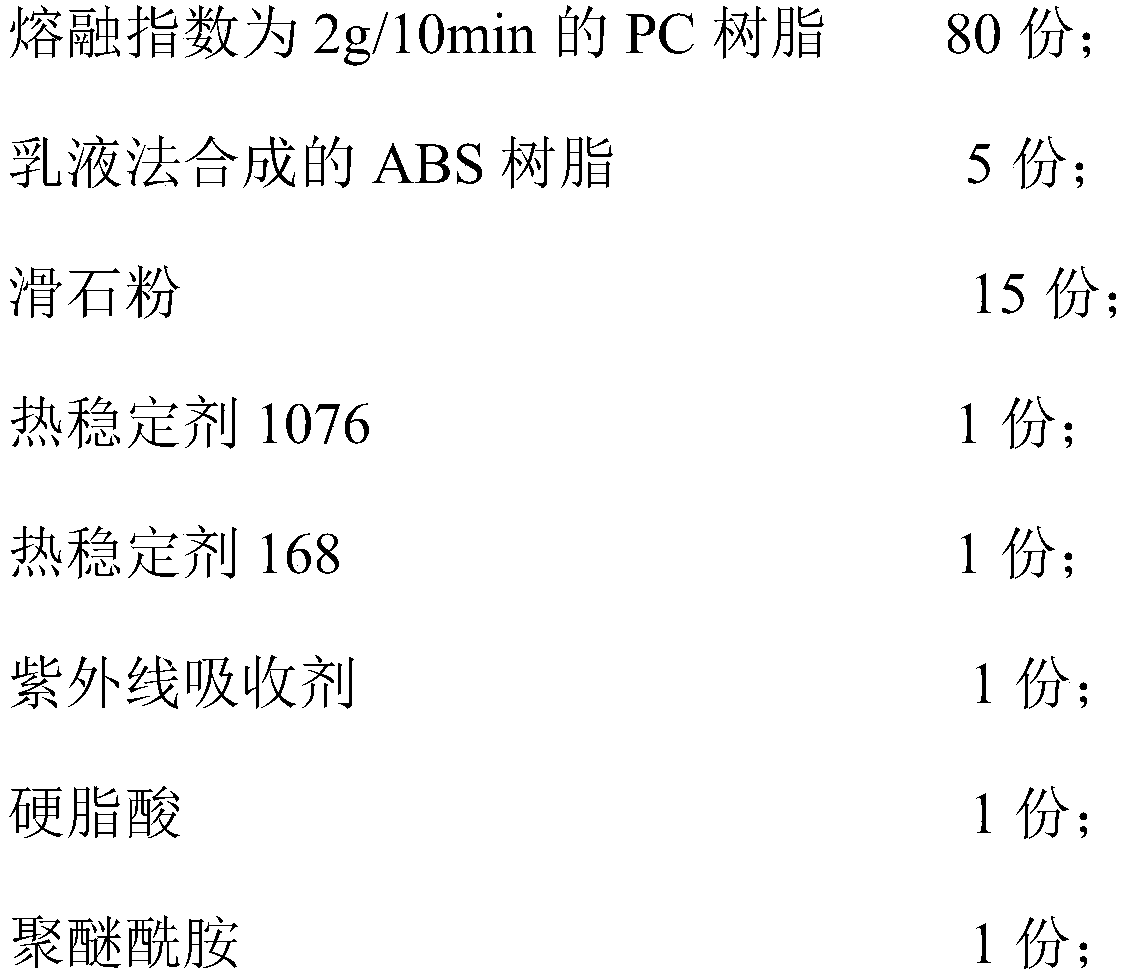

Embodiment 1

[0032] This embodiment provides a low-odor PC / ABS alloy and a preparation method thereof.

[0033] This low-odor PC / ABS alloy comprises following raw material (by weight):

[0034]

[0035] The preparation method of above-mentioned low odor PC / ABS alloy, step is as follows:

[0036] (1) mix PC resin, ABS resin, filler and auxiliary agent of described weight portion, obtain compound;

[0037] (2) Place the compound described in step (1) in the feeding port of a single-screw extruder with microwave as the heat source, set the microwave heating temperature to be 150°C, the microwave power to be 28kW, and the microwave frequency to be 250GHz;

[0038] (3) Cool the molten mixture extruded in step (2) to below the melting point, and cut it into pellets of uniform size through a pelletizer; obtain a low-odor PC / ABS alloy.

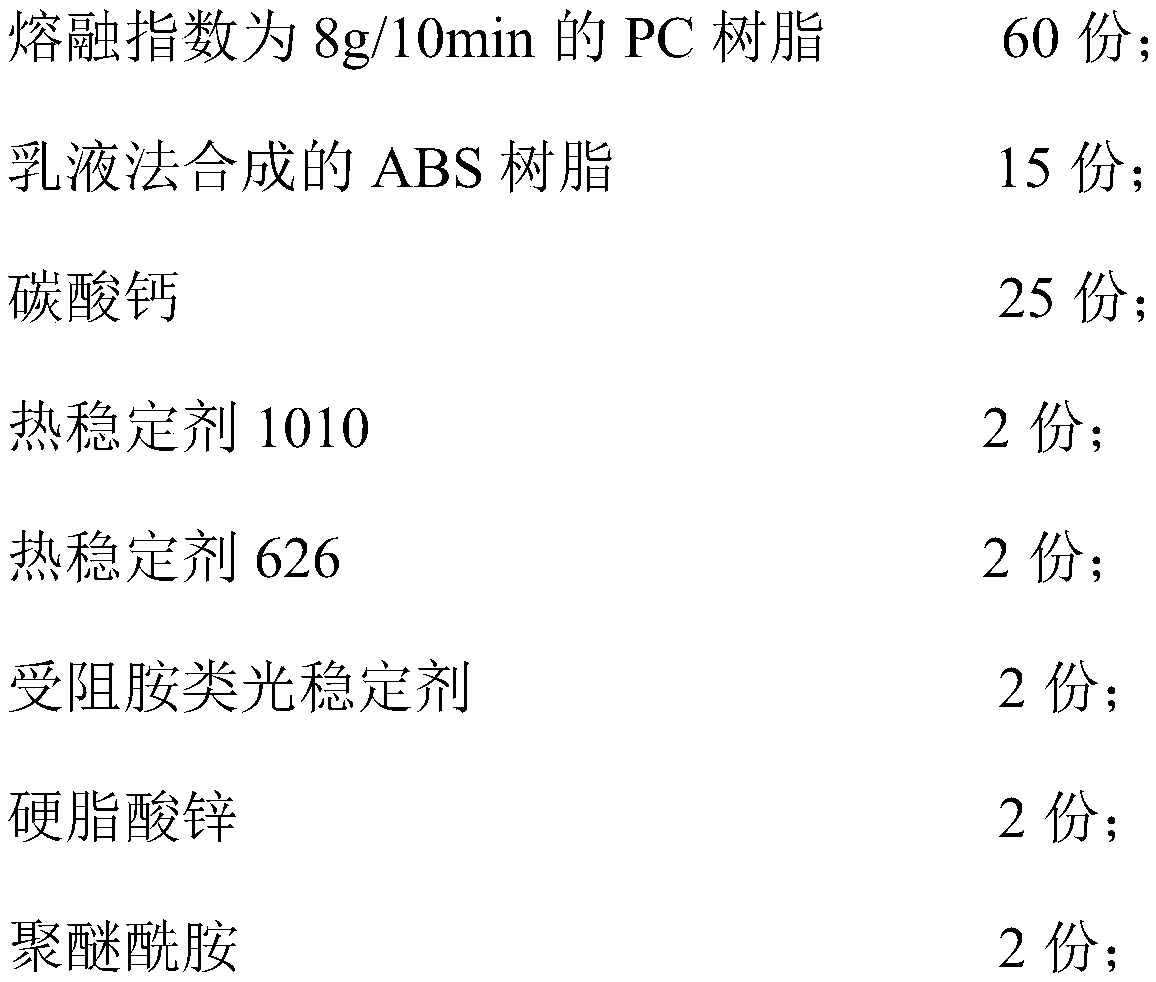

Embodiment 2

[0040] This embodiment provides a low-odor PC / ABS alloy and a preparation method thereof.

[0041] This low-odor PC / ABS alloy comprises following raw material (by weight):

[0042]

[0043] The preparation method of above-mentioned low odor PC / ABS alloy, step is as follows:

[0044] (1) mix PC resin, ABS resin, filler and auxiliary agent of described weight portion, obtain compound;

[0045](2) Place the compound described in step (1) in the feeding port of the twin-screw extruder with microwave as the heat source, set the microwave heating temperature to be 180°C, the microwave power to be 20kW, and the microwave frequency to be 100GHz;

[0046] (3) Cool the molten mixture extruded in step (2) to below the melting point, and cut it into pellets of uniform size through a pelletizer; obtain a low-odor PC / ABS alloy.

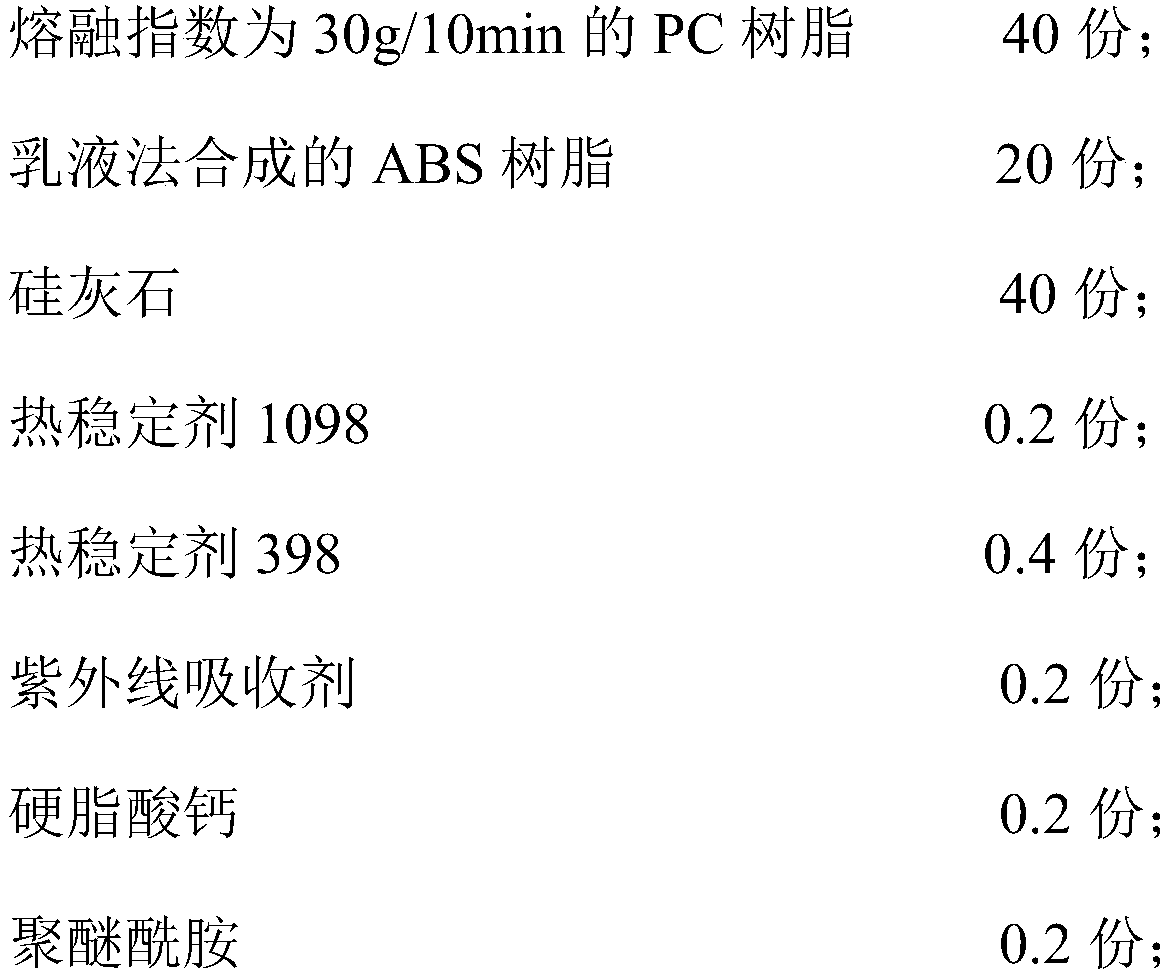

Embodiment 3

[0048] This embodiment provides a low-odor PC / ABS alloy and a preparation method thereof.

[0049] This low-odor PC / ABS alloy comprises following raw material (by weight):

[0050]

[0051] The preparation method of above-mentioned low odor PC / ABS alloy, step is as follows:

[0052] (1) mix PC resin, ABS resin, filler and auxiliary agent of described weight portion, obtain compound;

[0053] (2) Place the compound described in step (1) in the feed port of a single-screw extruder with microwave as the heat source, set the microwave heating temperature to 200°C, the microwave power to 5kW, and the microwave frequency to 30GHz;

[0054] (3) Cool the molten mixture extruded in step (2) to below the melting point, and cut it into pellets of uniform size through a pelletizer; obtain a low-odor PC / ABS alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com