Salt-tolerant polymer microsphere blocking agent and preparation method thereof

A technology of polymer and plugging agent, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., and can solve problems such as high cost, poor stability, and reduced oil phase relative permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] like Figure 9 Shown, a kind of preparation method of salt-tolerant polymer microsphere plugging agent comprises the following steps:

[0042] 1) taking raw materials by weight for subsequent use;

[0043] 2) At room temperature, add white oil, fumed silica, sorbitan fatty acid ester, and hydrophilic surfactant to a container equipped with a stirrer, a thermometer, and a reflux condensing device, and stir evenly. 200~300r / min to make solution A;

[0044] 3) Add the weighed acrylamide monomer, acrylic acid, and N,N-methylenebisacrylamide into water, stir to dissolve them completely, then add sodium hydroxide aqueous solution for neutralization, and the neutralization degree is 50-80%. Then add sodium bisulfite, stir to make it dissolve completely, and make solution B; the mass ratio of solution A to solution B is (1~4):1;

[0045] 4) Add solution B into solution A, emulsify at a stirring speed of 500-600r / min for 20-30min, then raise the temperature to 60-70°C, turn o...

Embodiment 1

[0051] Raw material weight ratio: white oil 40wt%, fumed silica 0.5wt%, acrylamide monomer 20wt%, acrylic acid 5wt%, Span-60 5wt%, N,N-methylenebisacrylamide is 0.03wt%, ammonium persulfate is 0.01wt%, sodium bisulfite is 0.015wt%, Tween-80 is 10wt%, and distilled water is the balance. Put white oil, fumed silica, Span-60, and Tween-80 into a reactor equipped with a stirrer, a reflux condenser, and a thermometer, and stir at a speed of 200r / min to make solution A; Add water to dissolve the amide, then add acrylic acid and N,N-methylenebisacrylamide, stir evenly on a magnetic stirrer, add sodium hydroxide aqueous solution to neutralize after completely dissolving, the neutralization degree is 50%, add sulfurous acid Sodium hydrogen is completely dissolved to prepare solution B, then slowly add solution B to A, and emulsify and stir at a speed of 500r / min for 20min, after emulsification is completed, the temperature is raised to 60°C, and ammonium persulfate is formulated into 1...

Embodiment 2

[0053] Raw material weight ratio: white oil 20wt%, fumed silica 1.1wt%, acrylamide monomer 25wt%, acrylic acid 10wt%, Span-40 10wt%, N,N-methylenebisacrylamide 0.08wt%, ammonium persulfate is 0.05wt%, sodium bisulfite is 0.08wt%, OP-10 is 25wt%, tap water is the balance. Put white oil, fumed silica, Span-40, and OP-10 into a reactor equipped with a stirrer, a reflux condenser, and a thermometer, and stir at a speed of 300r / min to make solution A; Add water to dissolve the amide, then add acrylic acid and N,N-methylenebisacrylamide, stir evenly on a magnetic stirrer, add sodium hydroxide aqueous solution to neutralize after completely dissolving, the neutralization degree is 60%, add sulfurous acid Sodium hydrogen is completely dissolved to prepare solution B, then slowly add solution B to A, and carry out emulsification and stirring at a speed of 600r / min for 25min. The aqueous solution was slowly added in batches, and after the initiator was dripped, the stirring reaction wa...

PUM

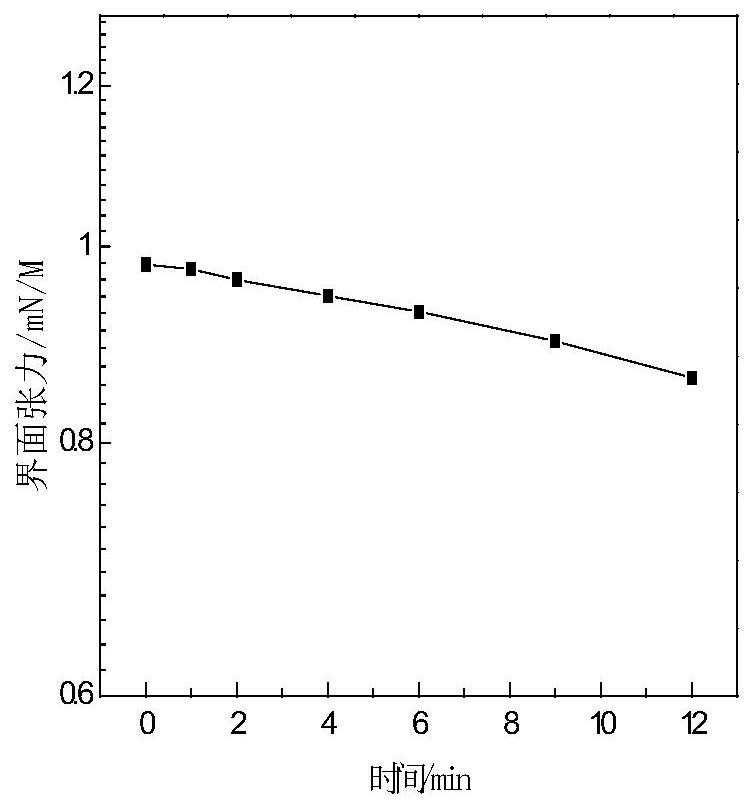

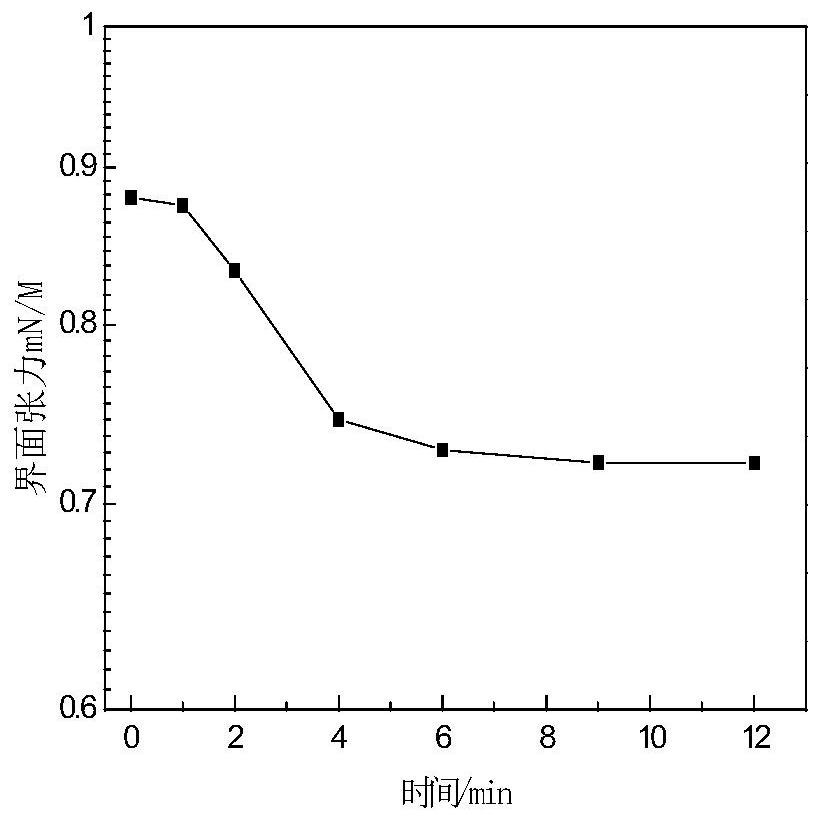

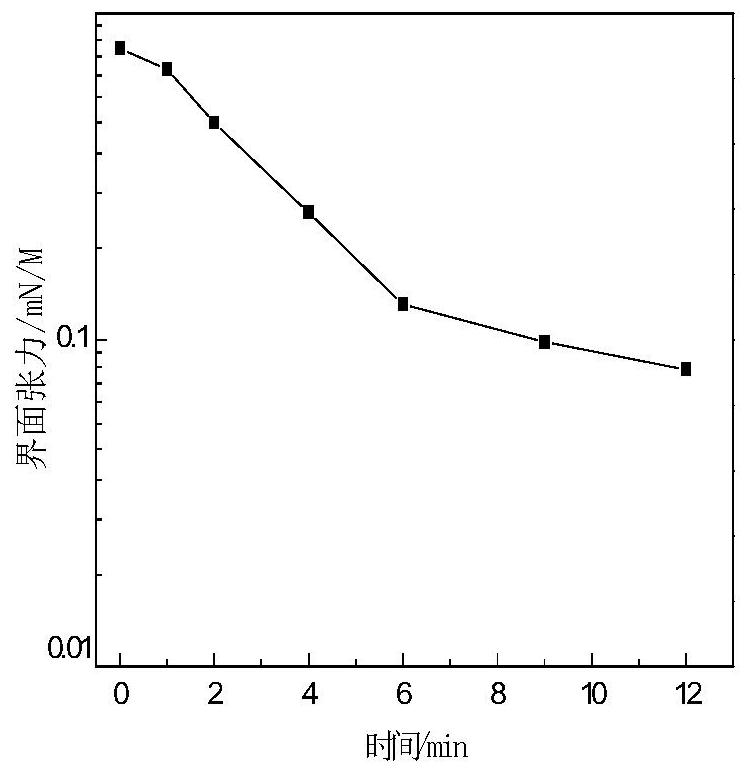

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com