Coal-gas producer phenolic water high-temperature treating device and treating process

A gas generator and high-temperature treatment technology, which is applied in the petroleum industry, the manufacture of combustible gas, and energy input, etc., can solve the problems of unsuitable ambient temperature, difficulty in acclimation of microorganisms, and excessive concentration of influent water, so as to improve the calorific value of gas and energy. Utilization rate, simple structure, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

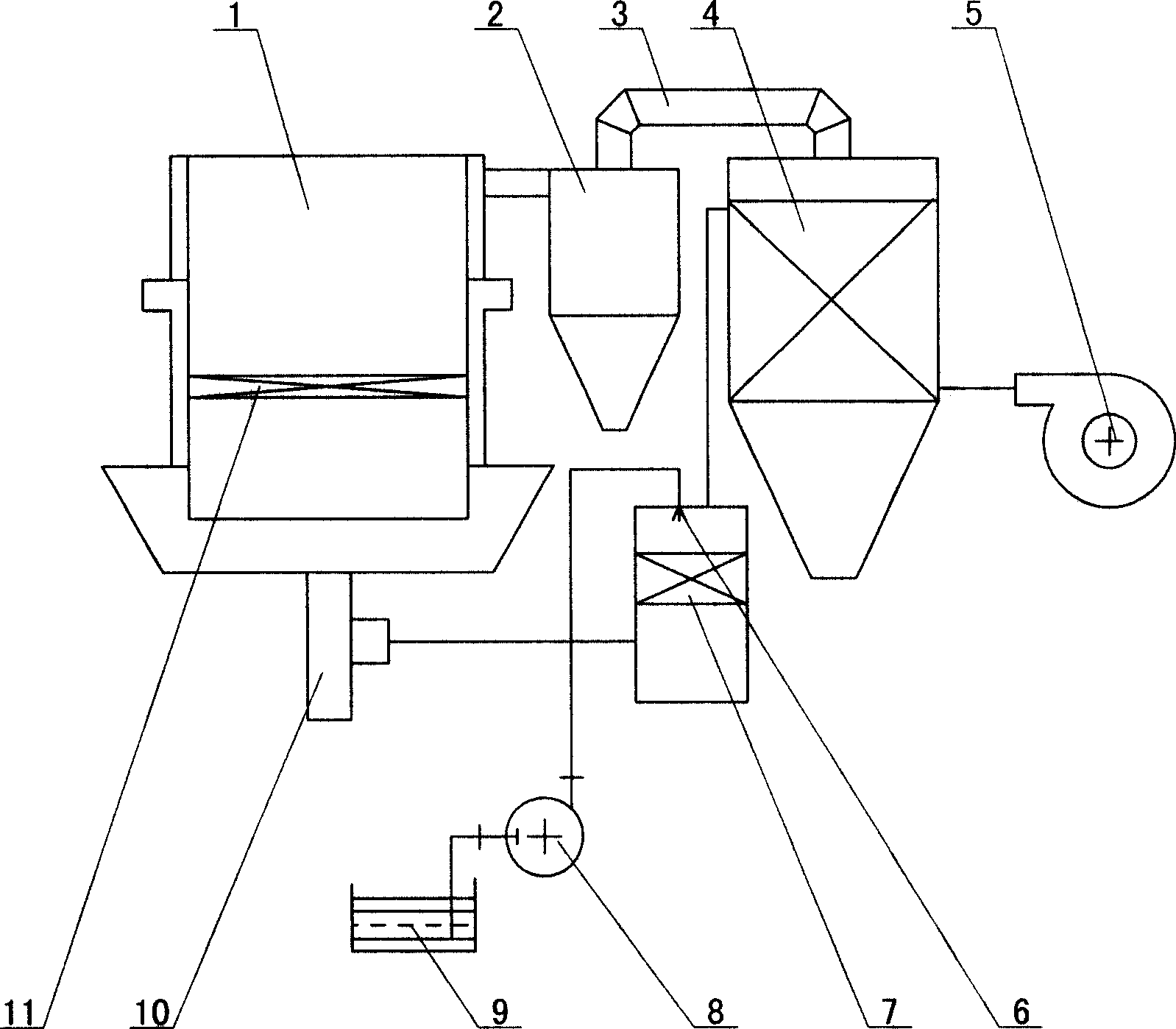

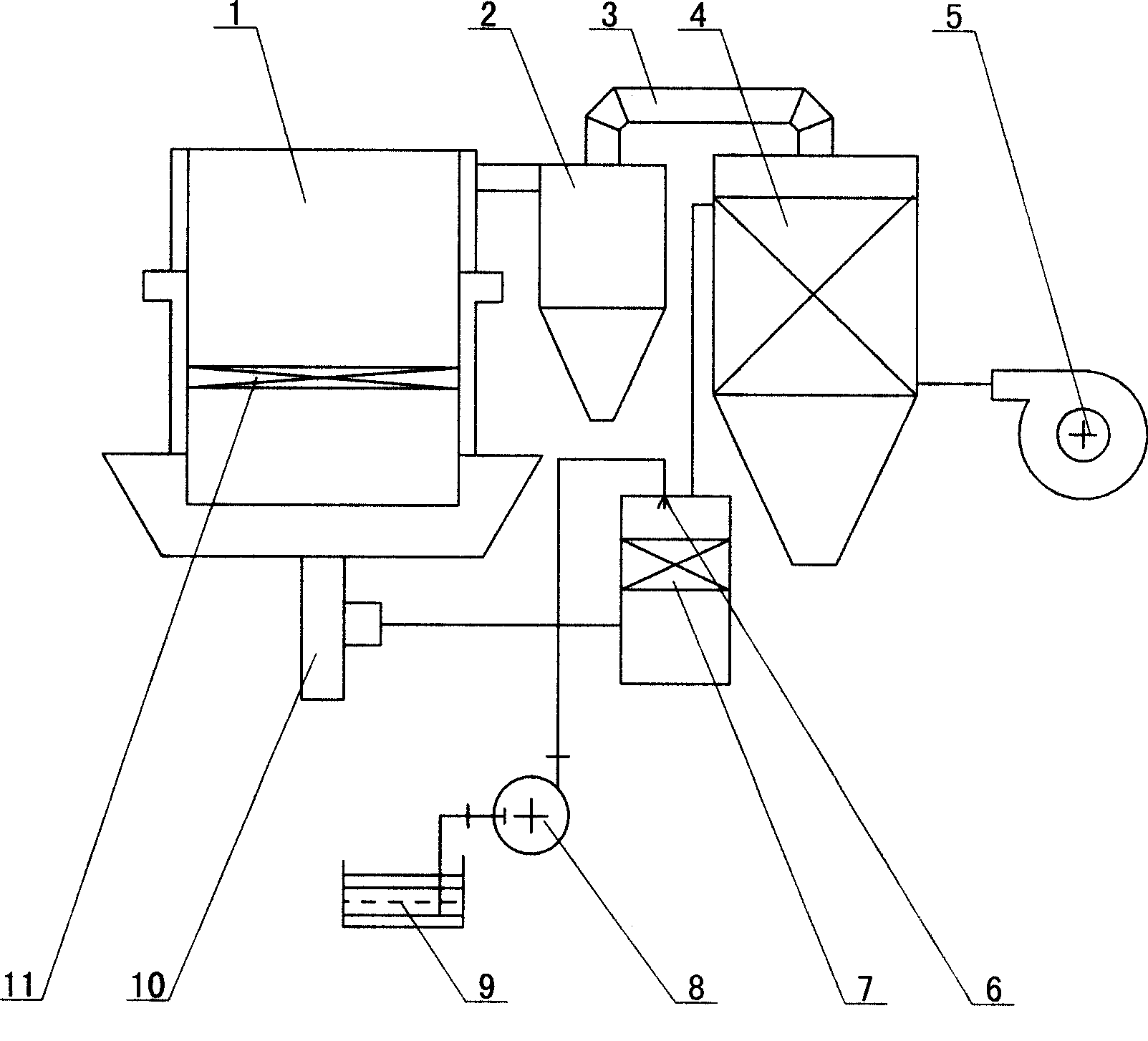

[0014] Such as figure 1 As shown, the primary dust collector 2 is installed on the side wall of the gas generator 1, the bottom of the gas generator 1 is provided with a tee 10, the top of the primary dust collector 2 is connected to the gas pipe 3, and the bottom shape of the primary dust collector 2 and the air preheater 4 Both are funnel-shaped, and the upper part of the air preheater 4 is provided with a tube-and-tube heat exchanger. The gas passes through the air preheater 4, and the side wall of the air preheater 4 is connected to the furnace bottom process fan 5 and the air humidifier 7 through pipelines. The phenol water pump 8 is connected with the pipeline, the phenol water pump 8 is connected with the phenol water pool 9 through the pipeline, the side wall of the air humidifier 7 is connected with the tee 10 through the pipeline, and the tee 10 is connected with the gas generator 1 .

[0015] The air waste heat device 4 and the air humidifier 7 may be made into an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com