High-toughness bridge reinforcing structural adhesive

A technology for strengthening structures and high toughness, which is applied in the direction of non-polymer adhesive additives, adhesives, epoxy resin glue, etc., and can solve the problems of affecting structural adhesiveness, affecting the life of structural adhesives, and adversely affecting the sealing performance of structural adhesives. , to achieve the effect of ensuring fluidity, simple composition, and suitable for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

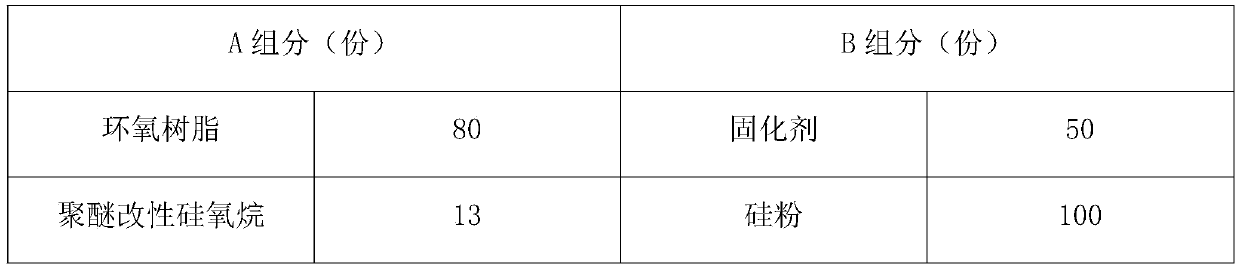

[0024] Table 1 is the composition content of A component and B component in the high-toughness bridge reinforcement structural adhesive of embodiment 1:

[0025] Table 1

[0026]

[0027]

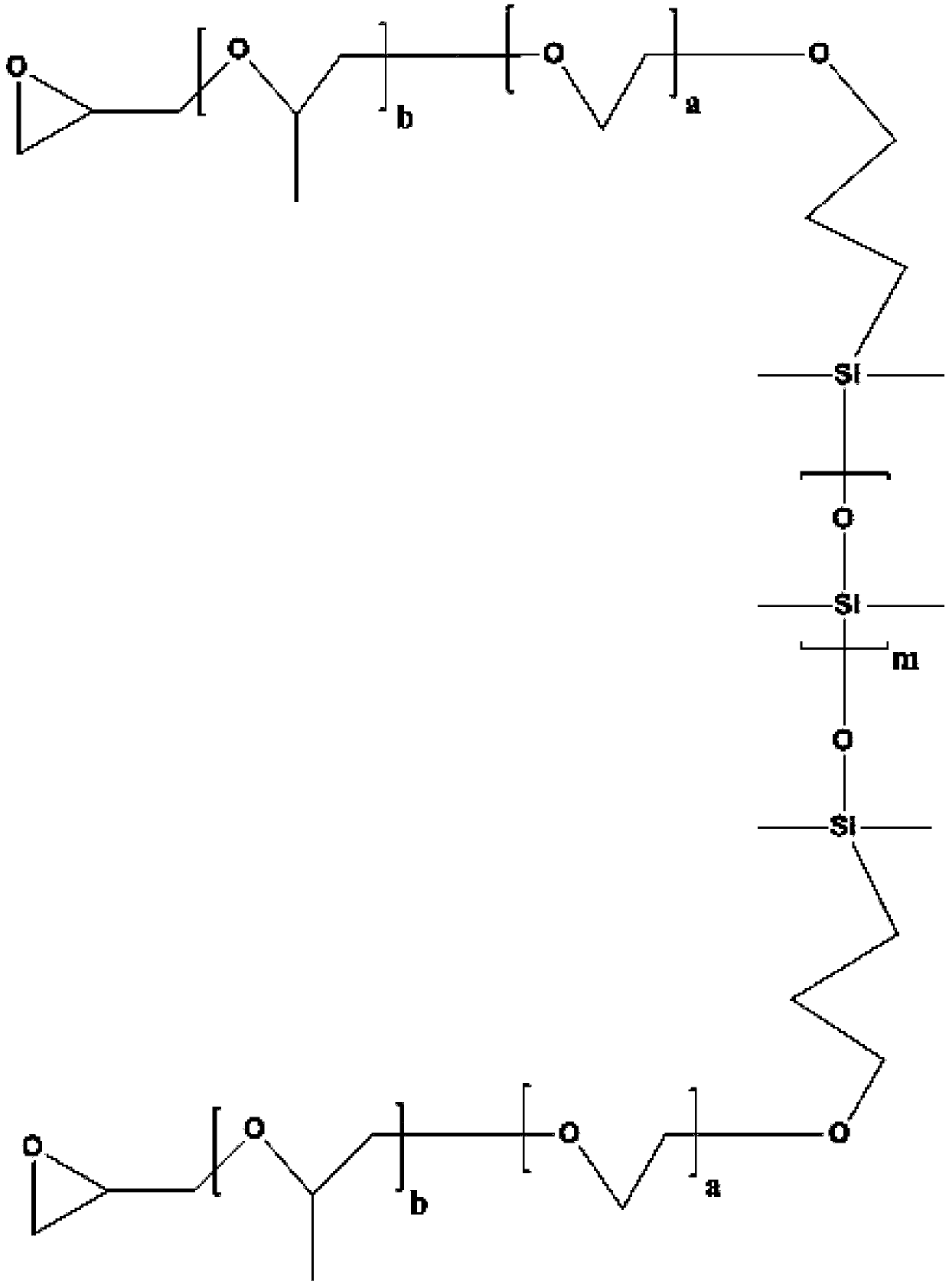

[0028] In this example, the polyether modified siloxane in component A is RSi(CH 3 ) 2 (OSi(CH3) 2 ) m OSi(CH 3 ) 2 R, where m=10, R is -C 3 h 6 (C 2 h 4 O) a (C 3 h 6 O) b (C 3 h 5 O), wherein a=10, b=10;

[0029] In this example, the proportion of component A and component B is 1:1. Add component B to component A according to the proportion of ingredients, disperse until the colloid is uniform and fine, and then vacuum stir and defoam, according to the size in GB2567-2008 Pouring in the corresponding mold, removing the mold after curing at room temperature for 7 days, and testing the tensile strength and bending strength immediately.

Embodiment 2

[0031] Table 2 is the composition content of A component and B component in the high-toughness bridge reinforcement structural adhesive of embodiment 2:

[0032] Table 2

[0033]

[0034] In this example, the polyether modified siloxane in component A is RSi(CH 3 ) 2 (OSi(CH3) 2 ) m OSi(CH 3 ) 2 R, where m=50, R is -C 3 h 6 (C 2 h 4 O) a (C 3 h 6 O) b (C 3 h 5 O), wherein a=50, b=40;

[0035] In this example, the proportion of component A and component B is 3:1. Add component B to component A according to the proportion of ingredients, disperse until the colloid is uniform and fine, and then vacuum stir and defoam, according to the size in GB2567-2008 Pouring in the corresponding mold, removing the mold after curing at room temperature for 7 days, and testing the tensile strength and bending strength immediately.

Embodiment 3

[0037] Table 3 is the component content of A component and B component in the high-toughness bridge reinforcement structural adhesive of embodiment 3:

[0038] table 3

[0039]

[0040] In this example, the polyether modified siloxane in component A is RSi(CH 3 ) 2 (OSi(CH3) 2 ) m OSi(CH 3 ) 2 R, where m=20, R is -C 3 h 6 (C 2 h 4 O)a (C 3 h 6 O) b (C 3 h 5 O), wherein a=10, b=20;

[0041] In this example, the proportion of component A and component B is 2:1. Add component B to component A according to the proportion of ingredients, disperse until the colloid is even and fine, and then vacuum stir and defoam, according to the size in GB2567-2008 Pouring in the corresponding mold, removing the mold after curing at room temperature for 7 days, and testing the tensile strength and bending strength immediately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com