Preparing method of gemcitabine intermediate

A gemcitabine and intermediate technology, applied in the field of pharmaceutical intermediate synthesis, can solve the problems of large operation difficulty coefficient, out-of-control reaction, low product yield, etc., and achieve the effects of avoiding severe reaction, good synergy and high product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The active zinc powder in this embodiment can be activated by the action of zinc in hydrochloric acid.

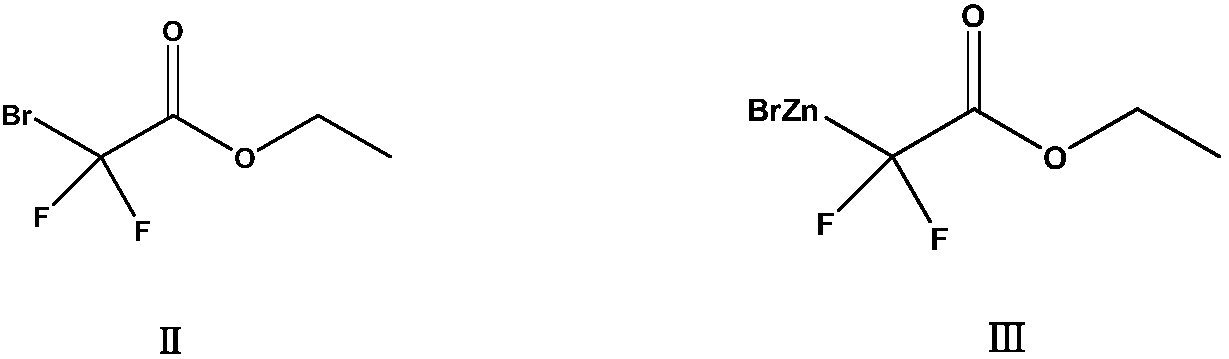

[0028] Put 70g of tetrahydrofuran and 40g of activated zinc powder into the clean reactor, stir evenly and raise the temperature to 40-42°C, start adding 74g of ethyl difluorobromoacetate dropwise, and control the temperature at 40-42°C after the dropwise addition Insulate the reaction to obtain the organic zinc intermediate after the reaction is complete, let it stand, take the supernatant (reaction solution containing the organic zinc intermediate), add 0.01 g of iodine particles, and set aside.

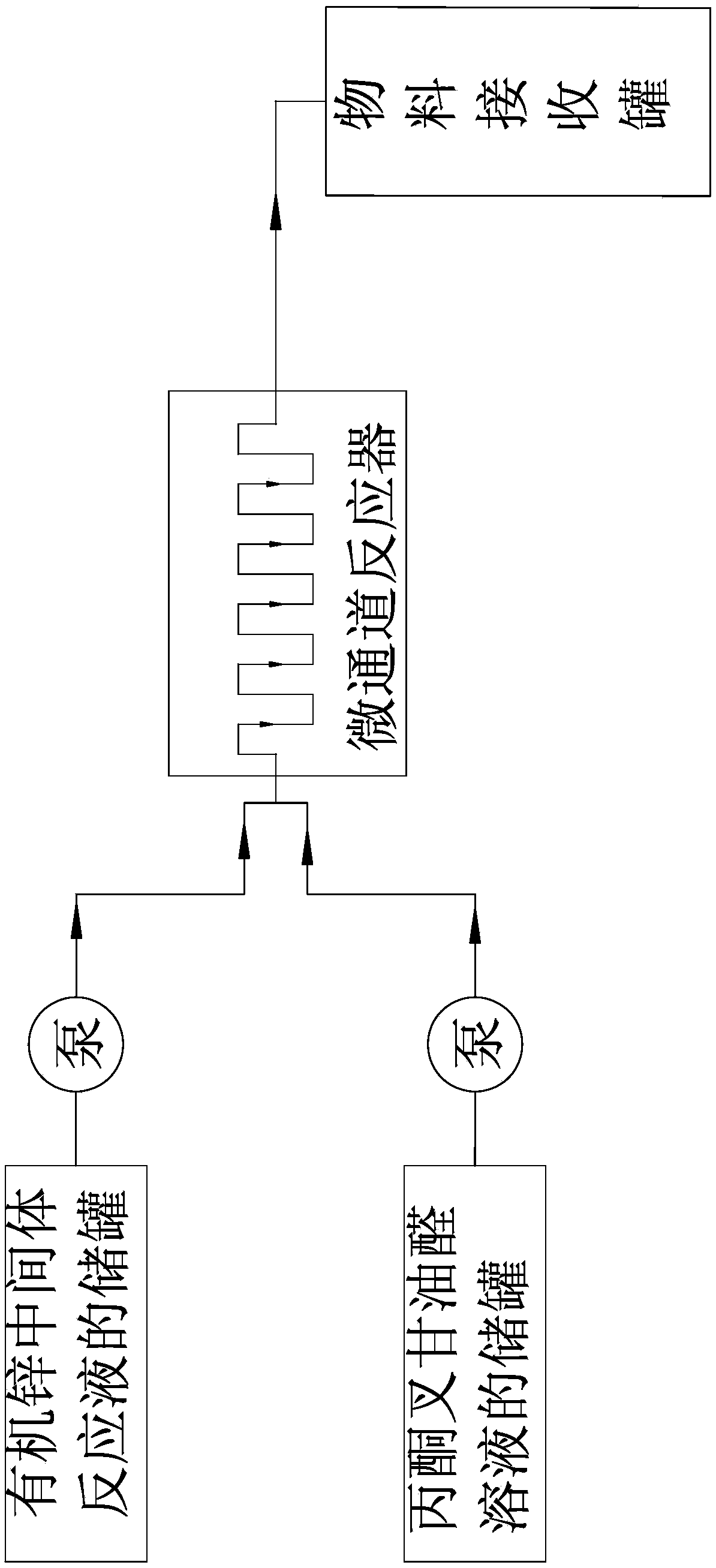

[0029] combine figure 1The equipment flow diagram shows that the organic zinc intermediate reaction liquid obtained in the previous step is transferred into the corresponding organic zinc intermediate reaction liquid storage tank, and then the organic zinc intermediate reaction liquid is pumped into the microchannel reactor by a constant flow pump. Another constant flow ...

Embodiment 2

[0031] The active zinc powder in this embodiment can be activated by the action of zinc in hydrochloric acid.

[0032] Put 80g of tetrahydrofuran and 40g of activated zinc powder into a clean reactor, stir evenly and raise the temperature to 45°C, start to add 78g of ethyl difluorobromoacetate dropwise, and control the temperature at 43-45°C for heat preservation reaction after the dropwise addition , to obtain the organic zinc intermediate after the reaction is complete, let it stand, get the supernatant (containing the organic zinc intermediate reaction solution), add 0.008g of iodine particles, and set aside.

[0033] to combine figure 1 The equipment flow diagram shows that the organic zinc intermediate reaction liquid obtained in the previous step is transferred into the corresponding organic zinc intermediate reaction liquid storage tank, and then the organic zinc intermediate reaction liquid is pumped into the microchannel reactor by a constant flow pump. Another const...

Embodiment 3

[0035] The active zinc powder in this embodiment can be activated by the action of zinc in hydrochloric acid.

[0036] Put 100g of tetrahydrofuran and 40g of activated zinc powder into a clean reactor, stir evenly and raise the temperature to 42°C, start to add 75g of ethyl difluorobromoacetate dropwise, after the dropwise addition, control the temperature at 41-43°C for heat preservation reaction , after the reaction is complete, the organozinc intermediate is obtained, let it stand, get the supernatant (the reaction solution containing the organozinc intermediate), add 0.023g of iodine particles, and set aside.

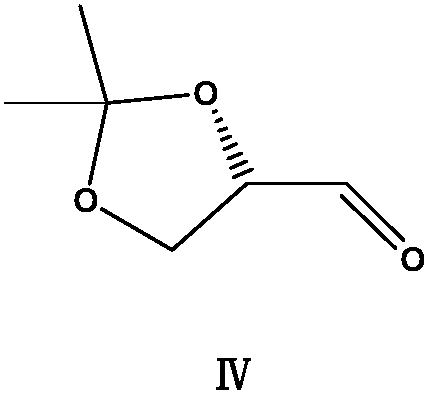

[0037] The reaction solution of the organozinc intermediate obtained in the previous step is pumped into the microchannel reactor with a constant-flow pump, and simultaneously the tetrahydrofuran solution (containing 45g acetonylidene glyceraldehyde, 80g tetrahydrofuran) of acetonylidene glyceraldehyde is pumped with another constant-flow pump The two solutions are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com