Device for producing sodium hypochlorite by using waste chlorine water and production method thereof

A technology for sodium hypochlorite and production equipment, applied in the directions of hypochlorous acid, hypochlorite, etc., can solve the problems of low resource recycling rate, high production cost, chlorine water pollution, etc., and achieve resource saving, stable reaction, and avoid violent reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

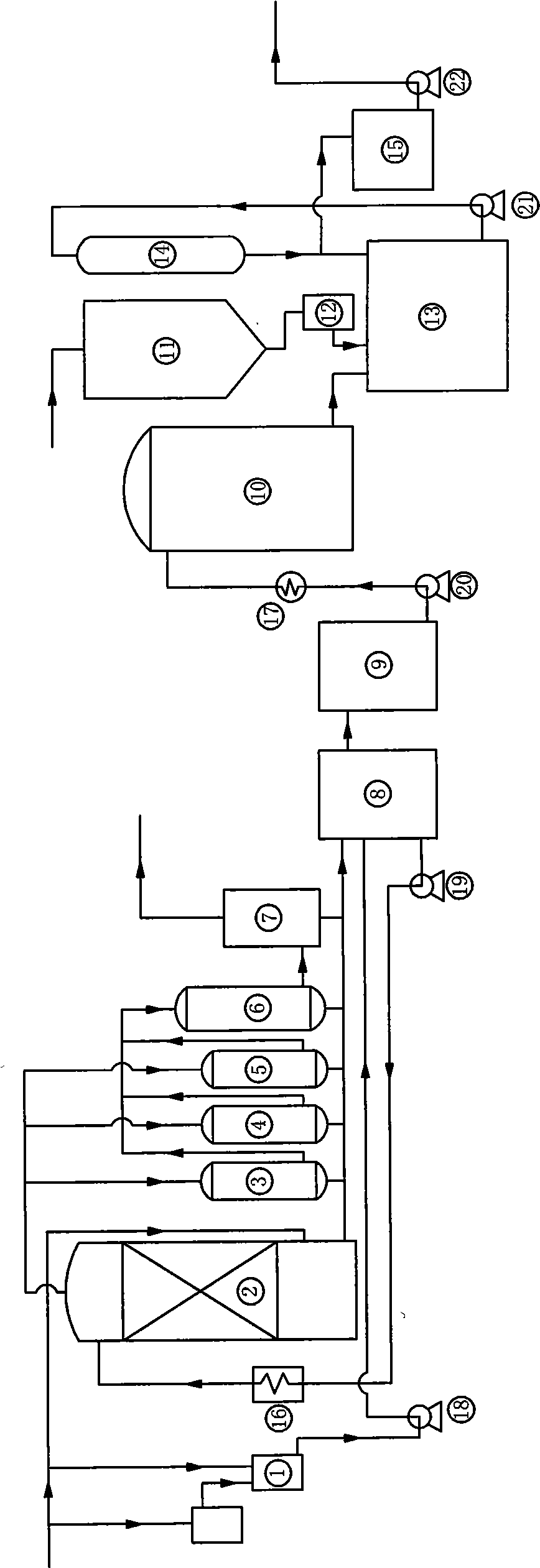

[0032] Embodiment, a kind of device that produces sodium hypochlorite with waste chlorine water, as shown in the figure, comprises chlor-alkali production device, waste chlorine collection device and reaction device, and chlor-alkali production device comprises electrolytic chlorine water storage tank 1, chlorine scrubber connected by pipeline successively 2. Cooler device and chlorine mist catcher 7, said cooler device is made up of one-stage titanium cooler 3, 4, 5 and two-stage titanium cooler 6 connected in parallel, said electrolytic chlorine water storage tank 1, chlorine gas The washing tower 2, the first titanium cooler 3, 4, 5 and the second titanium cooler 6 and the chlorine mist collector 7 are respectively provided with waste chlorine water collection pipes, and the waste chlorine collection device consists of the first chlorine water Storage tank 8, the second chlorine water storage tank 9 and the 3rd chlorine water storage tank 10 constitute, on the connecting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com