Heat conduction silicone grease as well as processing method and application thereof

A heat-conducting silicone grease and processing method technology, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of poor heat conduction effect, increased cross-sectional thermal resistance, unfavorable heat dissipation of electronic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

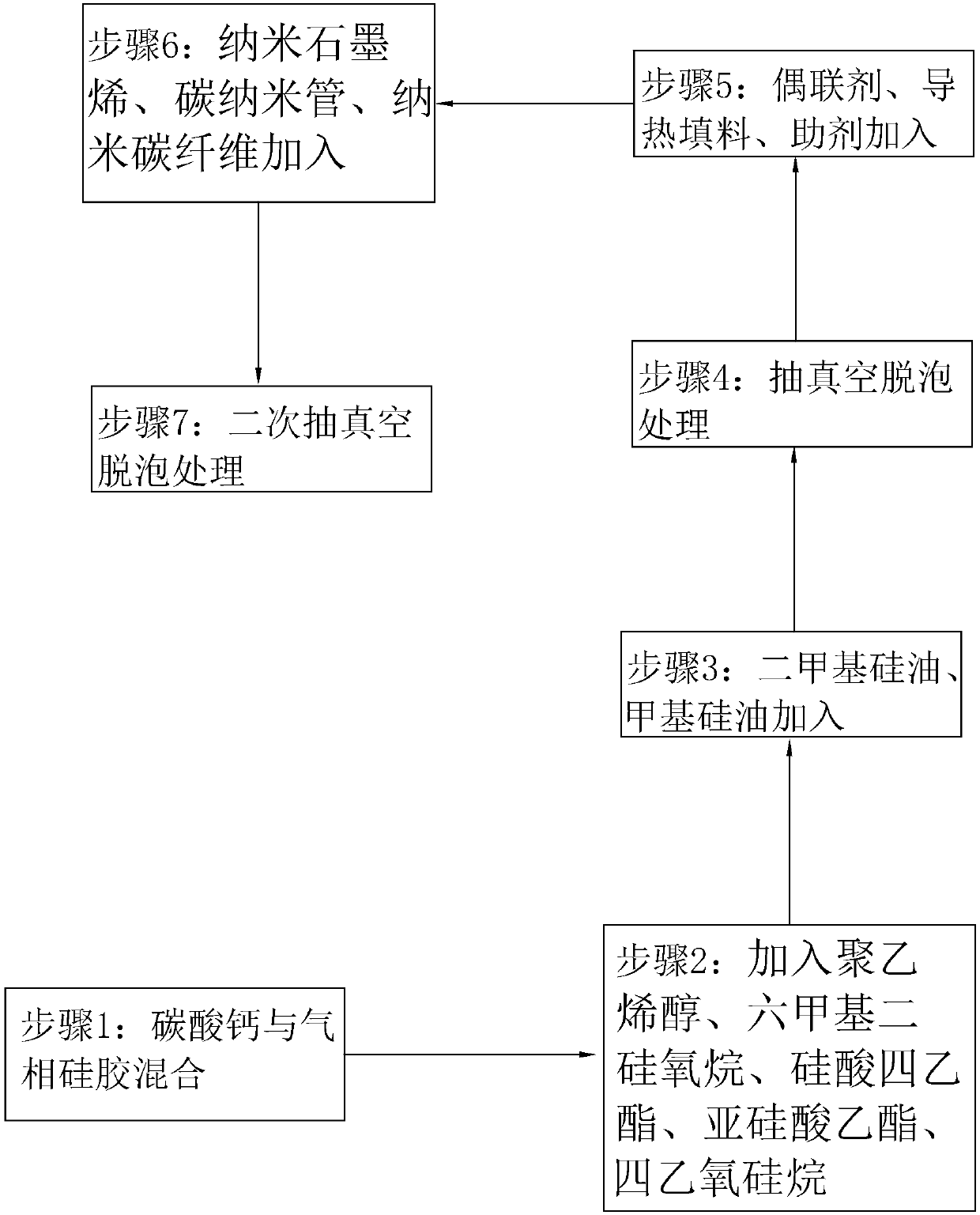

[0036] A processing method of thermally conductive silicone grease, such as figure 1 shown, including the following steps:

[0037] Step 1: Add the calcium carbonate powder into the gas phase silica gel for grinding and stirring. The grinding time is more than 2 hours. The particle size of the calcium carbonate powder is between 0.3-0.6 μm. In this embodiment, a smaller calcium carbonate powder is used to control the particle size. The diameter is between 0.3-0.4 μm.

[0038] Step 2: Add one or more of polyvinyl alcohol, hexamethyldisiloxane, tetraethyl silicate, ethyl silicate, and tetraethoxysilane, and keep stirring.

[0039] Step 3: Pour simethicone and methyl silicone oil slowly and keep stirring.

[0040] Step 4: Vacuumizing and defoaming treatment, control the temperature in this link to 35-40°C, and control the temperature to 35°C in this embodiment.

[0041] Step 5: Add coupling agent, thermally conductive filler and additives to it, and keep stirring;

[0042] St...

Embodiment 2

[0045] A processing method of thermally conductive silicone grease, such as figure 1 shown, including the following steps:

[0046] Step 1: Add the calcium carbonate powder into the gas phase silica gel for grinding and stirring. The grinding time is more than 2 hours. The particle size of the calcium carbonate powder is between 0.3-0.6 μm. In this embodiment, a smaller calcium carbonate powder is used to control the particle size. The diameter is between 0.5-0.6 μm.

[0047] Step 2: Add one or more of polyvinyl alcohol, hexamethyldisiloxane, tetraethyl silicate, ethyl silicate, and tetraethoxysilane, and keep stirring.

[0048] Step 3: Pour simethicone and methyl silicone oil slowly and keep stirring.

[0049] Step 4: Vacuumizing and defoaming treatment, controlling the temperature in this link to 35-40°C, and controlling the temperature to 40°C in this embodiment.

[0050] Step 5: Add coupling agent, thermally conductive filler and additives to it, and keep stirring;

[...

Embodiment 3

[0054] A processing method of thermally conductive silicone grease, such as figure 1 shown, including the following steps:

[0055] Step 1: Add the calcium carbonate powder into the gas phase silica gel for grinding and stirring. The grinding time is more than 2 hours. The particle size of the calcium carbonate powder is between 0.3-0.6 μm. In this embodiment, a smaller calcium carbonate powder is used to control the particle size. The diameter is between 0.4-0.5 μm.

[0056] Step 2: Add one or more of polyvinyl alcohol, hexamethyldisiloxane, tetraethyl silicate, ethyl silicate, and tetraethoxysilane, and keep stirring.

[0057] Step 3: Pour simethicone and methyl silicone oil slowly and keep stirring.

[0058] Step 4: Vacuumizing and defoaming treatment, control the temperature in this link to 35-40°C, and control the temperature to 38°C in this embodiment.

[0059] Step 5: Add coupling agent, thermally conductive filler and additives to it, and keep stirring;

[0060] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com