Patents

Literature

59results about How to "Play a defoaming role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-foaming anti-crease soft laundry detergent and preparation method thereof

ActiveCN102965222AGood flexibilityImprove antistatic performanceSurface-active non-soap compounds and soap mixture detergentsSurface-active agentsLaundry detergent

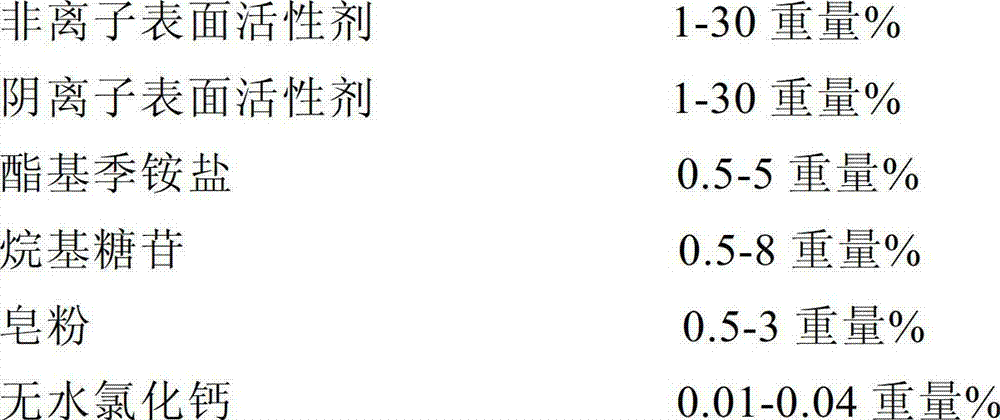

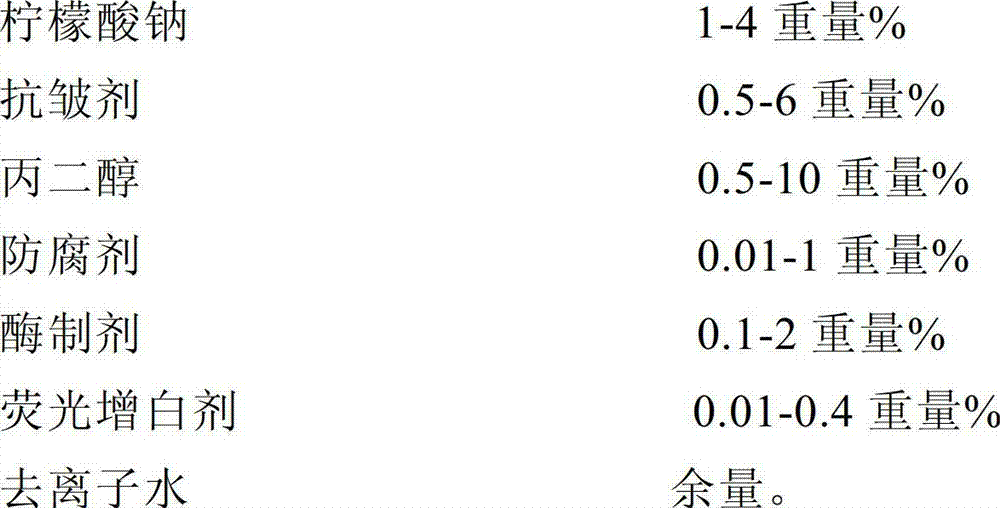

The invention relates to a low-foaming anti-crease soft laundry detergent and a preparation method thereof. The low-foaming anti-crease soft laundry detergent comprises the following components according to proportions: 1-30 percent by weight of nonionic surface active agent, 1-30 percent by weight of anionic surface active agent, 0.5-5 percent by weight of ester quaternary ammonium salt, 0.5-8 percent by weight of alkyl-glycoside, 0.5-3 percent by weight of soap powder, 0.01-0.04 percent by weight of anhydrous calcium chloride, 1-4 percent by weight of sodium citrate, 0.18-1.8 percent by weight of anti-crease agent, 0.5-10 percent by weight of propylene glycol, 0.01-1 percent by weight of preservative, 0.1-2 percent by weight of enzymic preparation, 0.01-0.4 percent by weight of fluorescent whitening agent and the balance of deionized water. The laundry detergent has the advantages of softness, crease resistance, low foaming, stable system, high enzymatic activity and strong detergency.

Owner:NEW ERA HEALTH IND GRP +1

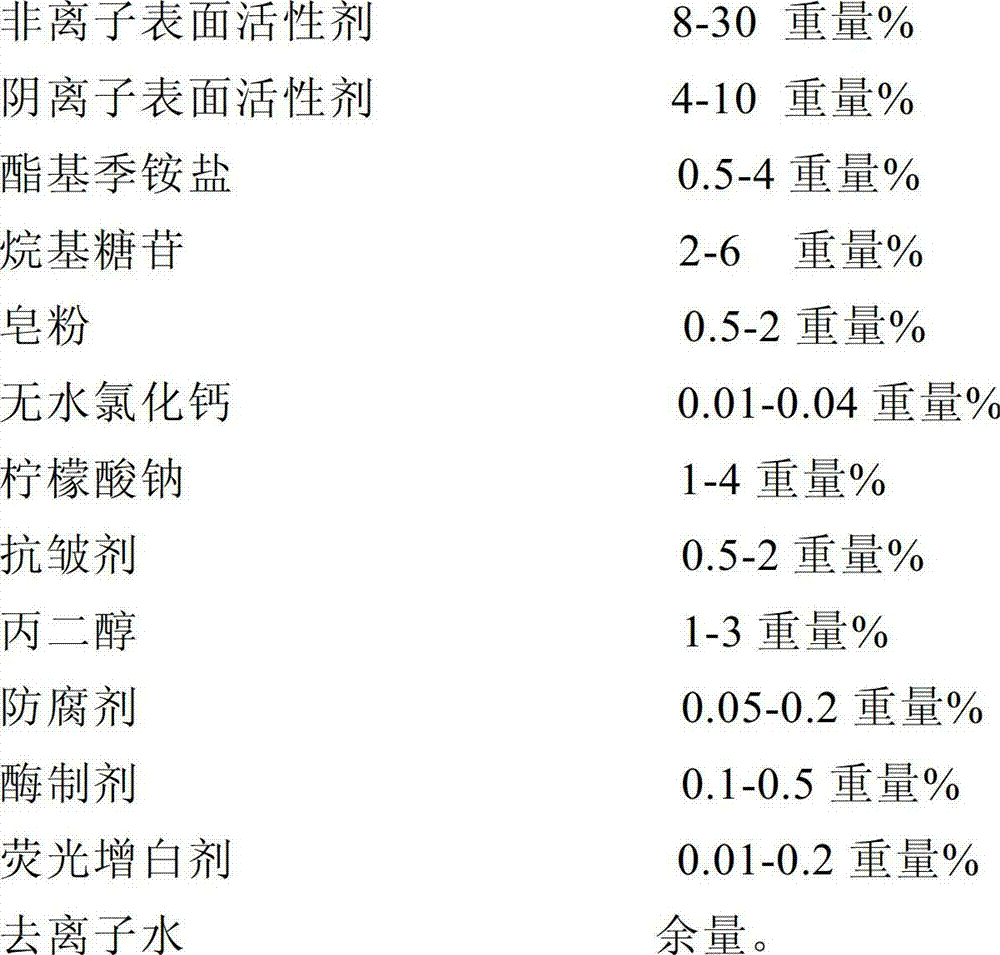

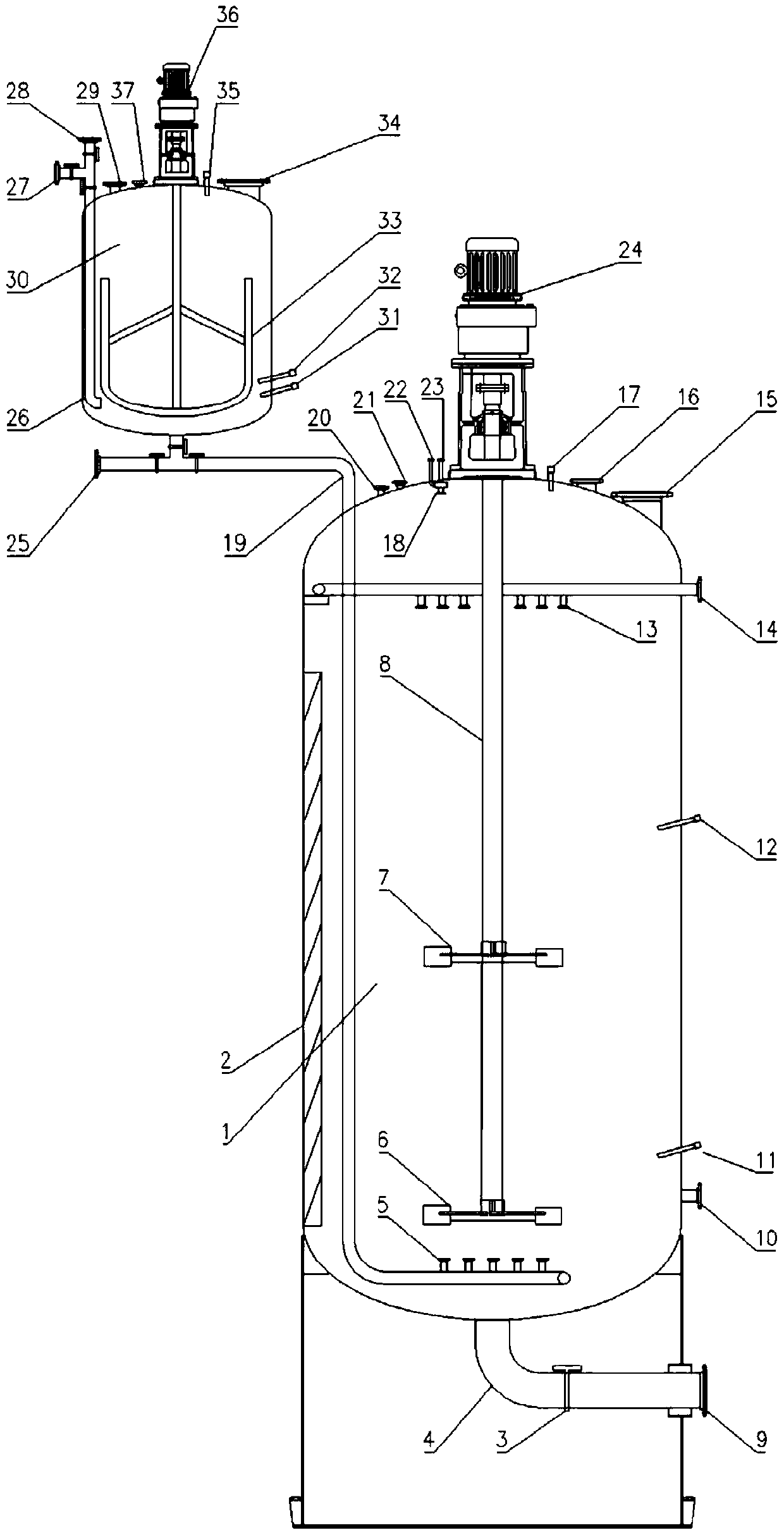

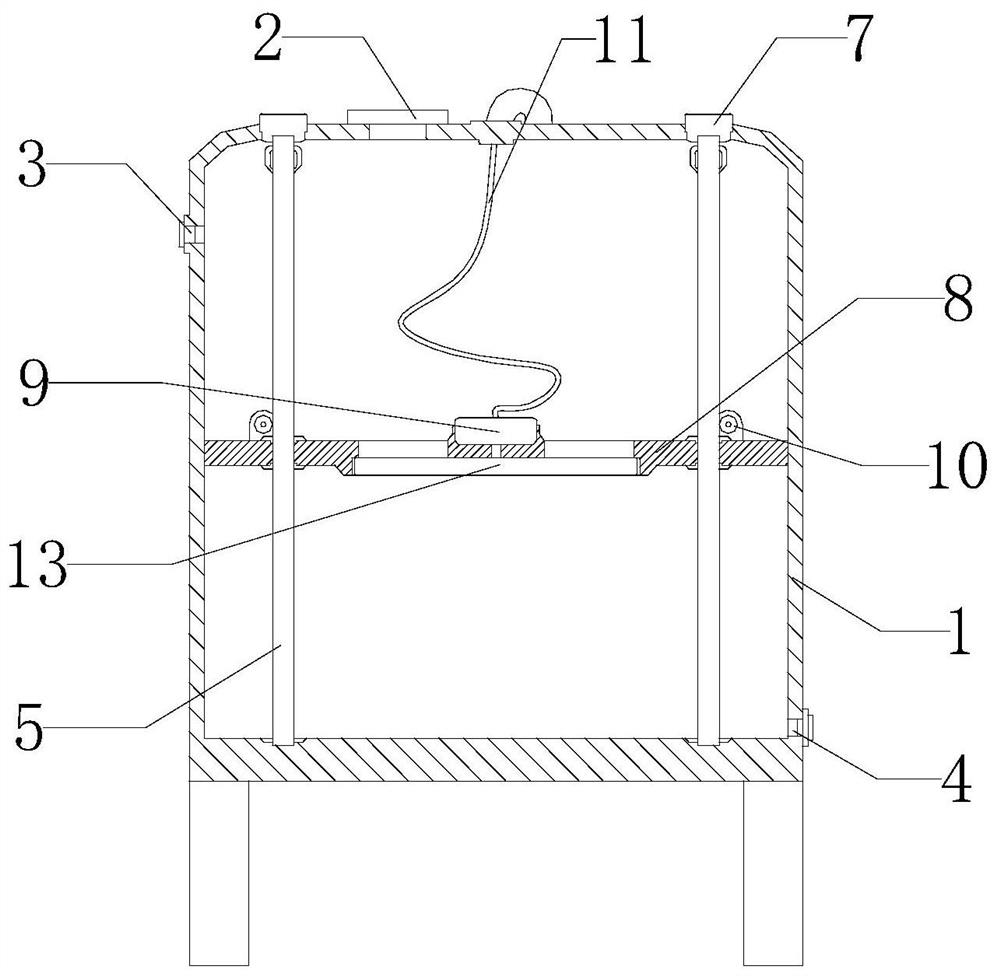

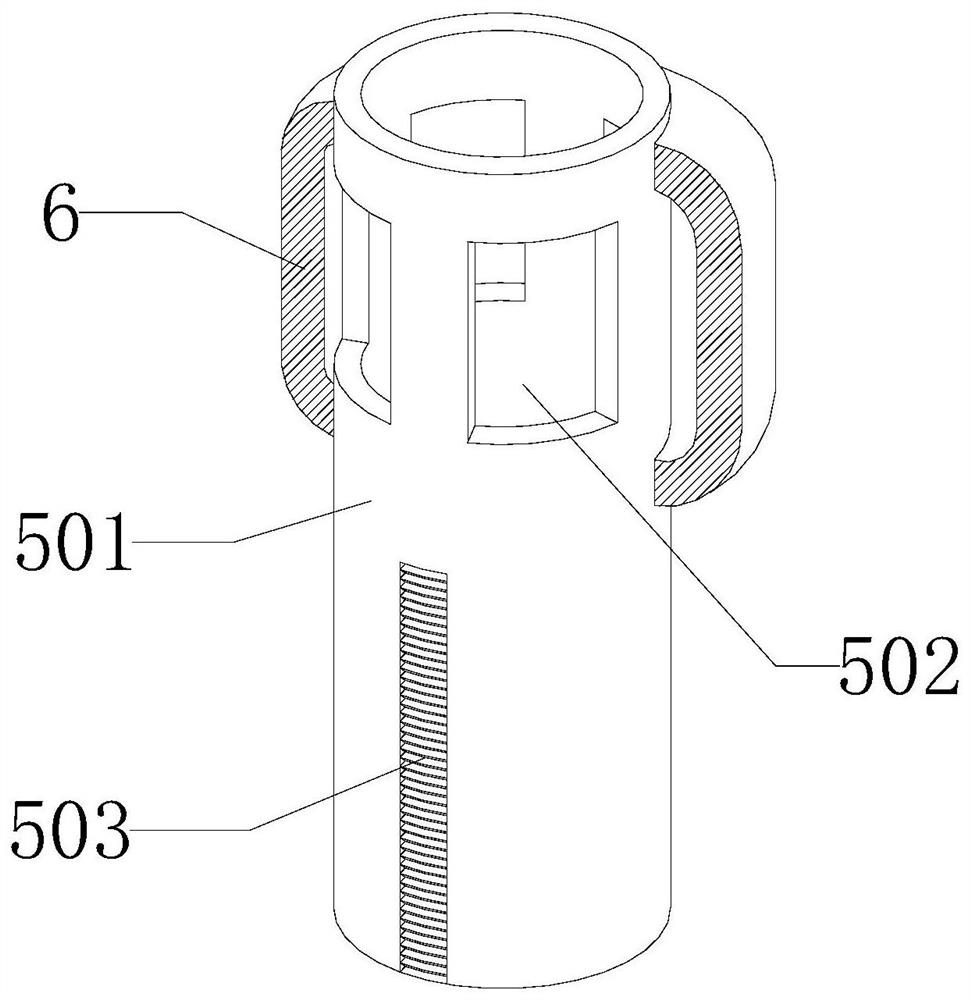

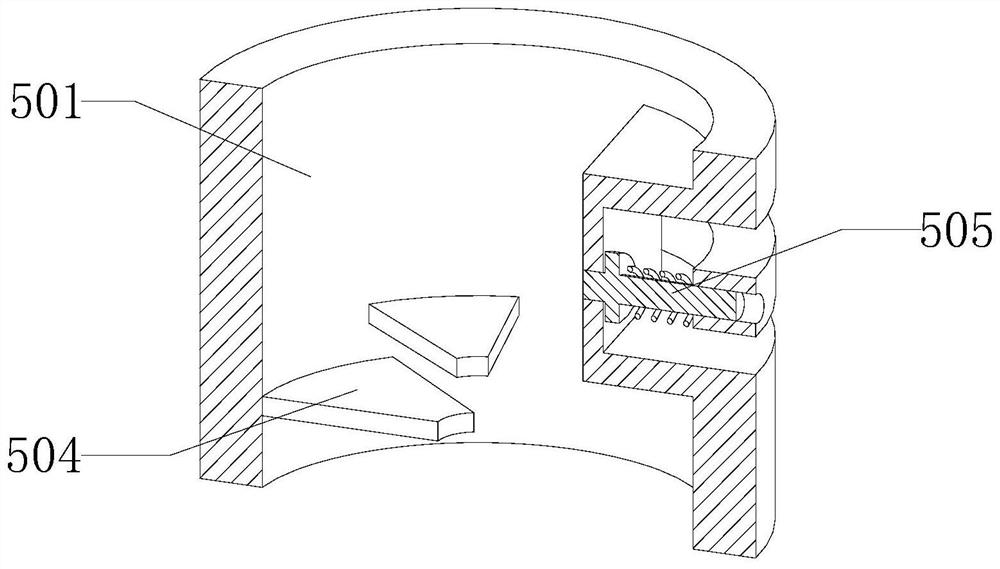

Nano calcium carbonate pressurized carbonation and surface modification integrated reaction kettle and application thereof

ActiveCN111013521AIncrease productivityControl accessCalcium/strontium/barium carbonatesProcess control/regulationCalcium hydroxideSlurry

The invention discloses a nano calcium carbonate pressurization carbonation and surface modification integrated reaction kettle and an application thereof, wherein the nano calcium carbonate pressurization carbonation and surface modification integrated reaction kettle comprises a main reaction kettle and a modification reaction kettle, and the main reaction kettle comprises a main reaction kettlemotor, a stirring shaft, a main reaction kettle stirrer, a slurry inlet pipeline, a slurry discharge pipeline and a CO2 and modifier conveying pipeline; the stirring shaft is arranged in the main reaction kettle, a main reaction kettle motor is arranged above the stirring shaft, the main reaction kettle motor is arranged at the top of the reaction kettle, and the main reaction kettle stirrer is arranged on the stirring shaft; the slurry inlet pipeline is arranged at the middle upper part of the main reaction kettle, the slurry discharge pipeline is arranged at the bottom of the main reactionkettle, and the CO2 and modifier conveying pipeline extends to the lower part of the stirrer from the main reaction kettle. According to the invention, the carbonation reaction and surface modification of nano calcium carbonate are carried out in one reaction kettle, and slurry does not need to be pumped to other reaction kettles, so that unreacted calcium hydroxide turbid liquid is effectively controlled to enter a surface modification system, the product quality is improved, the process is simplified, the production efficiency of calcium carbonate is improved, and the equipment cost is reduced.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Sleeve grouting material for steel bar connection

The invention discloses a sleeve grouting material for steel bar connection, relates to the technical field of concrete, and solves the technical problem that a conventional grouting material generates cracks easily. The grouting material comprises following components in parts by weight: 500 to 530 parts of silicate cement, 430 to 470 parts of quartz sand, 0.1 to 0.5 part of CSA expanding agent,25 to 30 parts of beads, 1.5 to 2.5 parts of polycarboxylic acid water reducer, and 0.3 to 0.4 part of antifoaming agent. The beads and polycarboxylic acid water reducer are used to improve the flowing performance and tensile strength of the grouting material, the expanding agent can generate uniform and compact pores, the shrinkage stress of the grouting material is eliminated, and the crack generation is avoided therefore.

Owner:上海住信住宅工业有限公司

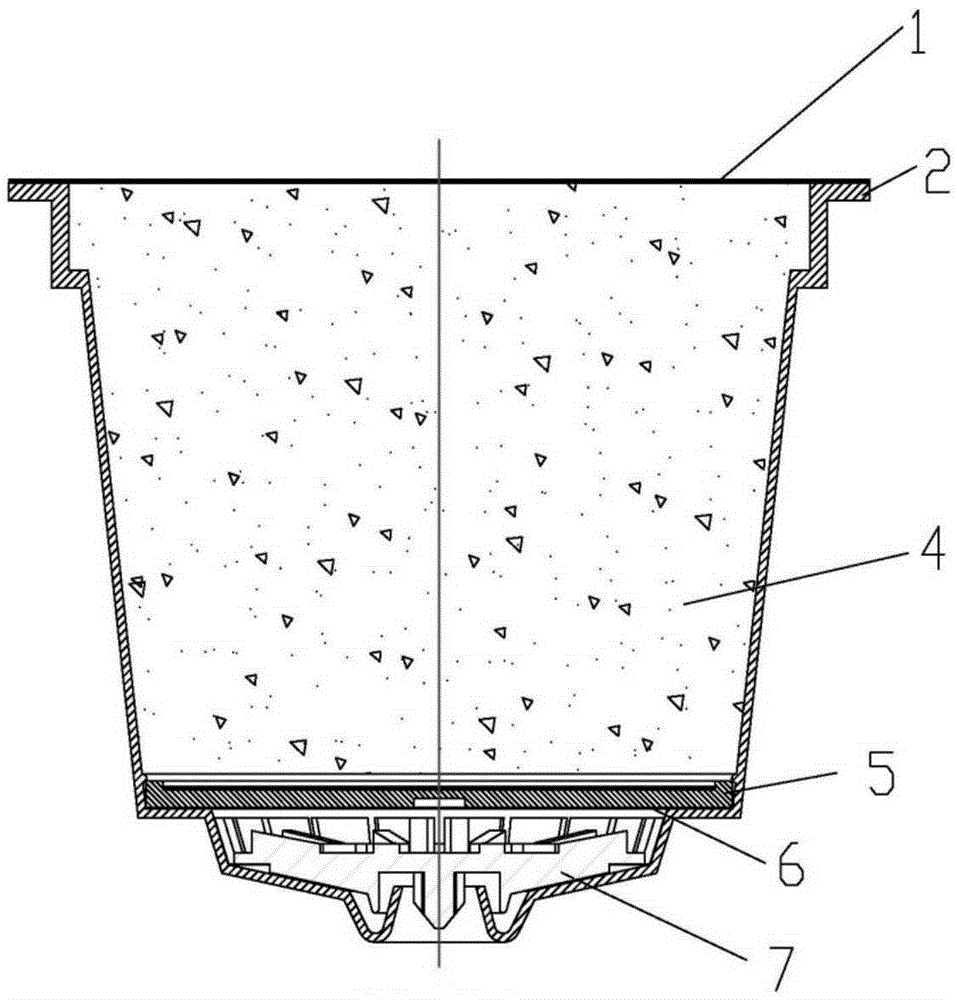

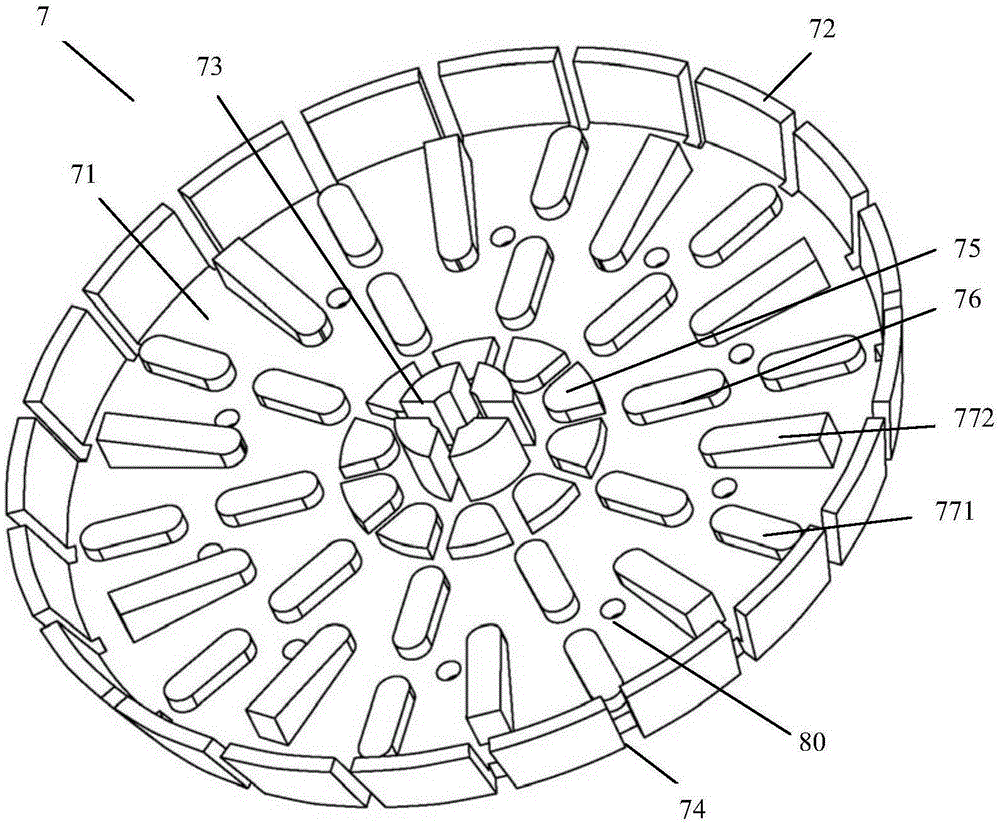

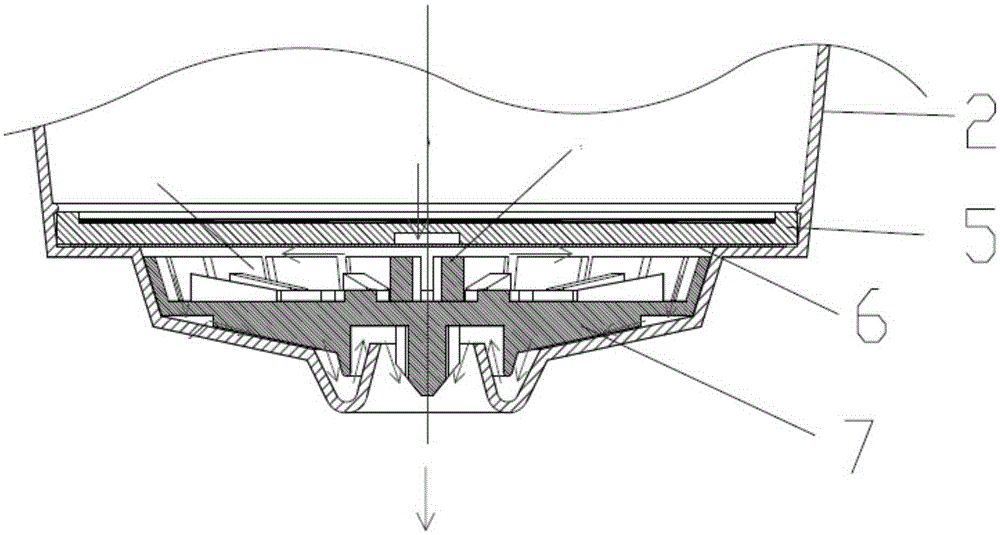

Capsule for making drinks

InactiveCN105286641AImprove buffering effectFacilitate depositionBeverage vesselsInternal pressureCircular disc

The invention relates to the field of drink products, and discloses a capsule for making drinks. The capsule comprises a hollow capsule body, wherein a liquid collector is arranged at the bottom of the capsule body and comprises a disc, multiple upward surrounding pieces arranged at intervals are distributed on the edge of the disc so as to form a big buffering space in the collector, at least two blunt puncturing needles forming a circle are further distributed in the center of the disc at intervals, the blunt puncturing needles and a second seal membrane above the blunt puncturing needles are arranged in a spaced mode, lateral grooves are formed in gaps between the surrounding pieces, and liquid flows to the lower portion of the disc from the upper portion of the disc through the lateral grooves; multiple through holes throughout the disc are further formed in the disc, pressure inside a cavity increases to puncture the second seal membrane forcibly through the puncturing needles, and finally, the liquid flows out of the center of the bottom inside the collector. The problem that according to an original capsule for making drinks, foam can not be controlled, so that too much foam is generated is solved.

Owner:HAIKOU WANKE FOOD

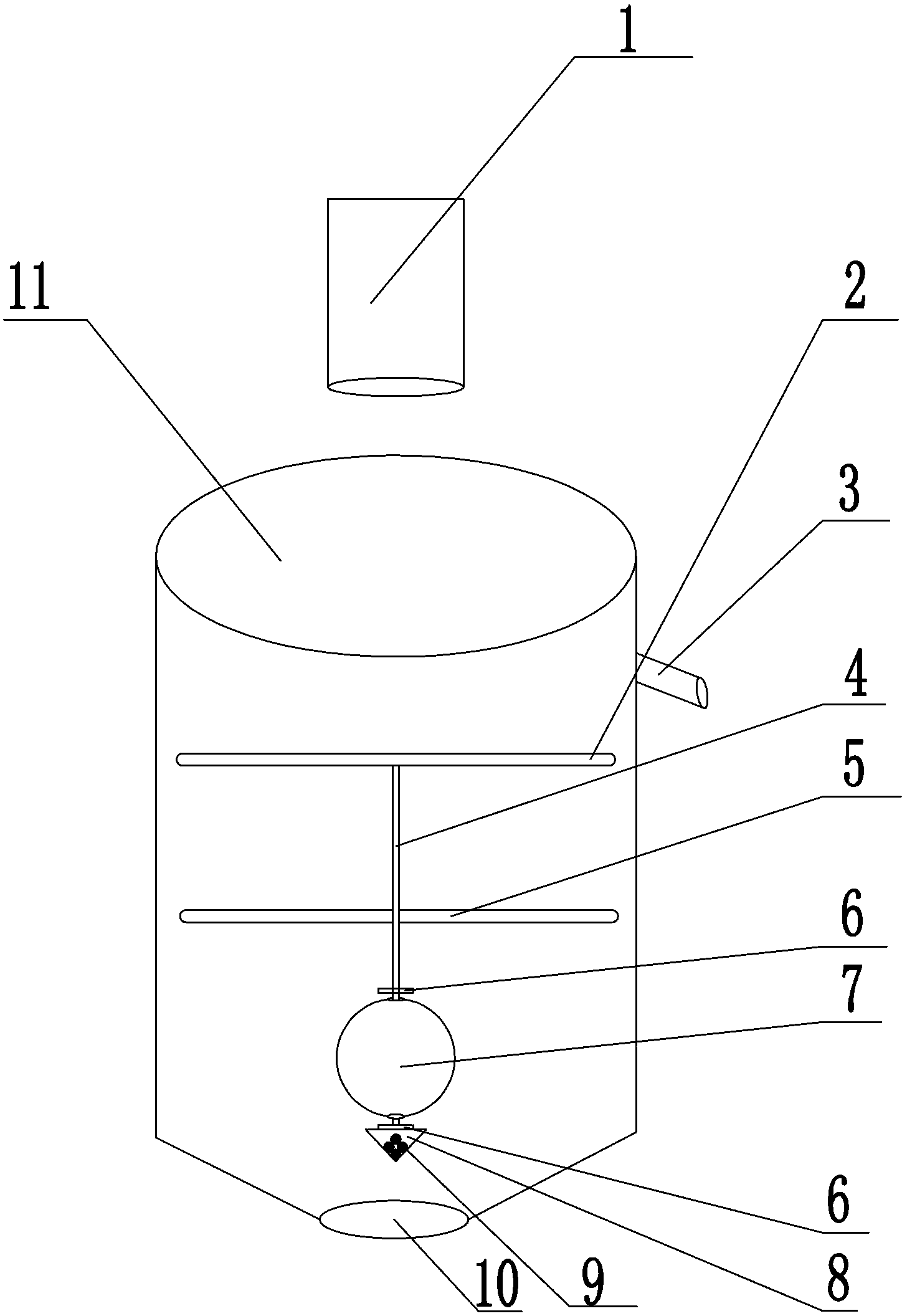

Device for measuring liquid level of flotation pulp

ActiveCN103398758AAvoid vertical fluctuationsAvoid Level Fluctuation EffectsFlotationLevel indicators by floatsCircular discObservational error

The invention belongs to the technical field of flotation liquid level measurement, in particular to a device for measuring the liquid level of flotation pulp. The device comprises a separation barrel, a measuring floater and a laser distance measuring sensor, wherein the measuring floater is arranged in the separation barrel, and the laser distance measuring sensor is arranged above the axial center line of the separation barrel. The device is characterized by further comprising a flushing water nozzle which is arranged on the top of the separation barrel, the measuring floater comprises a connecting rod, a reflecting disc, a balance disc, two limiting blocks, a balance weight cone and a floating ball, wherein the reflecting disc is arranged on the top of the connecting rod, the balance disc is arranged on the lower portion of the reflecting disc, the two limiting blocks are arranged at the bottom of the connecting rod, the balance weight cone is arranged at the bottom end of the connecting rod, and the floating ball is arranged between the two limiting blocks and connected with the connecting rod in a sliding mode. By the adoption of the novel measuring floater, the floating ball is prevented from being affected by the perpendicular fluctuation and the horizontal fluctuation of the pulp in the separation barrel, tangential flushing water is arranged on the top of the separation barrel, therefore, dynamical frictional resistance is reduced, the defoaming effect is achieved, measuring errors are small, and the liquid level of the pulp is stably and accurately measured.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

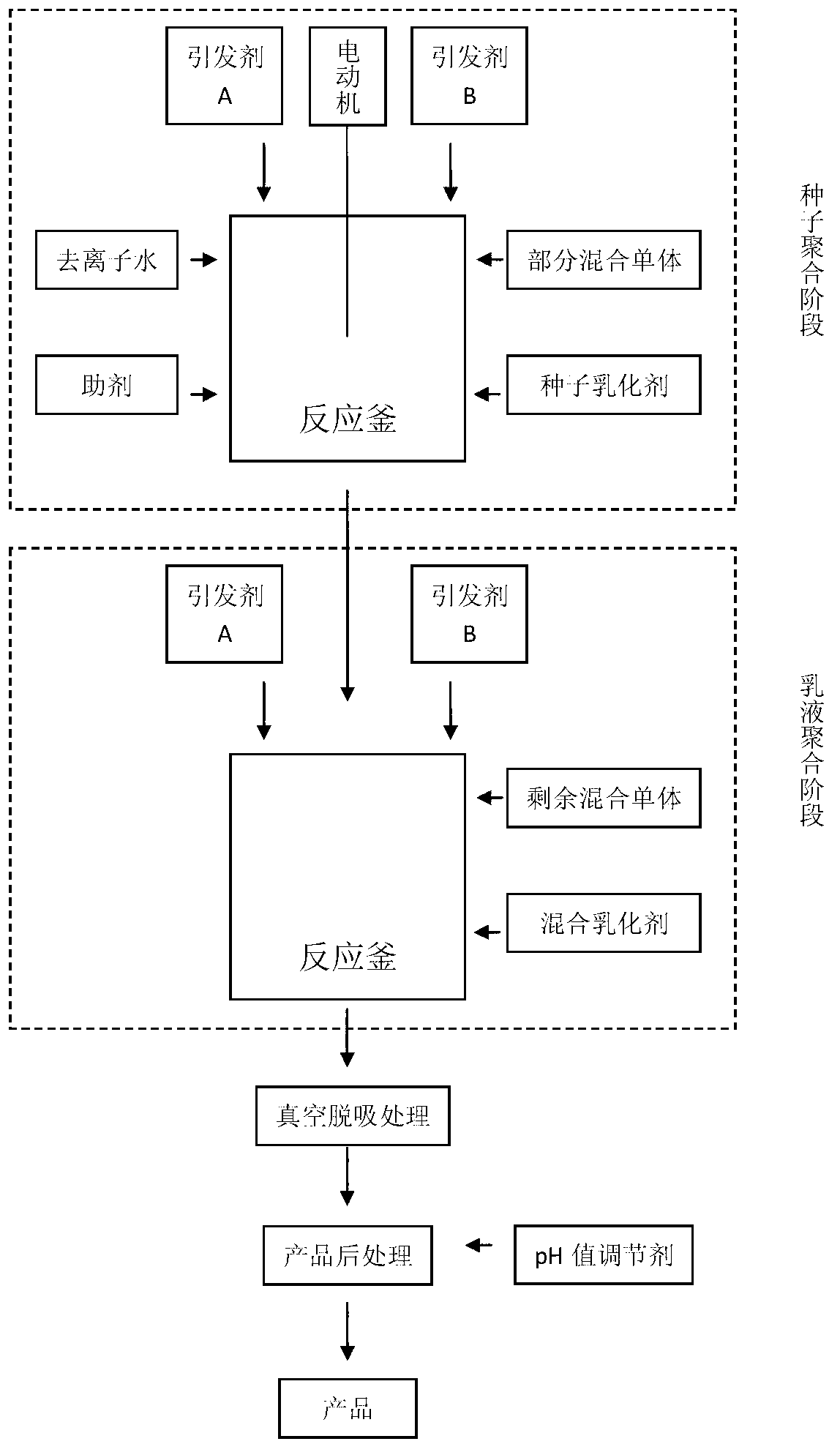

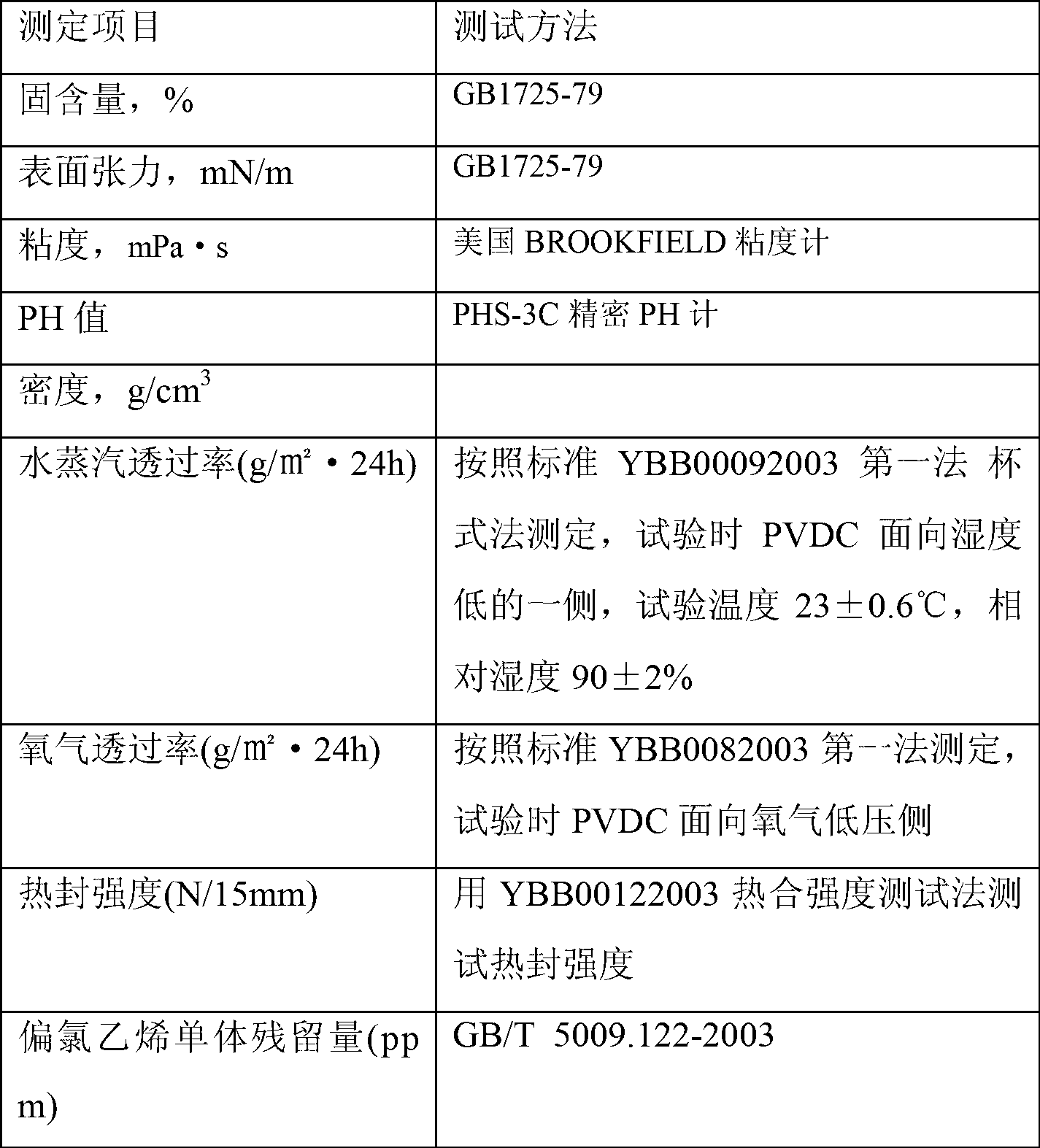

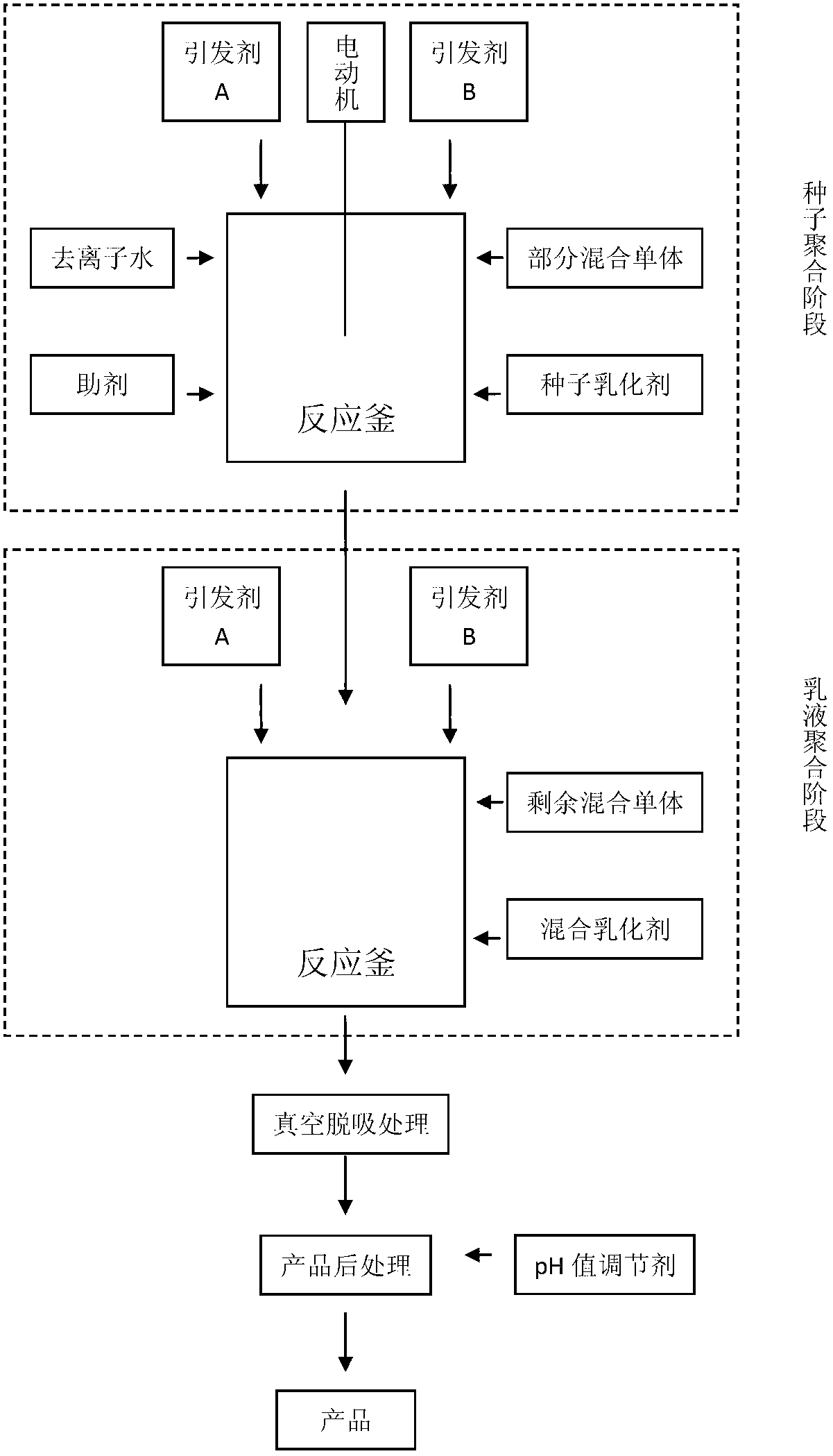

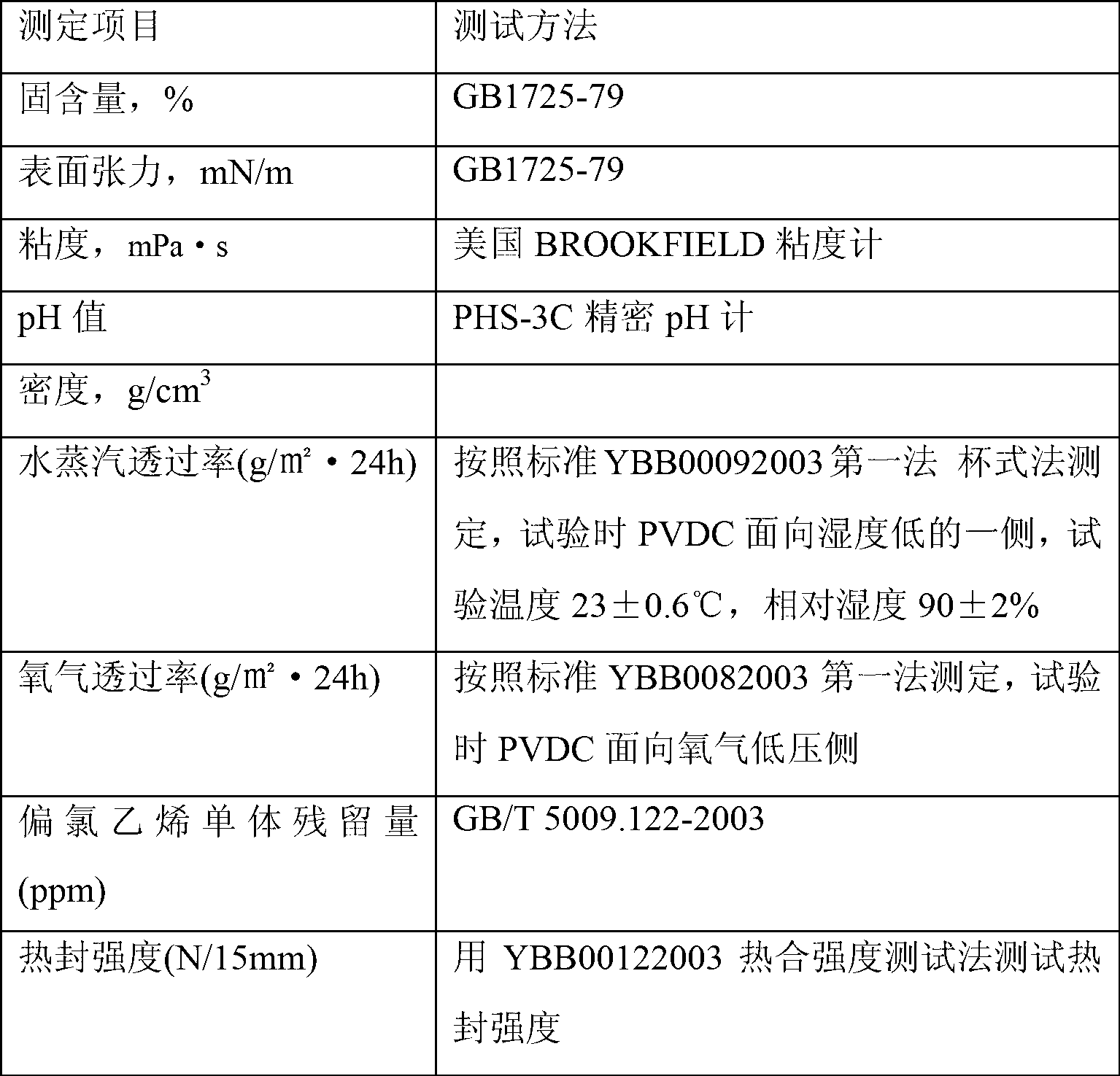

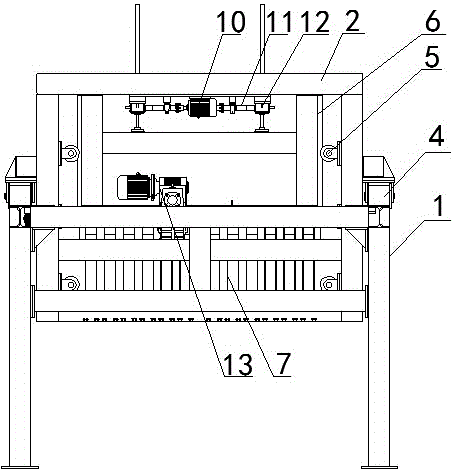

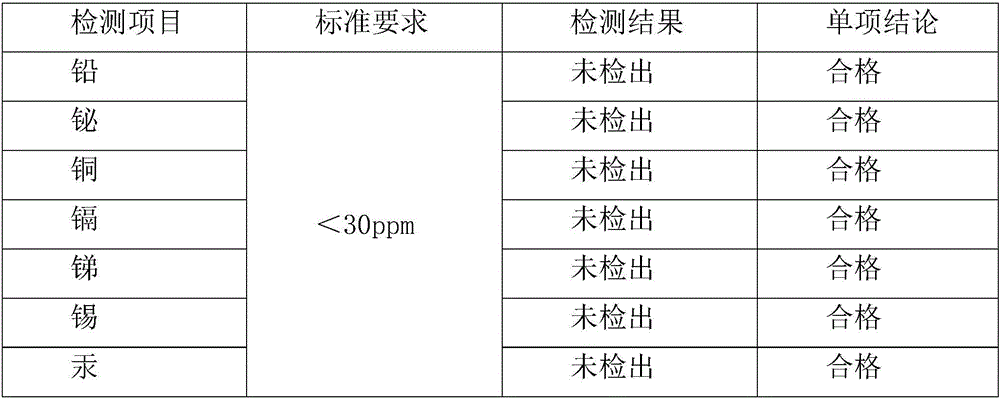

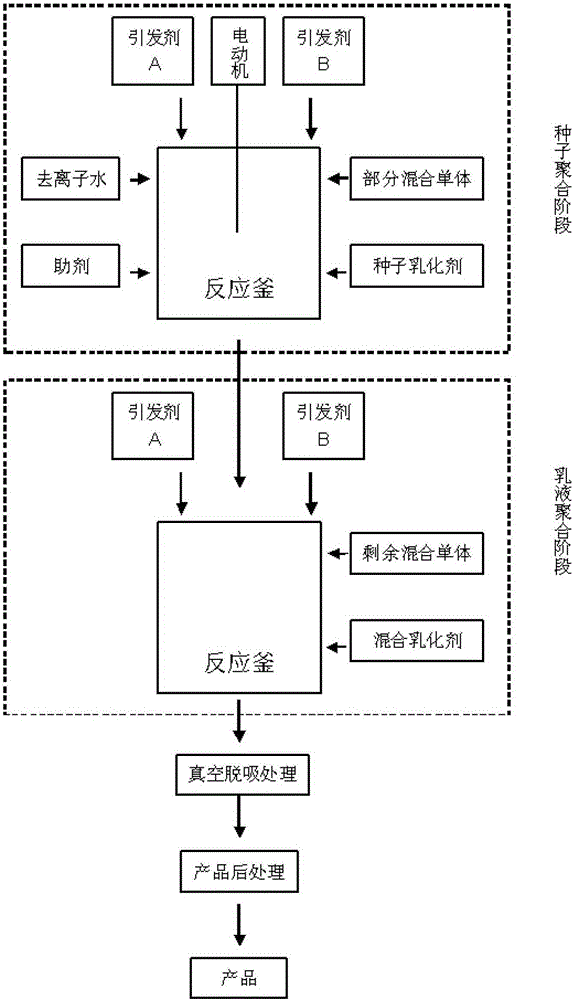

Polyvinyl dichloride (PVDC) latex special for kraft paper used for food packaging and preparation method thereof and application thereof

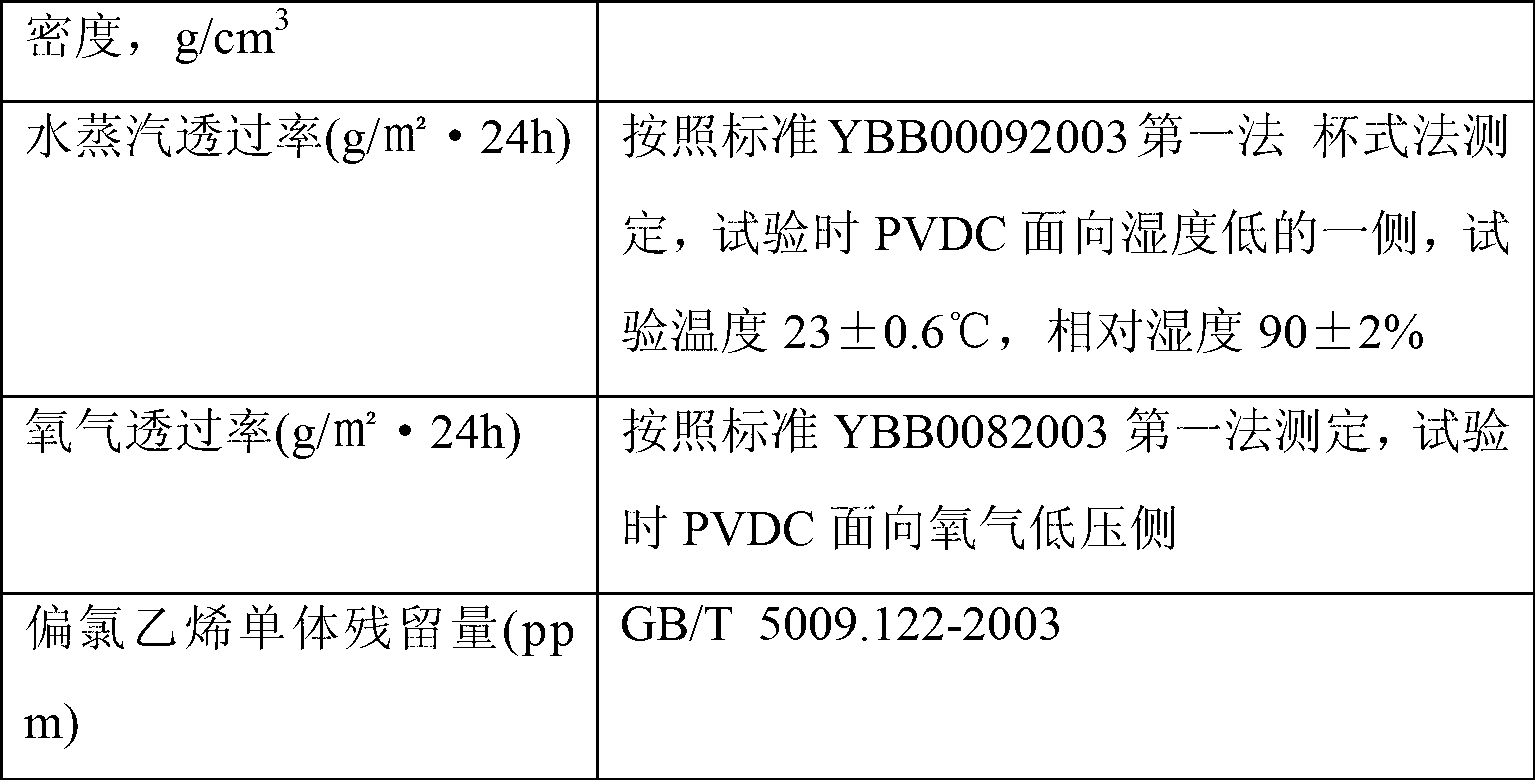

ActiveCN103059195AImprove stabilityLow monomer residuePaper coatingCoatingsOxygen permeabilityRelative humidity

The invention discloses a polyvinyl dichloride (PVDC) latex special for kraft paper used for food packaging and a preparation method thereof and application thereof. The kraft paper coated by the PVDC latex can be used for packaging of foods such as peanuts, melon seeds and walnuts. The PVDC latex is obtained by a mixed monomer, an auxiliary, an initiating agent, an emulsifying agent and a seeded emulsifying agent, wherein the mixed monomer contains a certain amount of vinylidene chloride, vinyl cyanide, butyl acrylate and acrylic acid, and the seeded emulsifying agent contains sodium dodecyl benzene sulfonate and a 2A-1 emulsifying agent. The prepared PVDC latex is good in stability and free of emulsification breaking and sediment after placed for 24 months under temperature of 30 DEG C and relative humidity (RH) of 70%. Monomer residual volume in the latex is lower. The kraft paper coated by the PVDC latex has the advantages of being environment-friendly, degradable, good in heat tightness, waterproof, damp proof and the like. When coating amount of the latex is 20g / m2, steam transit amount is less than or equal to 3g / m2.24h and oxygen permeability is less than or equal to 6g / m2.24h, monomer residual amount of the vinylidene chloride is less than or equal to 1ppm or not detected, and heating sealing intensity can reach 3N / 15mm.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Polyvinyl dichloride (PVDC) coating latex special for cigarette films and preparation method and application thereof

ActiveCN103059193AImprove stabilityLow monomer residueFlexible coversWrappersMicrocrystalline waxPolymer science

The invention discloses polyvinyl dichloride (PVDC) coating latex special for cigarette films and a preparation method and application of the PVDC coating latex special for the cigarette films. The PVDC latex is prepared from a certain amount of mixed monomers of vinylidene chloride, methyl acrylate and itaconic acid, a ptomotor, an initiator, an emulgator and a seed emulgator, and the preparation method is seed emulsion polymerization. According to the preparation method, microcrystalline wax capable of having a defoaming effect is added to enable the residual quantity of monomers in the latex is smaller. The cigarette films made of the latex has heat sealing performance and a high barrier property, and can maintain the scent of cigarettes and enable the cigarettes to not go bad and not be affected with damp. The heat sealing strength of the cigarette films is equal to or larger than 3N / 15mm, the coating weight is 3g / m<2>, the permeation amount of water vapor is equal to or smaller than 6g / m<2>*24h, the permeation volume of oxygen is equal to or smaller than 36g / m<2>*24h, and the residual quantity of vinylidene chloride monomers is equal to or smaller than 1mg / kg or is not detected.

Owner:海南聚能创新服务有限公司

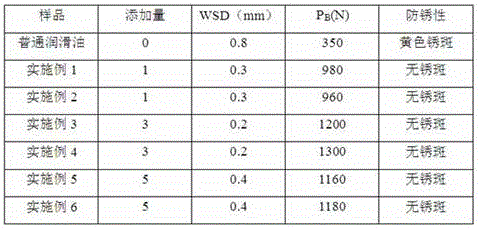

Graphene lubricant additive and preparation method thereof

ActiveCN106367164AAvoid it happening againPrevent precipitationAdditivesRare-earth elementAlkylphenol

The invention discloses a graphene lubricant additive. The graphene lubricant additive comprises the following raw materials by weight: 20-30 parts of polyving akohol, 5-10 parts of alkyl glycoside, 5-10 parts of alkylphenol polyoxyethylene ether, 1-3 parts of dimethyl silicone, 1-3 parts of rare earth element of which the particle size is 20-50 nm, 4-6 parts of Cu of which the particle size is 20-50 nm, 4-6 parts of SiO of which the particle size is 20-50 nm, 0.1-1 part of graphene, 1-3 parts of 2,6-ditertiary butyl-4-methylphenol, 1-3 parts of benzotriazole, 3-5 parts of sodium alkyl benzene sulfonate, 3-5 parts of 2-mercaptobenzothiazole, and 3-5 parts of sodium benzoate. The graphene lubricant additive is added to the lubricant for passivating the catalytic action of the metal to the oxidation reaction, and inhibiting the oxidation process of the oils, so that the anti-oxygenation effect of the lubricant is enhanced, the service life of the lubricant is prolonged, and the machine can be protected.

Owner:ZHENGZHOU UNIV OF IND TECH

Antifoam agent and production technique thereof

InactiveCN101310813AStrong anti-foaming abilityImprove permeabilityTransportation and packagingMixingParaffin waxEmulsion

The invention relates to a defoaming agent and a production process, and the defoaming agent is composed of components with the following parts by weight: 60 parts of dimethyl silicone oil, 15 parts of glyceryl polyether 3050, 15 parts of liquid paraffin and 10 parts of water. The production process comprises the following steps: 10 parts by weight of water is added in a reactor; 60 parts by weight of dimethyl silicone oil is slowly added in the reactor to be stirred at the normal temperature, thus forming emulsion-like solution; 15 parts by weight of glyceryl polyether 3050 is added to be continuously stirred at the normal temperature till the glyceryl polyether 3050 is fully dissolved in the emulsion-like solution; 15 parts by weight of liquid paraffin is further added to be continuously stirred at the normal temperature till the liquid paraffin is fully dissolved in the emulsion-like solution; the low-speed stirring is carried out for 30 minutes, the solution is kept at 18 DEG C to 22 DEG C, and the defoaming agent is prepared by carrying out the reactor for 24 hours. The defoaming agent and the production process have the advantages that: the production process has no waste gas, no waste water and no noise to be discharged to the outside; the product is fully dissolved in the water and non-toxic, thus not producing secondary environmental pollution, the product is used in a big water region, the defoaming speed is fast, the using amount is small and the cost is low.

Owner:闫承慧

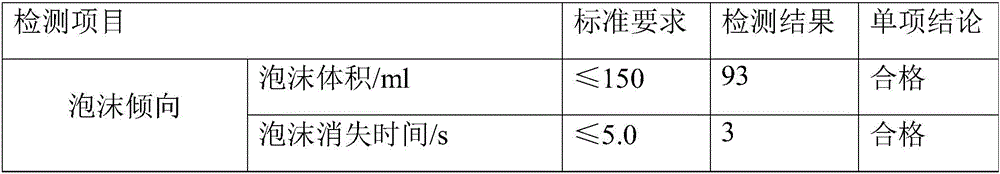

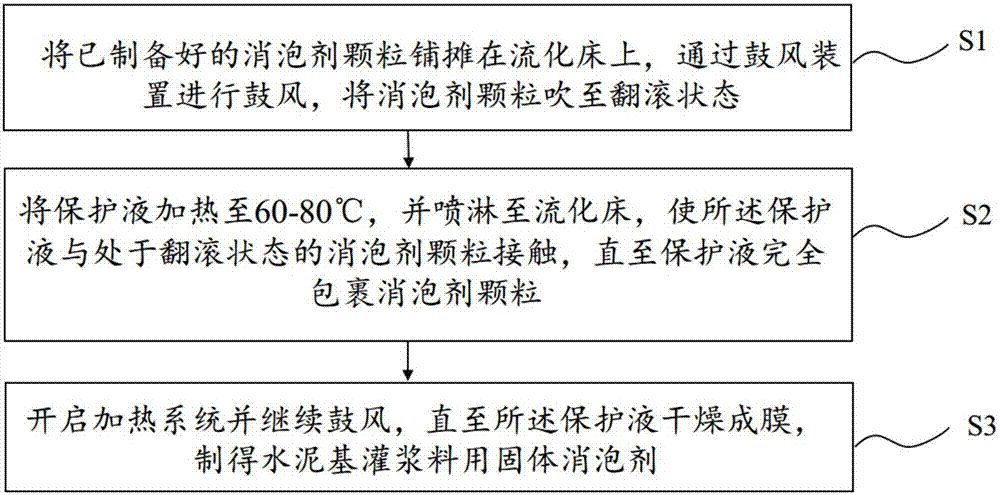

Motor vehicle antifreeze fluid and preparation method thereof

InactiveCN108192579AMitigates metal corrosionIncrease contact angleHeat-exchange elementsPre treatmentChemistry

The invention discloses a motor vehicle antifreeze fluid and a preparation method of the motor vehicle antifreeze fluid, and belongs to the field of auto accessories. A slow corrosion inhibitor is prepared from waste cooking oil through the processes of pretreatment, quaterisation reaction and the like, an imidazoline intermediate is obtained through the reaction of the slow corrosion inhibitor and hydroxyethyl ethylenediamine at the high temperature, an imidazoline quaternary ammonium corrosion inhibitor is obtained after the quaterisation of the imidazoline intermediate through benzyl chloride, an imidazole ring and a polar group in the molecule interact, the imidazoline quaternary ammonium corrosion inhibitor is preferentially adsorbed onto the surface of metal in the adsorption and isfavorable for forming a stable protection film on the surface of the metal, moreover, a dense hydrophobic film is formed far from the surface of the metal due to the free moving and extending of a hydrophobic branch and hinders the contact between a corrosive medium and a metal matrix, and the effect of relieving the metal corrosion is achieved. The motor vehicle antifreeze fluid solves the problems that the motor vehicle antifreeze fluid corrodes a metal part in the use process and also forms a scale easily at present.

Owner:吴迪

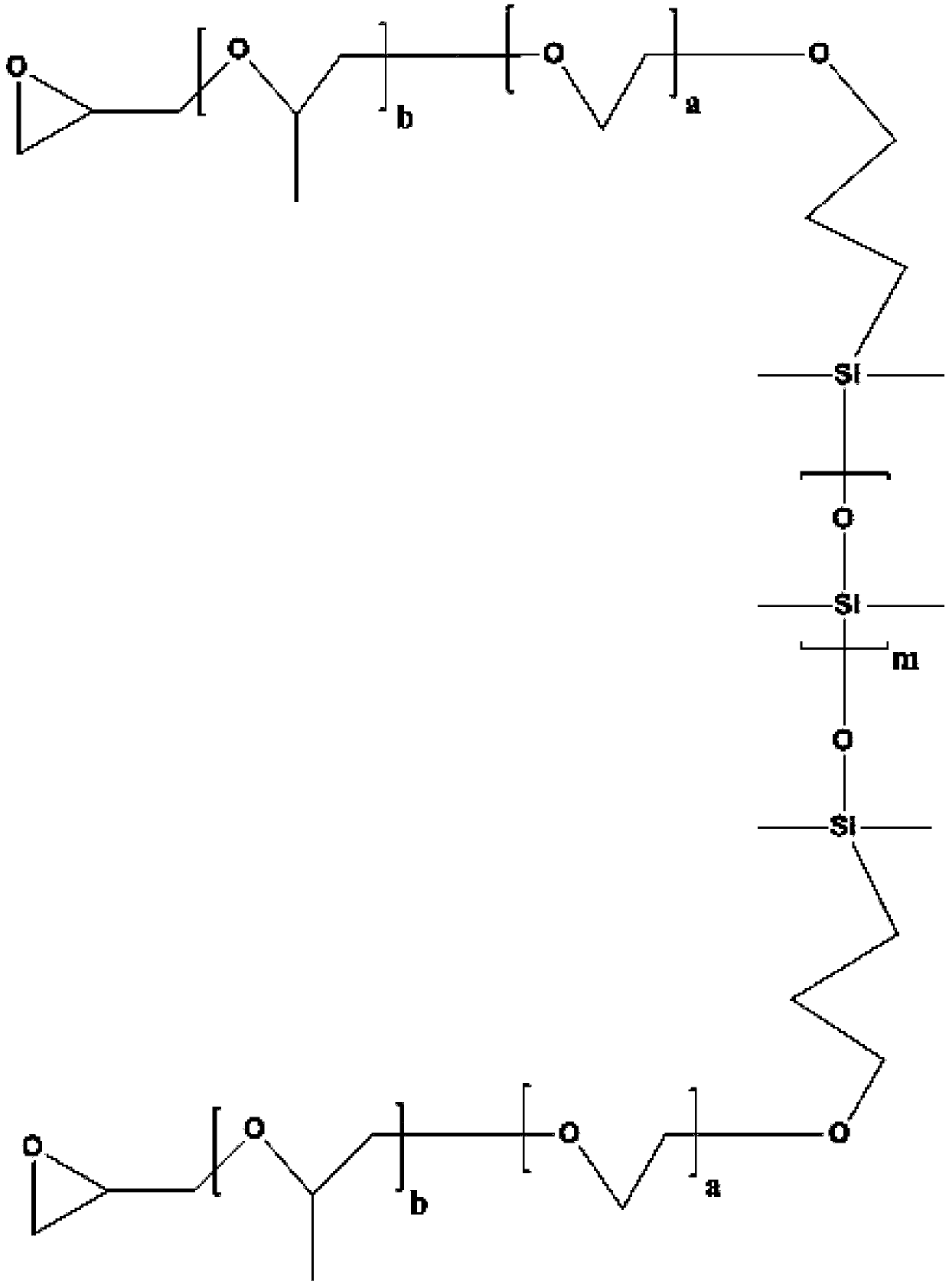

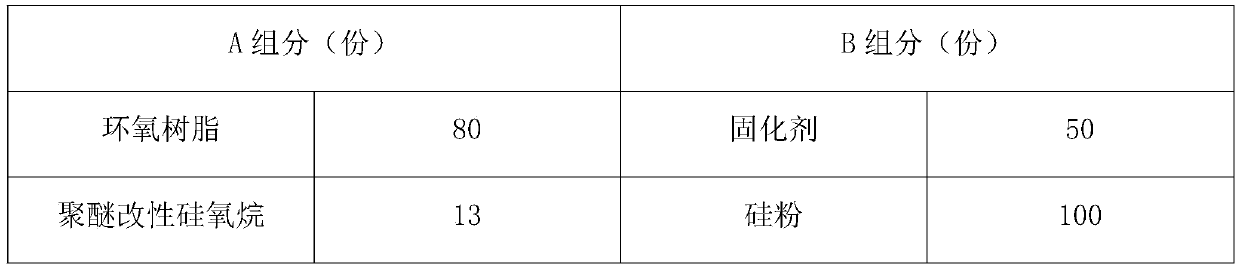

High-toughness bridge reinforcing structural adhesive

InactiveCN110903796AImprove toughnessGuaranteed toughnessNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceAdhesive

The invention provides a high-toughness bridge reinforcing structural adhesive. The structural adhesive is prepared from a component A and a component B by blending, wherein the component A comprisesepoxy resin, polyether modified siloxane and a filling material; the polyether modified siloxane has a structure of RSi(CH3)2(OSi(CH3)2)mOSi(CH3)2R, can significantly improve the toughness of the structural adhesive and greatly improve bending strength and tensile strength of a connection position, and has a defoaming effect as a surfactant, wherein m is in a range of 10 to 50, and R is an epoxy-terminated allyl polyether group and has a structure of -C3H6(C2H4O)a(C3H6O)b(C3H5O), wherein a is in a range of 10 to 50, and b is in a range of 10 to 40; and the component B comprises a curing agent,a filling material and a curing promoter; and a small amount of toner is added into the component B, so the color does not change in the long-term use process, and the appearance of the bridge is prevented from being influenced. The structural adhesive is simple in composition, easily available in raw materials and convenient in blending, can be properly adjusted in components according to needsto meet different requirements, can be used for sealing box girder surfaces in a preset segment matching method, and is applicable to popularization.

Owner:NANJING INST OF TECH

A kind of special latex for non-sticking lid of yogurt and its preparation method and application

The invention relates to a special latex for non-stick yogurt and its preparation method and application. The invention adopts a specific formula and process, so that the prepared latex has good barrier performance, prolongs the shelf life of yogurt, and has good waterproof performance , which solves the problem that yogurt is easy to stick to the yogurt lid, and the latex particle size distribution is uniform and has good stability. It can be stored at room temperature for 2 years without demulsification and precipitation. It is safe, environmentally friendly, and can be widely used in the yogurt packaging industry.

Owner:HAINAN SHINER IND

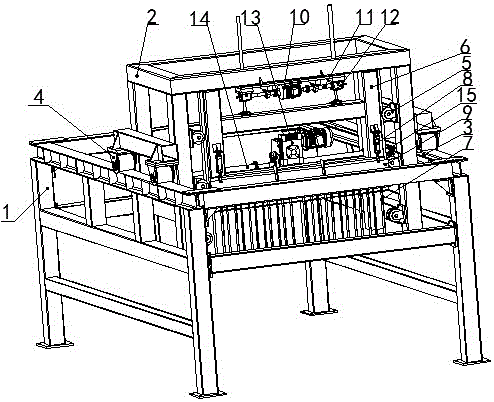

Pore removing device for light-weight wallboard

InactiveCN106182334AWalking smoothlyStable jobAuxillary shaping apparatusHorizontal transmissionDrive shaft

The invention discloses a pore removing device for a light-weight wallboard. The pore removing device comprises a rack; runners of a transverse walking support are arranged at the upper portions of a left vertical beam and a right vertical beam of the rack, at least three vertically-moving wheels are symmetrically arranged at the positions, on the inner walls of the two vertical beams, of the front end of the transverse walking support, a vertical beam is arranged on the inner side of each vertically-moving wheel, and a plurality of vibration plates are connected to the bottoms of the two vertical beams; air cylinders are arranged at the middle portions of the side walls of the front sides of the two vertical beams, the lower ends of the air cylinders are connected with a scraping plate; a double-shaft motor is arranged on the lower side of a transverse beam at the upper portion of the back end of the transverse walking support, and an output end of the double-shaft motor is connected with two screw lifters through lifter transmission shafts; and a hollow shaft reducer is arranged at the lower portion of the transverse walking support, a horizontal transmission shaft is connected to the hollow shaft reducer, and a gear is arranged at the end of the horizontal transmission shaft and meshed with racks arranged on the inner walls on the left side and the right side of the rack. By means of the above structure, the effects of being simple in structure, safe, high in efficiency, flexible in operation and higher in automation degree, saving time and labor, achieving mechanization and being capable of removing bubbles so as to guarantee the wallboard quality are achieved.

Owner:SHANDONG TIANYI MACHINERY

Environment-friendly nontoxic normal-temperature composite degreasing adsorbent for metal electroplating pretreatment and production method of environment-friendly nontoxic normal-temperature composite degreasing adsorbent

The invention discloses an environment-friendly nontoxic normal-temperature composite degreasing adsorbent for metal electroplating pretreatment. Each liter of the environment-friendly nontoxic normal-temperature composite degreasing adsorbent contains the following raw materials in parts by weight: 2.6-2.8 of isomeric alcohol polyoxyethylene ether, 3.4-3.7 of FMES, 1.4-1.7 of dodecyl glucoside, 4-5 of a polyethylenimine solution, 0.6-0.7 of sodium hydroxide, 3.3-3.4 of sodium citrate, 0.5-0.7 of sodium nitrate, 1.2-1.4 of aniline, 2-4 of orange oil, 2-3 of corn starch, 4-6 of quartz sand, 7-9 of sorghum stalks, 0.6-0.8 of mashed apple and a proper amount of water. A novel metal degreasing agent integrated with degreasing property, corrosion resistance and filterability is prepared by compounding the isomeric alcohol polyoxyethylene ether and the FMES, adding the compound into the raw materials, adding mixed filler with high adsorptivity and matching the mixed filler with other effective adjuvants, has the characteristics of environment friendliness, nontoxicity, degreasing thoroughness, high cleaning speed as well as energy and labor saving and brings great convenience for factory production.

Owner:当涂县金龙凤科技股份有限公司

Polyvinyl dichloride (PVDC) latex special for slick paper used for food packaging and preparation method thereof and application thereof

ActiveCN103059194AImprove stabilityEasy to wrapPaper coatingCoatingsMicrocrystalline waxSODIUM DODECYL BENZENE SULFONATE

The invention discloses a polyvinyl dichloride (PVDC) latex special for slick paper used for food packaging and a preparation method thereof and application thereof. The PVDC latex is obtained by a mixed monomer, an auxiliary, an initiating agent, a mixed type emulsifying agent and a seeded emulsifying agent, wherein the mixed monomer contains vinylidene chloride, vinyl cyanide and acrylic acid, the mixed type emulsifying agent contains a COPS-1 emulsifying agent and a 2A-1 emulsifying agent, and the seeded emulsifying agent contains sodium dodecyl benzene sulfonate. Due to the facts that according to the PVDC latex, the mixed type emulsifying agent containing reaction type emulsifying agents is adopted, and the acrylic acid is added together with the reaction type emulsifying agents in an emulsion polymerization stage, the prepared PVDC latex is good in stability. Microcrystalline wax which has a function of defoaming enables monomer residual volume in the latex to be lower. The slick paper coated with the PVDC latex is environment-friendly, degradable, good in barrier property and oil resistance, capable of reaching an effect of aluminum foil packaging materials when serving as packaging materials, and capable of being used for food packaging. When coating amount of the latex is 12g / m2, steam transit amount is less than or equal to 3g / m2.24h and oxygen permeability is less than or equal to 7g / m2.24h. When the coating amount is added to be 15g / m2, effects of aluminum foil packaging materials which are used for food packaging can be achieved.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

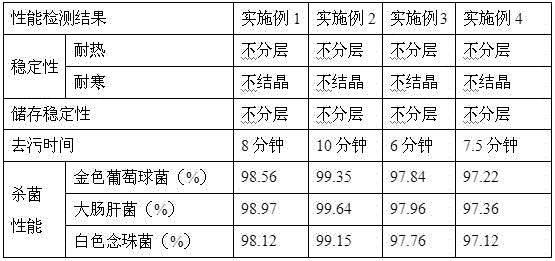

Decontaminating bactericidal clothing detergent

InactiveCN105820888AProtect colorPlay a defoaming roleOrganic detergent compounding agentsDetergent perfumesBiotechnologyPolyhexamethylene guanidine

The invention relates to a decontaminating bactericidal clothing detergent, belonging to the technical field of daily chemical washing. The decontaminating bactericidal clothing detergent is composed of the following effective components in percentage by weight: 2-10% of bioenzyme preparation, 2-8% of organosilicon conditioner, 0.5-5% of polycarboxylic acid, 3-12% of PHMG (polyhexamethylene guanidine) bactericide, 1-8% of color fixative, 0.1-1% of scent and 70-85% of deionized water. The decontaminating bactericidal clothing detergent has the advantages of favorable decontaminating effect, high decontaminating power, less and flushable foam, no irritation and no toxicity, does not damage the clothing, can avoid yellowing, discoloration and hardening, can effectively remove various fungi, does not hurt the hands due to mild properties, does not hurt the skin, is nontoxic for the human body and environment, and conforms to the environmental requirements.

Owner:刘爱华

Nanometer cooling water additive and preparation method thereof

ActiveCN106010471AGood dispersionFast heat absorptionHeat-exchange elementsRare-earth elementPhosphoric acid

The invention discloses a nanometer cooling water additive. The nanometer cooling water additive comprises the following raw materials by weight: 30 to 40 parts of alkaline ionized water with a pH value of 11 to 13.5, 25 to 35 parts of glycol, 15 to 20 parts of propylene glycol, 5 to 10 parts of alkyl glycoside, 5 to 8 parts of an rare earth element with a particle size of 20 to 50 nm, 2 to 3 parts of Cu with a particle size of 20 to 50 nm, 2 to 3 parts of SiO2 with a particle size of 20 to 50 nm, 0.1 to 0.3 part of ammonium dihydrogen phosphate, 3 to 5 parts of sodium silicate, 0.1 to 0.2 part of sodium molybdate, 0.1 to 0.2 part of benzotriazol, 3 to 5 parts of sodium benzoate, 2 to 3 parts of amino trimethylene phosphoric acid, 4 to 6 parts of p-hydroxybenzyl methyl ether and 0.01 to 0.05 part of fluorescent orange. According to detection results, the nanometer cooling water additive has a freezing point of 40 DEG or below and a boiling point of 115 DEG C or above.

Owner:广州和新实业有限公司

Motor vehicle tail gas purifying assistant and production method thereof

ActiveCN101543743AImprove the lubrication effectImprove stabilityTransportation and packagingDispersed particle separationAlcoholGranularity

The invention relates to an assistant used for producing a motor vehicle tail gas purifying converter, containing fatty acid, fatty acid glyceride, alcohol group or phenolic group polyethenoxy ether. The invention also relates to a production method of the assistant, which comprises the following steps: firstly, placing the fatty acid and the fatty acid glyceride into a reaction kettle to be heated to 60-80 DEG C; secondly, stirring the mixture for 2-3h at 60-80 DEG C until the mixture changes into transparency material; thirdly, adding the alcohol group or phenolic group polyethenoxy ether into the reaction kettle, stirring the mixture for 2-4h at 60-80 DEG C; fourthly, giving off the product of reaction before cooling, crushing solid after the product of reaction is naturally cooled so as to obtain the assistant. The invention shortens the milling time because assistant accounting for 8-20 percent of the weigh of the grout is added into the grout, can obtain the grout with uniform granularity, stable dispersion, no foam, and good levelability and easy loading. The invention has better comprehensive effect.

Owner:江门市资迪科技环保有限公司

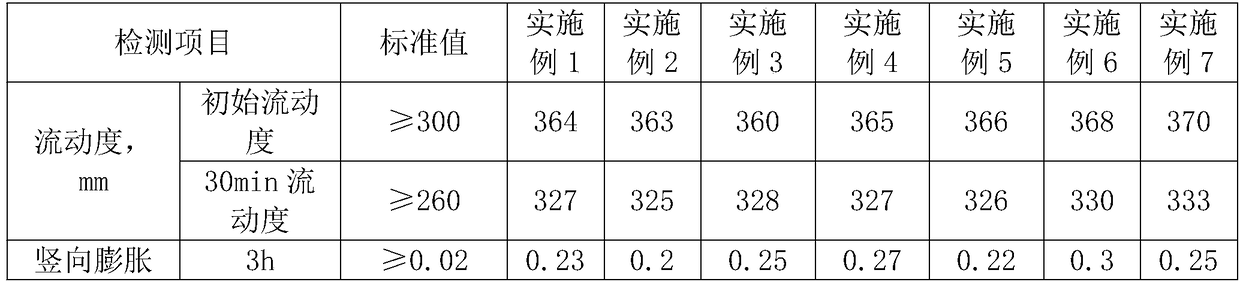

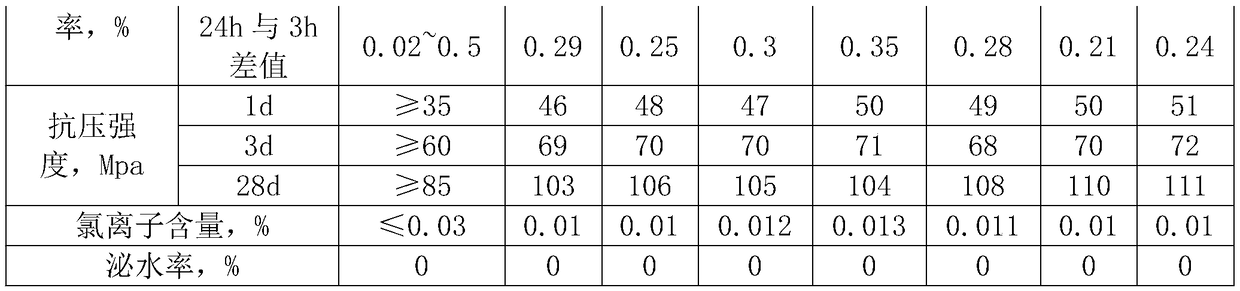

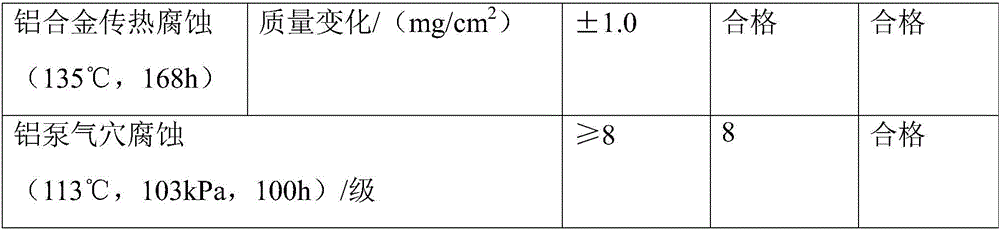

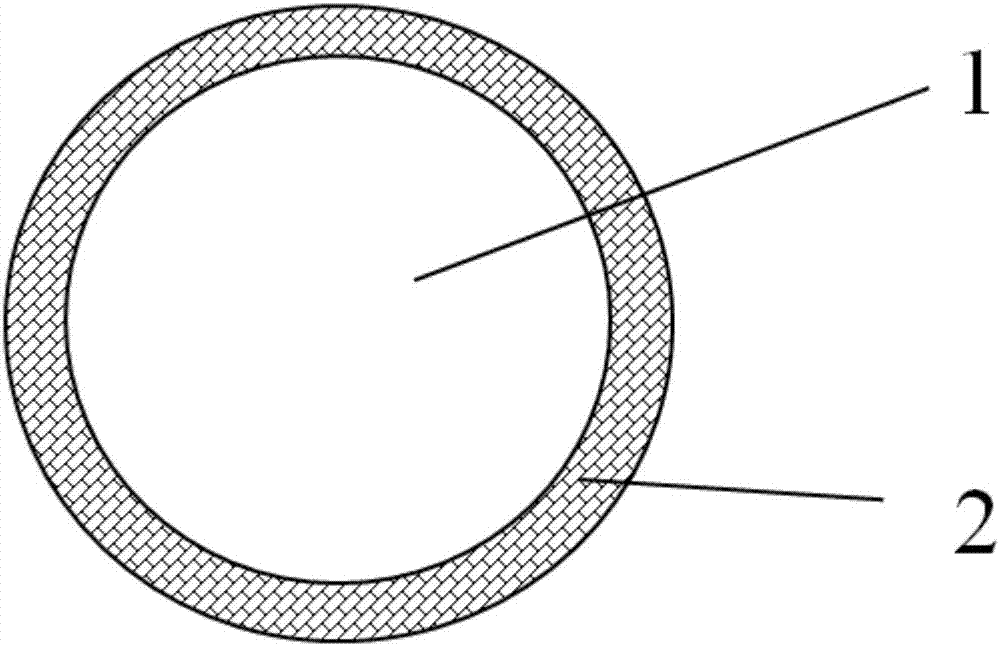

Solid defoamer for cement-based grouting materials and preparation method thereof

The invention discloses a solid defoamer for cement-based grouting materials. The defoamer is composed of defoamer particles and a protective film wrapping the defoamer particles, and the protective film is a water-soluble polymer film. Accordingly, the invention also discloses a preparation method of the solid defoamer for cement-based grouting materials. The defoamer with excellent alkali resistance is made directed at the special use conditions of cement-based grouting materials, the surfaces of the solid particles are wrapped with the protective film, thus effectively delaying the release of defoamer effective components and prolonging the product shelf life, during use, the solid defoamer can be quickly dissolved in a water phase and rapidly release effective components to play a defoaming role.

Owner:SUZHOU XINGBANG CHEM BUILDING MATERIALS

Normal-temperature composite oil removing adsorbent for selenium-enriched metal plating pretreatment and making method of normal-temperature composite oil removing adsorbent

The invention discloses normal-temperature composite oil removing adsorbent for selenium-enriched metal plating pretreatment. Each litre of the normal-temperature composite oil removing adsorbent is prepared from, by weight, 2.5-3.4 parts of isomeric alcohol ethoxylates, 2.9-3.4 parts of FMES, 1.9-2.4 parts of coconut diethanol amide, 0.5-0.8 part of sodium hydroxide, 3.3-3.6 parts of sodium citrate, 2-4 parts of coconut oil, 0.5-0.8 part of potassium ferrate, 0.4-0.6 part of oxalic acid, 1.2-1.5 parts of aluminum silicate fiber, 3-4 parts of attapulgite, 6-8 parts of selenium-enriched wheat straw, 1-2 parts of guar gum, 2-3 parts of sweet potato starch and a proper amount of water. According to the normal-temperature composite oil removing adsorbent for selenium-enriched metal plating pretreatment, isomeric alcohol ethoxylates and FMES are added into raw materials in a composite manner, high-adsorbability mixed filler is added, other effective auxiliaries are compatible, and the prepared novel metal oil removing agent integrating oil removing, corrosion prevention and filtration is rich in selenium, free of toxicity, phosphorus, pungent smell and residue, low in foam, capable of being completely biodegraded and high in oil contamination removing capacity.

Owner:当涂县金龙凤科技股份有限公司

Concrete liquid accelerator

The invention belongs to the technical field of accelerators, and particularly relates to a concrete liquid accelerator. Aiming at problems in the prior art that the existing powdery accelerator has the disadvantages of low dissolving speed, difficult dispersion and the like, and can be only applied to dry spraying process construction; most of the powdery accelerators contain strong alkaline substances so that eyes and skin of construction workers are easily injured and concrete strength is easily reduced, a scheme is provided, wherein the concrete liquid accelerator comprises 35-45 parts ofaluminum sulfate, 3-9 parts of sodium fluoride, 6-12 parts of a defoaming agent, 7-10 parts of a stabilizer, 5-10 parts of glycerol, 10-15 parts of hydroxycarboxylic acid, 4-10 parts of a preservative, 5-12 parts of a thickener, 10-20 parts of a peculiar smell adsorbent and 35-55 parts of water. The concrete liquid accelerator is convenient to prepare, the dissolving speed is increased, the working efficiency is improved, workers and the environment are not damaged, the anti-corrosion performance of concrete is improved, and the strength of the concrete is enhanced.

Owner:SHANXI HUANGTENG CHEM

Wood door adhesive preprocessing equipment

InactiveCN111760498ANot easy to produceNot affected by blending effectsFlow mixersRotary stirring mixersElectric machineMixing effect

The invention provides wood door adhesive preprocessing equipment. The equipment comprises a shell, wherein a feeding hole is formed in one side of the upper surface of the shell; an adhesive inlet and an adhesive outlet are respectively formed in the upper and lower ends of the side surface; at least one group of guide pipes are vertically arranged in the shell; a piston plate sleeves the guide pipes; space in the shell is divided into an upper chamber and a lower chamber by the piston plate; the piston plate can move up and down along the guide pipes; a first driving motor is mounted at thecenter of the piston plate; a mixing disc is mounted at the front end of a rotating shaft of the first driving motor; and the upper surface of the piston plate 8 is connected with a power supply wireextending to the outer side of the top of the shell. The interior of the shell is divided into the upper chamber and the lower chamber through the piston plate; through cooperation between the two chambers and the structure of the piston plate and the hollow guide pipes in the piston plate, raw materials circulate between the two chambers in a reciprocating mode and are mixed through movement andextrusion of the piston plate, so mixing effect is uniform, bubbles are not prone to being generated, and the phenomenon that mixing efficiency is low due to layering caused by different qualities ofthe raw materials can be effectively avoided; and the equipment has good development prospects.

Owner:宿州洛通木业有限公司

Adhesive and applications thereof, large power LED bulb lamp, and preparation method thereof

ActiveCN106032460AIncrease contact areaImprove heat dissipationNon-macromolecular adhesive additivesPoint-like light sourceThermal conductivityAdhesive

The invention provides an adhesive and applications thereof, a large power LED bulb lamp, and a preparation method thereof. The adhesive comprises the following components in parts by weight: 70 to 80 parts of component A, 5 to 15 parts of component B, and 10 to 15 parts of volatilizing agent. The component A comprises the following components in percentage by weight: 50 to 70% of alpha,omega-hydroxyl terminated dimethyl siloxane, 10 to 30% of first thermal conductive particles, and 20 to 40% of second thermal conductive particles. The component B comprises the following components in percentage by weight: 18 to 27% of polydimethyl siloxane, 4 to 8% of monomer fusing agent, 63 to 75% of third thermal conductive particles, and 2 to 7% of thermal conductivity aid. During the curing process of the adhesive, the volatilizing agent can form a vacuum force between the substrate where the adhesive is painted and a heat radiator, thus the substrate and the heat radiator can be bonded more tightly, the effective contact area is increased, and the heat radiating effect of the large power LED bulb lamp is effectively improved, so that the LED bulb lamp can sustain larger power.

Owner:CHANGZHOU INST OF TECH RES FOR SOLID STATE LIGHTING

Stain-resistant normal-temperature composite oil removal adsorbent for metal electroplating pretreatment and preparation method of stain-resistant normal-temperature composite oil removal adsorbent

The invention discloses a stain-resistant normal-temperature composite oil removal adsorbent for metal electroplating pretreatment. Each litre of the adsorbent is prepared from the following raw materials in parts by weight: 2.9-3.1 parts of isomeric alcohol polyoxyethylene ether, 3.3-3.7 parts of FMES, 0.7-0.8 parts of sodium hydroxide, 3.6-3.7 parts of sodium citrate, 1.1-1.4 parts of oleamide, 1.7-1.9 parts of sodium laureth sulfate, 0.6-0.7 parts of aluminum sulfate, 0.4-0.6 parts of nanometer titania, 1.6-1.8 parts of methyl triethoxysilane, 5-7 parts of sunflower straw, 4-6 parts of sepiolite, 1-2 parts of needles of bleached kraft pulp and a proper amount of water. Isomeric alcohol polyoxyethylene ether and FMES are composited and added to raw materials and interact synergistically, high-absorptivity mixed filler is added and compatible with other effective aids, and accordingly, the novel metal oil removal adsorbent integrating oil removal, corrosion resistance and filtrability is prepared. The oil removal adsorbent has the characteristics of being stain resistant, good in oil removal effect and pollution-free.

Owner:当涂县金龙凤科技股份有限公司

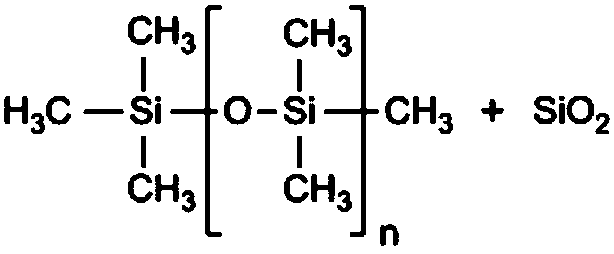

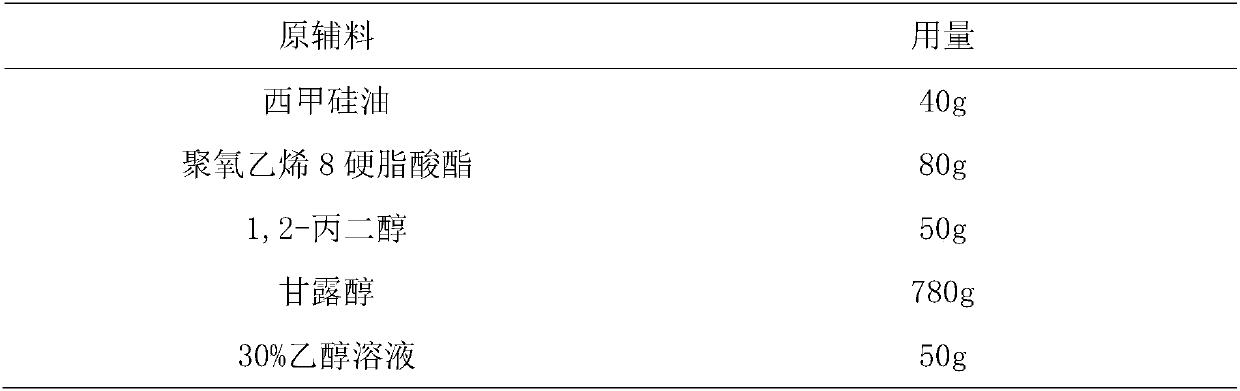

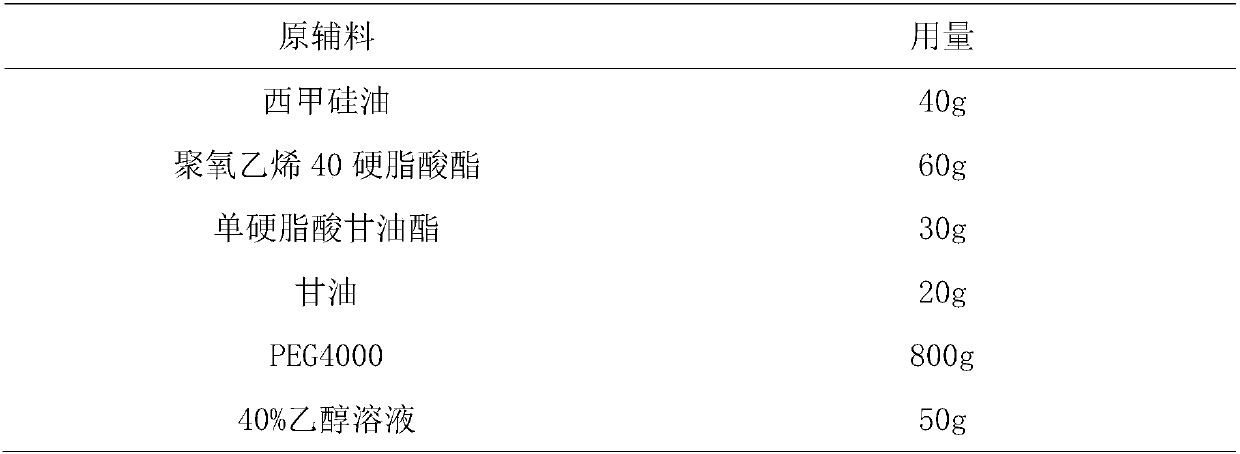

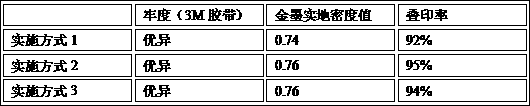

A kind of simethicone solid self-emulsifying preparation and preparation technology thereof

ActiveCN105878183BImprove hydrophobicityAct as an oil phaseDigestive systemSilicon compound active ingredientsSolubilityDissolution

The invention discloses a simethicone solid self-emulsifying preparation. The preparation is prepared from, by weight, 2.0-6.0% of simethicone, 2.0-30.0% of emulsifier, 1.0-20.0% of auxiliary emulsifier, 50.0-90.0% of pharmaceutically-acceptable solid adsorption material and 0-10.0% of wetting agent. The invention further provides a preparation method of the simethicone solid self-emulsifying preparation. The method is easy and convenient to operate, low in cost and suitable for industrial production; the obtained product has the advantages of being good in taste, uniform in distribution, high in solubility, stable in quality and the like; the preparation is rapid in dissolution, easy to take, rapid in effect and suitable for the aged, children and people who have difficulty in swallowing, the compliance of patients is increased, and the preparation has more advantages on the aspects of packaging, carrying, transporting and the like compared with a traditional liquid simethicone suspension and emulsifier and has good application prospects on the aspects of treating symptoms such as abdominal distension, abdominal discomfort, dyspepsia and postoperative abdominal distension caused when gas gathers in the abdomen.

Owner:SHANDONG UNIV

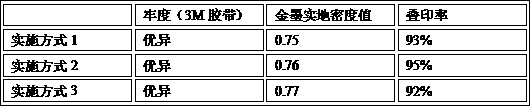

Water-based gold ink suitable for overprinting and preparation method thereof

The invention relates to the field of printing ink, and discloses water-based gold ink suitable for overprinting and a preparation method thereof. The water-based gold ink is prepared from, by weight,15-25 parts of bronze powder, 30-50 parts of a water-based binder, 15-25 parts of absolute ethyl alcohol, 10-25 parts of deionized water, 2-5 parts of a surfactant and 1-3 parts of auxiliaries. The preparation method comprises the following steps: mixing and stirring bronze powder and a mixed solvent of absolute ethyl alcohol and deionized water in parts by weight, fully wetting and dispersing the materials, soaking the prepared copper paste for 24 hours, adding the water-based binder into the copper paste in parts by weight, carrying out stirring at a high speed, fully dispersing the mixtureand adding the surfactant and auxiliaries into the materials, carrying out stirring at a high speed, and uniformly mixing the materials to obtain the water-based gold ink. Compared with the prior art, the phenomenon that copper powder undergoes an oxidation reaction when meeting water to generate verdigris is effectively avoided, the surface tension of the water-based gold ink can be adjusted byadjusting the proportion of the surfactant in the gold ink, and the overprinting problem of the gold ink can be effectively solved.

Owner:JIANGSU JIN JIA NEW PACKAGING MATERIALS CO LTD

Photochromic architectural glass and preparation method thereof

InactiveCN108929497ATo achieve the effect of light isolationGood light-shielding effectArchitectural glassCopper oxide

The invention discloses photochromic architectural glass and a preparation method thereof, and relates to the field of building materials. The photochromic architectural glass comprises the followingraw materials in parts by weight: 30-50 parts of a styrene-methyl methacrylate copolymer, 10-20 parts of organic glass, 0.1-0.3 part of an initiator, 50-60 parts of titanium dioxide, 6-8 parts of tungsten oxide, 6-8 parts of sodium bromide, 0.2-0.4 part of copper oxide, 0.3-0.5 part of an antifoaming agent, and 0.4-0.6 part of a catalyst. The photochromic architectural glass disclosed by the invention has significantly-improved quality, mechanical impact strength and transparency compared with glass prepared by a conventional process, and silver bromide in the raw material component can be decomposed in the case of strong light, so that the light transmittance of the architectural glass disclosed by the invention is obviously reduced, and the architectural glass has a light-insulating effect.

Owner:合肥卓创新材料有限公司

A kind of graphene lubricating oil additive and preparation method thereof

The invention discloses a graphene lubricant additive. The graphene lubricant additive comprises the following raw materials by weight: 20-30 parts of polyving akohol, 5-10 parts of alkyl glycoside, 5-10 parts of alkylphenol polyoxyethylene ether, 1-3 parts of dimethyl silicone, 1-3 parts of rare earth element of which the particle size is 20-50 nm, 4-6 parts of Cu of which the particle size is 20-50 nm, 4-6 parts of SiO of which the particle size is 20-50 nm, 0.1-1 part of graphene, 1-3 parts of 2,6-ditertiary butyl-4-methylphenol, 1-3 parts of benzotriazole, 3-5 parts of sodium alkyl benzene sulfonate, 3-5 parts of 2-mercaptobenzothiazole, and 3-5 parts of sodium benzoate. The graphene lubricant additive is added to the lubricant for passivating the catalytic action of the metal to the oxidation reaction, and inhibiting the oxidation process of the oils, so that the anti-oxygenation effect of the lubricant is enhanced, the service life of the lubricant is prolonged, and the machine can be protected.

Owner:ZHENGZHOU UNIV OF IND TECH

Latex for food packaging and its preparation method and application

The invention discloses latex for packaging foods, a preparation method of the latex, and application of the latex. According to the preparation method, vinylidene chloride, methyl methacrylate and methacrylic acid with a certain amount are adopted and used as mixing monomers, a specific seed emulsifier and a mixed emulsifier are selected, and the special seed emulsion polymerizing method is carried out, thus obtaining the latex. The latex can be directly coated on a food packaging film base material, so that a primer can be saved, and the production cost in food package can be greatly saved; the food packaging film made from the latex has high barrier performance, oil resistance, anticorrosive performance, odor barrier performance, moisture-proofing performance and mould-proofing performance, can be in direct contact with the foods, has the fire resistance, and is low in residues of the monomers. The latex is excellent in stability.

Owner:海南海达丰实业有限公司

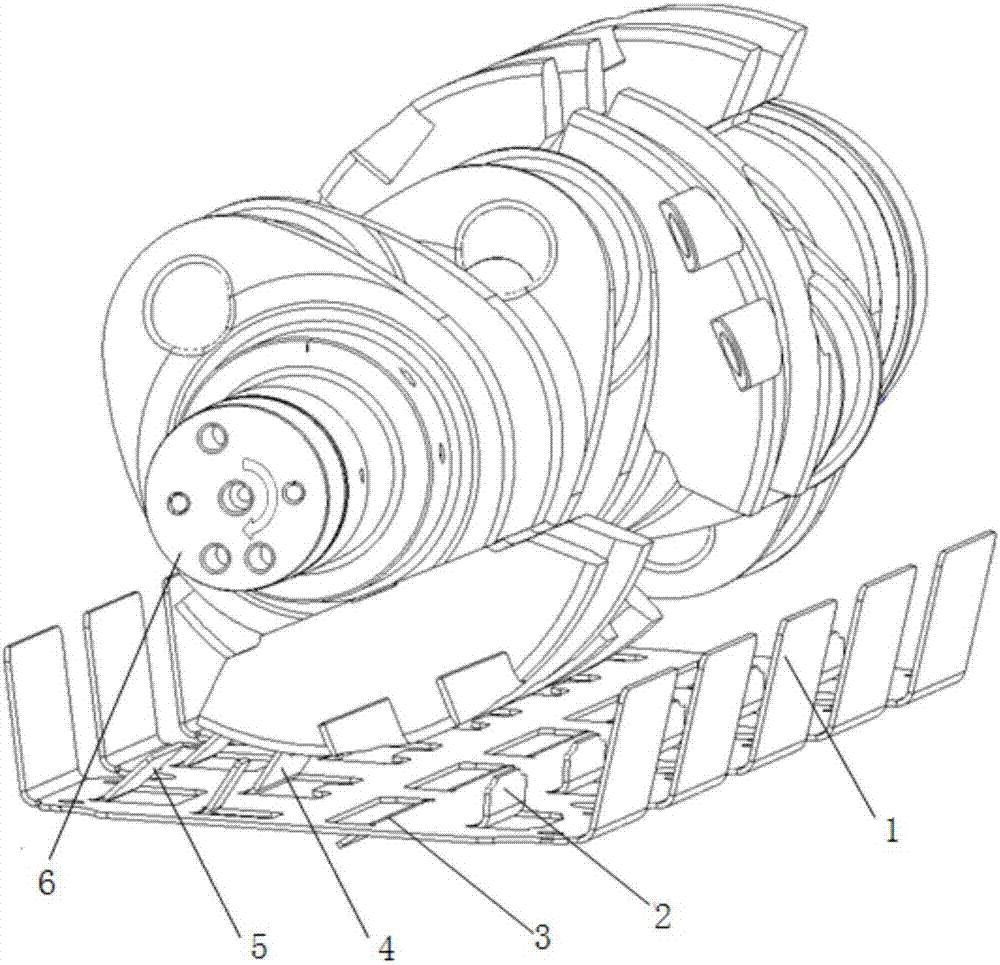

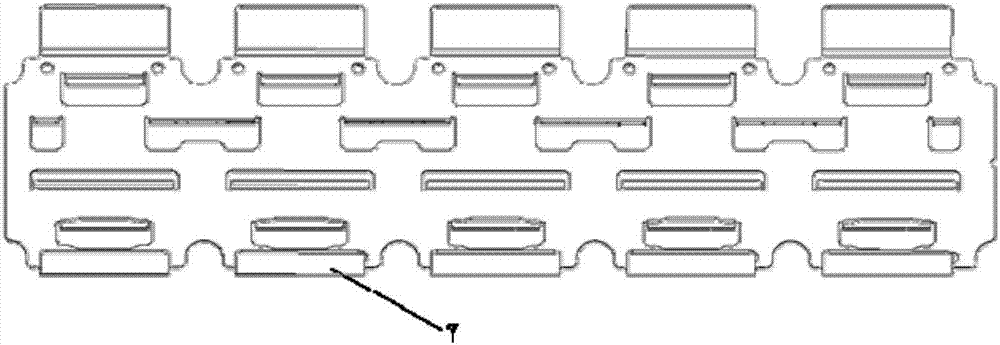

Defoaming device for engine oil inside crank case of engine

ActiveCN107013280APrevent splashPlay a defoaming roleMachines/enginesFoam dispersion/preventionCrankcaseEngineering

The invention provides a defoaming device for engine oil inside a crank case of an engine. The defoaming device comprises a structure body; the structure body is located below a crank; multiple first open slots, multiple second open slots, multiple third open slots and multiple fourth open slots are arranged and formed in the structure body; the first open slots are located in the front end of the structure body and correspond to the position of a journal of a crank connecting rod; the second open slots are located in the front side of the middle of the structure body and correspond to the position of the journal of the crank connecting rod; the third open slots are located in the back side of the middle of the structure body and correspond to the position of a balancing weight of the crank; the fourth open slots are located in the back end of the structure body and correspond to the position of the journal of the crank connecting rod; and flow guide plates are arranged on the four kinds of open slots. The defoaming device has the beneficial effects as follows: open slot structures at different angles are formed in different positions of the structure body according to the rotation direction of the crank of the engine, air bubbles produced by air flows produced due to movement of the crank are avoided, the flow direction of the engine oil falling back freely is guided, and splashing is prevented.

Owner:CHINA NORTH ENGINE INST TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com