Nano calcium carbonate pressurized carbonation and surface modification integrated reaction kettle and application thereof

A nano-calcium carbonate, surface modification technology, applied in the direction of calcium carbonate/strontium/barium, chemical/physical/physicochemical fixed reactors, calcium/strontium/barium compounds, etc., can solve problems such as unstable product quality, Achieve the effect of simple structure, simplified process and avoiding cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

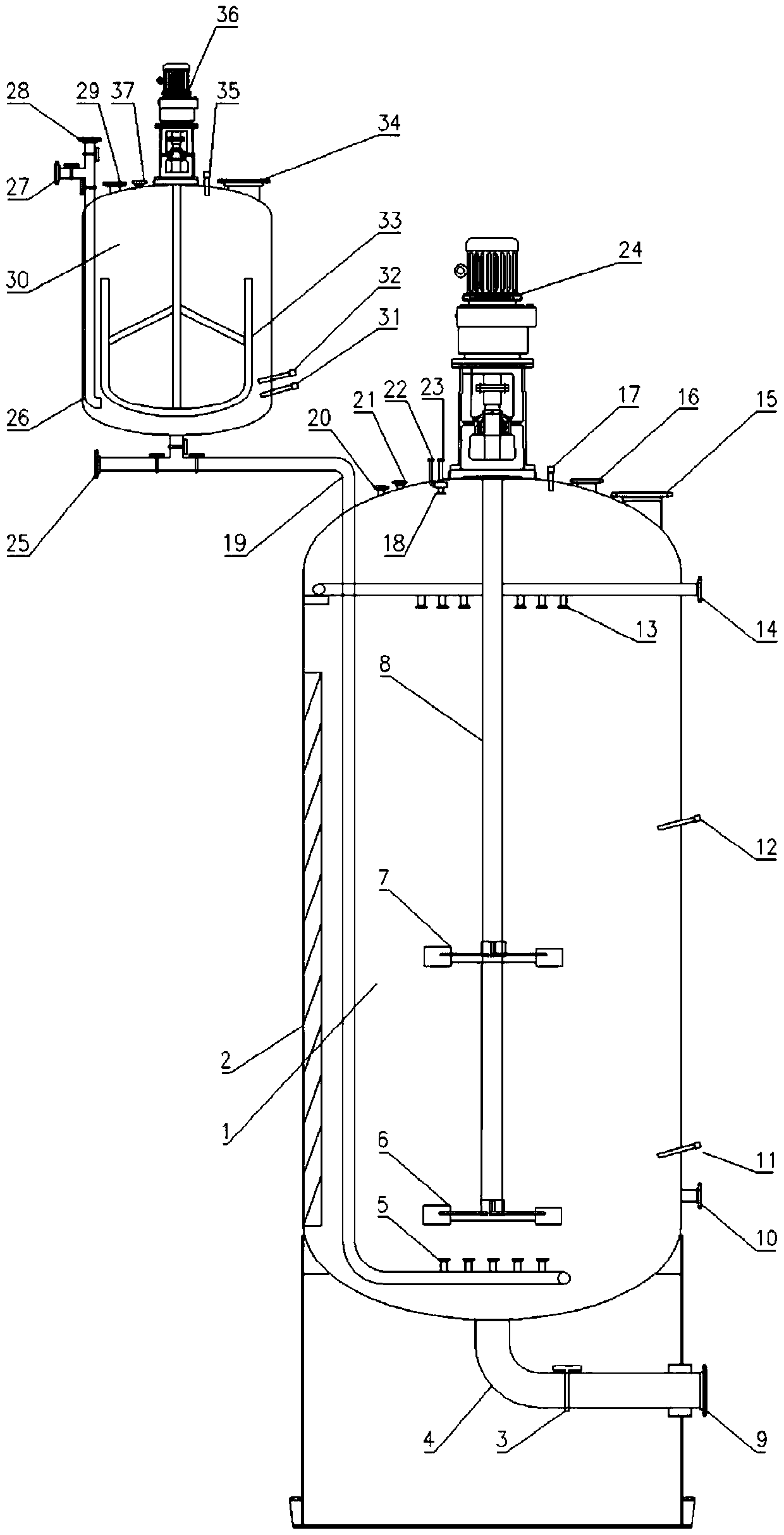

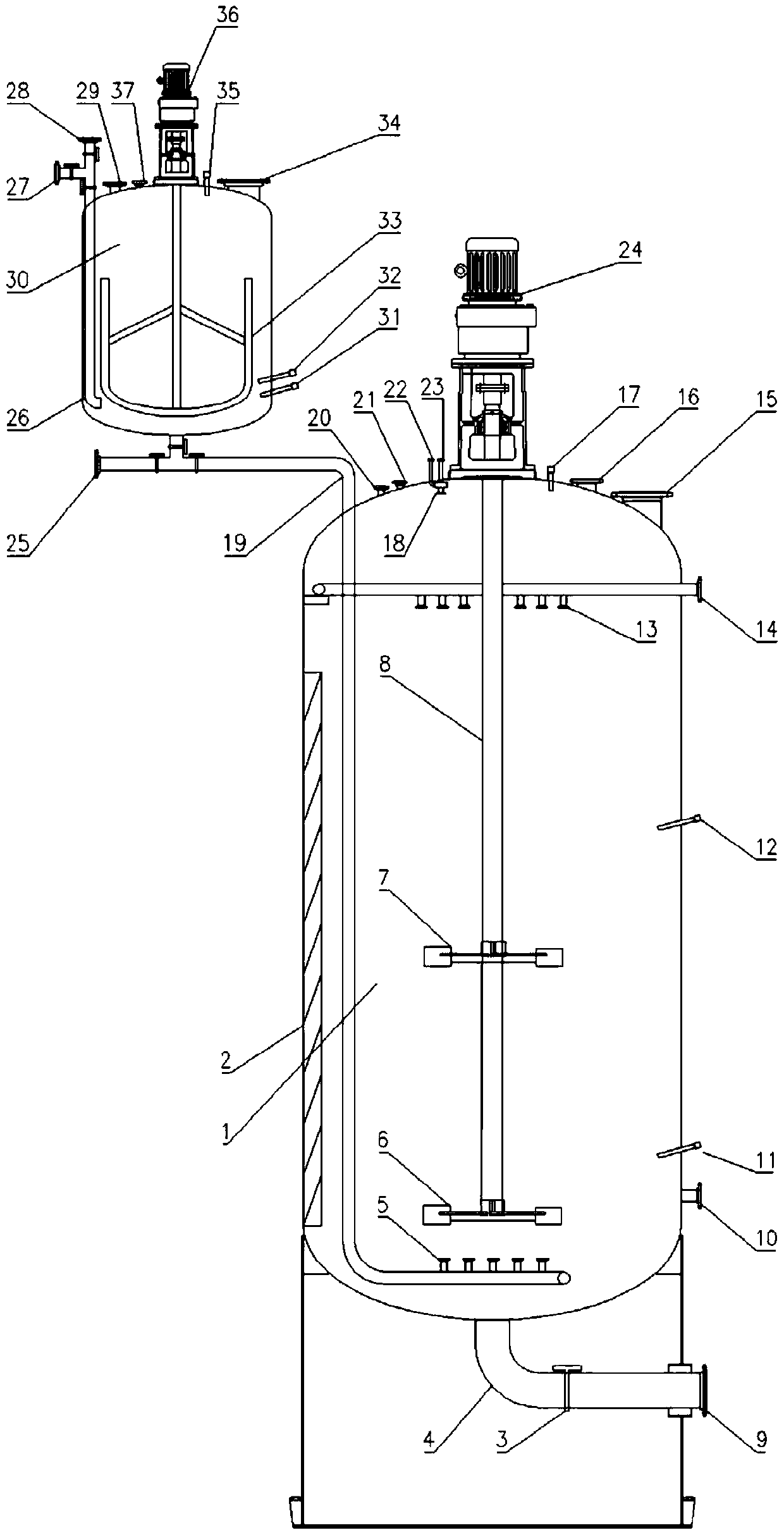

[0033] as attached figure 1 As shown, the nano-calcium carbonate pressurized carbonation and surface modification integrated reactor of the present invention includes a main reactor 1 and a modification reactor 30, and the main reactor 1 includes a main reactor motor 24, a stirring shaft 8 , main reactor agitator, slurry inlet pipeline 14, slurry discharge pipeline 4 and CO 2 And modifying agent delivery pipeline 19; The inside of main reactor 1 is provided with stirring shaft 8, and above stirring shaft 8 is provided with main reactor motor 24, and described main reactor motor 24 is located at the top of reactor, and described stirring A main reactor stirrer is arranged on the shaft 8; the main reactor stirrer is provided with two layers of stirrers, namely a primary stirrer 6 and a secondary stirrer 7, and the type of the stirrer is a disc turbine stirrer. The slurry inlet pipeline 14 is arranged at the middle and upper part of the main reaction kettle 1, and 6-10 liquid ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com