Silicon nitride and preparation method thereof

A silicon nitride and nitrogen technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of unfavorable large-scale production, harsh equipment requirements, high pressure, and achieve large-scale industrial production. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

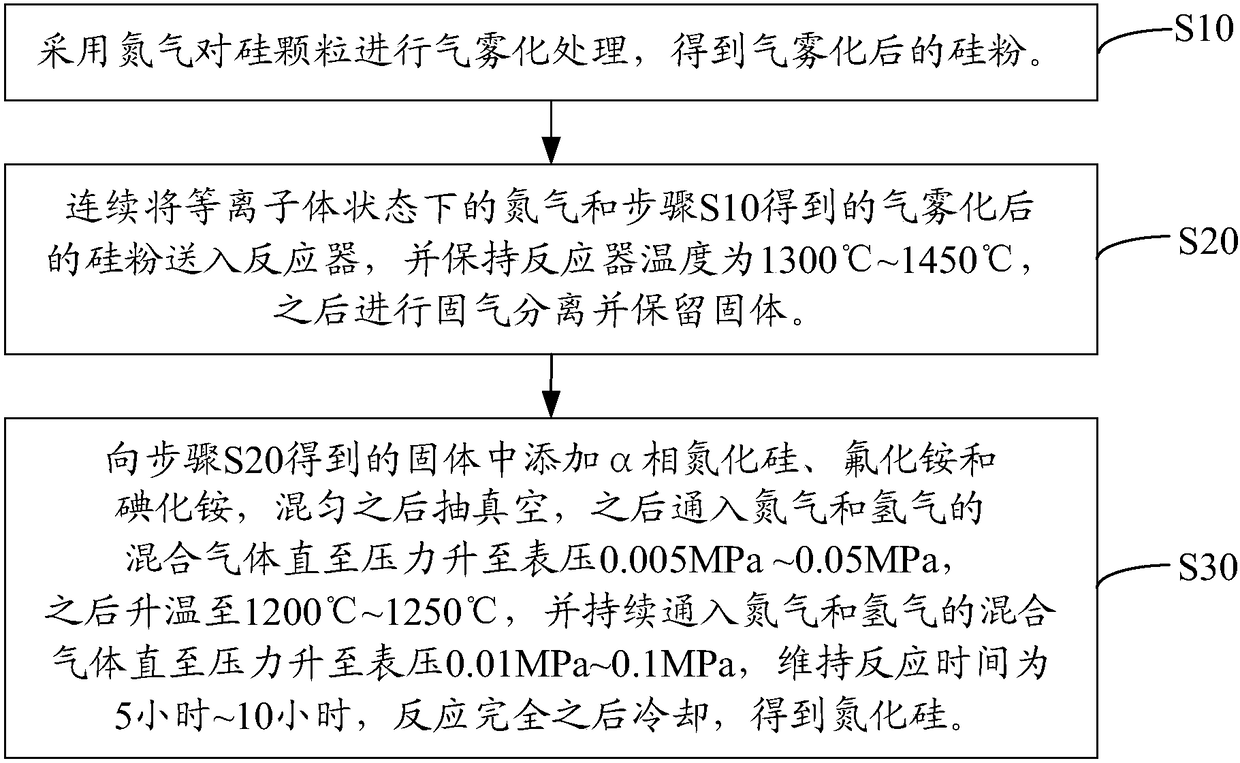

[0040] See figure 1 , the preparation method of silicon nitride of an embodiment, comprises the following steps:

[0041] S10, using nitrogen gas to perform gas atomization treatment on the silicon particles to obtain gas atomized silicon powder.

[0042] Preferably, the silicon particles have a size of 10 μm-2000 μm.

[0043] Preferably, the purity of the silicon particles is ≥6N (6N=99.9999%). Due to the high purity of silicon particles, high-purity silicon nitride can be prepared by using the silicon nitride preparation method of this embodiment, and the purity of silicon nitride can also reach 6N.

[0044] Preferably, the nitrogen in step S10 is high-purity nitrogen to avoid introducing impurities in the nitrogen.

[0045] S20. Continuously feed the nitrogen gas in the plasma state and the atomized silicon powder obtained in step S10 into the reactor, and keep the temperature of the reactor at 1300° C. to 1450° C., and then perform solid-gas separation and retain the so...

Embodiment 1

[0064] After mixing high-purity nitrogen, hydrogen and argon, pass it into the plasma generator, start the plasma power supply, and make the plasma generator generate a plasma arc, and the mixed gas flowing through the plasma arc is heated to above 5000°C to obtain Nitrogen in plasma state in protective gas atmosphere.

[0065] Use high-purity nitrogen gas to conduct gas atomization treatment on industrial silicon particles to obtain gas atomized silicon powder.

[0066] Continuously feed the nitrogen gas in the plasma state and the atomized silicon powder into the reactor, and keep the temperature of the reactor at 1300°C to 1450°C, and then carry out solid-gas separation and retain the solid.

[0067] Take 1000g of the obtained solid, after testing, it contains 400g of unreacted silicon, add 120g of α-phase silicon nitride, 38g of ammonium fluoride and 4.2g of ammonium iodide, mix it and put it into a graphite crucible, then put the graphite crucible Put it in a heating fur...

Embodiment 2

[0070]After mixing high-purity nitrogen, hydrogen and argon, pass them into the plasma generator, start the plasma power supply, and make the plasma generator generate a plasma arc, and the mixed gas flowing through the plasma arc is heated to above 5000°C to obtain Nitrogen in plasma state in protective gas atmosphere.

[0071] High-purity silicon particles (≥6N) are subjected to gas atomization treatment with high-purity nitrogen gas to obtain gas-atomized silicon powder.

[0072] The nitrogen gas in the plasma state and the atomized silicon powder are continuously fed into the reactor, and the temperature of the reactor is kept at 1300°C to 1450°C, and then the solid and gas are separated and the solid is retained.

[0073] Take 1000g of the obtained solid, after testing, it contains 600g of unreacted silicon, add 200g of α-phase silicon nitride, 70g of ammonium fluoride and 5.6g of ammonium iodide to the solid, mix it and put it into a graphite crucible, then put the graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com