Wax oil hydrogenated treatment and catalytic cracking combined method

A catalytic cracking and hydrotreating technology, applied in the field of gasoline production, can solve the problems of limited and reduced coke yield, and achieve the effects of improving utilization rate, reducing the difficulty of hydrogenation reaction, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

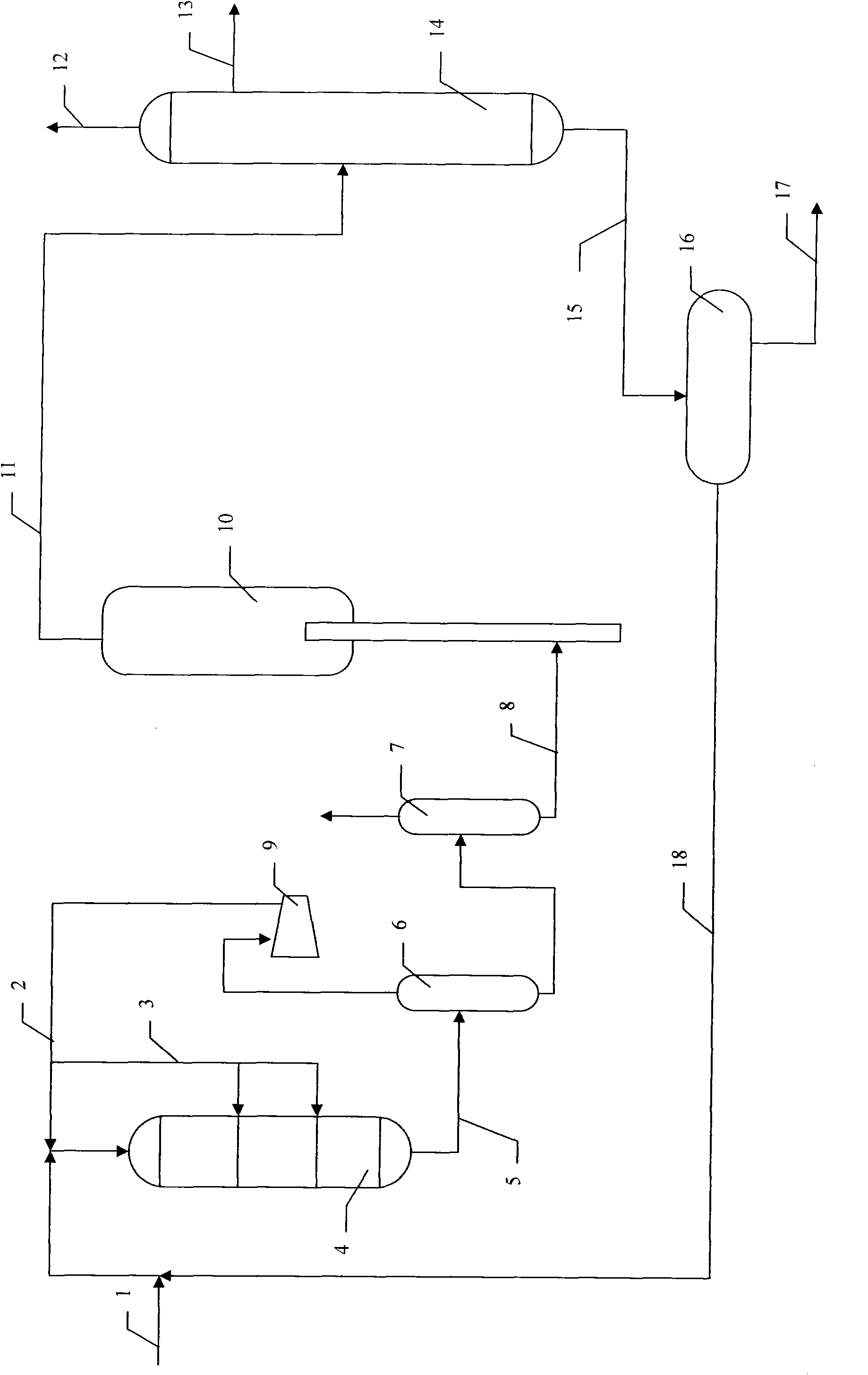

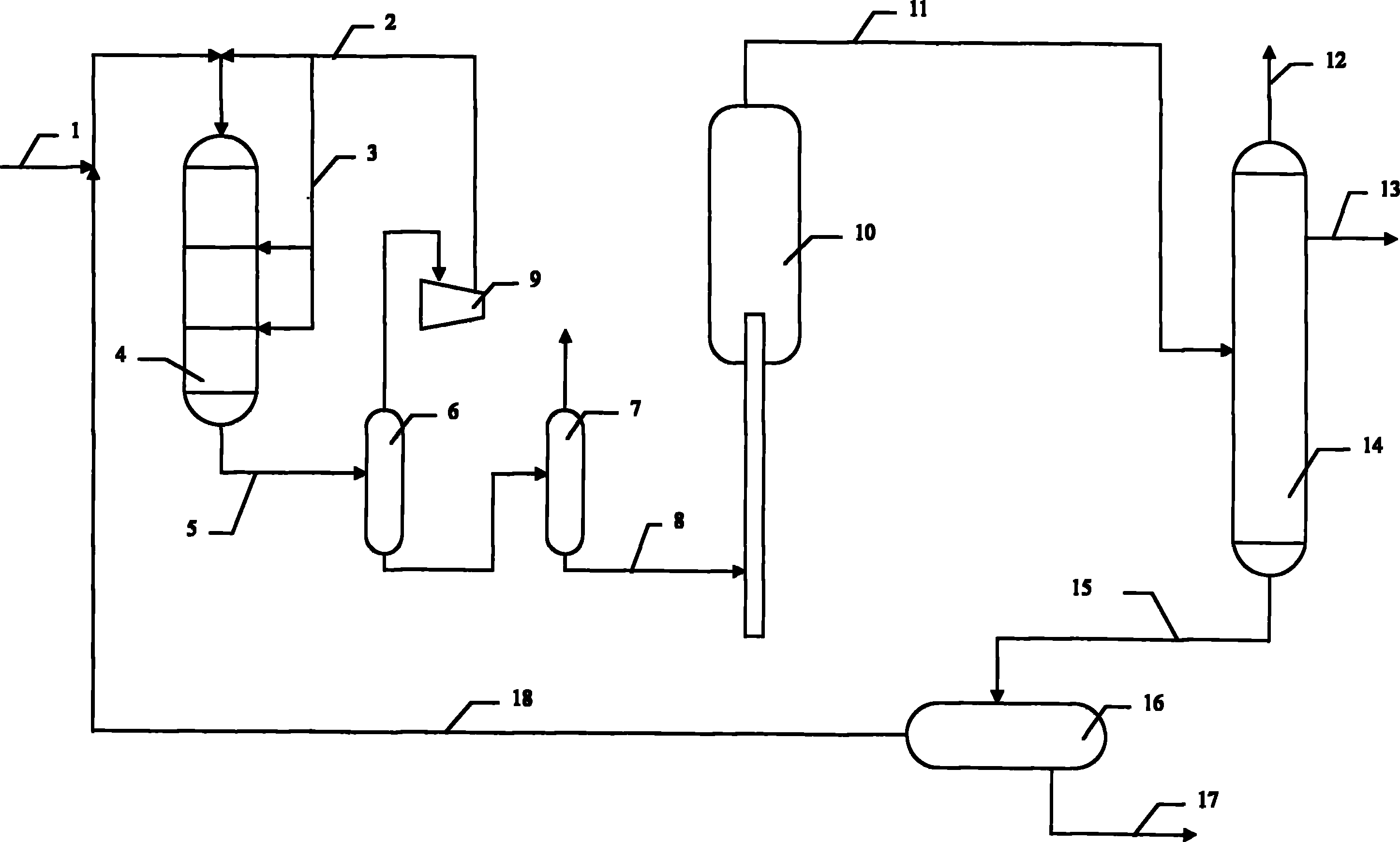

Method used

Image

Examples

Embodiment

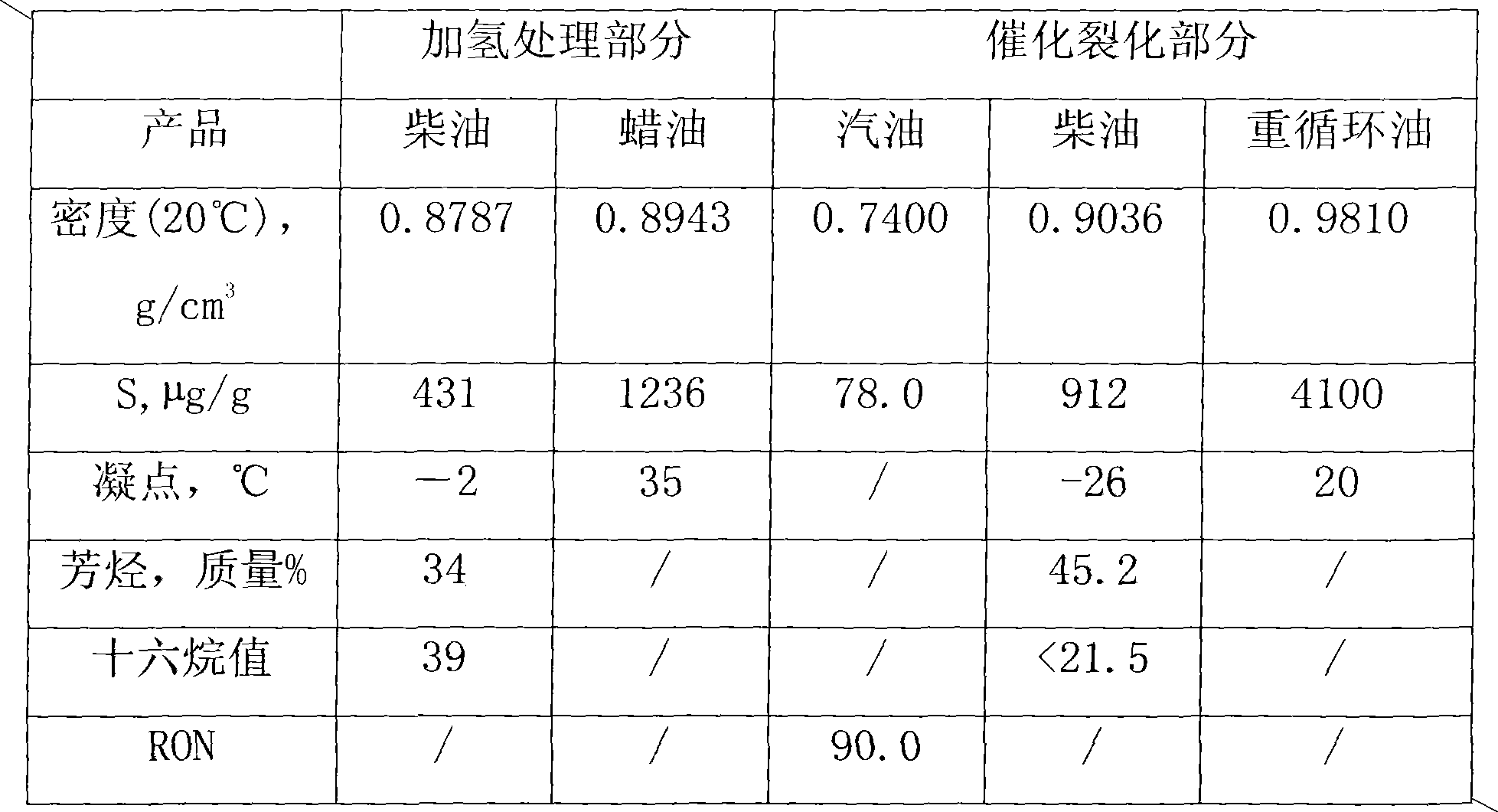

[0036] In this example, the combined method of wax oil hydrotreating and catalytic cracking provided by the present invention is used to circulate the catalytically cracked heavy fraction including catalytically cracked diesel oil, catalytic heavy cycle oil and catalytic oil slurry to a hydrotreating unit for further processing. Table 2, Table 3, and Table 5 are process conditions, product distribution, and main product properties, respectively.

[0037] The comparison results show that the yield of FCC gasoline increases by 22.96 percentage points, the yield of coke decreases, and the yield of dry gas and liquefied gas increases after the mixed hydrotreating of FCC heavy distillate oil and fresh wax oil feedstock. This method can well satisfy enterprises wishing to increase gasoline production.

[0038] Table 1 Raw Oil Properties

[0039] Density (20℃), g / cm 3

0.9237

S, mass%

1.95

N, μg / g

2542

Carbon residue, mass%

0.46

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com