Production method and system for co-production of acetyl chloride by 1-hydroxyethylidene-1,1-diphosphonicacid

A technology of hydroxyethylene diphosphoric acid and its production method, which is applied in the field of co-production of acetyl chloride by hydroxyethylene diphosphoric acid, can solve the problem that it is difficult to realize the dynamic adjustment of HEDP and acetyl chloride, increase the difficulty of recovering acetic acid, and the inability to directly produce acetic acid containing water. Use and other problems to achieve the effect of reducing operation difficulty and labor intensity, high energy consumption and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

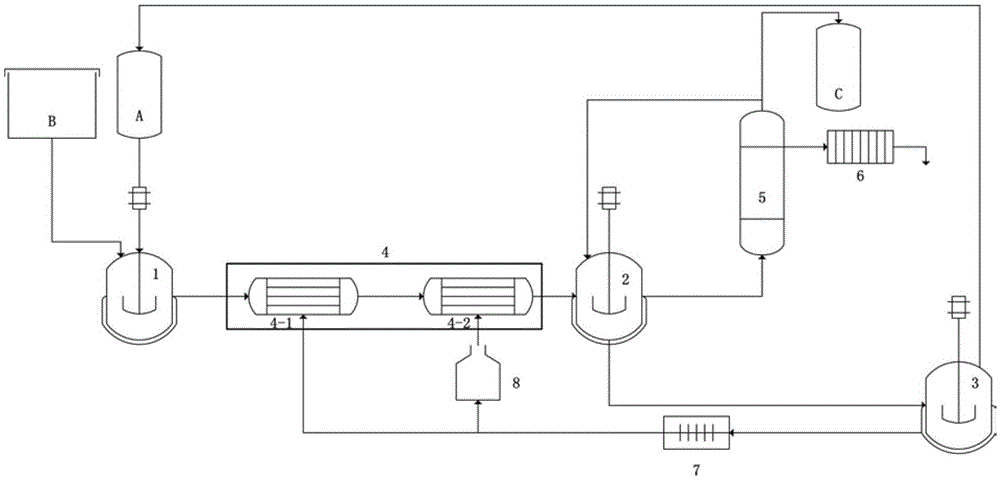

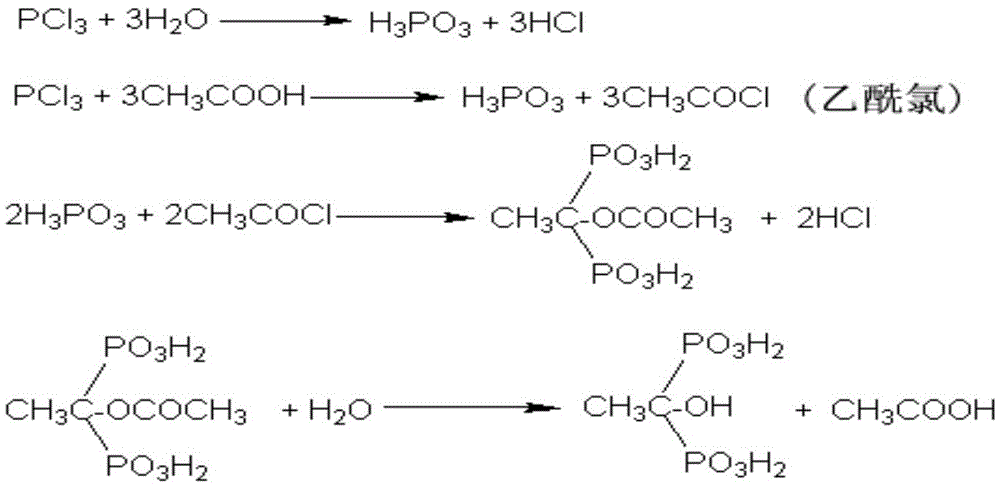

[0031] A kind of production method of hydroxyethylene diphosphoric acid co-production acetyl chloride is carried out with the following process steps:

[0032] (1) Under normal pressure, start the reactor 1 to stir, put the phosphorus trichloride B stored in the storage tank into 2400kg in the phosphorus trichloride head tank, and pump 3150kg of acetic acid A stored in the storage tank into the reaction Kettle 1, control the speed of 310L / h, and start to drop phosphorus trichloride B into the reaction kettle at the same time, control the speed of 160L / h, and the temperature in the reaction kettle 1 is less than 45°C;

[0033] (2) The mixed material is preheated by the two-stage heat exchanger 4, the temperature of the first-stage heat exchanger 4-1 is 70°C, the heat source comes from waste heat recovery, the temperature of the second-stage heat exchanger 4-2 is 100°C, and the heat source comes from the boiler 8 steam;

[0034] (3) After the material is preheated, it enters th...

Embodiment 2

[0038] A kind of production method of hydroxyethylene diphosphoric acid co-production acetyl chloride is carried out with the following process steps:

[0039] (1) Under normal pressure, start the reactor 1 to stir, put the phosphorus trichloride B stored in the storage tank into 2200kg in the phosphorus trichloride head tank, and pump 3000kg of acetic acid A stored in the storage tank into the reaction Kettle 1, control the speed of 290L / h, and start to drop phosphorus trichloride B into the reaction kettle at the same time, control the speed of 150L / h, and the temperature in the reaction kettle 1 is less than 45°C;

[0040] (2) The mixed material is preheated by the two-stage heat exchanger 4, the temperature of the first-stage heat exchanger 4-1 is 80°C, the heat source comes from waste heat recovery, the temperature of the second-stage heat exchanger 4-2 is 105°C, and the heat source comes from the boiler 8 steam;

[0041] (3) After the material is preheated, it enters th...

Embodiment 3

[0045] A kind of production method of hydroxyethylene diphosphoric acid co-production acetyl chloride is carried out with the following process steps:

[0046] (1) Under normal pressure, start the reactor 1 to stir, put the phosphorus trichloride B stored in the storage tank into 2500kg in the phosphorus trichloride head tank, and pump 3300kg of acetic acid A stored in the storage tank into the reaction Kettle 1, control the speed of 320L / h, and at the same time start to drop phosphorus trichloride B into the reaction kettle, control the speed of 180L / h, and the temperature in the reaction kettle 1 is less than 45°C;

[0047] (2) The mixed material is preheated by the two-stage heat exchanger 4, the temperature of the first-stage heat exchanger 4-1 is 65°C, the heat source comes from waste heat recovery, the temperature of the second-stage heat exchanger 4-2 is 95°C, and the heat source comes from the boiler 8 steam;

[0048] (3) After the material is preheated, it enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com