Improved reaction and separation synchronous reactor

A technology of reaction separation synchronization and reactor, which is applied in the field of reactors, can solve the problems affecting the continuous progress of the reaction separation process, blockage of the external circulation system of the equipment, blockage of the three-way switch of the connecting pipe, etc., to eliminate blockage, reduce blockage, prevent The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

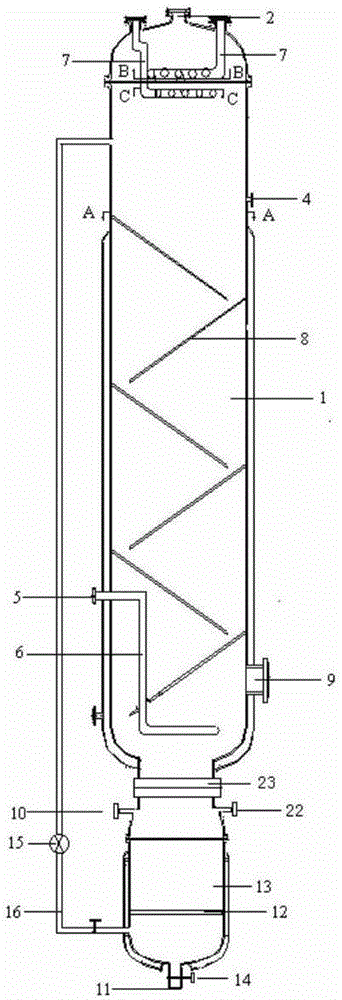

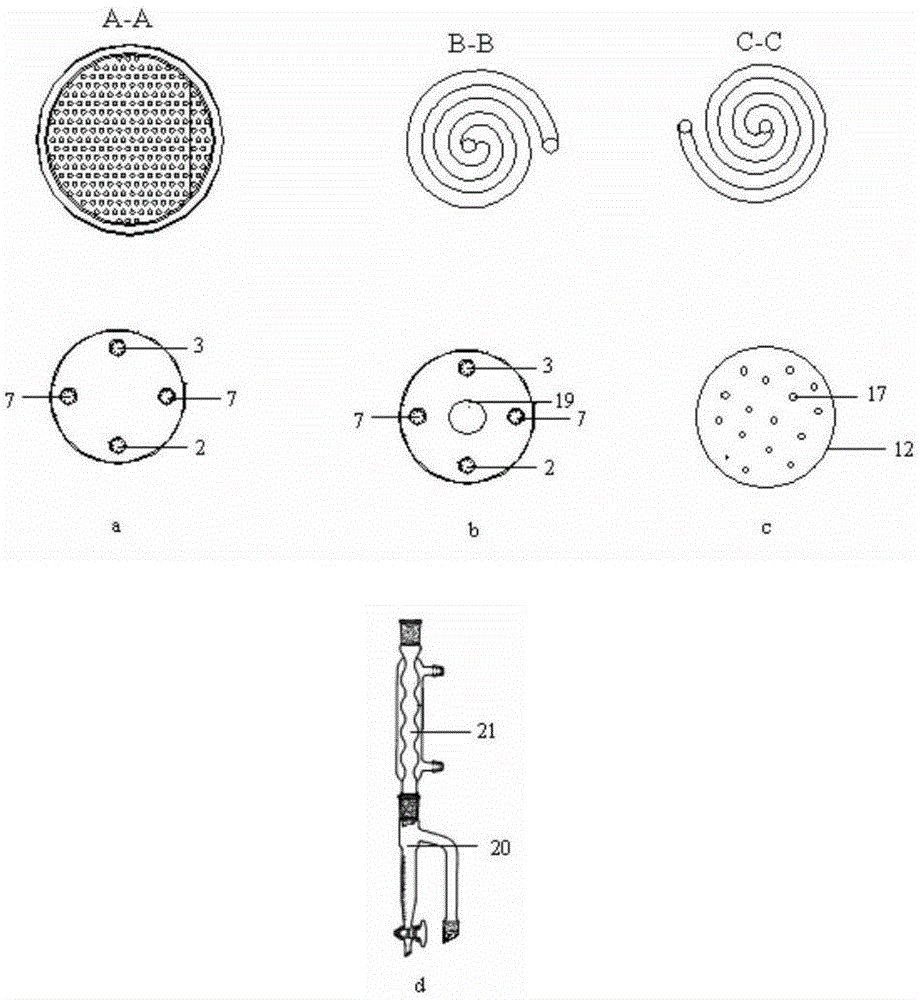

[0035] figure 1 A synchronous reactor is separated for a reaction consisting of a bubbling gravity reaction tower and a constant temperature settling tower. The reaction separation synchronous reactor includes a bubbling gravity reaction tower and a constant temperature settling tower connected to the bottom of the bubbling gravity reaction tower. The bubbling gravity reaction tower and the constant temperature settling tower are connected by flanges, and the bubbling gravity reaction tower and the constant temperature settling tower are detachable. The bubbling gravity reaction tower includes an upper gas phase zone, a middle and lower reaction zone and a reaction gas outlet at the top; the boundary between the reaction zone and the gas phase zone is at the 1 / 3 wall height of the bubbling gravity reaction tower from the top of the tower. The diameter-to-height ratio of the bubbling gravity reaction tower is 1:30. The top of the bubbling gravity reaction tower is equipped wi...

Embodiment 2

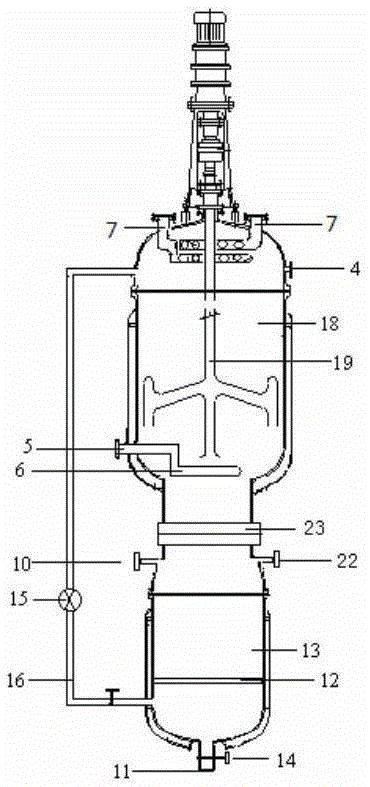

[0038] figure 2 A synchronous reactor is separated for a reaction consisting of a stirring reaction tower and a constant temperature settling tower. The reaction separation synchronous reactor includes a stirred reaction tower and a constant temperature settling tower connected to the bottom of the stirred reaction tower. The stirring reaction tower and the constant temperature settling tower are connected by flanges, and the bubbling gravity reaction tower and the constant temperature settling tower are detachable. The stirred reaction tower includes an upper gas phase zone, a middle and lower reaction zone and a reaction gas outlet at the top; the boundary between the reaction zone and the gas phase zone is at the 2 / 5 height of the tower wall from the stirred reaction tower to the top of the tower. The diameter-to-height ratio of the stirred reaction tower is 1:35. The top of the stirred reaction tower is equipped with a reaction gas outlet and a condensed liquid inlet; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com