Polyolefin composite material and preparation method thereof

A composite material and polyolefin technology, applied in the field of polyolefin composite materials, can solve problems such as unacceptable, odor overflow, and long-term performance attenuation of materials, and achieve the effects of optimizing, reducing, and promoting elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

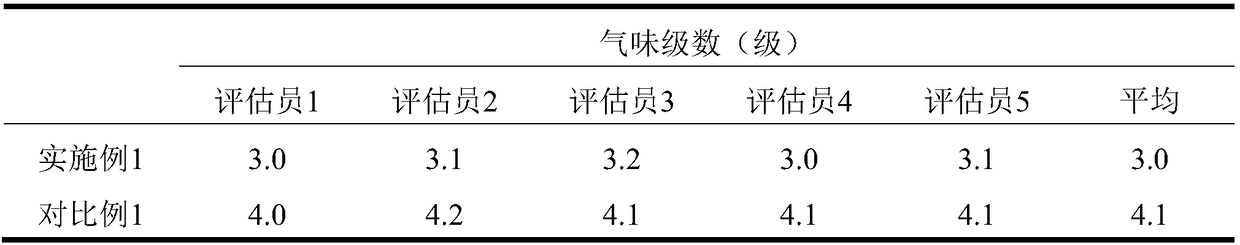

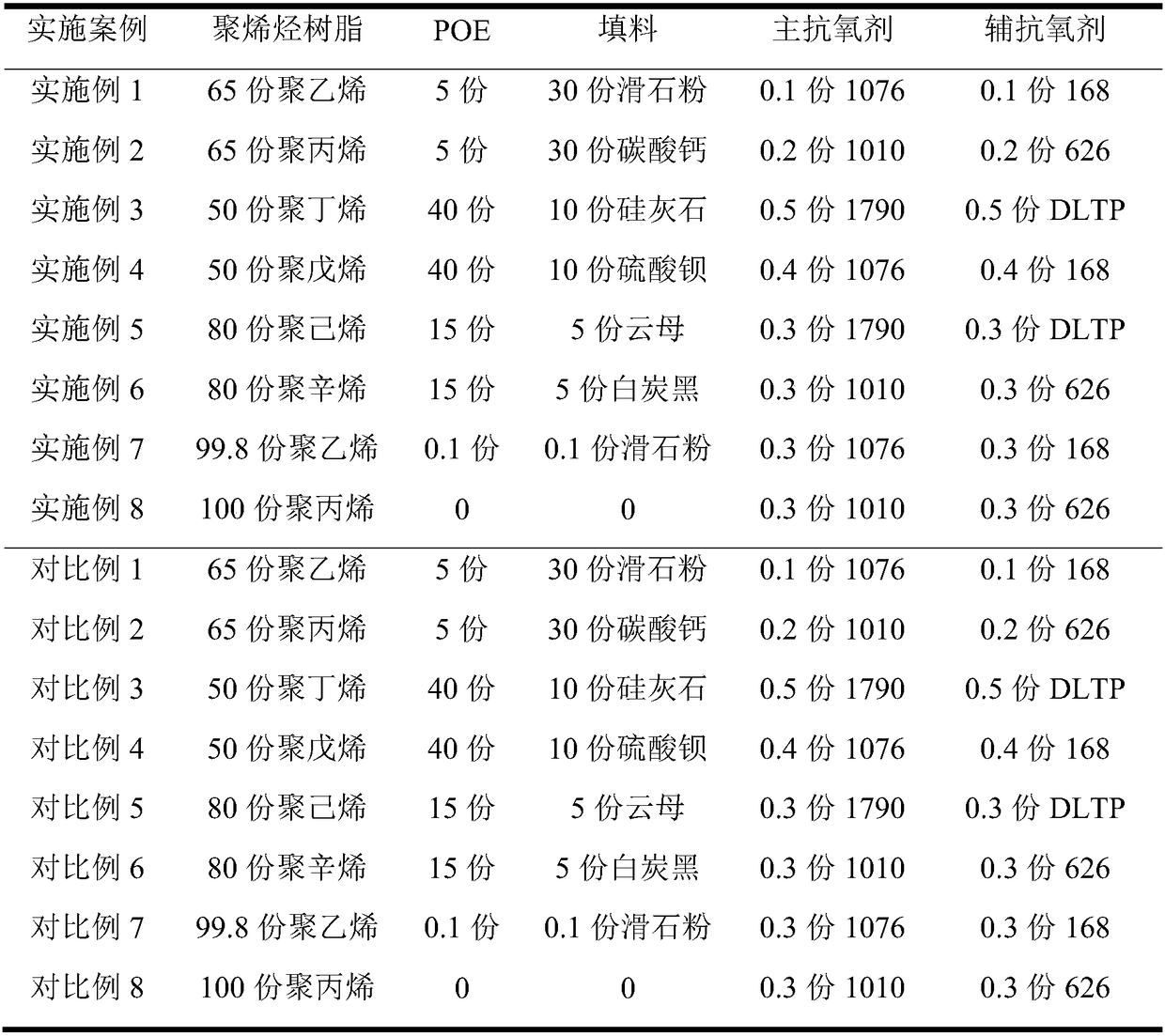

Embodiment 1

[0034] The preparation method of a kind of polyolefin composite material of present embodiment, the steps are as follows:

[0035] (1) Take 130g polyethylene, 10g POE, 60g talcum powder, 0.2g primary antioxidant 1076 and 0.2g secondary antioxidant 168, and blend these compounds uniformly to obtain a mixture;

[0036] (2) Add the mixture into a microwave reaction tank, set the microwave reaction power to 1000W, microwave frequency to 250000MHz, and microwave to heat to 200°C for 200s; after the reaction, cool to obtain a polyethylene composite material.

Embodiment 2

[0053] The preparation method of a kind of polyolefin composite material of present embodiment, the steps are as follows:

[0054] (1) Get 130g polypropylene, 10gPOE, 60g calcium carbonate, 0.4g primary antioxidant 1010 and 0.4g secondary antioxidant 626, and blend these compounds uniformly to obtain a mixture;

[0055] (2) Add the mixture into a microwave reaction tank, set the microwave reaction power to 3000W, microwave frequency to 50000MHz, and microwave heating to 250°C for 400s; after the reaction, cool to obtain a polypropylene composite material.

[0056] After the odor evaluation of the above polypropylene composite material, the odor grade is 2.6.

Embodiment 3

[0063] The preparation method of a kind of polyolefin composite material of present embodiment, the steps are as follows:

[0064] (1) Get 100g polybutene, 80gPOE, 20g wollastonite, 1.0g primary antioxidant 1790 and 1.0g secondary antioxidant DLTP, and blend these compounds uniformly to obtain a mixture;

[0065] (2) Add the mixture into a microwave reaction tank, set the microwave reaction power to 6000W, microwave frequency to 800MHz, and microwave heating to 230°C for 80s; after the reaction, cool to obtain a polybutene composite material.

[0066] After carrying out the odor evaluation to the above polybutene composite material, the odor rating is 2.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com