Water-based gold ink suitable for overprinting and preparation method thereof

A water-based and suitable technology, applied in the field of printing inks, can solve the problems of insignificant results, high energy consumption, and high equipment requirements, and achieve good printing effects, clear printed graphics, and increased scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0033] This embodiment provides a water-based gold ink suitable for overprinting, including the following components and parts by weight: 25 parts of copper and gold powder, 35 parts of water-based binder, 17.5 parts of absolute ethanol, 17.5 parts of deionized water, 0.5 parts of poly Acrylic acid, 0.2 parts of defoamer, 0.5 parts of wax liquid, 0.5 parts of emulsified silicone oil, 0.3 parts of coconut oleic acid amide, 2.5 parts of alkyl phosphorus carboxylate (AEC).

[0034] The preparation steps of above-mentioned water-based gold ink are as follows:

[0035] 1) Mix the copper gold powder and the mixed solvent of absolute ethanol and deionized water evenly, fully wet and disperse, and soak the prepared copper paste for 24 hours;

[0036] 2) Put the water-based binder into the copper slurry by weight and stir at high speed to fully disperse;

[0037] 3) Add surfactants and additives, stir at high speed, and mix well to obtain water-based gold ink.

Embodiment approach 2

[0039] This embodiment provides a water-based gold ink suitable for overprinting, including the following components and parts by weight: 25 parts of copper and gold powder, 35 parts of water-based binder, 17.5 parts of absolute ethanol, 17.5 parts of deionized water, 0.2 parts of poly Acrylic acid, 0.6 part of defoamer, 0.5 part of wax liquid, 0.2 part of emulsified silicone oil, 0.5 part of coconut oleic acid amide, 3 parts of alkyl phosphorus carboxylate (AEC).

[0040] The preparation steps of the above-mentioned water-based gold ink are exactly the same as those in Embodiment 1, and will not be repeated here.

Embodiment approach 3

[0042] This embodiment provides a water-based gold ink suitable for overprinting, including the following components and contents in parts by weight: 30 parts of copper and gold powder, 35 parts of water-based binder, 18 parts of absolute ethanol, 12 parts of deionized water, 0.1 part of poly Acrylic acid, 0.2 parts of defoamer, 0.5 parts of wax liquid, 0.5 parts of emulsified silicone oil, 0.3 parts of coconut oleic acid amide, 2.5 parts of alkyl phosphorus carboxylate (AEC).

[0043] The preparation steps of the above-mentioned water-based gold ink are exactly the same as those in Embodiment 1, and will not be repeated here.

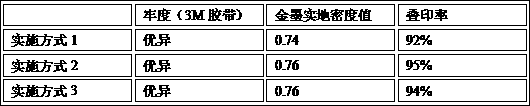

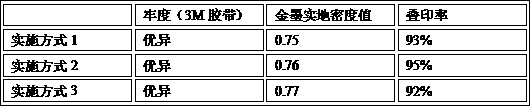

[0044] It is known that on different printing substrates and printing inks, the overprinting effect of water-based gold ink is different. The three embodiments of the present invention are respectively adapted to different printing inks, and can effectively improve the overprinting of water-based gold ink. Table 1 and Table 2 respectively show the over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com