Centrifugal centripetal flow beam tube type water bed reactor

A bundle tube and reactor technology, applied in the direction of chemical methods, chemical instruments and methods, chemical/physical processes, etc. that make gas medium react with gas medium, can solve the problems of increased power consumption, short residence time, and low reaction efficiency and other problems, to achieve the effect of reducing power consumption, reducing the number of cycles, and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

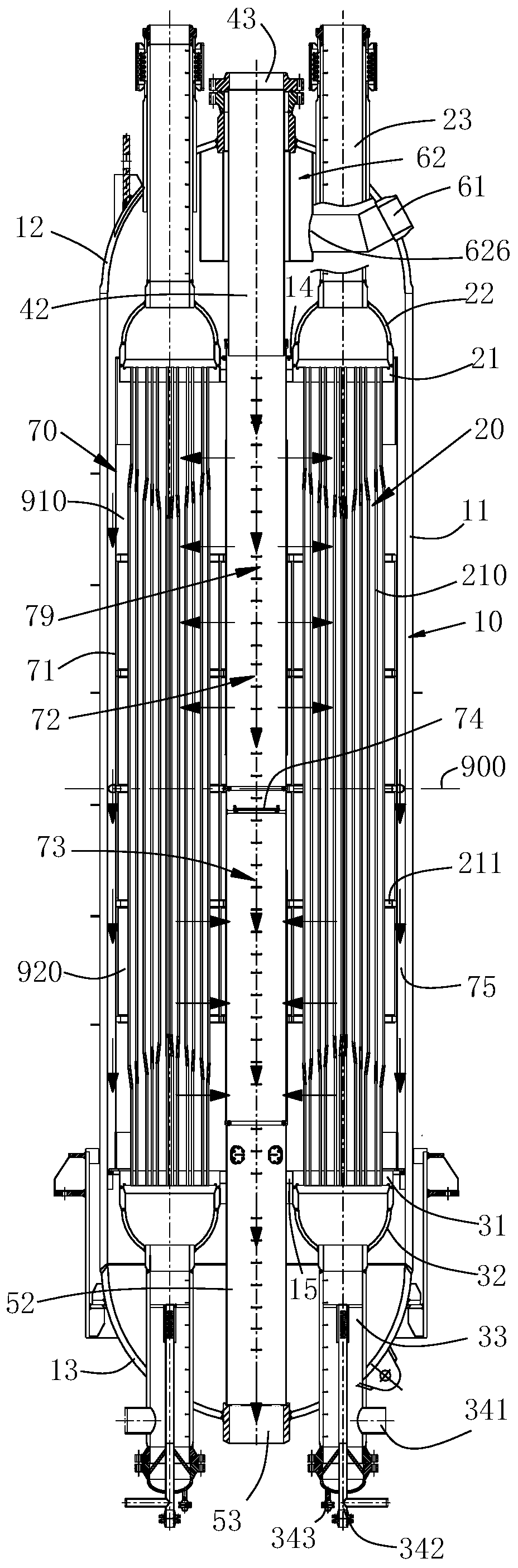

[0041] see figure 1 , a centrifugal centripetal flow beam tubular water bed reactor, which includes a shell 10, the shell 10 includes a cylindrical shell 11, an upper head 12 installed on the upper end of the shell 11 and an upper head 12 installed on the shell The lower head 13 of the lower end of 11. Inside the housing a radial distributor 70 is arranged.

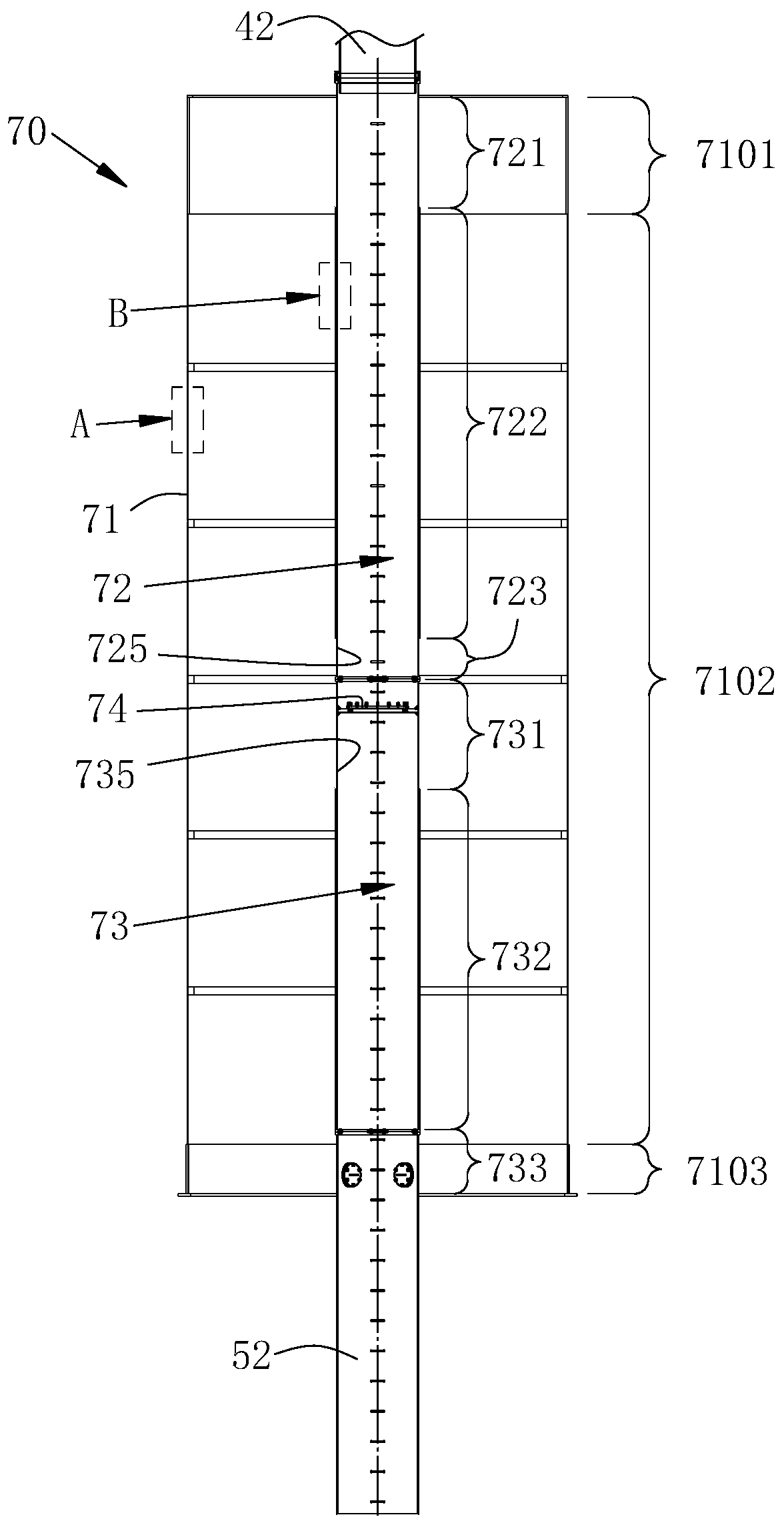

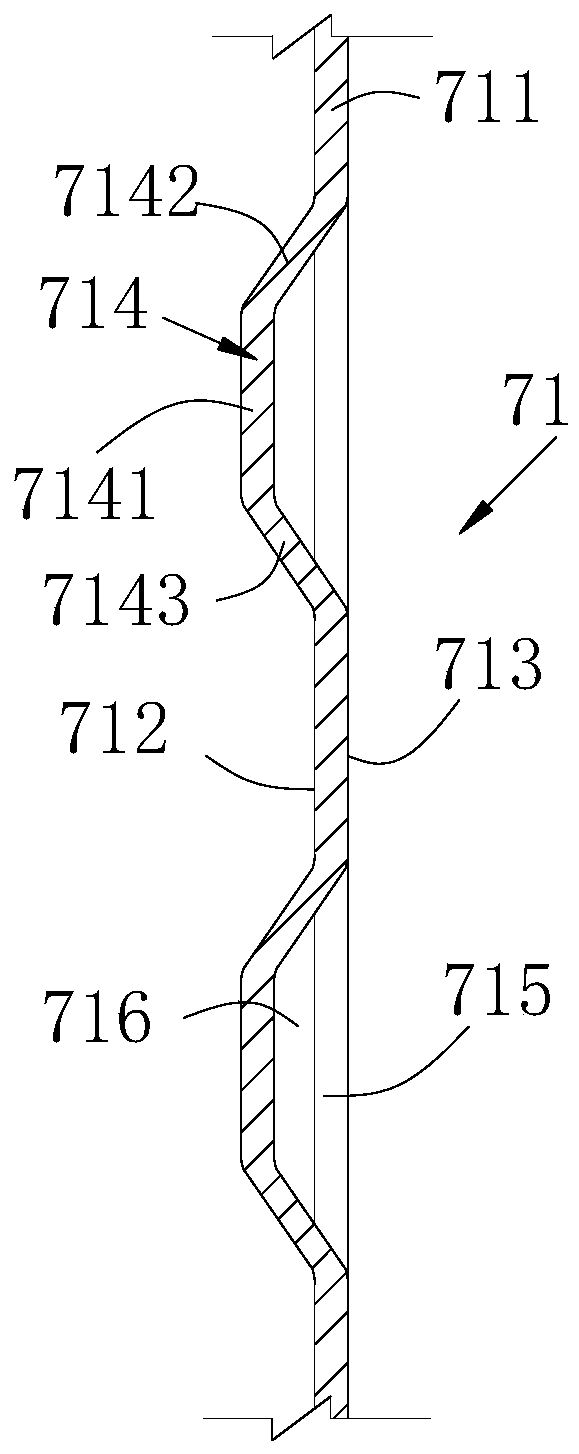

[0042] Please also see figure 2 The radial distributor 70 includes an inner radial basket 79 and an outer radial basket 71 sleeved on the outside of the inner radial basket. There is an annular gap 75 between the outer radial frame 71 and the cylinder 11, and the catalyst cover plate 14 is installed on the top of the inner radial basket 79 and the outer radial basket 71, and the catalyst support plate 15 is installed on the bottom of the inner radial basket 79 and the outer radial basket 71; the inner radial basket, outer radial basket, catalyst cover plate and catalyst The space between the support plates is formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com