Pore removing device for light-weight wallboard

A technology of lightweight wall panels and degassing holes, which is applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of unguaranteed wall panel quality, low production efficiency, and low safety factor, and achieve stable walking and work. Smooth and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

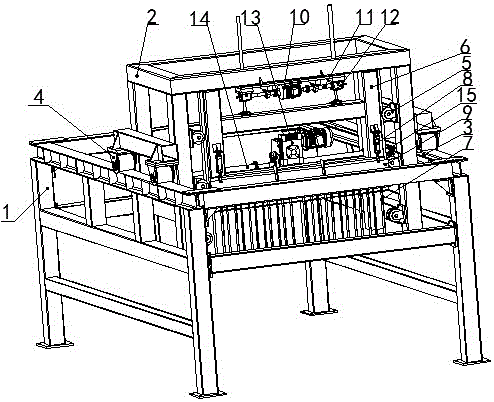

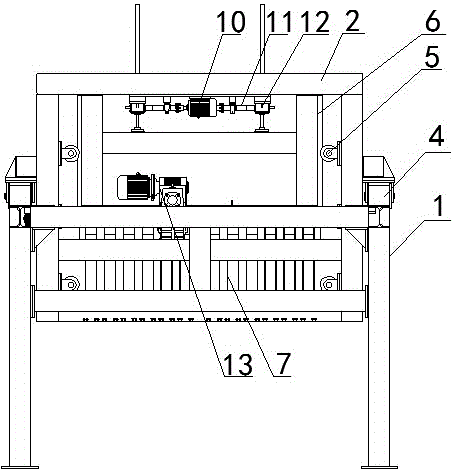

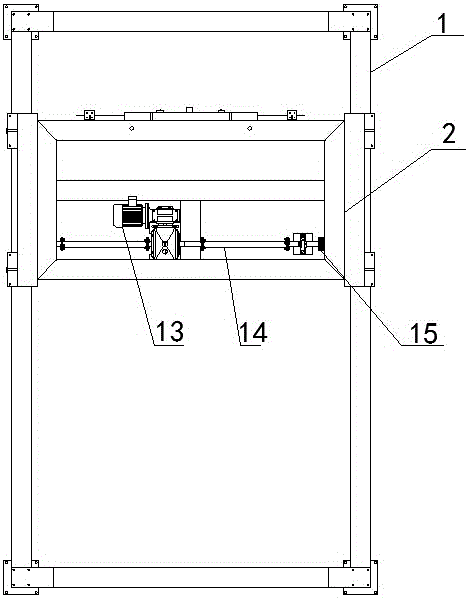

[0010] according to figure 1 , 2 As shown in , 3, the present invention relates to a light-weight wallboard degassing hole device (sliding machine), which includes a frame 1, and a runner 4 of a transverse walking frame 2 is arranged on the left and right vertical beams of the frame 1. On the upper part, at least three upper and lower wheels 5 are symmetrically arranged on the inner walls of the two vertical beams at the front end of the transverse walking frame 2, and the inner sides of each of the upper and lower wheels 5 are respectively provided with upper and lower beams 6, and the upper and lower beams 6 of the two The bottom is connected with a number of vibrating plates 7, and the middle parts of the front and side walls of the two upper and lower beams 6 are respectively provided with cylinders 8. The lower side is provided with a biaxial motor 10, the output ends of the biaxial motor 10 are respectively connected with two screw elevators 12 through the elevator tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com