Low smell glass fiber-reinforced polycarbonate/acrylonitrile-butadiene styrene (PC/ABS) alloy and preparation method thereof

A low-odor, glass fiber technology, applied in the field of low-odor glass fiber reinforced PC/ABS alloy and its preparation, can solve the problems of poor compatibility, harsh processing conditions, increased production cost and production difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

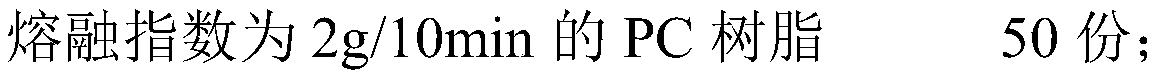

[0033] This embodiment provides a low-odor glass fiber reinforced PC / ABS alloy and a preparation method thereof.

[0034] This low-odor glass fiber reinforced PC / ABS alloy comprises the following raw materials (by weight):

[0035]

[0036]

[0037] The preparation method of above-mentioned low odor glass fiber reinforced PC / ABS alloy, the steps are as follows:

[0038] (1) mixing PC resin, ABS resin, compatibilizer, filler and auxiliary agent of described weight portion, obtain compound;

[0039] (2) the compound described in step (1) is placed in the main feeding port of the single-screw extruder that microwave is the heat source, long glass fiber is placed in the measuring feeding port of the extruder, and the microwave heating temperature is set to be 150 ℃, the microwave power is 28kW, and the microwave frequency is 250GHz;

[0040](3) Cool the molten mixture extruded in step (2) to below the melting point, and cut it into pellets of uniform size through a pelleti...

Embodiment 2

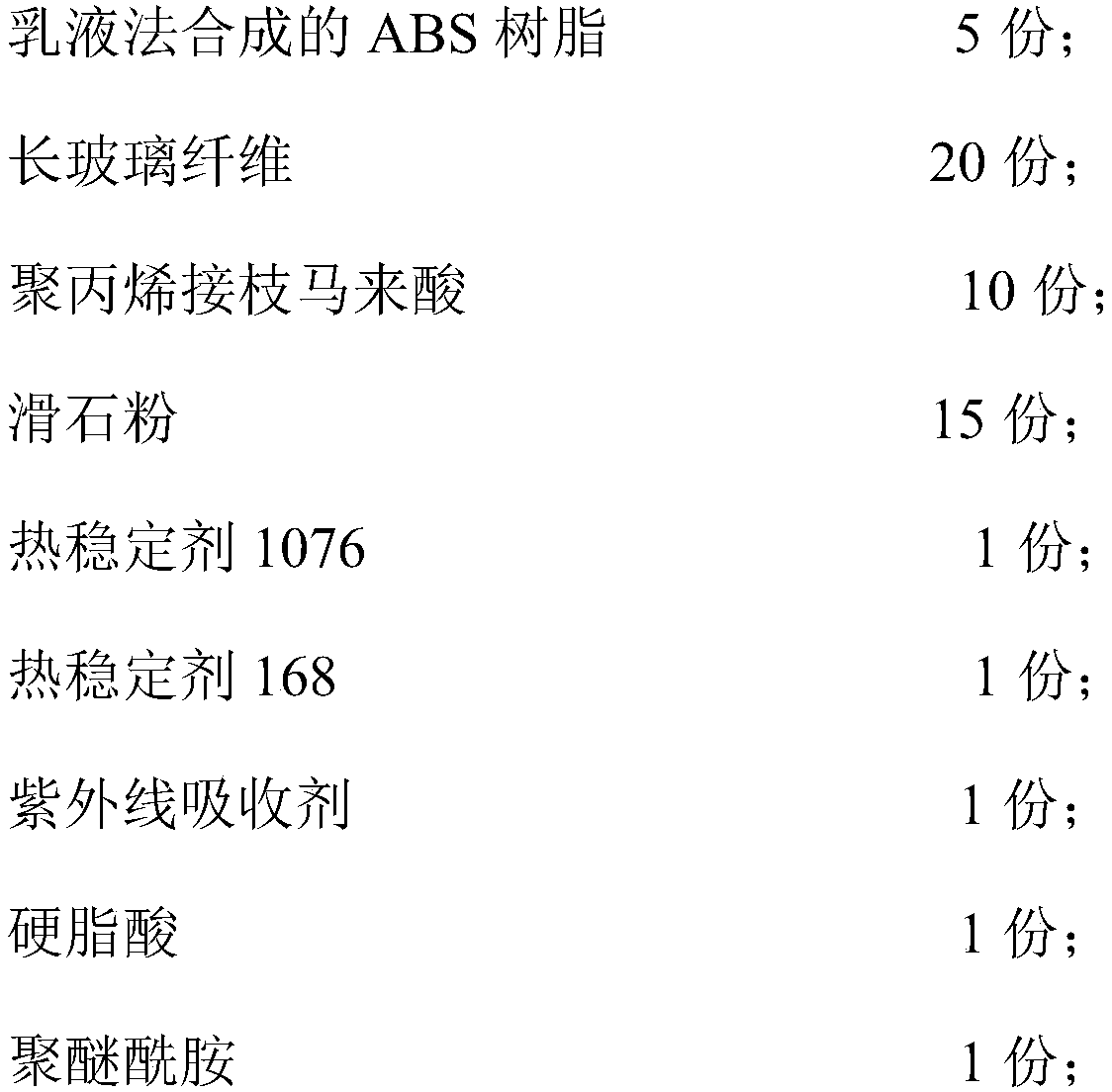

[0042] This embodiment provides a low-odor glass fiber reinforced PC / ABS alloy and a preparation method thereof.

[0043] This low-odor glass fiber reinforced PC / ABS alloy comprises the following raw materials (by weight):

[0044]

[0045]

[0046] The preparation method of above-mentioned low odor glass fiber reinforced PC / ABS alloy, the steps are as follows:

[0047] (1) mixing PC resin, ABS resin, compatibilizer, filler and auxiliary agent of described weight portion, obtain compound;

[0048] (2) the compound described in step (1) is placed in microwave as the main feed port of the twin-screw extruder of the heat source, long glass fiber is placed in the test feed port of the extruder, and the microwave heating temperature is set to be 180 ℃, the microwave power is 20kW, and the microwave frequency is 100GHz;

[0049] (3) Cool the molten mixture extruded in step (2) to below the melting point, and cut it into pellets of uniform size through a pelletizer; obtain a ...

Embodiment 3

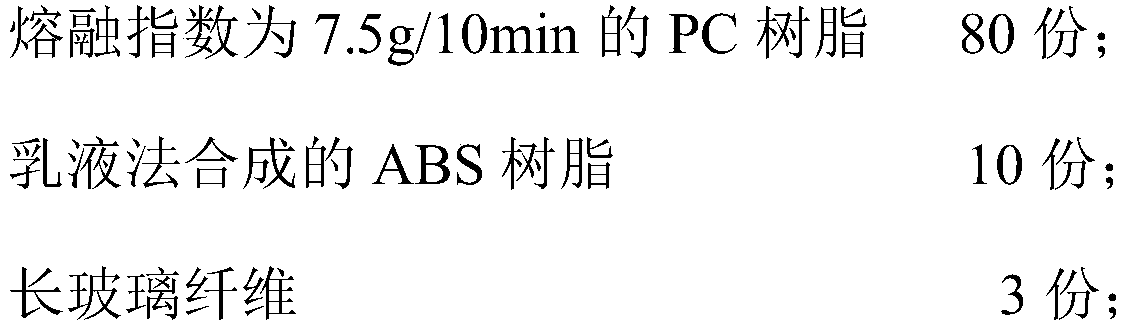

[0051] This embodiment provides a low-odor glass fiber reinforced PC / ABS alloy and a preparation method thereof.

[0052] This low-odor glass fiber reinforced PC / ABS alloy comprises the following raw materials (by weight):

[0053]

[0054]

[0055] The preparation method of above-mentioned low odor glass fiber reinforced PC / ABS alloy, the steps are as follows:

[0056] (1) mixing PC resin, ABS resin, compatibilizer, filler and auxiliary agent of described weight portion, obtain compound;

[0057] (2) the compound described in step (1) is placed in microwave as the main feed port of the single-screw extruder of the heat source, long glass fiber is placed in the test feed port of the extruder, and the microwave heating temperature is set to be 200 ℃, the microwave power is 5kW, and the microwave frequency is 30GHz;

[0058] (3) Cool the molten mixture extruded in step (2) to below the melting point, and cut it into pellets of uniform size through a pelletizer; obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com