Environment-friendly degradable composite film for packaging and preparation method thereof

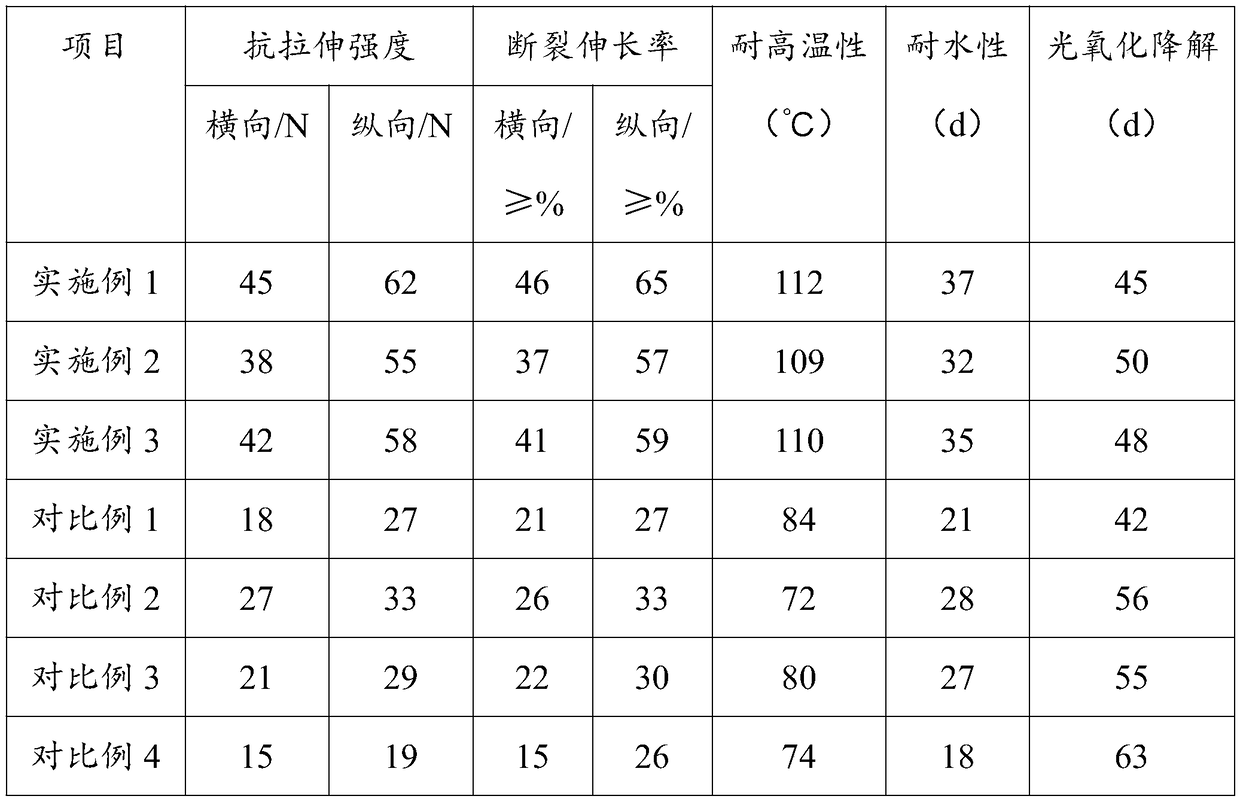

An environmentally friendly, composite film technology, applied in the field of packaging materials, can solve the problems of poor tensile strength, elongation at break, poor water resistance, limited wide application, etc., achieve good compatibility, reduce costs, and improve compatibility and interface. adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

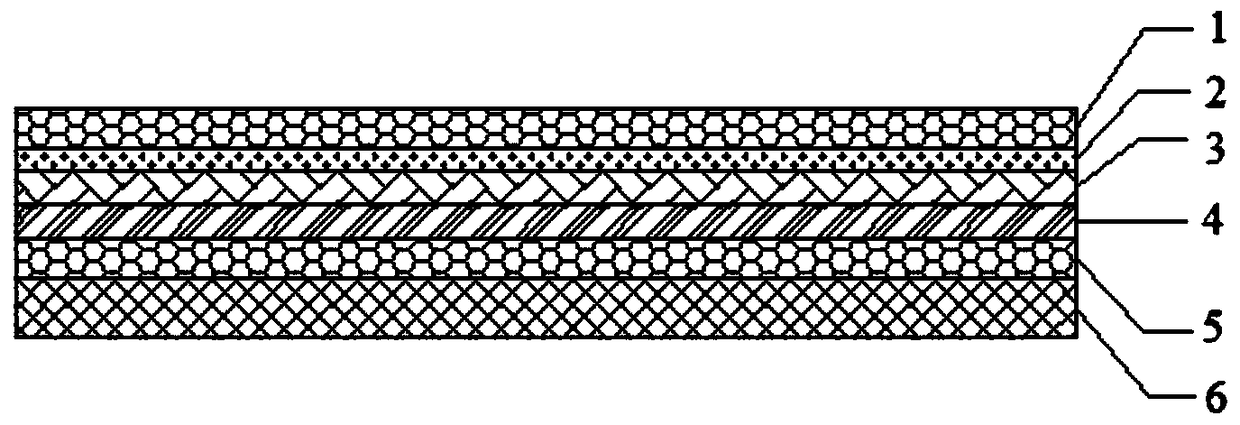

[0037] refer to figure 1 As shown, an environmentally friendly degradable composite film for packaging in this embodiment includes a first modified polyvinyl alcohol layer 1, an insulating layer 2, a titanium dioxide fireproof layer 3, and a polyethylene composite layer that are sequentially bonded from outside to inside. 4. The second modified polyvinyl alcohol layer 5 and the PET release film layer 6 .

[0038] Wherein, the insulating layer includes 40-50wt% polyesterimide and 50-60wt% polyamideimide, and its thickness is 0.5-0.8mm. The titanium dioxide fireproof layer includes the following raw materials in parts by weight: 105 parts of nano-titanium dioxide, 36 parts of hollow glass microspheres, 12 parts of maleic anhydride grafted polyethylene copolymer, 7 parts of chlorinated palm oil methyl ester; maleic anhydride grafted polyethylene The copolymer is formed by mixing 90wt% maleic anhydride and 10wt% polyethylene.

[0039] The preparation method of titanium dioxide f...

Embodiment 2

[0050] An environment-friendly degradable composite film for packaging in this embodiment includes a first modified polyvinyl alcohol layer, an insulating layer, a titanium dioxide fireproof layer, a polyethylene composite layer, a second modified polyvinyl alcohol layer, and a second modified polyvinyl alcohol layer bonded sequentially from outside to inside. Vinyl alcohol layer, PET release film layer.

[0051] Wherein, the insulating layer includes 40-50wt% polyesterimide and 50-60wt% polyamideimide, and its thickness is 0.5-0.8mm. The titanium dioxide fireproof layer includes the following raw materials in parts by weight: 112 parts of nano-titanium dioxide, 35 parts of hollow glass microspheres, 17 parts of maleic anhydride grafted polyethylene copolymer, 8 parts of chlorinated palm oil methyl ester; maleic anhydride grafted polyethylene The copolymer is formed by mixing 90wt% maleic anhydride and 10wt% polyethylene. The preparation method of the titanium dioxide firepro...

Embodiment 3

[0057] An environment-friendly degradable composite film for packaging in this embodiment includes a first modified polyvinyl alcohol layer, an insulating layer, a titanium dioxide fireproof layer, a polyethylene composite layer, a second modified polyvinyl alcohol layer, and a second modified polyvinyl alcohol layer bonded sequentially from outside to inside. Vinyl alcohol layer, PET release film layer.

[0058] Wherein, the insulating layer includes 40-50wt% polyesterimide and 50-60wt% polyamideimide, and its thickness is 0.5-0.8mm. The titanium dioxide fireproof layer includes the following raw materials in parts by weight: 117 parts of nano-titanium dioxide, 38 parts of hollow glass microspheres, 17 parts of maleic anhydride grafted polyethylene copolymer, 9 parts of chlorinated palm oil methyl ester; maleic anhydride grafted polyethylene The copolymer is formed by mixing 90wt% maleic anhydride and 10wt% polyethylene. The preparation method of the titanium dioxide firepro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com