Polyvinyl dichloride (PVDC) latex special for slick paper used for food packaging and preparation method thereof and application thereof

A food packaging and glossy technology, which is applied in the direction of textiles and papermaking, papermaking, paper coating, etc., to achieve the effect of improving stability, good wrapping, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

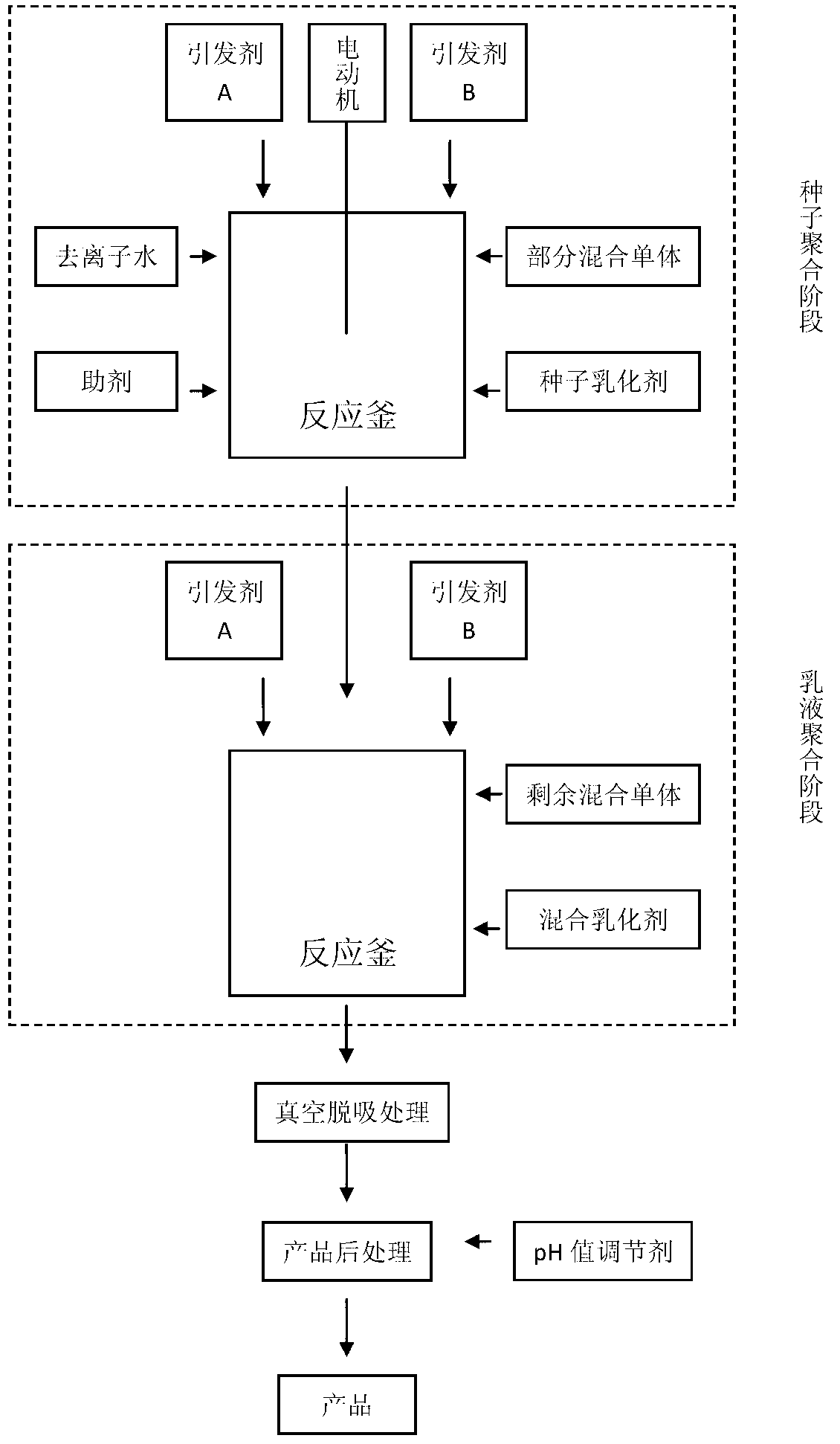

Method used

Image

Examples

Embodiment 1

[0035] Special PVDC latex for glossy paper, the total weight of the copolymerization system is 200kg, and the mixed monomer accounts for 110kg;

[0036] Vinylidene chloride 98.45kg;

[0037] Acrylonitrile 11kg;

[0038] Acrylic acid 0.55kg;

[0039] Additives: 24g ammonium acetate and 0.8g ferrous chloride;

[0040] Initiator: 160g of tert-butyl hydroperoxide and 160g of sodium formaldehyde sulfoxylate;

[0041] Mixed emulsifier: 1.2kg for COPS-1 and 0.6kg for 2A-1 emulsifier;

[0042] Seed emulsifier: sodium dodecylbenzenesulfonate 80g;

[0043] The specific operation process is:

[0044] 1) Preparation of raw materials:

[0045] (1) The preparation of mixed monomers, mix above-mentioned vinylidene chloride and acrylonitrile, stir 2h, set aside;

[0046] (2) The preparation of mixed emulsifier, the above-mentioned COPS-1 and 2A-1 emulsifier and acrylic acid are added to 10 parts of water to make emulsifier solution, and set aside;

[0047] (3) the preparation of initi...

Embodiment 2

[0057] Special PVDC latex for glossy paper, the total weight of the copolymerization system is 200kg, and the mixed monomer accounts for 116kg;

[0058] Vinylidene chloride 104.4kg;

[0059] Acrylonitrile 11.37kg;

[0060] Acrylic acid 0.23kg;

[0061] Additives: 30g of ammonium acetate and 1g of ferrous chloride;

[0062]Initiator: 320g of tert-butyl hydroperoxide and 320g of sodium formaldehyde sulfoxylate;

[0063] Mixed emulsifier: 1.4kg for COPS-1 and 1kg for 2A-1 emulsifier

[0064] Seed emulsifier: sodium dodecylbenzenesulfonate 180g;

[0065] The specific operation process is:

[0066] 1) Preparation of raw materials: The preparation of mixed monomers, reactive emulsifiers, and initiators is the same as in Example 1.

[0067] 2) Seed polymerization reaction: add deionized water to the reaction kettle, add additives and seed emulsifier, seal the kettle, replace the air in the reaction kettle with nitrogen three times, vacuumize, inhale 3% mixed monomer of seed mon...

Embodiment 3

[0070] Special PVDC latex for glossy paper, the total weight of the copolymerization system is 200kg, and the mixed monomer accounts for 120kg;

[0071] Vinylidene chloride 111kg;

[0072] Acrylonitrile 8.77kg;

[0073] Acrylic acid 0.23kg;

[0074] Additives: 36g of ammonium acetate and 1.2g of ferrous chloride;

[0075] Initiator: 400g of tert-butyl hydroperoxide and 400g of sodium formaldehyde sulfoxylate;

[0076] Mixed emulsifier: 1.6kg for COPS-1 and 1.4kg for 2A-1 emulsifier;

[0077] Seed emulsifier: sodium dodecylbenzenesulfonate 400g;

[0078] The specific operation process is:

[0079] 1) Preparation of raw materials: The preparation of mixed monomers, reactive emulsifiers, and initiators is the same as in Example 1.

[0080] 2) Seed polymerization reaction: Add deionized water to the reactor, add additives and seed emulsifier, seal the reactor, replace the air in the reactor with nitrogen for three times, vacuumize, inhale 3% mixed monomer, and cold disperse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com