Sleeve grouting material for steel bar connection

A sleeve grouting and steel bar technology, which is applied in the field of concrete, can solve the problems of poor compatibility, easy shrinkage of materials, and easy cracks, etc., and achieve the effects of good compatibility, improved self-resistance strength, and stress relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

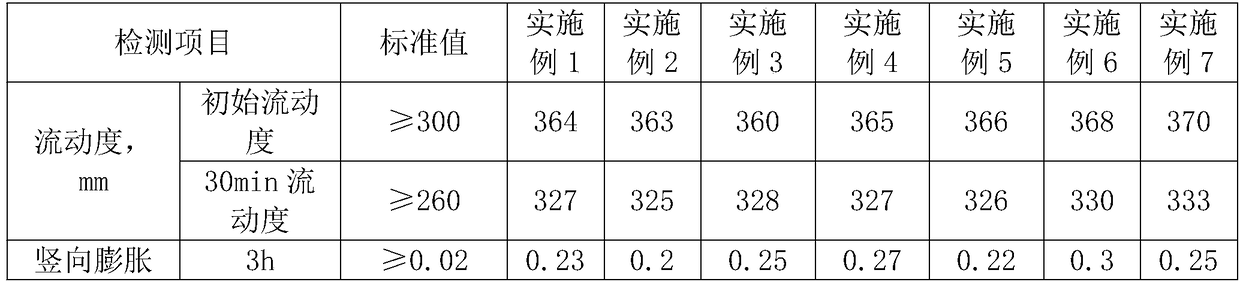

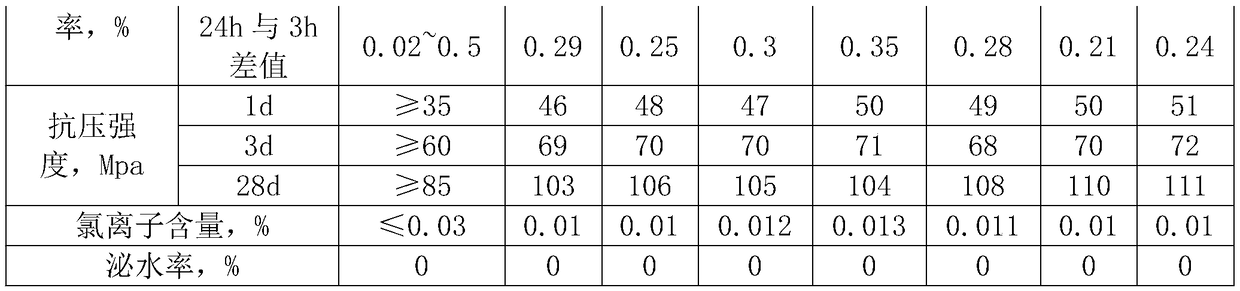

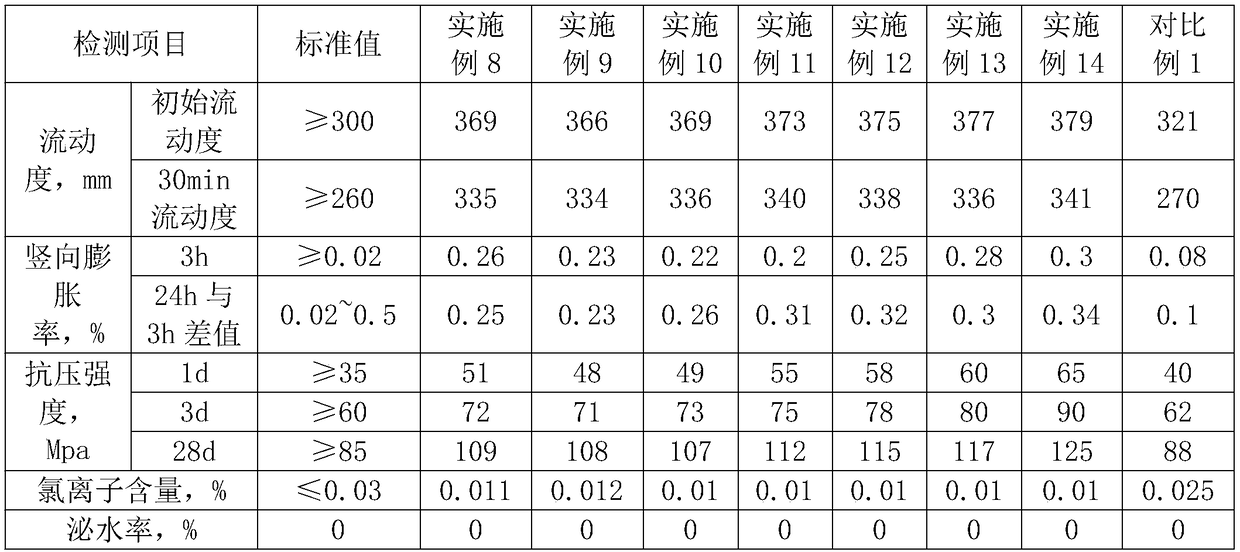

Examples

Embodiment 1

[0038] Embodiment 1: the sleeve grouting material for reinforcing bar connection, comprises the component of following parts by weight:

[0039] Portland cement 518 parts;

[0040] 450 parts of quartz sand;

[0041] 0.3 parts of CSA expansion agent;

[0042] 29.5 parts of microbeads;

[0043] 2 parts of polycarboxylate superplasticizer;

[0044] 0.34 part of antifoaming agent, wherein antifoaming agent is emulsified silicone oil, and the particle size of microbead is 320 orders.

Embodiment 2

[0045] Embodiment 2: the sleeve grouting material for reinforcing bar connection, comprises the component of following parts by weight:

[0046] Portland cement 510 parts;

[0047] 440 parts of quartz sand;

[0048] 0.2 parts of CSA expansion agent;

[0049] 26 copies of microbeads;

[0050] 1.8 parts of polycarboxylate superplasticizer;

[0051] 0.38 part of antifoaming agent, wherein antifoaming agent is emulsified silicone oil, and the particle size of microbead is 325 orders.

Embodiment 3

[0052] Embodiment 3: the sleeve grouting material for steel bar connection, comprising the following components in parts by weight:

[0053] Portland cement 525 parts;

[0054] 460 parts of quartz sand;

[0055] 0.4 parts of CSA expansion agent;

[0056] 28 copies of microbeads;

[0057] 2.3 parts of polycarboxylate superplasticizer;

[0058] 0.32 part of antifoaming agent, wherein antifoaming agent is emulsified silicone oil, and the particle size of microbead is 300 orders.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com