Low-foaming anti-crease soft laundry detergent and preparation method thereof

A laundry detergent and softening technology, applied in the field of laundry detergent, can solve the problems of loss of decontamination effect, affecting the stability of enzyme preparations, etc., and achieve the effects of good softness, enhanced stability, and good antistatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The preparation of embodiment 1 anti-wrinkle soft laundry detergent (1)

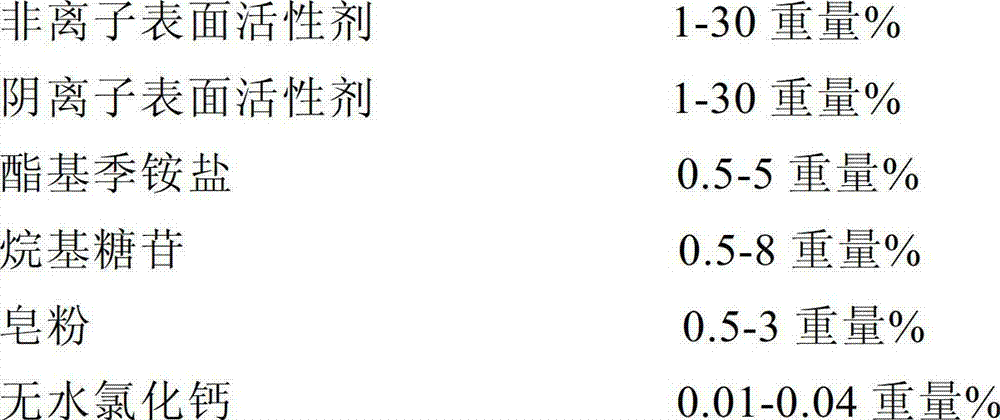

[0061] (1) Raw materials

[0062]

[0063]

[0064] (2) Preparation steps

[0065]A. Put deionized water into the reaction kettle, add sodium citrate and anhydrous calcium chloride, stir to dissolve, and heat up to 50-60°C;

[0066] B. Add soap powder and stir for 10-15 minutes; add fatty alcohol polyoxyethylene ether sodium sulfate and keep the temperature

[0067] 50-60°C, stir to dissolve;

[0068] D. Add fatty alcohol polyoxyethylene ether and alkyl glycoside, keep the temperature at 30-60°C and stir to dissolve;

[0069] E. Keep the temperature at 30-50°C, add 1-methyl-1-oleamidoethyl-2-oleic imidazolin ammonium methyl sulfate, wheat protein / silicone copolymer and propylene glycol, and stir to dissolve;

[0070] F. Add preservative Samp K15 when the temperature drops below 45°C;

[0071] G. Lower the temperature to below 40°C, add enzyme Libo lipase, super protease 16XL and fluores...

Embodiment 2

[0072] The preparation of embodiment 2 anti-wrinkle soft laundry detergent (two)

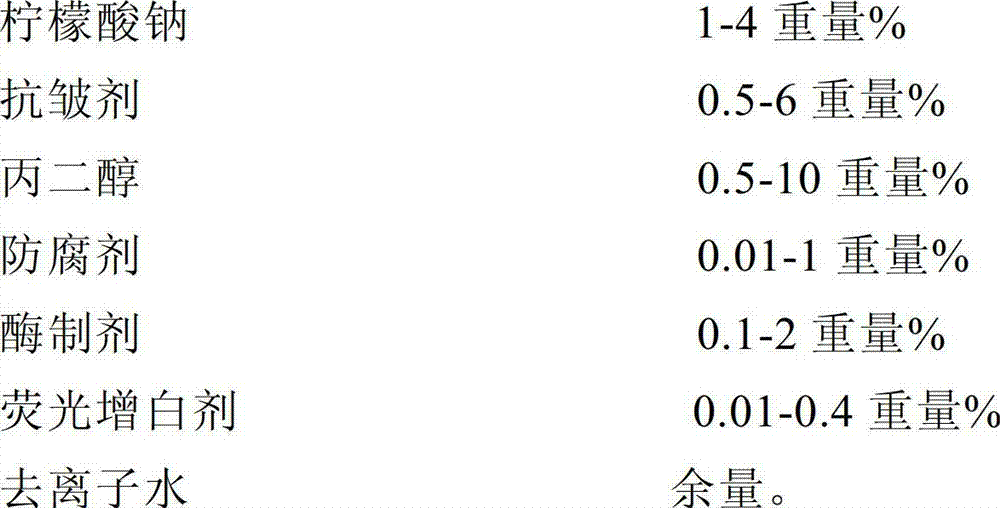

[0073] (1) Raw materials

[0074]

[0075]

[0076] (2) Preparation steps

[0077] A. Put deionized water into the reaction kettle, add sodium citrate and anhydrous calcium chloride, stir to dissolve, and heat up to 50-60°C;

[0078] B. Add soap powder and stir for 10-15 minutes;

[0079] C. Add fatty alcohol polyoxyethylene ether sodium sulfate, keep the temperature at 50-60°C, and stir to dissolve;

[0080] D. Add fatty alcohol polyoxyethylene ether and alkyl glycoside, keep the temperature at 30-60°C and stir to dissolve;

[0081] E. Keep the temperature at 30-50°C, add 1-methyl-1-oleamidoethyl-2-oleic imidazolin ammonium methyl sulfate, wheat protein / silicone copolymer and propylene glycol, and stir to dissolve;

[0082] F. Add preservative Samp K15 when the temperature drops below 45°C;

[0083] G. When the temperature is lowered to below 40°C, add Libo lipase, super protease 16X...

Embodiment 3

[0084] The preparation of embodiment 3 anti-wrinkle soft laundry detergent (three)

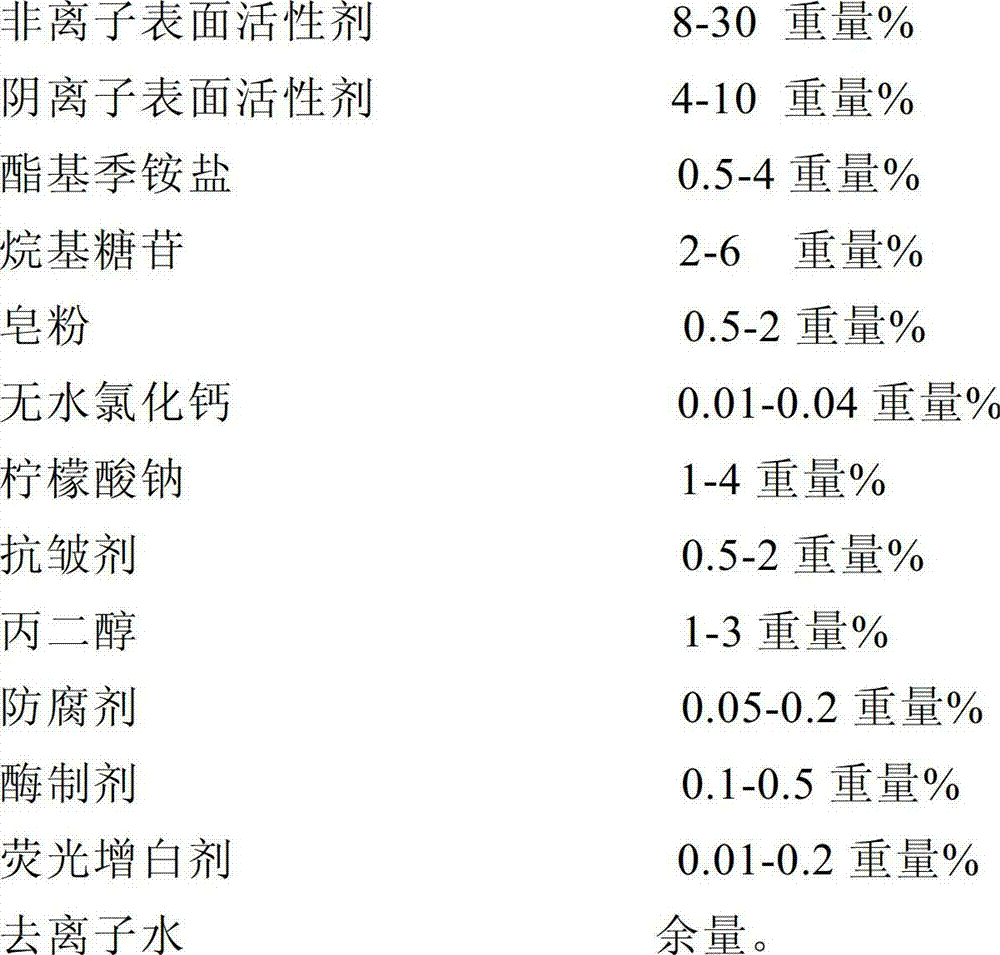

[0085] (1) Raw materials

[0086]

[0087]

[0088] (2) Preparation steps

[0089] A. Put deionized water into the reaction kettle, add sodium citrate and anhydrous calcium chloride, stir to dissolve, and heat up to 50-60°C;

[0090] B. Add soap powder and stir for 15-20 minutes;

[0091] C. Add fatty alcohol polyoxyethylene ether sodium sulfate, keep the temperature at 50-60°C, and stir to dissolve;

[0092] D. Add fatty alcohol polyoxyethylene ether and alkyl glycoside, keep the temperature at 30-60°C and stir to dissolve;

[0093] E. Keep the temperature at 30-50°C, add 1-methyl-1-oleamidoethyl-2-oleic imidazolin ammonium methyl sulfate, wheat protein / silicone copolymer and propylene glycol, and stir to dissolve;

[0094] F. Add preservative Samp K15 when the temperature drops below 45°C;

[0095] G. When the temperature is lowered to below 40°C, add Libo lipase, super protease 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com