Secondary doped silicon-based negative electrode material and preparation method thereof

A silicon-based negative electrode material and secondary doping technology, which is applied in the direction of negative electrodes, secondary batteries, battery electrodes, etc., can solve the problem of hindering the development of silicon-based negative electrode materials, failing to meet high energy requirements, and reducing the first coulombic efficiency of secondary batteries and other issues, to achieve the effect of easy mass production, low cost, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Correspondingly, the embodiment of the present application also provides a method for preparing the above-mentioned secondary doped silicon-based negative electrode material, including:

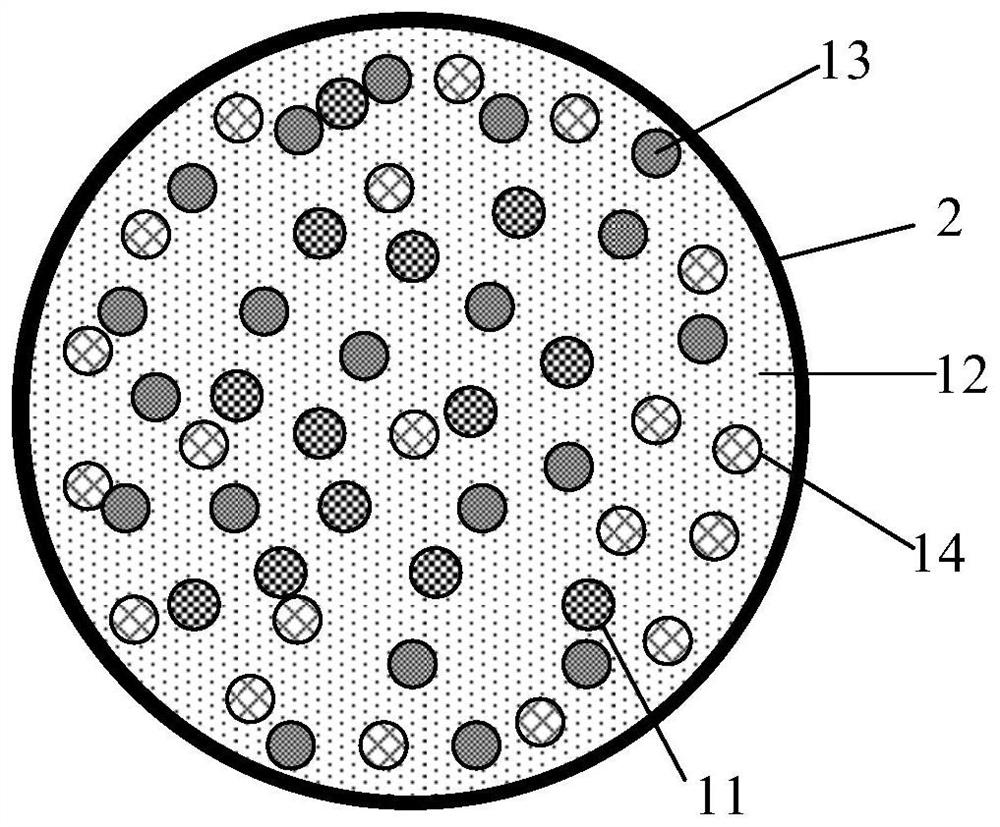

[0044] Step S1: Reacting silicon, silicon dioxide, and a substance including a first metal element to form a first product, the first product includes silicon, silicon oxide, and a silicate of the first metal element, wherein the silicon The general formula of the oxide is SiOx, 0<x<2, and the first metal element is evenly distributed in the first product;

[0045] Step S2: Make the median particle size of the first product 1 μm-99 μm, and then perform carbon coating on the surface of the first product to form a second product, the second product includes an inner core and a carbon coating layer , the inner core at this time includes silicon, silicon oxide and silicate of the first metal element;

[0046] Step S3: making the second product react with a substance including a second met...

Embodiment 1

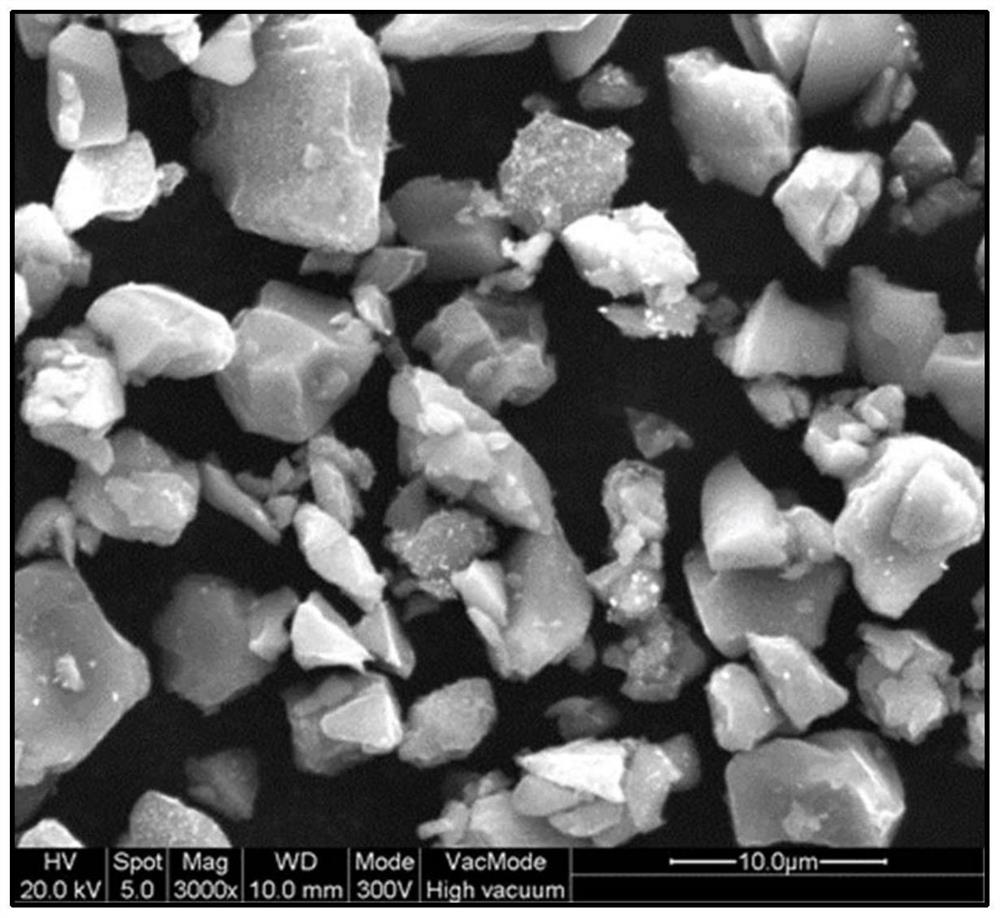

[0054] Mix 10Kg of silicon powder and silicon dioxide powder evenly at a molar ratio of 1:1, then add 1Kg of magnesium, and heat at high temperature under high temperature and vacuum conditions (0.01-5Pa, 1000°C-1400°C), a gas phase reaction occurs to form magnesium-doped Silicon oxide A, cooled and precipitated at a temperature of 700°C-800°C;

[0055] Put magnesium-doped silicon oxide into a ball mill by ball milling method, and ball mill for 4 hours under the condition of 1200r / min until the particle size of magnesium-doped silicon oxide is 5 μm;

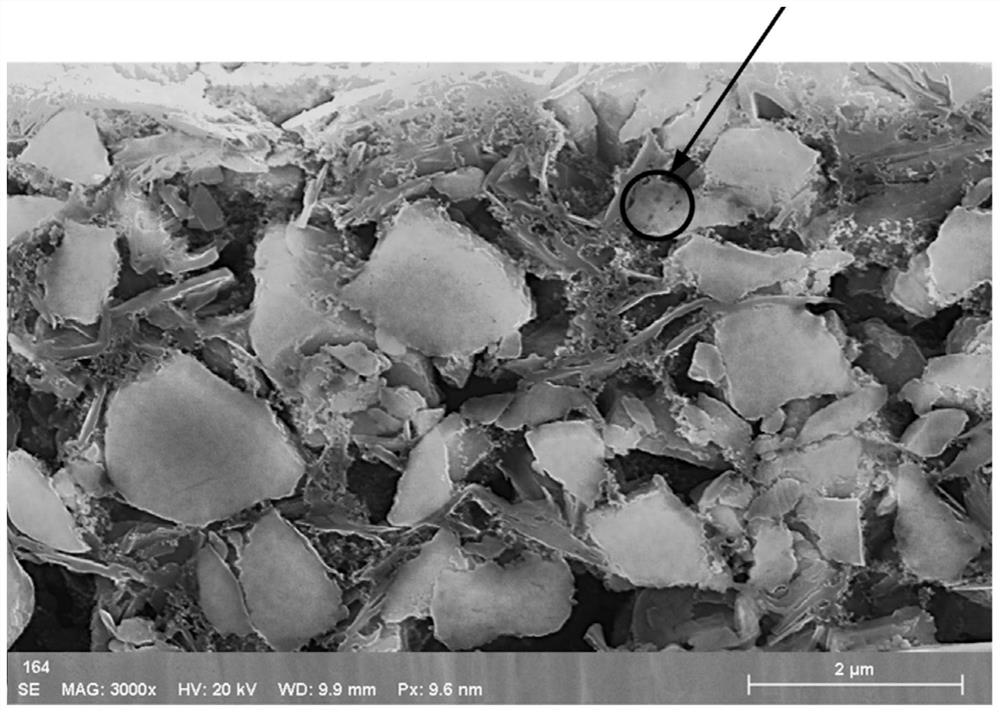

[0056] Put the ground magnesium-doped silicon oxide into the rotary furnace, use the gas phase coating method, under the condition of nitrogen protection, heat up to 900°C at a speed of 3°C / min, then start to pass the propanol gas, the propanol gas The gas flow rate is 0.8L / min, the constant temperature is 10h, and the material B is obtained. In the material B, the weight percentage of the carbon weight in the material A is 5% fo...

Embodiment 2

[0059] Mix 10Kg of silicon powder and silicon dioxide powder evenly at a molar ratio of 1:1, then add 1Kg of magnesium, and heat at high temperature under high temperature and vacuum conditions (0.01-5Pa, 1000°C-1400°C), a gas phase reaction occurs to form magnesium-doped Silicon oxide A, cooled and precipitated at a temperature of 700°C-800°C;

[0060] Put magnesium-doped silicon oxide into a ball mill by ball milling method, and ball mill for 4 hours under the condition of 1200r / min until the particle size of magnesium-doped silicon oxide is 5 μm;

[0061] Put the ground magnesium-doped silicon oxide into the rotary furnace, use the gas phase coating method, under the condition of nitrogen protection, heat up to 900°C at a speed of 3°C / min, then start to pass the propanol gas, the propanol gas The gas flow rate is 0.8L / min, the constant temperature is 10h, and the material B is obtained. In the material B, the weight percentage of the carbon weight in the material A is 5% fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com