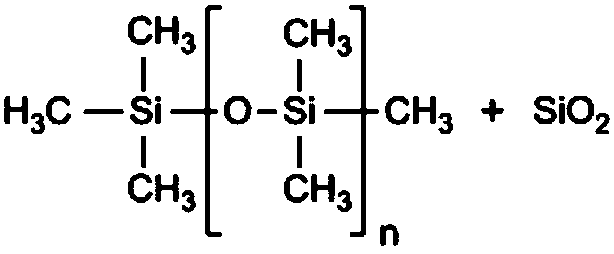

A kind of simethicone solid self-emulsifying preparation and preparation technology thereof

A simethicone and self-emulsifying technology, applied in the directions of silicon compound active ingredients, digestive system, emulsion delivery, etc., can solve the problems of complex production process of simethicone soft capsules, unfavorable for patients to take, difficult emulsification process, etc., and achieve good application prospects , low cost and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

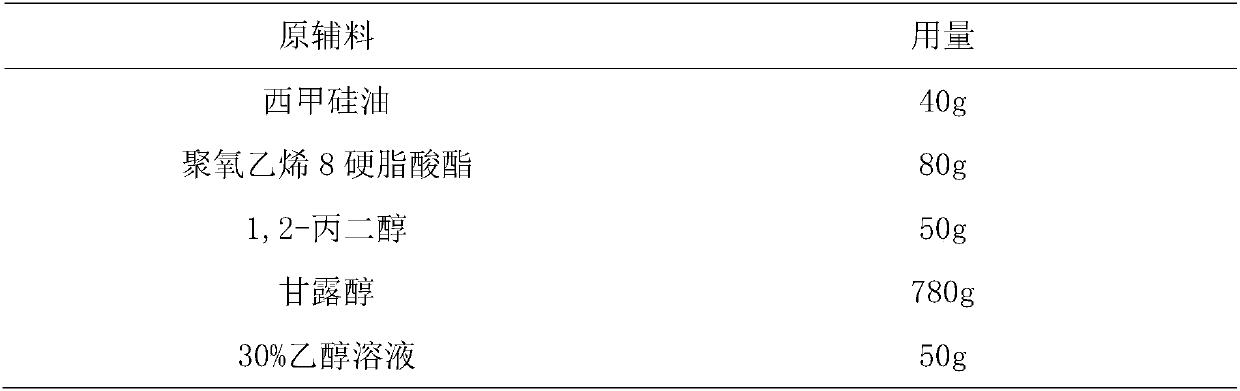

[0047] Embodiment 1: the preparation of Simethicone solid self-emulsifying preparation

[0048] The raw and auxiliary materials are composed of:

[0049]

[0050] Preparation:

[0051] (1) Measure simethicone, polyoxyethylene 8 stearate, 1,2-propanediol, mannitol, and 30% ethanol solution according to the above prescription. Add simethicone, polyoxyethylene 8 stearate and 1,2-propylene glycol into the reaction tank, keep warm at 70°C, stir for 30 minutes, and mix well to obtain simethicone self-emulsifying concentrate;

[0052] (2) Pulverize the above-mentioned mannitol, pass through a 100-mesh sieve, then mix evenly with the self-emulsifying concentrated solution obtained in step (1), spray an appropriate amount of 30% ethanol solution, and make a soft material, so as to achieve "lightly holding into a ball and lightly pressing". Scattered" state, passed through a 20-mesh sieve to granulate;

[0053] (3) Dry the granules obtained in the step (2) at 50° C. until the wate...

Embodiment 2

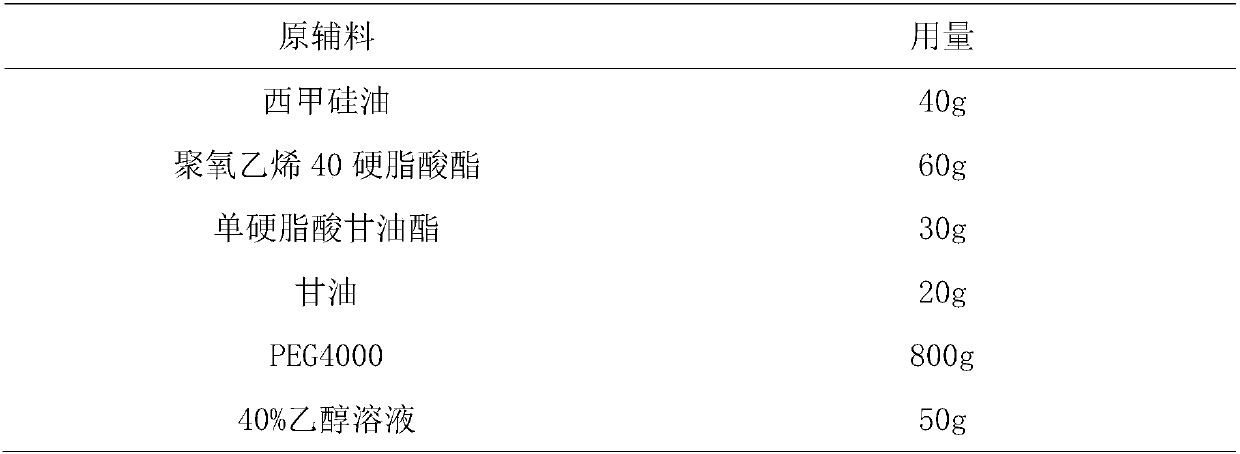

[0054] Embodiment 2: the preparation of Simethicone solid self-emulsifying preparation

[0055] The raw and auxiliary materials are composed of:

[0056]

[0057] Preparation:

[0058] (1) Measure simethicone, polyoxyethylene 40 stearate, glyceryl monostearate, glycerin, PEG4000, 40% ethanol solution according to the above prescription. Add simethicone, polyoxyethylene 40 stearate, glycerol monostearate, and glycerin into a reaction tank, keep the temperature at 75°C, stir for 30 minutes, and mix well to obtain a simethicone self-emulsifying concentrate;

[0059] (2) Grind the above-mentioned PEG4000, pass through a 100-mesh sieve, then mix evenly with the self-emulsifying concentrated solution obtained in step (1), spray an appropriate amount of 40% ethanol solution, and make a soft material, so as to achieve "lightly hold into a ball and lightly press to disperse" ” state, pass through a 20-mesh sieve and granulate;

[0060] (3) Dry the granules obtained in step (2) at...

Embodiment 3

[0061] Embodiment 3: the preparation of Simethicone solid self-emulsifying preparation

[0062] The raw and auxiliary materials are composed of:

[0063]

[0064] Preparation:

[0065] (1) Measure simethicone, polyoxyethylene hydrogenated castor oil, glyceryl monostearate, macrogol 400, lactose, and purified water according to the above prescription. Add simethicone, polyoxyethylene hydrogenated castor oil, glyceryl monostearate, and polyethylene glycol 400 into the reaction tank, keep the temperature at 65°C, stir for 30 minutes, and mix well to obtain the simethicone self-emulsifying concentrate;

[0066] (2) Grind the above-mentioned lactose, pass through a 100-mesh sieve, then mix evenly with the self-emulsifying concentrate obtained in step (1), spray an appropriate amount of purified water, and make a soft material to achieve the effect of "lightly holding into a ball and lightly pressing to disperse" state, granulated through a 20-mesh sieve;

[0067] (3) Dry the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com