Direct-current type short contact rotational flow reactor

A reactor and reaction technology, applied in the petroleum industry, cracking, catalytic cracking, etc., can solve the problems of large axial back-mixing, high gasoline olefin content, coking, etc., to suppress secondary reactions and coking, and reduce contact time , the effect of improving the contact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

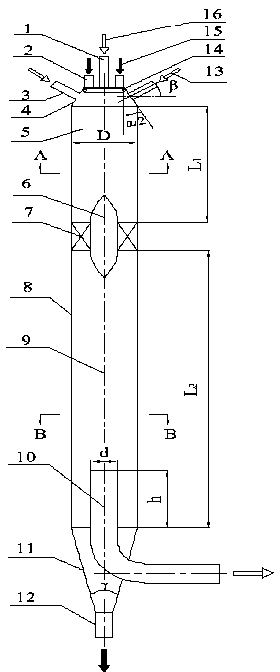

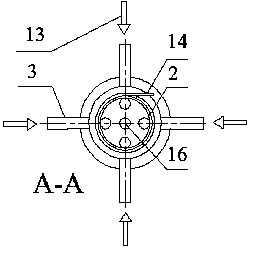

[0032] Refer to attached figure 1 , 2 , 4: The straight-through short-contact swirl reactor includes an inlet cone section 4, a rectifying cone 6, a guide vane 7, a cylinder body 8, an exhaust pipe 10, and a dust guide cone 11. The cone angle of the inlet cone section 4 is α=30~120°. Multiple catalyst feed pipes 2 are installed on the top of the inlet cone section 4, and the same number of fresh raw material introduction devices 3 are installed on the conical side of the inlet cone section 4. The number of fresh raw material introduction devices 3 and catalyst feed pipes 2 are both 4, and the arrangement method is evenly arranged on the circumference, that is, they are evenly arranged in the same direction of rotation in the same section. The fresh raw material introduction device 3 and the inlet cone section 4 The connection method is the direct plug-in type, and the angle between the axis and the horizontal direction is β=0~60°.

[0033] At the center of the top of the inl...

Embodiment 2

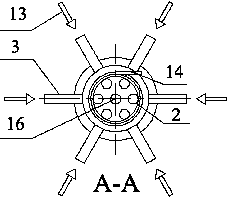

[0042] Refer to attached image 3 : the number of the fresh raw material introduction device 3 and the catalyst feed pipe 2 of this straight-through short-contact cyclone reactor is 6, and its arrangement mode also takes the circumferential uniform arrangement, and all the other settings are also the same as in embodiment 1.

[0043] The working principle is as follows: when working, the upper end of the fresh raw material introduction device 3 is connected to the feed nozzle, and the catalyst 15 is ejected from the feed nozzle so that the catalyst 15 enters the mixing zone 5 from the catalyst feed pipe 2, and enters the mixing zone from the fresh raw material introduction device 3 The fresh raw material 13 of 5 is in cross-flow contact. Due to the momentum exchange and the effect of the gas-solid gravity field, the catalyst and oil and gas start to move downward. This can achieve three purposes. One is to make the fresh raw material atomized steam and catalyst in the mixing zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com