Solid defoamer for cement-based grouting materials and preparation method thereof

A technology of solid defoaming agent and grouting material, which is applied in the field of chemical building materials, can solve the problems of strong alkali resistance and anti-attenuation and long-term stability, and achieve the effects of low cost, delayed release, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

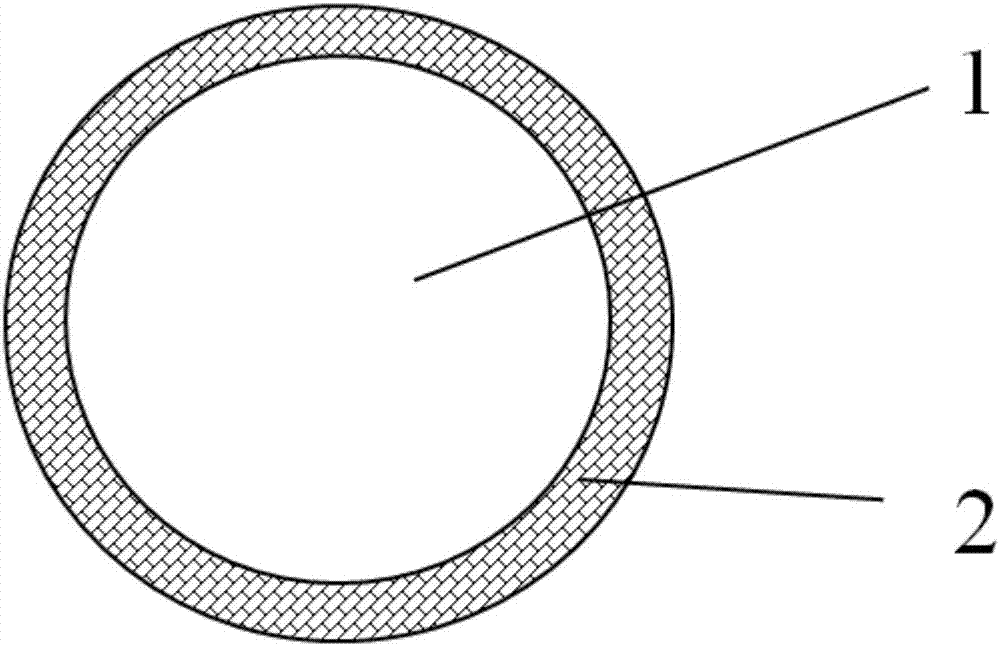

[0049] Such as figure 1 As shown, the present invention provides a solid defoamer for cement-based grouting material, the defoamer is composed of defoamer particles 1 and a protective film 2 wrapped on the defoamer particles 1, the protective film 2 It is a water-soluble polymer film, and the protective film 2 includes the following raw materials in weight percentage: polyvinyl alcohol 60%, cellulose ether 35% and coloring agent 5%.

[0050] Wherein, the polyvinyl alcohol is PVA17-88; the cellulose ether is hydroxyethyl cellulose; and the colorant is a water-soluble organic color paste.

[0051] The defoamer particles 1 include the following raw materials in parts by weight: 20 parts of polyether-modified silicone active components and 80 parts of carriers, and the diameter of the defoamer particles 1 is 0.1-0.2 mm.

[0052] Wherein, the raw materials of the polyether-modified silicone active component include reactants, catalysts, white carbon black and emulsifiers, the reac...

Embodiment 2

[0063] Such as figure 1 As shown, the present invention provides a solid defoamer for cement-based grouting material, the defoamer is composed of defoamer particles 1 and a protective film 2 wrapped on the defoamer particles 1, the protective film 2 It is a water-soluble polymer film, and the protective film 2 includes the following raw materials in weight percentage: polyvinyl alcohol 72%, cellulose ether 25% and coloring agent 3%.

[0064] Wherein, the polyvinyl alcohol is PVA17-92; the cellulose ether is hydroxymethyl hydroxyethyl cellulose; and the colorant is a water-soluble organic color paste.

[0065] The defoamer particles 1 include the following raw materials in parts by weight: 25 parts of polyether-modified silicone active components and 75 parts of carriers, and the diameter of the defoamer particles 1 is 0.2-0.4 mm.

[0066] Wherein, the raw materials of the polyether-modified silicone active component include reactants, catalysts, white carbon black and emulsif...

Embodiment 3

[0077] Such as figure 1 As shown, the present invention provides a solid defoamer for cement-based grouting material, the defoamer is composed of defoamer particles 1 and a protective film 2 wrapped on the defoamer particles 1, the protective film 2 It is a water-soluble polymer film, and the protective film 2 includes the following raw materials in weight percentage: 80% polyvinyl alcohol, 19% cellulose ether and 1% coloring agent.

[0078] Wherein, the polyvinyl alcohol is PVA17-99; the cellulose ether is a mixture of hydroxypropylmethylcellulose and hydroxyethylmethylcellulose; and the colorant is a water-soluble organic color paste.

[0079] The defoamer particles 1 include the following raw materials in parts by weight: 30 parts of polyether-modified silicone active components and 70 parts of carriers, and the diameter of the defoamer particles 1 is 0.4-0.5 mm.

[0080] Wherein, the raw materials of the polyether-modified silicone active component include reactants, cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com